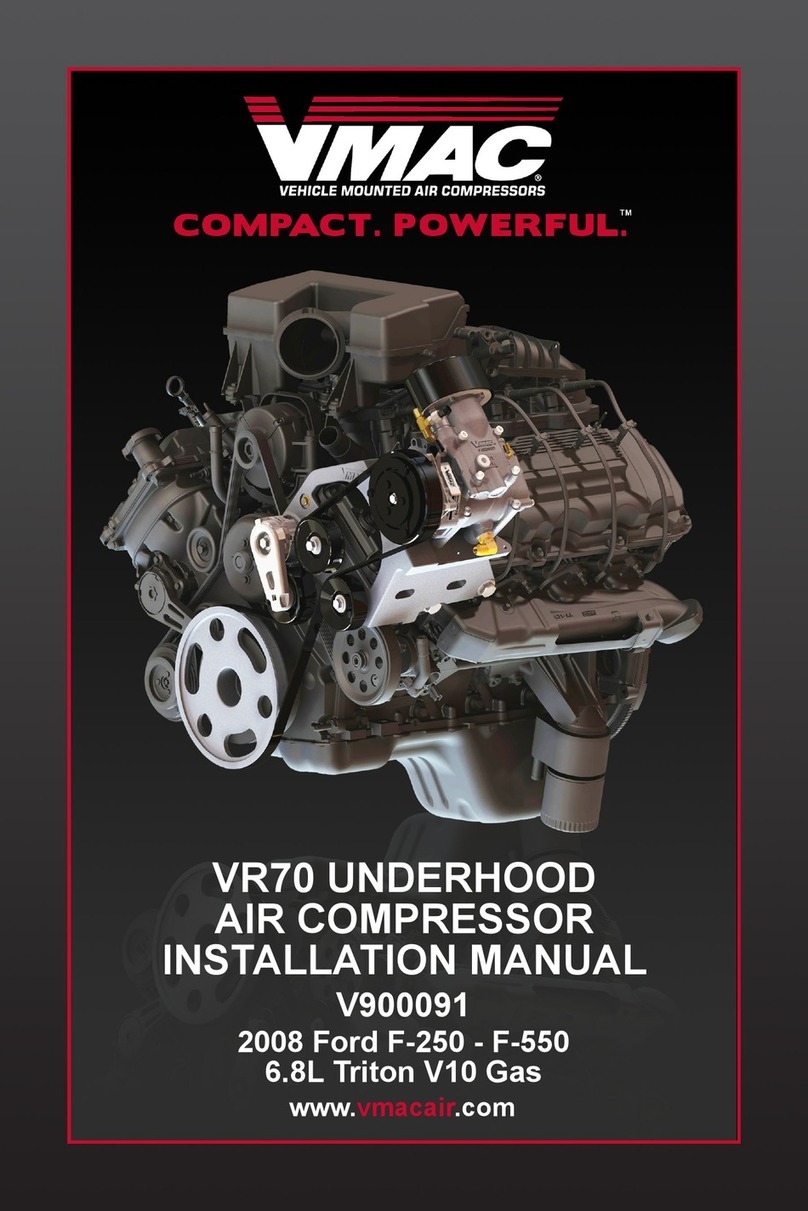

Vmac VR70 User manual

Other manuals for VR70

24

Table of contents

Other Vmac Air Compressor manuals

Vmac

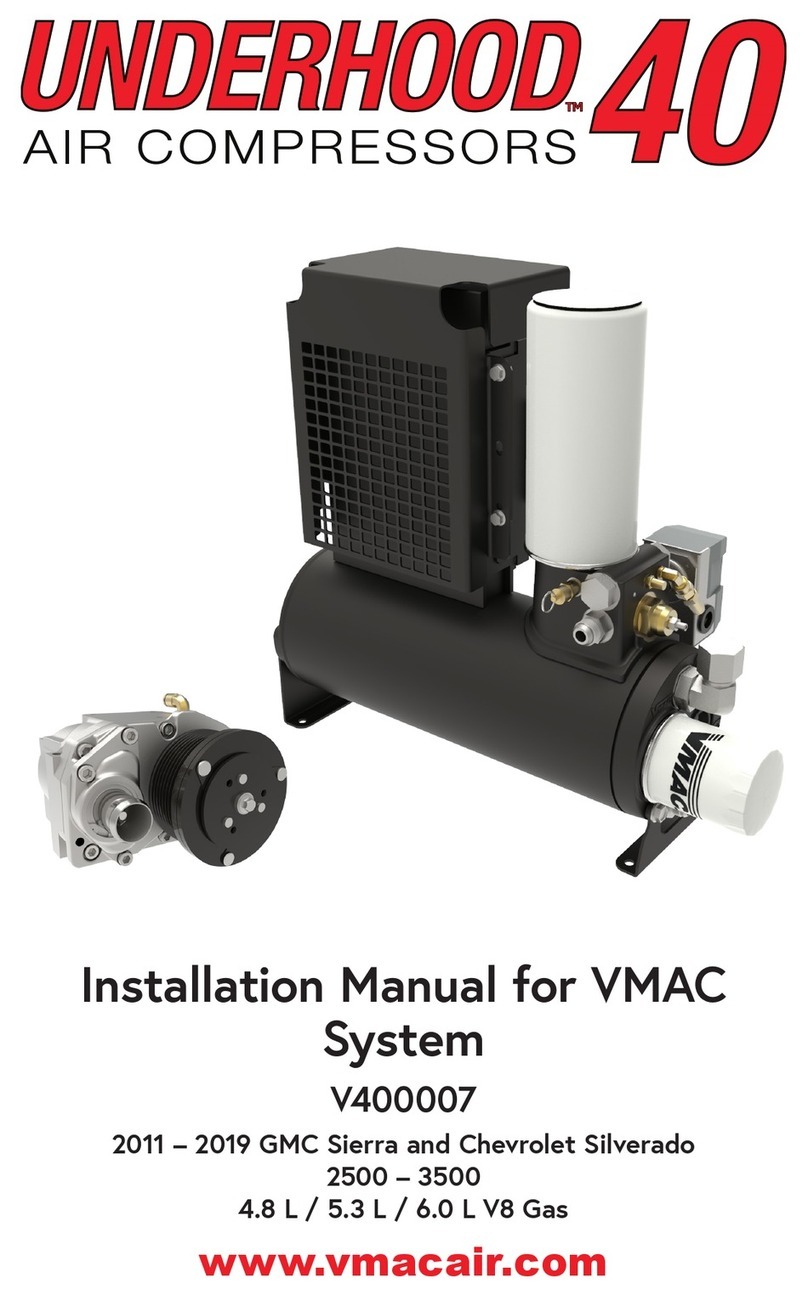

Vmac UNDERHOOD 40 Series User manual

Vmac

Vmac AIR INNOVATED H600009 Installation instructions

Vmac

Vmac VR70 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac D600003 Installation instructions

Vmac

Vmac V400007 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac Underhood 70 User manual

Vmac

Vmac RAPTAIR60 Manual

Popular Air Compressor manuals by other brands

Craftsman

Craftsman PERMANENTLY LUBRICATED 2-STAGE TWIN V PORTABLE AIR COMPRESSOR... Operator's manual

Tech West

Tech West ACL2S2 Installation and service manual

Pentair

Pentair Aquatic Eco-Systems Sweetwater AQ3 Operating and maintenance instructions

KAESER

KAESER M26 Service manual

Sealey

Sealey SSQC0903P instruction manual

Sharper Image

Sharper Image 206888 user guide

Danfoss

Danfoss DCJ Series instructions

DeWalt

DeWalt DXCM602 instruction manual

Metabo

Metabo Basic 280-50 W OF Original instructions

Campbell Hausfeld

Campbell Hausfeld FP204100 Operating instructions and parts manual

OMEGA AIR

OMEGA AIR AWS Installation and operating manual

Schneider Airsystems

Schneider Airsystems CPM 310-10-20 WX Original operating manual