2

TABLE OF CONTENTS

Forward. 3

Machine Specifications.. 4

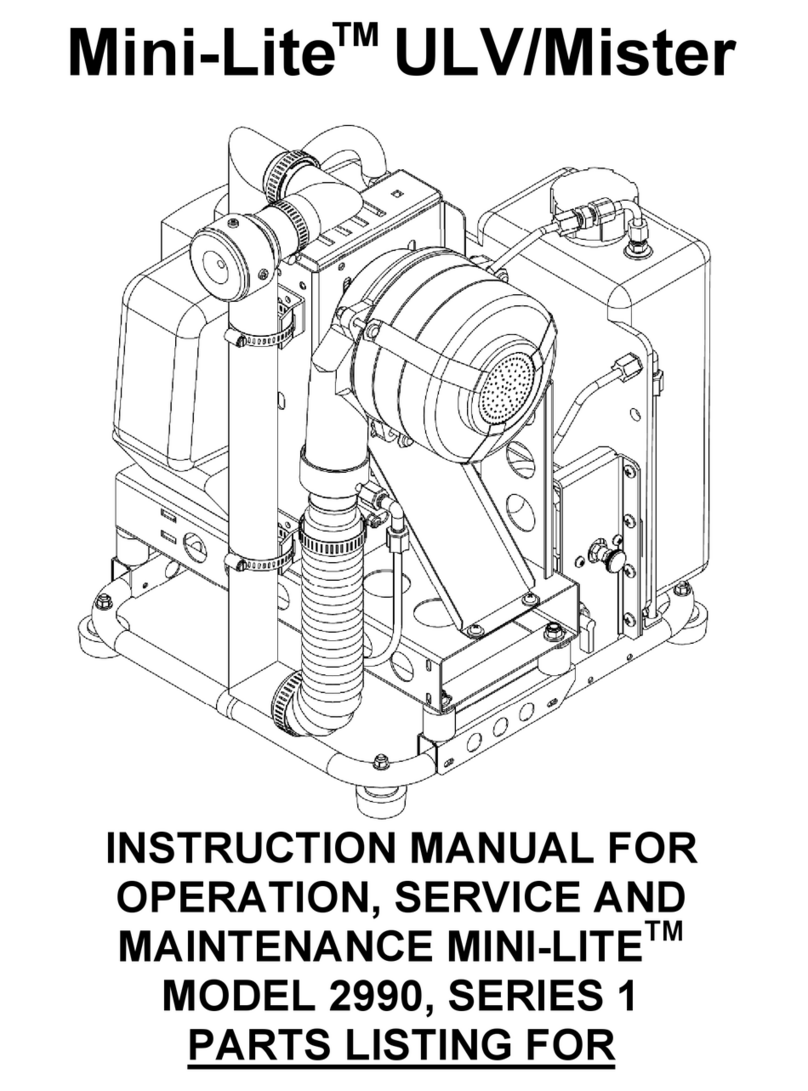

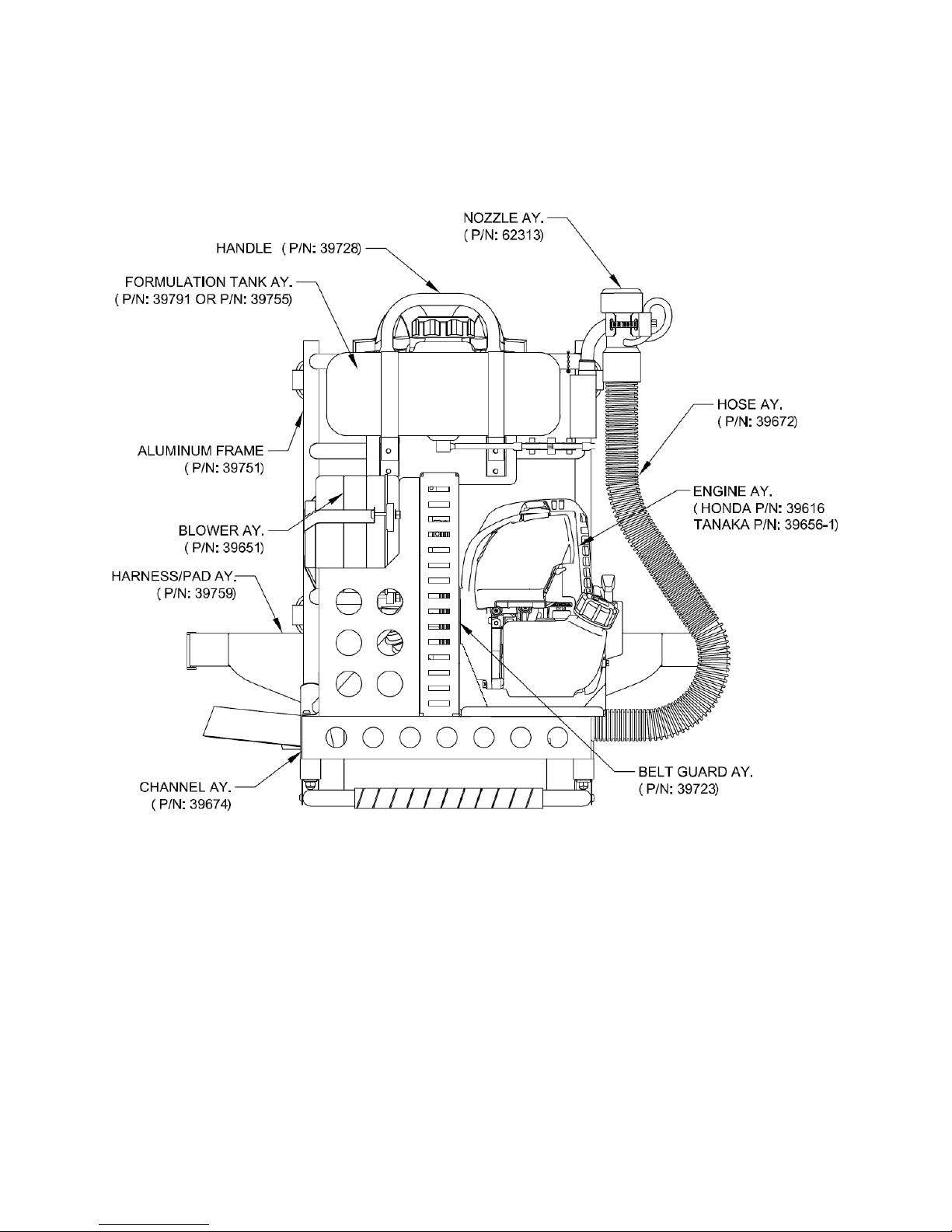

Main omponents Diagram.. 5

Working Principles.. 6

Machine Operation. 7

Pre-Spray hecklist 8

Engine Operation Instructions.. 9-10

Operator Safety 11

On/Off ontrol Valve.. 12

Measuring Liquid Flowability. 13

Flow Rate hart.. 14

Honda Engine Maintenance.. 15

Speed Adjustment.. 15

Air Filter 15

Oil Level heck 16

Oil hange 17

Spark Plug 18-19

