1. 8mm open-ended spanner dealer to source

2. 19mm open-ended spanner dealer to source

3. Thermometer (K-type)/salinity meter 6005-0996

4. 2m/kG calibrated torque wrench 6005-0997

with 19mm socket (½” square drive)

5. Digital volt meter and leads dealer to source

6. BathyCorrometer®service tool (T-bar) 6005-0313

7. BathyCorrometer®locking ring tool 6004-0007

8. Pipe grips dealer to source

9. De-ionized water (10L) dealer to source

10. K-Cell adaptor leads 6004-0018

11. Tamper-evident seal/paint dealer to source

12. Crimp tool JST WC-240 (Farnell 3617270)

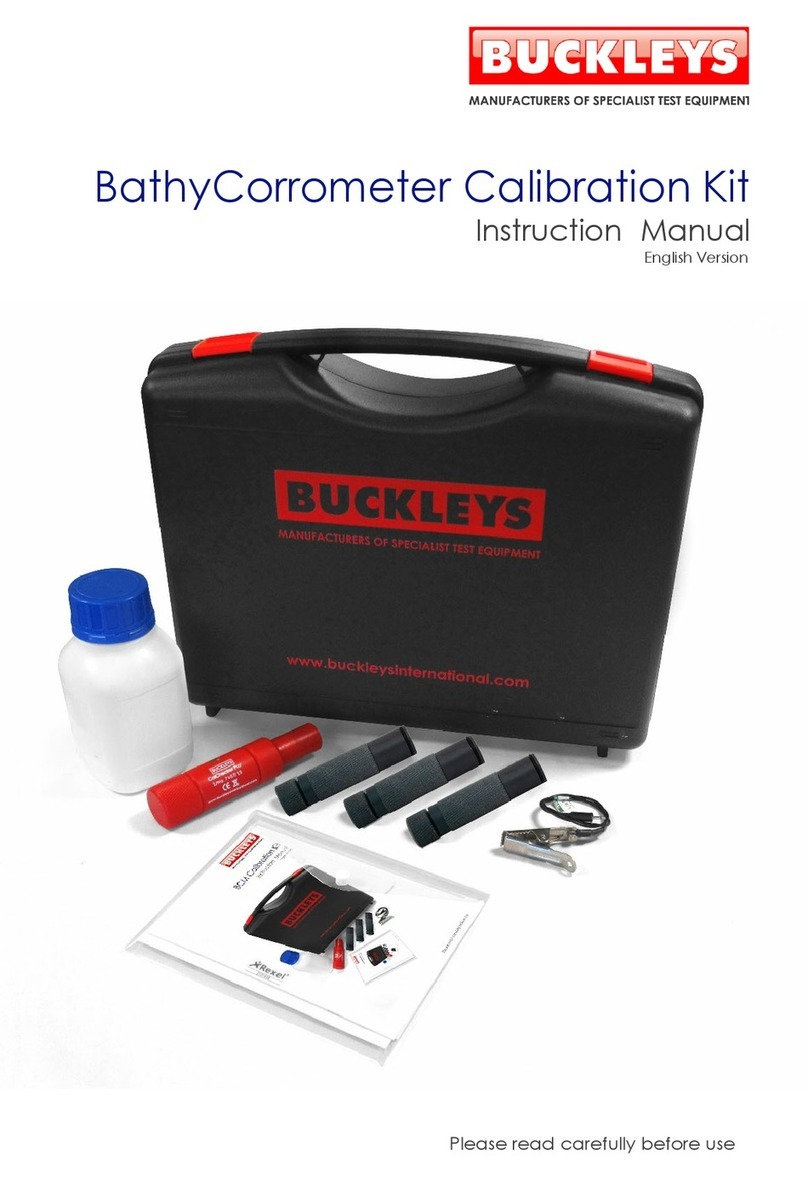

13. BathyCorrometer®Calibration Kit 6004-0031

14. Soldering Iron dealer to source

15. Wire cutters dealer to source

16. Long nose pliers dealer to source

17. Lead-free solder dealer to source

18. Cleaning cloth dealer to source

19. Hammer dealer to source

20. Handle sealing plug 6005-0312

21. Half-cell sealing plug 6005-0311

22. Trim Tool 6005-0084

23. Suction puller cup 2006-0036

24. Pressure tank capable of 600psi dealer to source

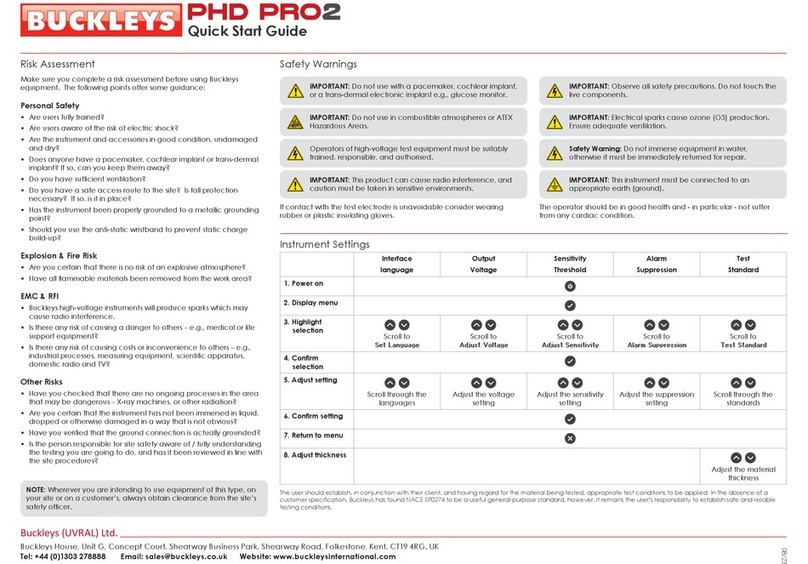

2. Preparation

Workspace

A robust workspace/bench is required and should be clean and free from debris. All testing and calibration equipment such as pressure chambers

and multimeters should be checked and calibrated annually by recognised or approved sources.

Tools required

In order to check and fully test a BathyCorrometer®Pro’, the following service and calibration tools are required:

Items with part numbers may be

purchased from Buckleys

1 2

3 4

5 6

7 8

16

17 14 1512 13911

23 2421 2219 2010 18

BathyCorrometer®

M k V t o P R O ’ U P G R A D E M A N U A L

HOME ReassemblyDescription Preparation Disassembly Repairs & test certificate production