CTI-CRYOGENICS 8510 Manual

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

HELIX TECHNOLOGY CORPORATION

http://www.helixtechnology.com

8510 High-Voltage Compressor

(For Use with On-Board High-Vacuum Pumps)

Installation, Operation and Service

Instructions

8040265

Rev. P (3/97)

The information in this document is believed to be accurate and reliable. However,

Helix Technology Corporation, cannot accept any financial or other responsibilities that may

result from the use of this information. No warranties are granted or extended by this document.

Helix Technology Corporation reserves the right to change any or all

information contained herein without prior written notice. Revisions may be issued at the time of

such changes and/or deletions.

Any duplication of this manual or any of its parts without expressed written permission from

Helix Technology Corporation is strictly prohibited.

Any correspondence regarding this document should be forwarded to:

Helix Technology Corporation

Mansfield Corporate Center

Nine Hampshire Street

Mansfield, Massachusetts 02048-9171 U.S.A.

Telephone: (508) 337-5000

FAX: (508) 337-5464

The following Helix Technology Corporation trademarks and service marks may appear in this

document:

CTI-Cryogenics®GUTS®

Cryo-Torr®Cryodyne®

Cryogem®Cryogenerator®

On-Board® Helix®

RetroFast®

Value Line™RetroEase®

FastRegen™TurboPlus®

TurboLink™

ThinLine™

All other trademarks or registered trademarks are the property of their respective holders.

Copyright© 2000 Helix Technology Corporation Printed in U.S.A.

8510 High-Voltage Compressor (For Use With On-Board High-Vacuum Pumps)

P/N 8040265 iii

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Table of Contents

Section 1 - Introduction

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Installation, Operation and Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Section 2 - Inspection

Packaging of the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

The Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Section 3 - Installation

Compressor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Preparing the Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Assembling the Compressor Input-Power Cable . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Electrical Preparation of Compressor Control Module . . . . . . . . . . . . . . . . . . . 3-4

Cooling Water: Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Cooling Water: General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Cooling Water: Flow and Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . . 3-7

Cooling Water: Temperature Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Oil Circuit Stabilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting the Compressor to the Cryopump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Electrical Connection of Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

8510 High-Voltage Compressor Electrical Phase Check and Automatic

ON/OFF Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

System Phase Input Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Automatic ON/OFF Control of the Compressor Using the On-Board

Setpoint Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Multipump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Section 4 - Maintenance Procedures

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing the Compressor Adsorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Installing the Compressor Adsorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Unscheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Suggested Unscheduled Maintenance Equipment . . . . . . . . . . . . . . . . . . . . . . . 4-4

Adding Helium Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Helium Circuit Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Cryopump Decontamination Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Compressor Decontamination Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Priming the Compressor Oil System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

8510 High-Voltage Compressor (For Use With On-Board High-Vacuum Pumps)

iv P/N 8040265

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Table of Contents (continued)

Appendix A - Customer Support Centers

Appendix B - Troubleshooting Procedures

Appendix C - Electrical Schematic for 8510 High-Voltage Compressor

Appendix D - Components in the Electrical Control Module of 8510

High-Voltage Compressor

Appendix E - Compressor Flow Diagram

Appendix F - Multiple Cryopump Installation with Single 8510 High-Voltage

Compressor

Figures

Figure 1-1: 8510 High-Voltage Compressor: Front and Side Views . . . . . . . . 1-2

Figure 1-2: 8510 High-Voltage Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