Engine Fins... 19

Fuel Filter and Fuel Tank 20

Spark Arrester.. 21

Tanaka Engine Maintenance.. 22

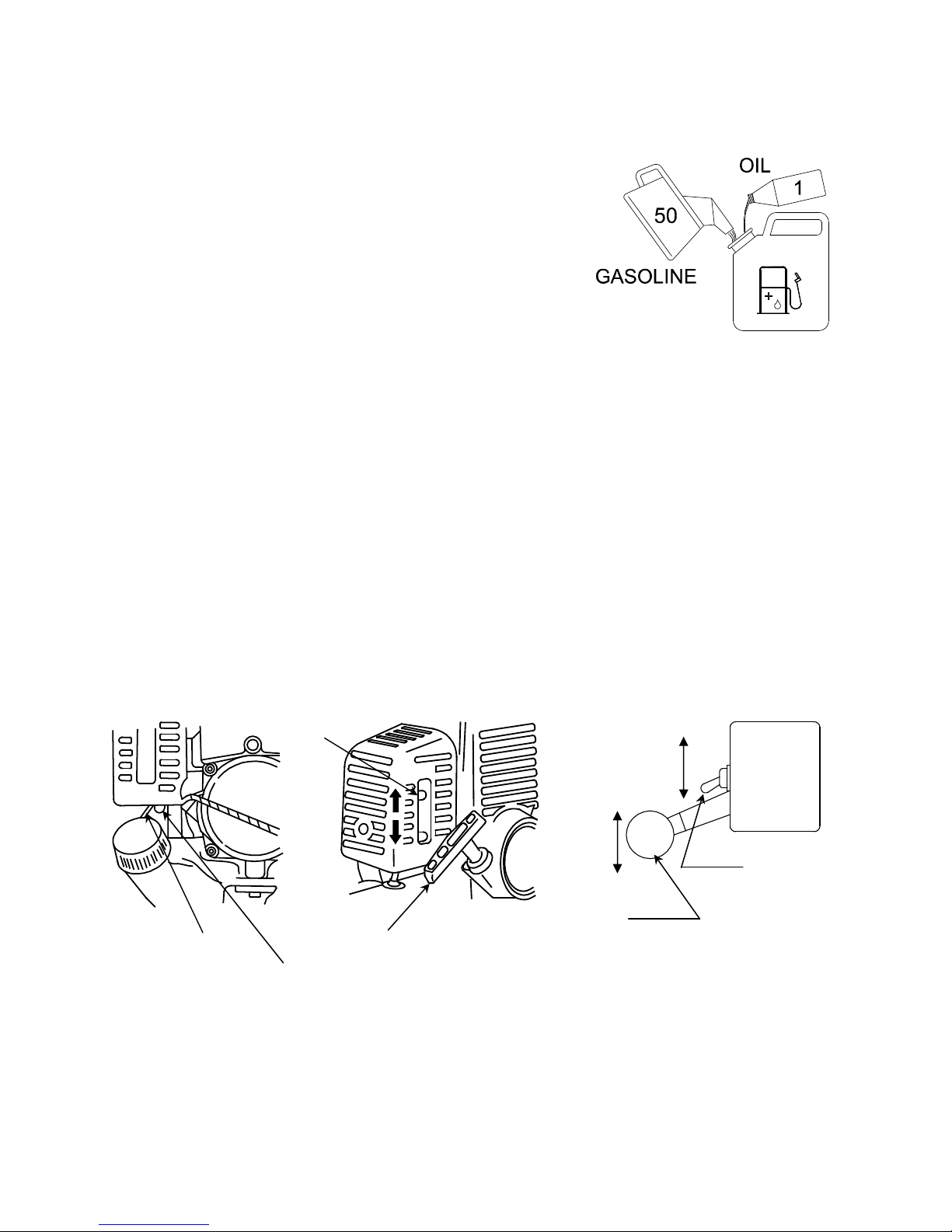

Speed Adjustment.. 22

Air Filter 22

Fuel Filter. 23

Spark Plug 23

Muffler 23

Engine Fins... 23

Blower Assembly.. 24

Inspection of the Blower.. 24-25

Air Filter Assembly 26

Removal and leaning 26

Poly-V Belt and Sheave Drive 27-28

Belt Alignment.. 27-28

Belt Tension.. 29

Flushing the System 30

Preventive Maintenance Schedule 31-32

Flow Rate Verification.. 33

Trouble Shooting Guide.. 34-35

Exploded Machine Diagram and Parts List.. 36-37

Straps. 38

Engine Blower Plate Assembly.. 39-40

Blower Assembly – Exploded. 41

Engine Assembly.. 42

Remote Nozzle Assembly 43

Hose Assembly. 44

Nozzle/Adaptor Assembly 45

Formulation Tank Assembly 46

ontrol Assembly, Throttle.. 47

Flow Regulating Orifices.. 48

Labels.. 49

Dual Nozzle Attachment Diagram and Parts List. 50-51

Installation instructions for Dual Nozzle. 52

Tanaka Engine Information 53-60