3

INTRODUCTION

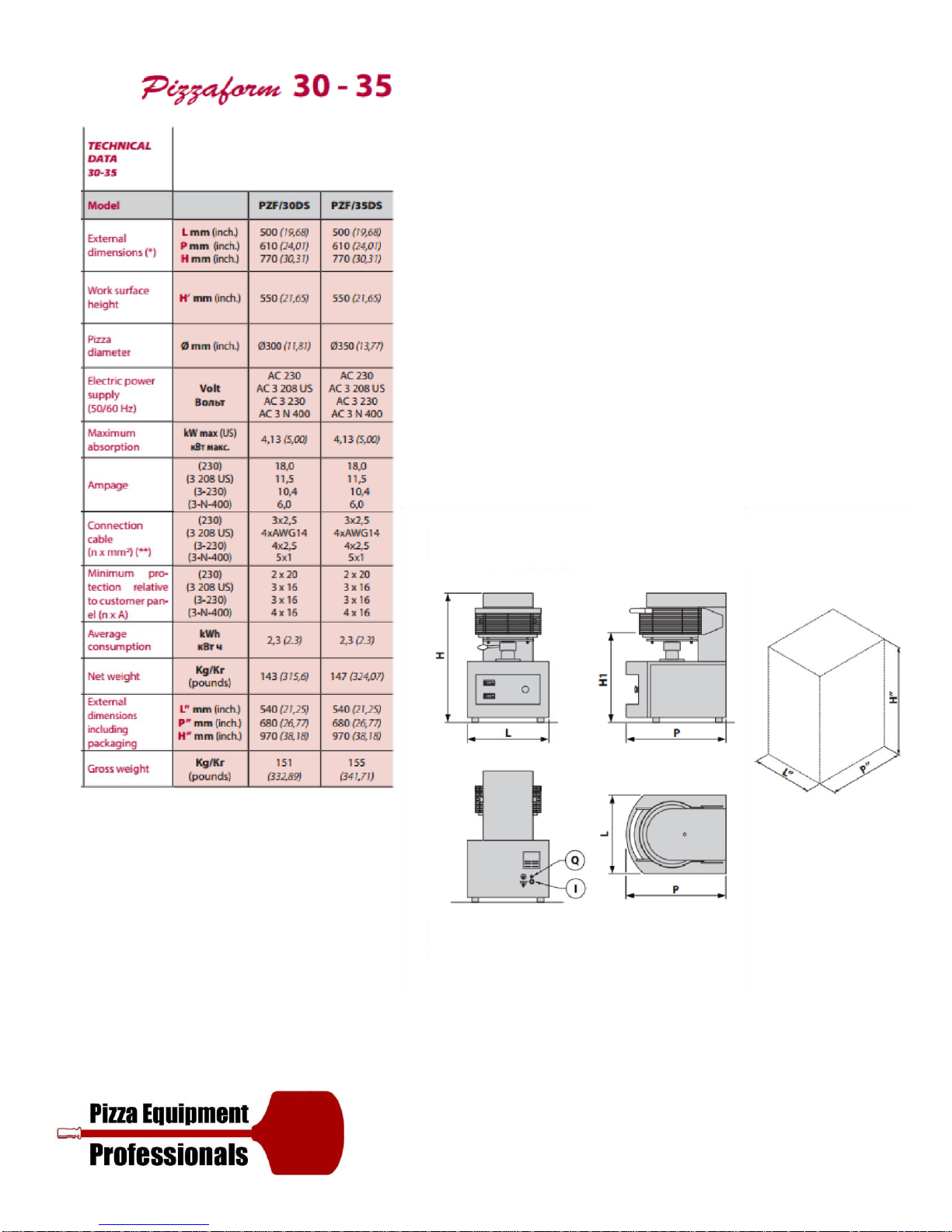

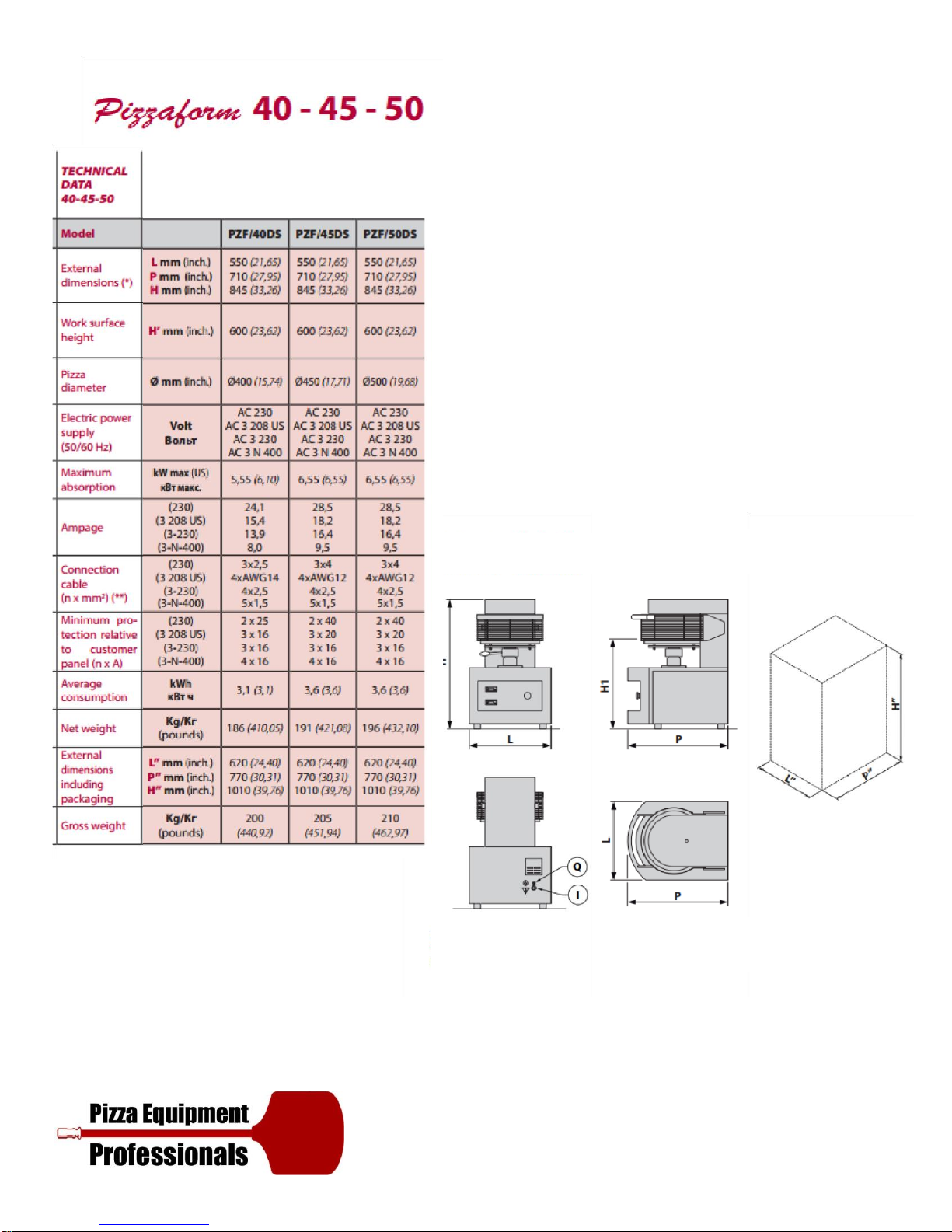

The present manual refers to various electronic control PIZZAFORM pizza hot forming machine models.

The present manual was originally written in Italian. All other languages are translations.

Congratulations on selecting a product that was designed and constructed with advanced technology.

We recommend that you read through this manual fully before using this equipment. It contains very

important information and instructions regarding installation, use and maintenance.

The equipment you have purchased was carefully designed and constructed and has been subjected to strict

inspection tests in our laboratories, therefore we can guarantee its absolute safety and functionality.

Installation must be done according to the instructions by professionally qualified personnel who are able to

take on the responsibility for the installation and guarantee the best conditions for operation and safety.

TECHNICAL SUPPORT

The manufacturer is able to solve any technical problem concerning use and maintenance. In the remote

possibility of poor operation or a repair, only use qualified personnel or contact our authorized service

centers.

INITIAL INSTRUCTIONS

ATTENTION! Failure to comply with what is described in this handbook could jeopardize safety.

The manual must be kept carefully in an accessible location, it must also always accompany the product

during its life.

Before installing and using the equipment, this manual must be read carefully and the instructions it contains

must be followed scrupulously.

The manufacturer declines all civil and criminal liability for damage to people, property or animals deriving

from the failure to observe current safety regulations, failure to respect the contents of this manual and

from any printing or transcription errors.

It also declares that it reserves the right to make any changes to the product that it considers appropriate

without the obligation to provide notice.

Before handling, installing, or using the product, verify the suitability of the room where it will be located.

Make sure that all safety measures have been taken in order to avoid any accidents.