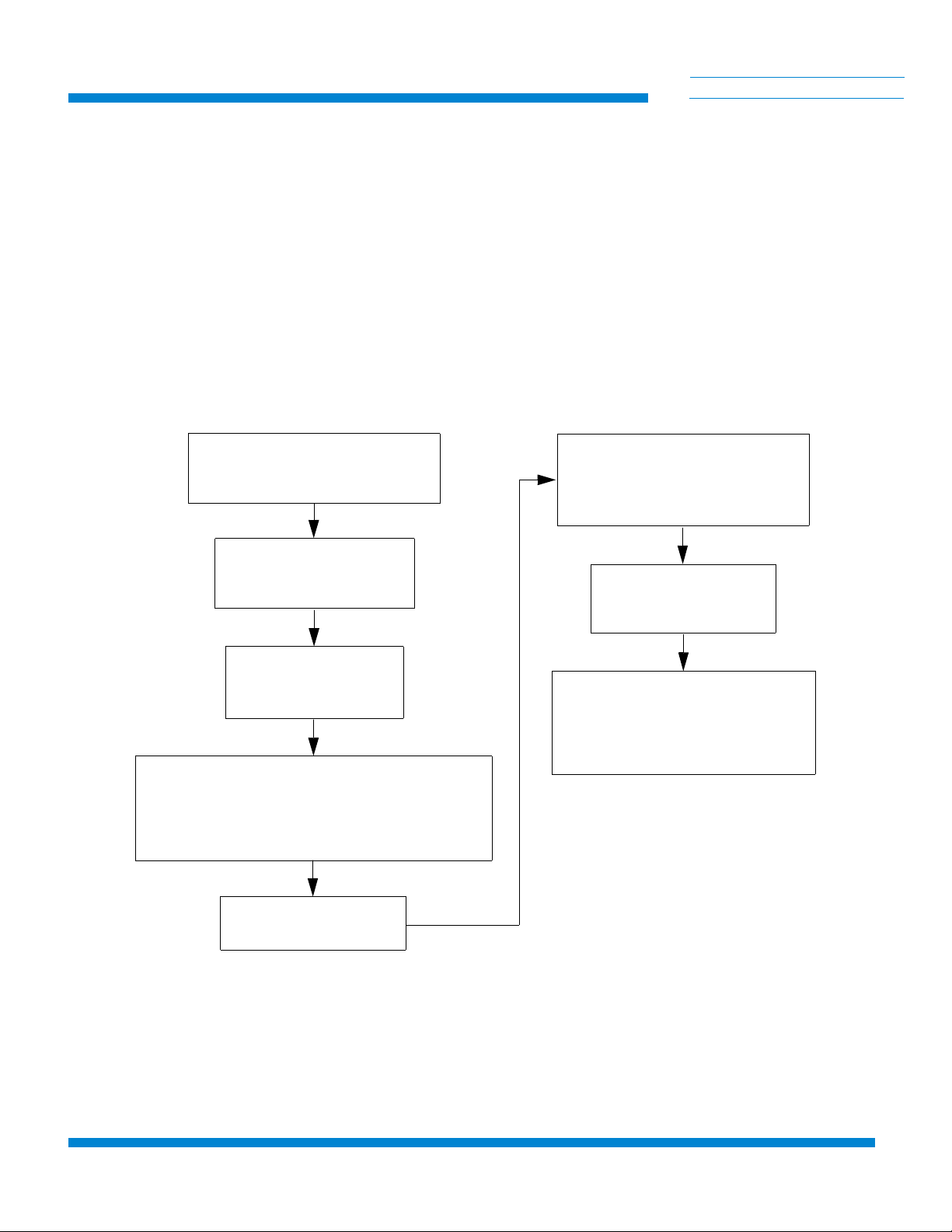

Figure 3-1: Block Diagram for 8510 High-Voltage Compressor Installation . . 3-1

Figure 3-2: Removing Compressor Pump Shipping Supports . . . . . . . . . . . . . . 3-2

Figure 3-3: Preparing the 8510 High-Voltage Compressor Control Module . . 3-6

Figure 3-4: Model 8510 High-Voltage Compressor Cooling Water Flow and

Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-5: 8510 High-Voltage Compressor Water Discharge

Temperature Increase (°F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-6: 8510 High-Voltage Compressor Installation . . . . . . . . . . . . . . . . 3-13

Figure 4-1: Connecting/Disconnecting the Adsorber Self-sealing Couplings . . 4-2

Figure C-1: 8510 (High Voltage) Compressor Schematic . . . . . . . . . . . . . . . . . C-2

Figure D-1: Components in the Electrical Control Module of 8510

High-Voltage Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

8510 High-Voltage Compressor (For Use With On-Board High-Vacuum Pumps)

P/N 8040265 v

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Table of Contents (continued)

Figure E-1: 8510 High-Voltage Compressor Flow Diagram . . . . . . . . . . . . . . . E-1

