1

This Curtis Gold Cup Unit is Factory Pre-Set and Ready to Go Right from the Box.

Following are the Factory Settings for your Coffee Brewing System:

•BrewTemperature=200°F

•BrewVolume=SettoVesselRequirement.

SystemRequirements:

•WaterSource20–90PSI(MinimumFlowRateof½GPM)

•Electrical:Seeattachedschematicforstandardmodelorvisitwww.wilburcurtis.com

for your model.

Models

CGC

CGC1

CAUTION: DO NOT

connect this brewer to hot

water. The inlet valve is

not rated for hot water.

CAUTION: Please use

this setup procedure

before attempting to use

this brewer. Failure to follow the

instructions can result in injury or the

voiding of the warranty.

IMPORTANT: Equipment

to be installed to comply

with applicable govern-

mental plumbing/electrical codes

having jurisdiction.

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO., INC.

6913 West Acco Street

Montebello, CA 90640-5403

For the latest information go to

www.wilburcurtis.com

Tel: 800-421-6150

Fax: 323-837-2410 For the latest specications and information go to www.wilburcurtis.com

Thisequipmentisdesignedforcommercialuse.Anyservicingotherthancleaningand

routinemaintenanceshouldbeperformedbyanauthorizedWilburCurtisCompanySer-

viceTechnician.

• DONOTimmersetheunitinwateroranyotherliquid

• Toreducetheriskofreorelectricshock,DONOTopenservicepanels. There

arenouserserviceablepartsinside.

• Keephandsandotheritemsawayfromhotareasoftheunitduringoperation.

• Nevercleanwithscouringpowdersorharshchemicals.

Important Safeguards/Symbols

Service Manual – Curtis Gold Cup

Wilbur Curtis Co., inC.

Symbols:

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Sanitation Requirements

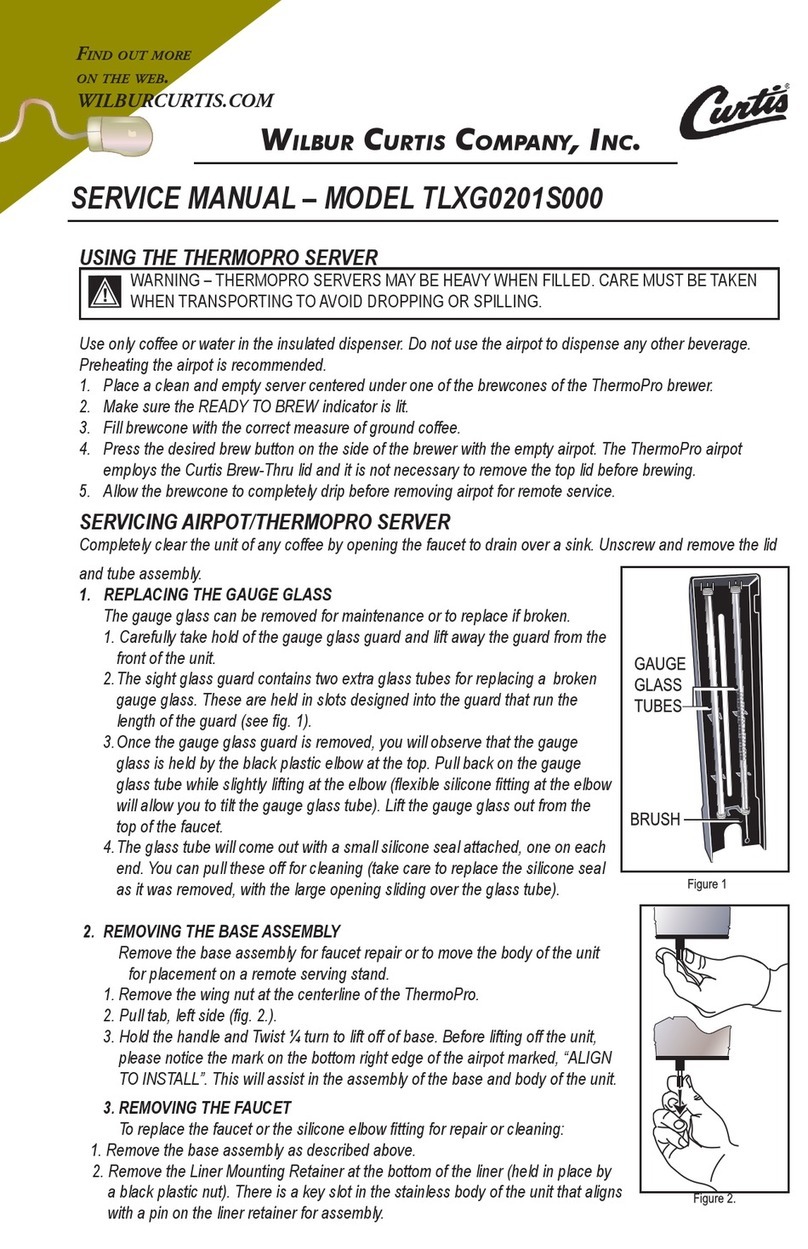

NSF International requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) is required so

that the unit can be moved for cleaning.

2. This unit must be installed with adequate backow protection to comply with applicable federal,

state and local codes.

3. Water pipe connections and xtures directly connected to a potable water supply shall be sized,

installed and maintained in accordance with federal, state, and local codes.

3. Connect the unit to electrical circuit with appropriate amperage rating; refer to serial tag on the machine and

local/national electrical codes to determine circuit requirements.

4. Once power has been supplied to the unit, ip the toggle switch to the ‘ON’ position (located on the rear of

the unit), the water tank will begin to ll. When the water level in the tank reaches the probe, the heating

element(s) will turn on.

5. Water in the heating tank will require approximately a half hour before reaching operating temperature (factory

setting of 200°F). Where applicable, turn on the Universal Control Module (UCM). When the unit reaches

operating temperature, it will display “READY TO BREW”.

NOTE: A water ltration system must be used to help maintain trouble-free operation. Air must be

purged from the cartridge prior to connection to equipment. In areas with extremely hard wa-

ter, we highly recommend the use of a Curtis approved water lter. For our full line of lters, please

log on to www.wilburcurtis.com.

SETUP STEPS

1. The unit should be level (left to right - front to back), on a secure surface.

2. Connect the water line to the water inlet tting on the rear of the unit. Water volume ow to the machine

should be consistent. Use tubing sized sufciently to provide a minimum ow rate of one gallon per minute.

NOTE: Electrical source should have a minimum 30A internal common trip circuit breaker between

the brewer and the main supply, which breaks all poles with a contact separation of at least 3 mm.