Catalogue ES560 Series frequency conversion drive user manual

05 Timer & counter....................................................................................32

06 Drive status............................................................................................34

08 Fault & Alarm Log................................................................................39

09 System Info............................................................................................40

10 Start/Stop/Dir.........................................................................................40

11 Start/Stop Mode.....................................................................................43

13 Analog & pulse in..................................................................................44

14 Digital I/O..............................................................................................49

15 Analog & pulse out................................................................................54

16 System ...................................................................................................59

18 Fault log................................................................................................63

19 Speed calculation...................................................................................64

20 Limits.....................................................................................................65

21 Speed reference......................................................................................66

22 Speed Ramp(Speed Given Ramp Generator) ........................................68

23 Speed control.........................................................................................70

25 Critical speed.........................................................................................71

26 Constant speeds .....................................................................................72

27 Process PID ...........................................................................................75

30 Fault function.........................................................................................79

31 Motor therm prot ...................................................................................81

34 Logic function .......................................................................................83

35 Math function ........................................................................................89

47 Multi step ctrl ........................................................................................93

48 Switch Sync...........................................................................................96

50 Fieldbus .................................................................................................97

51 Embedded Modbus................................................................................98

52 VF Cruve.............................................................................................100

60 Motor control.......................................................................................101

62 Motor parameter..................................................................................103

63 Startup parameter.................................................................................104

6.chapter Field Bus .....................................................................................107

6.1 data set ··················································································107

6.2 Modbus ···············································································108

6.3 Function Code And Frame Format··············································109

6.4 Parameter address ···································································110

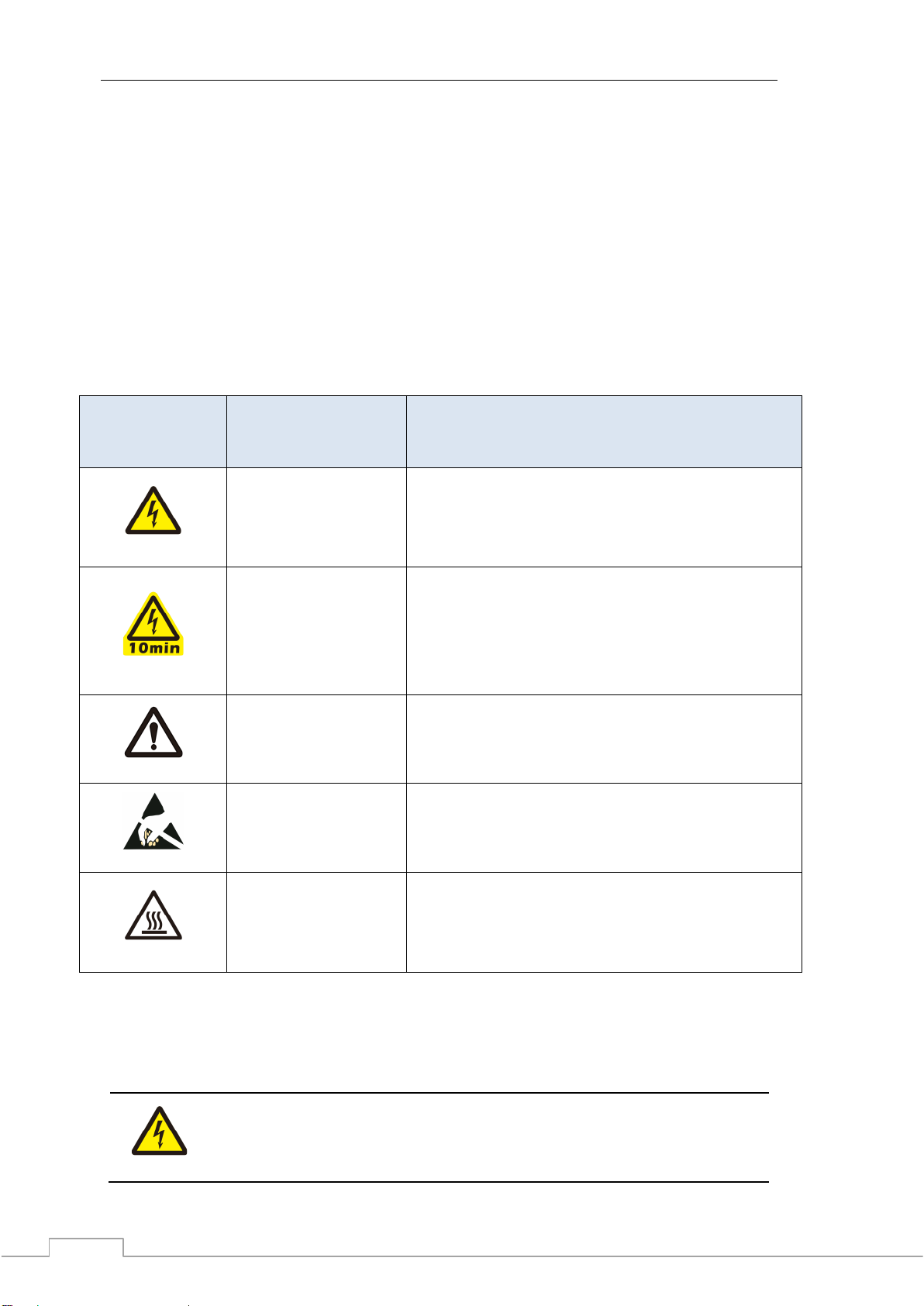

chapter 7 EMC Electromagnetic Compatibility.......................................... 111

7.1 Electromagnetic compatibility definition·······································111

7.2 EMC guide ·············································································112

7.3 EMC filters·············································································115

7.3.1 When do you need the EMC filter?.................................................115

7.3.2 How to disconnect the built-in EMC filter with ground screw........115

chapter 8 Maintenance................................................................................ 117