Figure F-1: Typical Multiple Cryopump Installation with Single 8510

High-Voltage Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

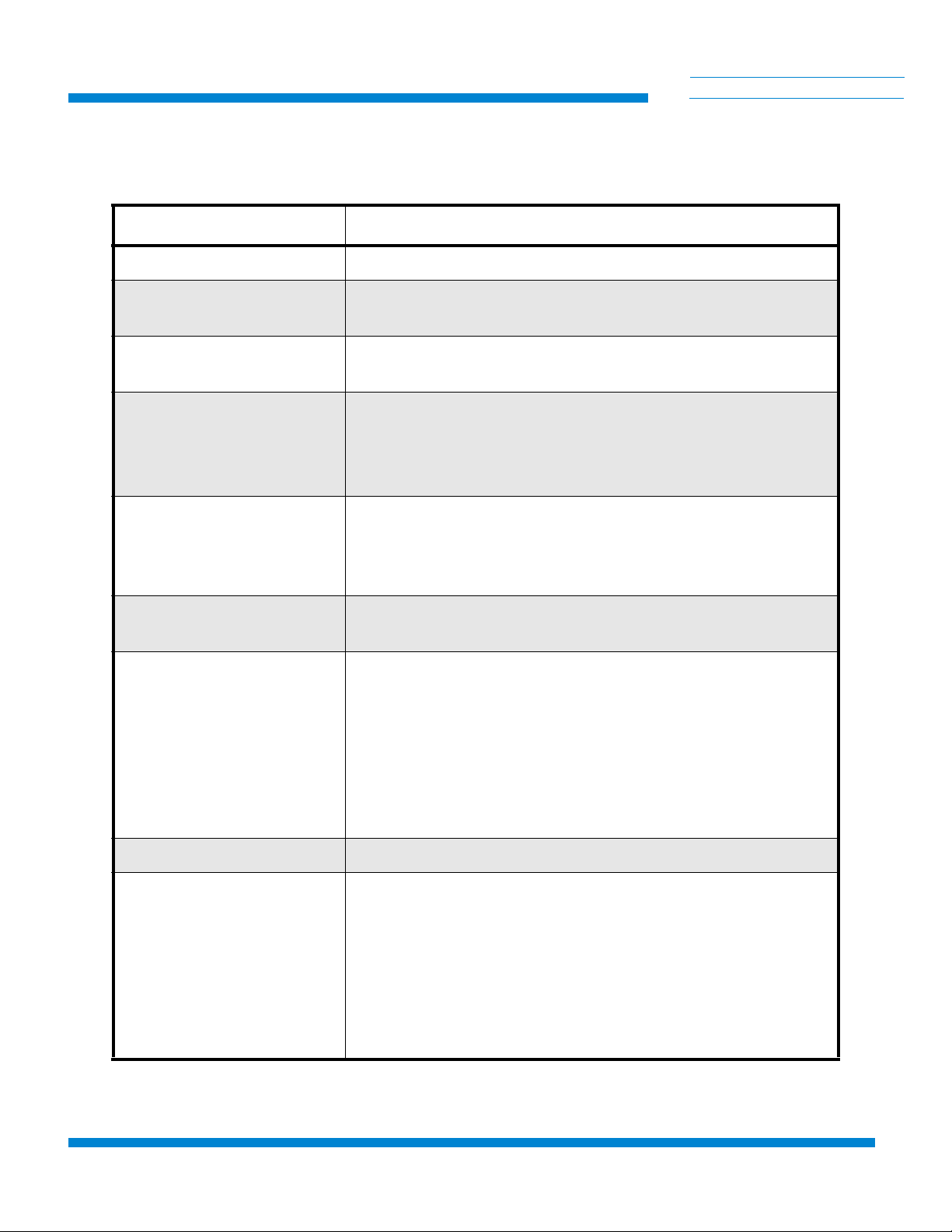

Tables

Table 1-1: Compressor Dimensions P/N 8031400G002 . . . . . . . . . . . . . . . . . . 1-2

Table 1-2: Power Requirements (Steady-State Conditions) . . . . . . . . . . . . . . . 1-2

Table 1-3: General Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 2-1: 8510 Carton Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Table 3-1: 8510 High-Voltage Compressor Power Specifications . . . . . . . . . . 3-6

Table 3-2: Setpoint Relay Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Table A-1: Customer Support Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table B-1: Compressor Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . B-2

Table D-1: Legend for Figure D-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

8510 High-Voltage Compressor (For Use with On-Board High-Vacuum Pumps)

P/N 8040265 1-1

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Section 1 - Introduction

General

The manual provides instructions for installing, operating and servicing the

8510 High-Voltage Compressor, P/N 8031400G002 (380-460 volts). If you

are installing or operating an On-Board High-Vacuum System you should

also have available the On-Board High-Vacuum Pump Manual that applies

to your particular system:

• 8040215 On-Board 8 and 8F High-Vacuum Pumps

• 8040233 On-Board 10 and 400 High-Vacuum Pumps

The manuals for a system cover two basic components: the high-vacuum

pump and the compressor. Each manual outlines the details necessary for

installation, operation and servicing of that component. A manual is

shipped with each system component (high-vacuum pump and

compressor). When you purchase a system, you will receive the two

manuals necessary for system installation, plus a loose-leaf binder with

index tab separators, allowing you to compile a complete indexed system

notebook.

Installation, Operation and Service Instructions

Installation, Operation and Service Instructions for your 8510 High-

Voltage Compressor provide easily accessible information. All personnel

with installation, operation, and servicing responsibilities should become

familiar with the contents of these instructions to ensure high quality, safe,

reliable performance. Unit must be wired by an authorized electrician in

accordance with the national electrical code, ANSI/NFPA 70-1987, as well

as the local codes.

Introduction

1-2 P/N 8040265

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Figure 1-1: 8510 High-Voltage Compressor: Front and Side Views

Table 1-1: Compressor Dimensions P/N 8031400G002

Location Compressor Dimension Inches

(mm)

A 19.52 max.

(496 mm)

B21.50 max.

(546 mm)

C 24.24 max.

(616 mm)

D 2.30

(58 mm)

Table 1-2: Power Requirements (Steady-State Conditions)

Compressor Volts Hz Phase Full Load

Current

(Amps)

Ooperating

Voltage Range

(Volts)

Maximum

Phase Run

Current

(Amps)

8510, Part No.

8031400G002 460

380 60

50 3

38

8395-506

342-457 11

11

B

A

C

D

8510 High-Voltage Compressor (For Use with On-Board High-Vacuum Pumps)

P/N 8040265 1-3

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Table 1-3: General Specification

Specification Description

Weight 340 lbs (154 kg) approximate

Weight

(shipping) 445 lbs (202 kg) approximate

Power

consumption 5.4 kw, nominal operating power, 6.2 kw maximum

0.8 power factor, 7.8 kva maximum

Compressor input-power

cable

(customer-supplied)

Recommended type SO-4 conductor, 600V, neoprene jacket

and 10-gauge or 4mm2 minimum wire.

Install per Figure B-1, Electrical Schematic Diagram, ensuring

compliance with all national, state and local standards.

Helium pressure Static: 195-205 psig (1345-1415 kPa) at 70 to 80°F (21 to

27°C)

Return: Normal operation: 75-85 psig (517-590 kPa) at operat-

ing temperature.

Ambient operating

temperature range 50 to 100°F (10 to 38°C)

Interface Cold head power receptacles (3): Mates with plugs on cold

head power cables.

Compressor input-power termination: Connects with #10

(5mm) ring terminals.

Gas-supply connector: 1/2-inch self-sealing coupling

Gas-return connector: 1/2-inch self-sealing coupling

Remote control receptacle 24VAC, 150ma: Mates with J5 con-

nector P/N MS3106A-20, supplied by CTI-CRYOGENICS.

Adsorber service schedule Replace every three years.

Cooling water requirements 70°F water supply, 2.5 gpm, 14 psid (pressure drop: water inlet

to water outlet).

The pressure value does not consider discharge back-pressure

conditions.

Maximum/minimum water requirements

Maximum outlet temperature 100°F (38°C)

Minimum inlet temperature 40°F (4°C)

Maximum inlet pressure 100 psig

Introduction

1-4 P/N 8040265

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

This compressor has been designed to operate with water having a pH

value of 6.0 to 8.0 and a calcium carbonate concentration of less than 75

parts per million (typical municipal drinking water quality). For

applications of lower pH or greater hardness, water conditioning may be

necessary.

