Page 5-C

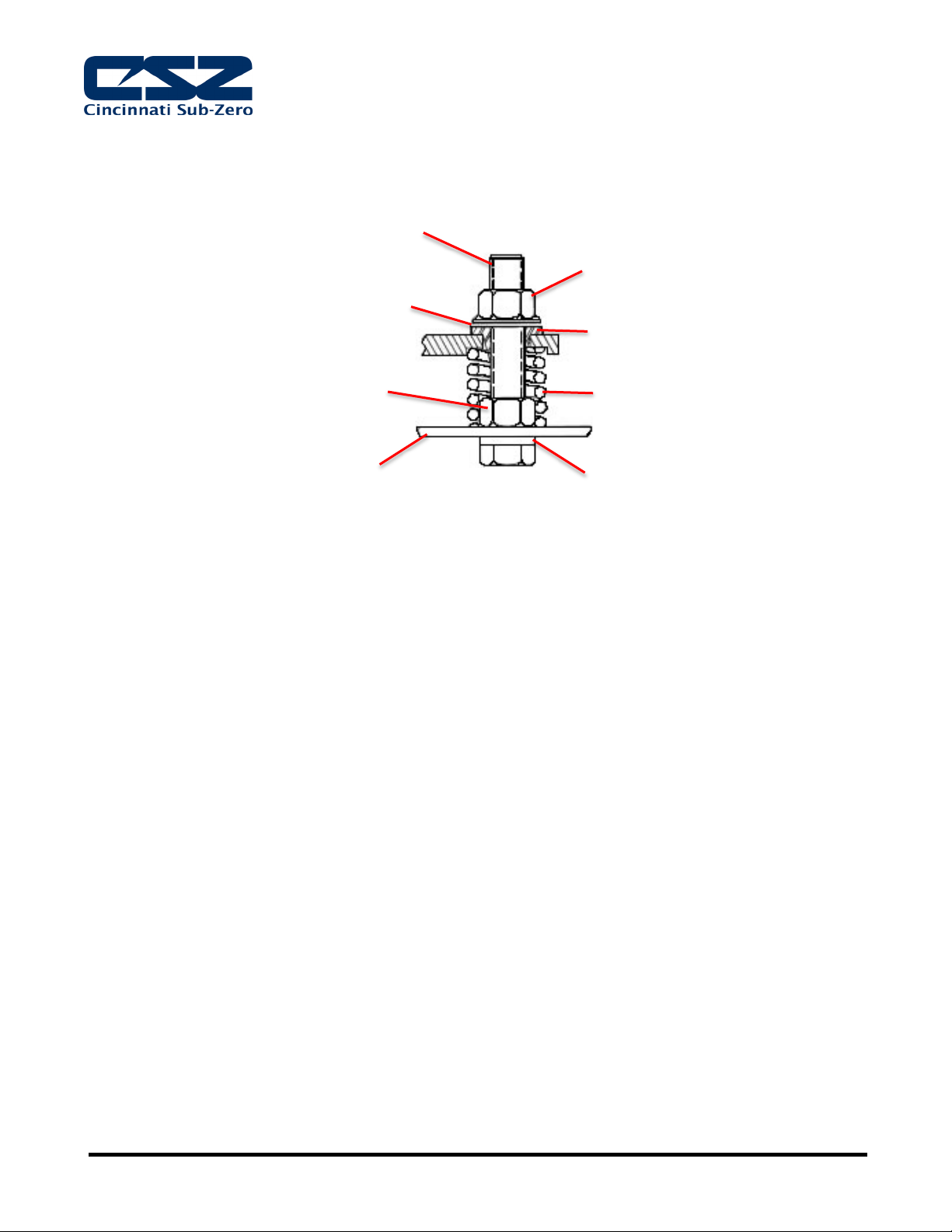

4.8. If unit is installed with Semi Hermetic Spring Mounted Compressors, follow these steps:

4.8.1. Loosen the upper nuts and washers until compressor floats on springs.

4.8.2. Discard the shipping spacers.

4.8.3. Allow 1/16 inch space between the upper mounting nut and rubber spacer. See Figure 4-2 below.

5. Unit Startup

5.1. The Installation Section in the ZP Manual (Page 55) should be

referenced for the detailed start up procedures.

5.2. The following must be performed prior to starting the unit:

5.2.1. Check the system pressures using the refrigeration system pressure gauges.

5.2.1.1. DO NOT START if the R-508B / R23 (System 2) static pressure is more than 30 PSI (2

bar(g)) lower than that specified on the data plate, contact the CSZ Service Department.

5.2.1.2. DO NOT START if the R-404A (System 1) or R-410A (Tundra) pressure is less than 100PSI

(6.9bar(g)), contact the CSZ Service Department.

5.2.2. Units with semi-hermetic compressors: loosen nuts holding them in place to allow the compressor

to float freely on the spring system.

5.2.3. Water cooled unit supply flow rates are determined by the inlet water temperature, please see chart

in Section 4.4.1 for proper flow rates.

5.2.3.1. Open Loop Systems require a minimum supply pressure of 40 PSI (275 kPa) with a

maximum supply pressure of 60 PSI (515 kPa).

5.2.3.2. Closed Loop Systems require a minimum pressure differential (supply pressure minus return

pressure) 40 PSI (275 kPa) with a maximum supply pressure of 60 PSI (515 kPa).

5.2.3.3. Verify that the incoming water flow rate is adequate based on temperature.

5.3. Once power is applied the unit, it must sit for 4 hours prior to refrigeration operation to allow the

crankcase on the compressor to heat properly.

5.4. 3 Phase Scroll Compressors will run backwards if the power leads are installed incorrectly.

5.4.1. Correct Installation: The discharge pressure increases and the suction pressure decreases

5.4.2. Incorrect Installation: The discharge pressure decreases and the suction pressure increases.

Reverse any two power leads to correct the issue.

5.5. 10hp refrigeration systems and above are equipped with “Pumpdown”

5.5.1. “Pumpdown” protects System 1 compressor on start up by forcing refrigerant to the high side.

5.5.2. If supply power is off for more than 30 minutes the “Pumpdown Disabled” alarm will occur and the

chamber will not operate

5.5.3. “Pumpdown Disabled” will automatically clear after the power has been restored for more than 4

hours.

5.5.4. If power has been restored to the unit with-in 4 hours after the 30 minute off period the alarm can

be reset manually.

(Upper)

after Installation

(Lower)