5

MACHINE SPECIFICATIONS

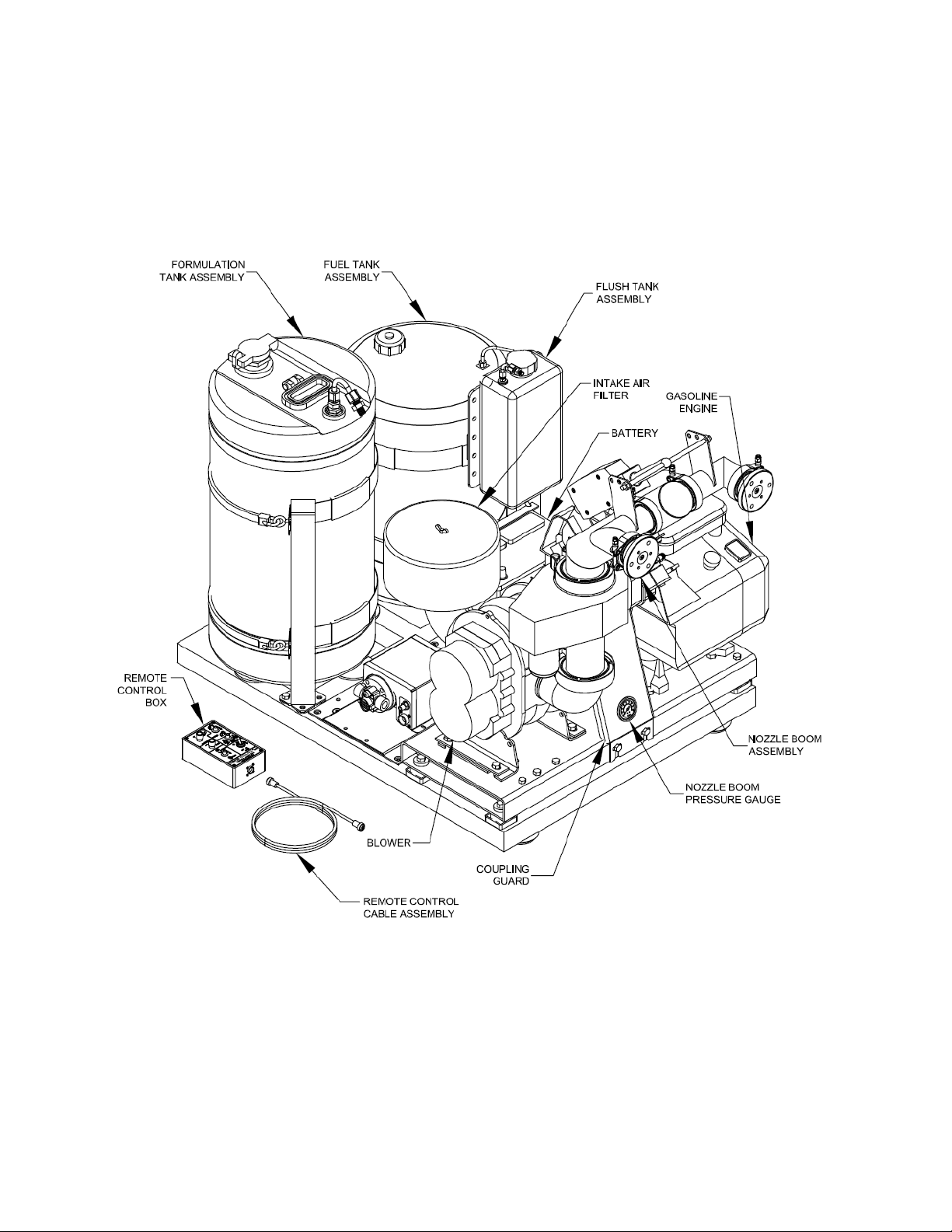

MAXI-PRO 2D, MODEL 2745 SERIES 2

TYPE: ULV Chemical Aerosol Applicator

ENGINE: Briggs & Stratto , OHV Commercial Grade, Twi Cyli der,

4-cycle, gasoli e powered, electric start with heavy duty

alter ator. Tachometer /Hour meter.

BLOWER: Positive displaceme t. Straight lobe, rotary type, direct drive.

Output Air Pressure: Rated at 0-10 PSI (.68 Bar). Output Air

Flow: Rated at 0-400 CFM (11.2 m³/mi .)

FORMULATION PUMP: 2-Types Available:

1) High volume, corrosio resista t diaphragm pump.

Flow rate: 0-128 oz/mi (0-3.79 L/mi )

2) Stai less steel gear pump, digital display with optio al

radar sy croflow co trol.

Flow rate: 0-18 oz/mi (0-.53 L/mi )

NOZZLE SYSTEM: Boom type with dual ULV ozzles. Full, remote co trol

ozzle operatio from 0-180° horizo tal a d 70° total vertical

travel. Speed of horizo tal ozzle rotatio is 180° i 3

seco ds.

TANK METERIALS: Corrosio resista t, high de sity polyethyle e.

TANK CAPACITIES: Formulatio : 15 US Gallo s (56.8 liters)

Flush: 1 US Gallo (3.79 liters)

Gasoli e: 12.2 US. Gallo s (46 liters)

PARTICLE SIZE: Meets or exceeds all curre tly available chemical

ma ufacturers label requireme ts with 90% or more droplets

u der 20 micro s VMD a d ca be co figured to produce

larger droplets if required for special applicatio s. (Co sult

the ma ufacturer for further details).

WEIGHT EMPTY: 415 lbs. (188 Kg.)

WEIGHT FILLED: 587 lbs. (266 Kg.)

LENGTH: 59 i . (149.9 cm.)

WIDTH: 37 i . (94 cm.)

HEIGHT: 44 i . (111.8 cm.)

MOUNTING BASE

FRAME: 39” L x 30” W (97 cm x 76 cm)

SHIPPING INFORMATION (CRATED).

DIMENSIONS: 47.0” L x 39.5” W x 39” H (119 x 100 x 99 cm.)

VOLUME: 41.9 cu. ft. (1.2 cu. Meter)

SHIPPING WEIGHT: 482 lbs. (219 Kg.)