8510 High-Voltage Compressor (For Use with On-Board High-Vacuum Pumps)

P/N 8040265 1-5

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Figure 1-2: 8510 High-Voltage Compressor

1

319

4

5

6

7

810

14

18

15

17

16

911

1. Compressor Power ON/OFF Switch (with ON lamp)

2. On-Board System Power Switch (with ON Lamp)

3. Oil sight glass

4. Cooling water output.

5. Cooling water input.

6. Helium gas-return connector self-sealing coupling.

7. Helium gas-supply connector self-sealing coupling.

8. Compressor overload reset.

9. Voltage selector switches (S3).

10. Voltage selector switches (S2).

11. Elapsed time meter (ETM).

12. Cold head power circuit breakers (CB2 and CB3).

13. Cold head power cable receptacles (J2, J3, and J4).

14. Input power cable receptacle (J1).

15. Helium return pressure gauge.

16. Helium gas charge fitting and valve.

17. Safety interlock.

18. System power ON/OFF switch circuit breaker (CB1).

19. System remote control receptacle (J5) (Jumper plug

installed).

2

LEGEND

12 13

8510 High-Voltage Compressor (For Use with On-Board High-Vacuum Pumps)

P/N 8040265 2-1

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Section 2 - Inspection

Packaging of the System

The On-Board High-Vacuum Pump System is packaged in three separate

cartons. Listed below are the contents of each carton, as they relate to these

two system applications. Note that an Installation, Operation, and Service

Manual is included in cartons for the high-vacuum pump and compressor.

Each manual covers the component packaged in that carton.

When installing an On-Board High-Vacuum Pump System,

CTI-CRYOGENICS recommends that as you unpack a component:

perform an inspection and the necessary tasks for system installation for

the component according to the manual included with the component. Final

system installation and operation will be performed following procedures

in the On-Board 8/8F or 10 and 400 Cryopump Manual (No. 8040215 or

8040233 respectively).

The Compressor

On receipt, remove the 8510 High-Voltage Compressor from its shipping

carton and inspect the compressor for evidence of damage as described in

this Section.

1. Unpackage and remove the compressor from its shipping

carton.

2. Check the carton contents. It should contain:

a. 8510 High-Voltage Compressor.

Table 2-1: 8510 Carton Contents

Carton Label On-Board 8/8F, 10 And 400 High-vacuum

Pump System Carton Contents Manual

Included

On-Board On-Board 8/8F Cryopumps 8040215

On-Board On-Board 10 and 400 Cryopumps 8040233

Compressor 8510 High-Voltage Compressor 8040265

Accessories Installation and Scheduled Maintenance

Tool Kit and Accessories,

P/N 8032040G014

—

Inspection

2-2 P/N 8040265

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

b. Two barbed fittings for compressor cooling water connec-

tions.

c. Compressor remote start connector.

d. Input power connector.

e. Oil prime manifold, P/N 8018129.

f. 8510 High-Voltage Compressor Manual P/N 8040265.

8510 High-Voltage Compressor (For Use with On-Board High-Vacuum Pumps)

P/N 8040265 3-1

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Section 3 - Installation

Figure 3-1: Block Diagram for 8510 High-Voltage Compressor Installation

Removing Compressor Pump

Shipping Supports

(Refer to Page 3-2)

Assemble Compressor

Input-Power Cable

(Refer to Page 3-3)

Setting Voltage

Tap Switches

(Refer to Page 3-4)

Cooling Water Connections to Compressor

Cooling Water PH Factors and Conservation

Cooling Water Flow and Pressure Requirements

Cooling Water Temperature Rise

(Refer to Page 3-4)

Oil Circuit Stabilization

(Refer to Page 3-9)

Helium Gas Return and

Supply Connections

Verifying Helium Static Pressure

(Refer to Page 3-9)

Connecting Relay Connector Pins

Programming Relay #1 to the

Cryopump Function

(Refer to Page 3-11)

Making Electrical

Connections

(Refer to Page 3-10)

Installation

3-2 P/N 8040265

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Compressor Installation

Installation of your compressor requires no special tools other than those

supplied in the Installation and Scheduled Maintenance Tool Kit.

Preparing the Compressor

1. After removing the compressor front panel, refer to Figure 3-2 and

remove the front two compressor pump shipping supports.

a. Remove the front two nuts and red flat washers that secure

the compressor pump tightly in position.

NOTE: Retain the two red flat washers for use during shipment.

b. Remove the two rubber grommets that are in the package

attached to the compressor: install them, flat side up, onto

the front two mounting posts.

c. Reinstall the two nuts and screw them down flush with the

tops of the mounting posts.

d. Replace the compressor front panel.

