2

TABLE OF CONTENTS — 281 BENDING TABLE

Safety Alerts ................................................................................ 2-4

Components – 281 Bending Table .................................................4

Major Components & Parts List – 254 Bender .............................5

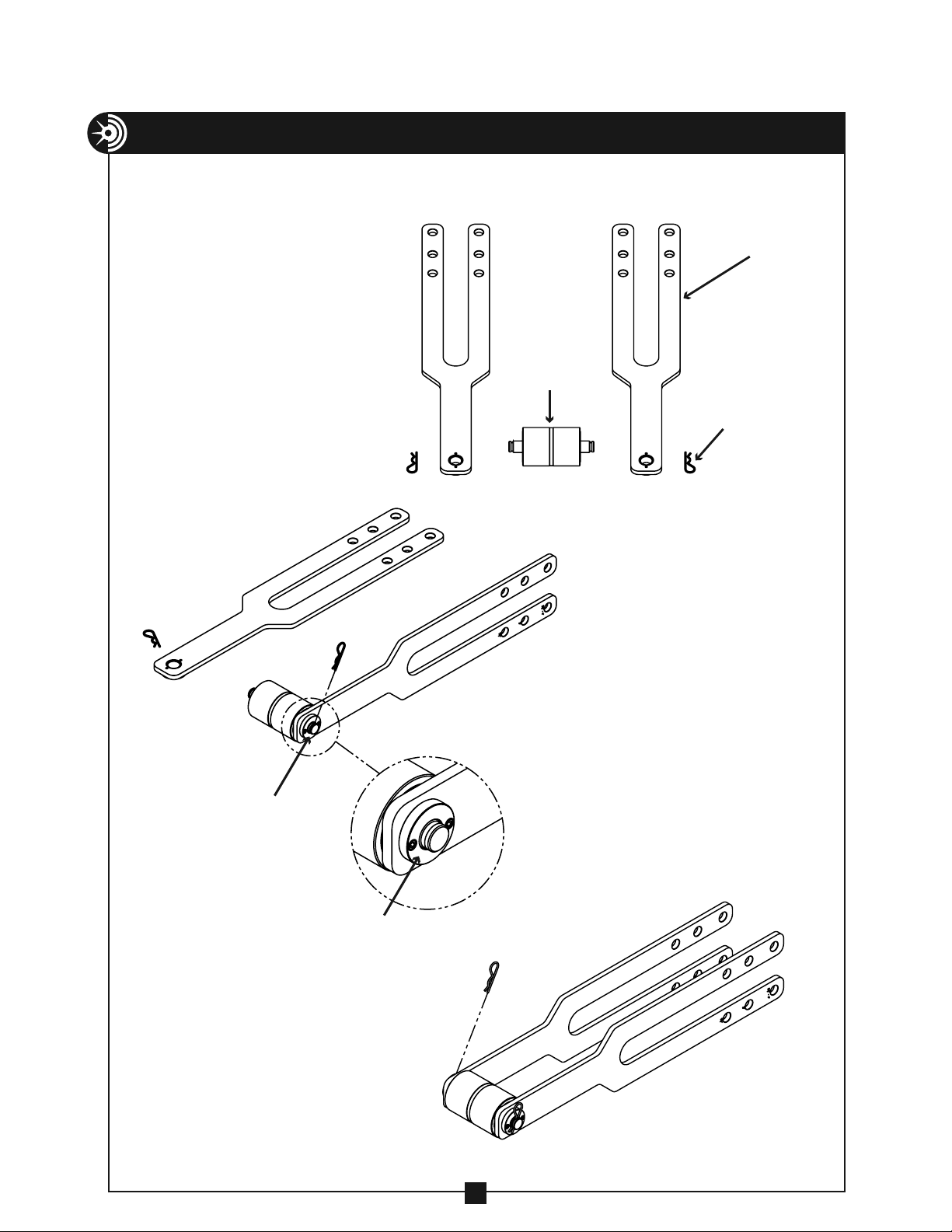

Assembly Instructions ................................................................ 6-9

Bender Assembly & Mounting Instructions ......................... 10-26

Exploded Views & Parts List.................................................. 27-28

RETAIN SAFETY INFORMATION

This manual should be read and understood by all personnel who assemble,

operate or service this bending table and hydraulic bender. Failure to

understand how to safely assemble and operate these units could result

in injury or death. This bending table and hydraulic bender should only be

assembled, operated and serviced by qualified personnel.

SAFETY ALERTS

Hazards or unsafe practices which, if not avoided,

COULD result in serious personal injury or death.

WARNING

Hazards or unsafe practices which, if not avoided,

COULD result in minor personal injury or property damage.

CAUTION

Immediate hazards which, if not avoided, WILL result in

serious personal injury or death.

DANGER

THIS SAFETY SYMBOL is used to call your attention to instructions

that concern your personal safety. It means: ATTENTION! BE AWARE!

THIS IS AN IMPORTANT SAFETY INSTRUCTION!

Read, understand, and follow these safety instructions. Failure to follow

these safety instructions may result in injury or death.

Safety Alert

Symbol

Hazards or unsafe practices which, if not avoided,

COULD result in serious personal injury or death.

WARNING

Hazards or unsafe practices which, if not avoided,

COULD result in minor personal injury or property damage.

CAUTION

Immediate hazards which, if not avoided, WILL result in

serious personal injury or death.

DANGER

THIS SAFETY SYMBOL is used to call your attention to instructions

hat concern your personal safety. It means: ATTENTION! BE AWARE!

THIS IS AN IMPORTANT SAFETY INSTRUCTION!

Read, understand, and follow these safety instructions. Failure to follow

hese safety instructions may result in injury or death.

Safety Alert

Symbol

THIS SAFETY SYMBOL is used to call your

attention to instructions that concern your

personal safety. It means: ATTENTION! BE

AWARE! THIS IS AN IMPORTANT SAFETY

INSTRUCTION!

Read, understand and follow these safety

instructions. Failure to follow these safety

instructions my result in injury or death.

* Greenlee®and CamTrack®are registered

trademarks of Emerson Electric Co. , which has no

affiliation with Current Tools.

Refer to the Current Tools Model #254 Assembly, Operating and Maintenance,

Safety and Parts Manual for complete bending instructions, charts, etc.

When using the 281 Bending Table with Greenlee®881 or 881 CamTrack®*

Bender, read and understand the bender manufacturer’s operating and safety

instructions before attaching to or operating with the 281 Bending Table.

Failure to do so may result in serious injury or death.

IMPORTANT