Page 3 of 25

CERTEX Danmark A/S - Trekanten 6-8 - DK-6500 Vojens - Tlf.: +45 74 54 14 37 - E-mail: info@certex.dk - www.certex.dk

Table of Contents

DOCUMENT REVISION...............................................................................................................................................2

ADDITIONAL INFO......................................................................................................................................................2

1INTRODUCTION ..................................................................................................................................................4

2DEFINITIONS .......................................................................................................................................................5

2.1 SIGNAL WORDS...............................................................................................................................................6

2.2 SAFETY SYMBOLS............................................................................................................................................7

2.3 DISCLAIMER....................................................................................................................................................7

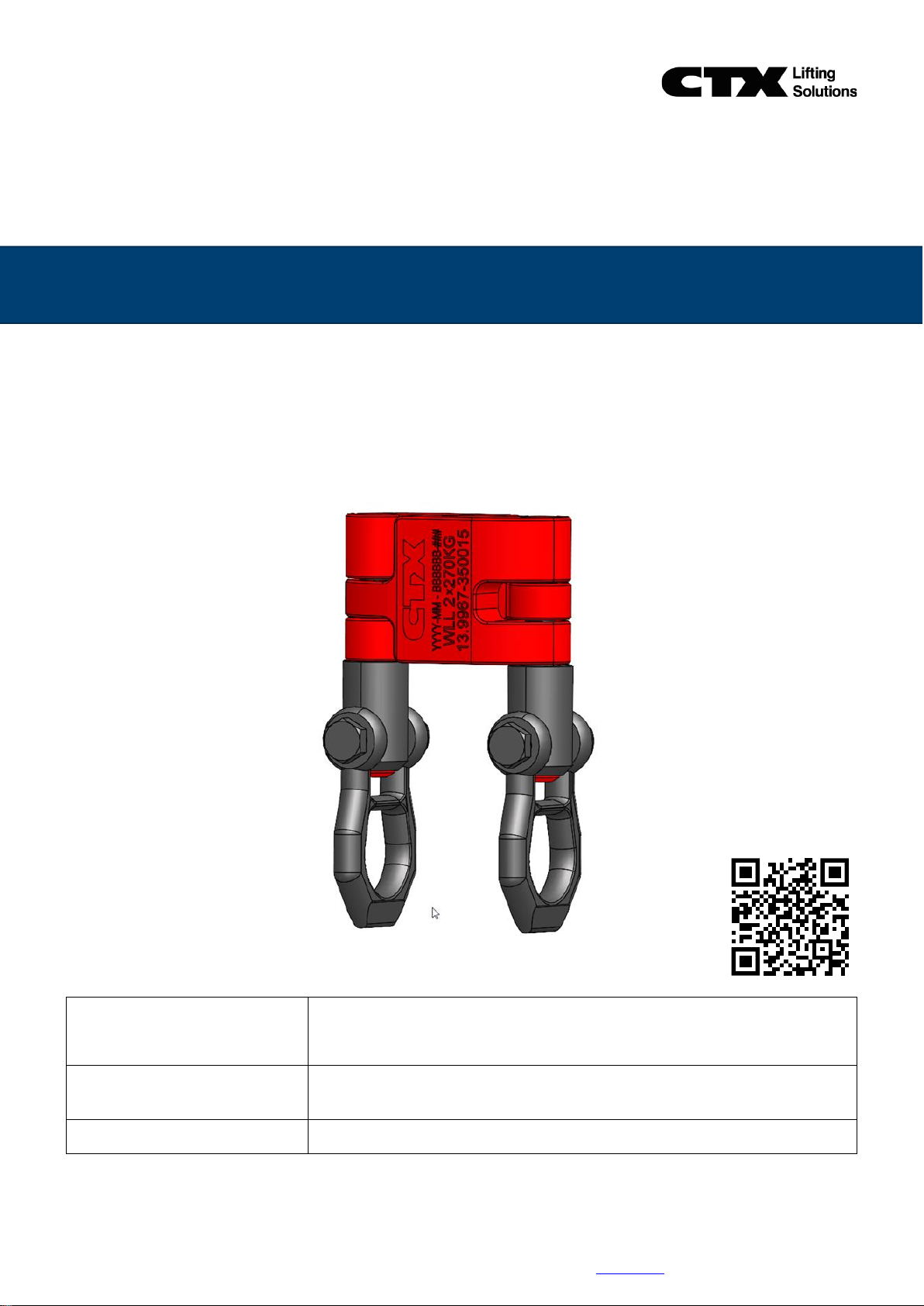

3PRODUCT SPECIFICATION ...............................................................................................................................8

3.1 PRODUCT TYPE AND DESIGNATION...................................................................................................................8

3.2 DIMENSIONS AND WEIGHT ...............................................................................................................................9

4GENERAL SAFETY INFORMATION...................................................................................................................9

5OPERATING INSTRUCTION.............................................................................................................................11

5.1 BEFORE FIRST USE........................................................................................................................................11

5.1.1 Chain size ...............................................................................................................................................11

5.2 INSTRUCTIONS BEFORE USE...........................................................................................................................11

5.3 USE..............................................................................................................................................................12

5.4 LIMITS OF USE...............................................................................................................................................15

5.5 STORAGE .....................................................................................................................................................15

5.6 DISPOSAL OF WASTE .....................................................................................................................................15

6INSPECTION AND MAINTENANCE .................................................................................................................16

6.1 DAILY INSPECTIONS BY USER .........................................................................................................................16

6.2 ANNUAL INSPECTION BY A SKILLED PERSON....................................................................................................16

6.3 DEFECTS......................................................................................................................................................18

7SERVICE AND REPAIR BY SERVICE AGENT................................................................................................19

7.1 SPARE PARTS ...............................................................................................................................................19

7.2 SERVICE AGENT ADDRESS .............................................................................................................................19

8SPARE PARTS ..................................................................................................................................................20

9DRAWING / ADDITIONAL DETAILS.................................................................................................................21

10 LOG / NOTES.....................................................................................................................................................25