Figure 3-2: Removing Compressor Pump Shipping Supports

Compressor Base

Red Flat Washer

Hex Head Nut

Red Flat Washer

Hex Head Nut

Rubber Grommets

8510 High-Voltage Compressor (For Use with On-Board High-Vacuum Pumps)

P/N 8040265 3-3

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Assembling the Compressor Input-Power Cable

To supply input power to the compressor requires the fabrication of a 600-

volt power cable that has an SO-4 conductor, 600-volt rating neoprene

jacket and 10-gauge or 4 mm2wire. Proceed as follows:

WARNING

Do not connect the compressor to the power source at this time. All of

the preparation must be completed and all panels reinstalled before elec-

trically connecting the compressor.

Unit must be wired by an authorized electrician in accordance with the

national Electrical Code, ANSI/NFPA 70-1996, as well as the local

codes. This shall include installation of a readily accessible disconnect

device into the fixed wiring supplying power.

An insulated safety grounding conductor that is identical in size, insula-

tion material and thickness to the circuit supply conductors, except that it

is green with or without one or more yellow stripes is to be installed as

part of the branch circuit which supplies the unit or system. The ground-

ing conductor described is to be connected to the equipment grounding

conductor of the supply circuit.

1. Prepare the input power cable by terminating each of the four

conductors with a #10 ring terminal. Follow the terminal

manufacturer’s instructions to insure proper crimping.

2. Disassemble the electrical terminal enclosure cover, mounted on

the control module, as shown in Figure 3-3. Remove the two screws

securing the cover and lift it off.

3. If necessary, back off strain relief screws.

4. Thread input power cable end up through the strain relief into the

enclosure.

5. Attach the three conductors onto the appropriate terminals of the

terminal block; attach the ground conductor to the ground stud of

the enclosure. See Figure 3-3. Check that there are no bare conduc-

tors exposed.

6. Tighten all terminals to 18-22 in.-lbs. torque.

7. Tighten down screws on strain relief.

Installation

3-4 P/N 8040265

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

CAUTION

Ensure that strain relief is tightened down on the outer insulation of

the input power cable and that the cable does not slide.

8. Remount the terminal enclosure cover and secure with two screws.

9. Refer to Electrical Connection of Compressor for correct phasing

checkout procedure.

WARNING

Insure that the ground wire is returned to the equipment grounding con-

ductor of the circuit supplying the receptacle.

Electrical Preparation of Compressor Control Module

1. Refer to Table 1-2, for electrical power requirements. Then,

using a voltmeter, measure the phase-to-phase voltage from the

power source.

2. Prepare the compressor voltage selector switches S2 and S3 as

required in accordance with Figure 3-3.

Cooling Water: Preparation

If flexible water hose connections are used, install the barbed fittings

supplied with the compressor on the input and output connections:

1. Apply a light coating of standard plumbing thread sealant on

the barbed fitting threads.

2. Tighten fittings on 1/2-inch FPT input and output connections. DO

NOT OVERTIGHTEN.

3. Connect flexible hoses to the fittings and secure with hose clamps.

If hard piping is desired, install the water lines directly onto the compressor

1/2-inch FPT input and output connections. DO NOT OVERTIGHTEN.

CAUTION

Check water connections for leaks.

8510 High-Voltage Compressor (For Use with On-Board High-Vacuum Pumps)

P/N 8040265 3-5

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Cooling Water: General Considerations

NOTE: Adjust your water flow to maintain an optimum discharge water

temperature of 80° with a minimum input pressure of 7 psi. For detailed

water requirements, see below.

1. Cooling water must meet flow and pressure requirements as

indicated in the following subsections.

2. Cooling water having a pH value of 6.0 to 8.0 and a calcium-car-

bonate concentration of less than 75 ppm, the quality of typical

municipal drinking water, is acceptable. If the cooling water has a

pH value lower than 6.0 or a calcium-carbonate concentration

higher than 75 ppm, water conditioning may be required.

3. To conserve water, the cooling water should be shut off when the

compressor is not running.

CAUTION

If cooling water below 45°F (7°C) is allowed to run through the

compressor while the compressor is not operating, the compressor oil

will change viscosity and thicken, causing the compressor to overheat

and shut off at startup. In this event, repeatedly restart the compressor

and allow it to run until it has shut off several times. The oil

temperature will rise and thereby allow continuous compressor

operation.

Installation

3-6 P/N 8040265

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Figure 3-3: Preparing the 8510 High-Voltage Compressor Control Module

4. Drain and purge water from the compressor before shipping it back

to the factory or subjecting it to freezing conditions. Purge water

from the compressor by blowing compressed air, regulated to 30 to

40 psig (200 to 275 kPa) into the compressor output connection and

allowing water to exit from the water input connection.

Table 3-1: 8510 High-Voltage Compressor Power Specifications

Compressor

Configuration Frequency

(Hz) Voltage Voltage Selector Switch Setting

S2 S3

P/N 8031400G002

380/460VAC, 50/60 Hz 50 342-405

406-457 2

2* 3

4

60 395-450

451-506 2

2* 3

4

*Factory setting

1. Terminal Block 1

2. Terminal Block Cover Screws

3. Cold Head Power Connector (J12)

4. Cold Head Power Connector (J11)

5. Cold Head Power Connector (J10)

6. System Power Switch (CB1)

7. Cold Head Circuit Breaker (CB3)

8. Cold Head Circuit Breaker (CB2

9. On-Board Circuit Breaker (CB7)

10. On-Board Circuit Breaker (CB7)

11. Heater Circuit Breaker (CB5)

12. Heater Circuit Breaker (CB4)

13. Elapsed time meter

14. Voltage selector switch (S2)

15 Voltage selector switch (S3)

16. System Control Interface Connector (J5)

12 11 10 987

1

6

5

4

3

2

16

15

14

13

8510 High-Voltage Compressor (For Use with On-Board High-Vacuum Pumps)

P/N 8040265 3-7

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

Cooling Water: Flow and Pressure Requirements

CAUTION

If your water supply pressure falls below 7 psig due to back pressure,

the compressor will overheat and shut down.

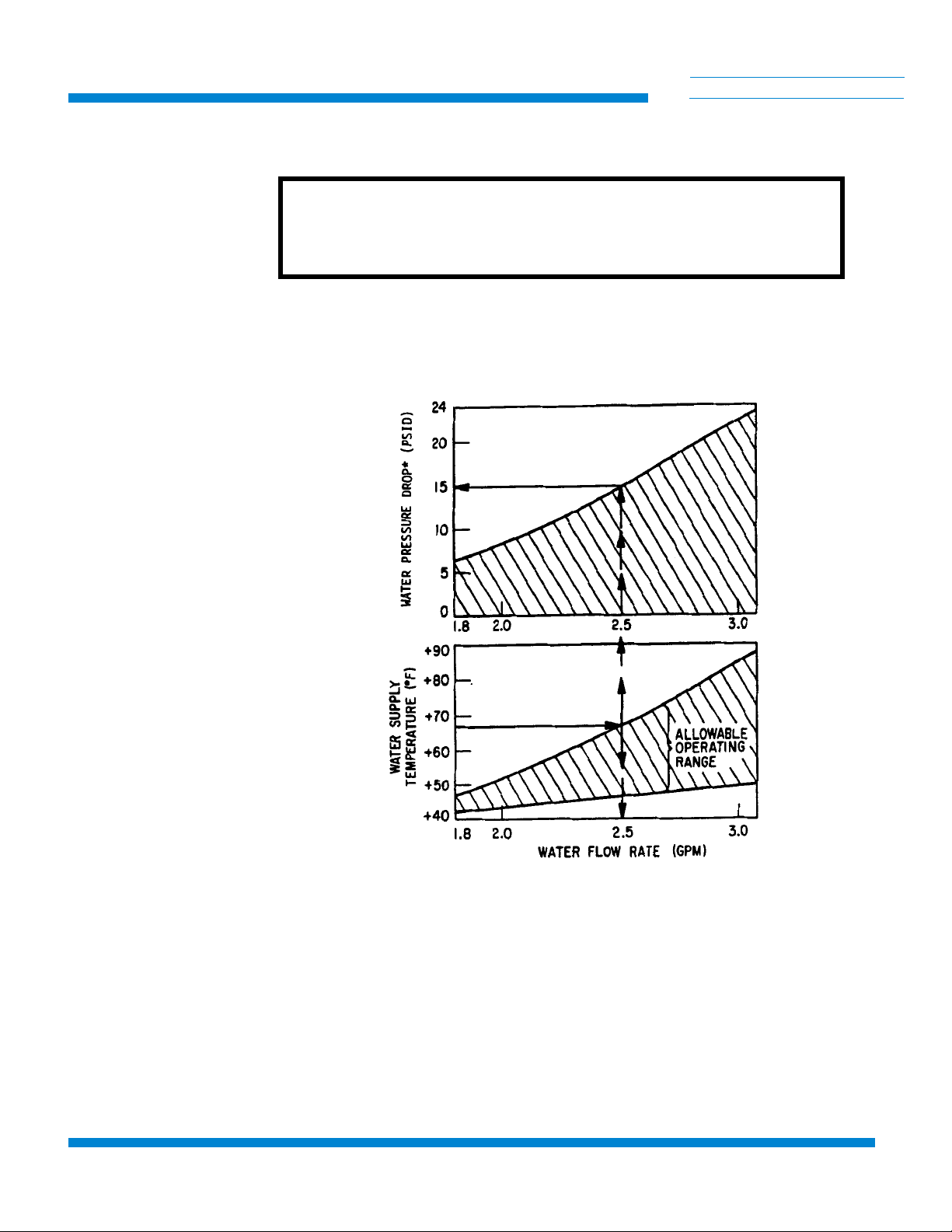

Use the two graphs in Figure 3-4, to determine the minimum acceptable

cooling water supply pressure at different flow rates and temperatures.

Find the minimum pressure:

Figure 3-4: Model 8510 High-Voltage Compressor Cooling Water Flow and Pressure

Requirements

1. Determine the temperature variation of the cooling water.

Allow a ±10°F to the present water temperature if a variation

cannot be ascertained. Plot the high and low temperatures on

the vertical axis of the lower graph.

The example describes cooling water that varies between 45°F and 67°F.

NOTE: Without

consideration of back

pressure.

Installation

3-8 P/N 8040265

C

HELIX TECHNOLOGY CORPORATION

-

TI CRYOGENICS

2. Determine the optimum water flow rate by drawing a horizontal

line from the upper temperature variation figure on the lower graph

to the upper curve of the allowable operating range indicated by

cross-hatching. Draw a line from this intersecting point straight

down to the horizontal axis to find the optimal flow rate.

The example shows a solid arrow extending from 67°F and intersecting the

allowable operating range. Dashed arrows pointing downward indicate a

water flow rate of 2.5 gallons per minute.

3. Determine the cooling water supply pressure drop by drawing a line

straight up from the flow rate in the lower graph to the upper graph.

At the point at which this line intersects the upper graph, draw a

line leftward to the vertical axis and find the water supply pressure

drop.

The example shows dashed arrows extending from the lower to the upper

graph. On the upper graph the dashed arrows intersect the graph curve at

approximately 15 psig.

4. Determine the total cooling water supply pressure drop by adding

the pressure drop determined from the graph to the water back pres-

sure at the installation site.

Cooling Water: Temperature Rise

CAUTION

The temperature of the cooling water as it leaves the compressor should

not exceed 100°F.

Use the graph in Figure 3-5 to determine the rise in cooling water

temperature as it passes through the compressor. The recommended

discharge temperature for the compressor is 80° F. This information is used

by plant engineering personnel to determine cooling water requirements.

Find the temperature rise:

1. Draw a vertical line upward from the horizontal axis of the

graph at the water flow rate determined from the previous

section, until it hits the graph curve.

The example shows dashed arrows pointing upward to the graph curve

from 2.5 gpm on the water flow rate axis.

Table of contents

Popular Air Compressor manuals by other brands

CLAS

CLAS OM 1170 manual

RIDGID

RIDGID OF60150HB Operator's manual

Waeco

Waeco mobitronic PC-100-12/P operating instructions

California Air Tools

California Air Tools 10020DC-22060 owner's manual

KAESER KOMPRESSOREN

KAESER KOMPRESSOREN EPC-2-G Series Assembly and operating manual

Atlas Copco

Atlas Copco AUTOMAN AC40 instruction manual

Gude

Gude 400/10/50 N operating instructions

California Air Tools

California Air Tools 2010A owner's manual

KAESER KOMPRESSOREN

KAESER KOMPRESSOREN SIGMA CONTROL SMART M114 Operator's manual

Vmac

Vmac VR70 installation manual

Bristol

Bristol A Series Installation & service instructions

Bambi

Bambi VT75 Operator's handbook