2

ref: MA-ED-0008-EN-V16.0-MIÑO DESCALCIFICADOR D-DF-M3 & D-UF-M3.pdf

1. -PRESENTATION.

In this manual, what is described are the required actions for the instalment, start up and

maintenance of the D-DF and D-UF softener systems.

It is important to read this manual carefully before installation and the start-up of the equipment.

Keep this manual for future reference and if you have any doubt or question please contact your

distributer’s technical assistance service.

The guarantee will be void in case of faulty installation or if it has not been done by a qualified

service technician.

2. - SOFTENENING PROCESS:SERVICE & REGENERATION

Water softening in your system is done through an ion exchange process.

To do so, resins which have ionic exchange are used, which the chemical ability to capture calcium (Ca) and

magnesium (Mg) ions, eliminating them from the treated water.

At the same time that the calcium and magnesium ions are captured by the resin, a sodium ion (Na) is

released, which, due to its chemical characteristics, forms salts with a much higher solubility, avoiding

problems associated hardness.

It is important to take into account that as indicated above, softener systems increase the concentration of

sodium in the treated water more so than that of the water that enters the system.

Depending on the concentration of sodium and hardness in the water which enter the system, the value of

sodium in the treated water can be above the values recommended in European Directive 98/83 CE

If the water is to be consumed by people who must follow low sodium diets, it is recommended to install a

reverse osmosis system.

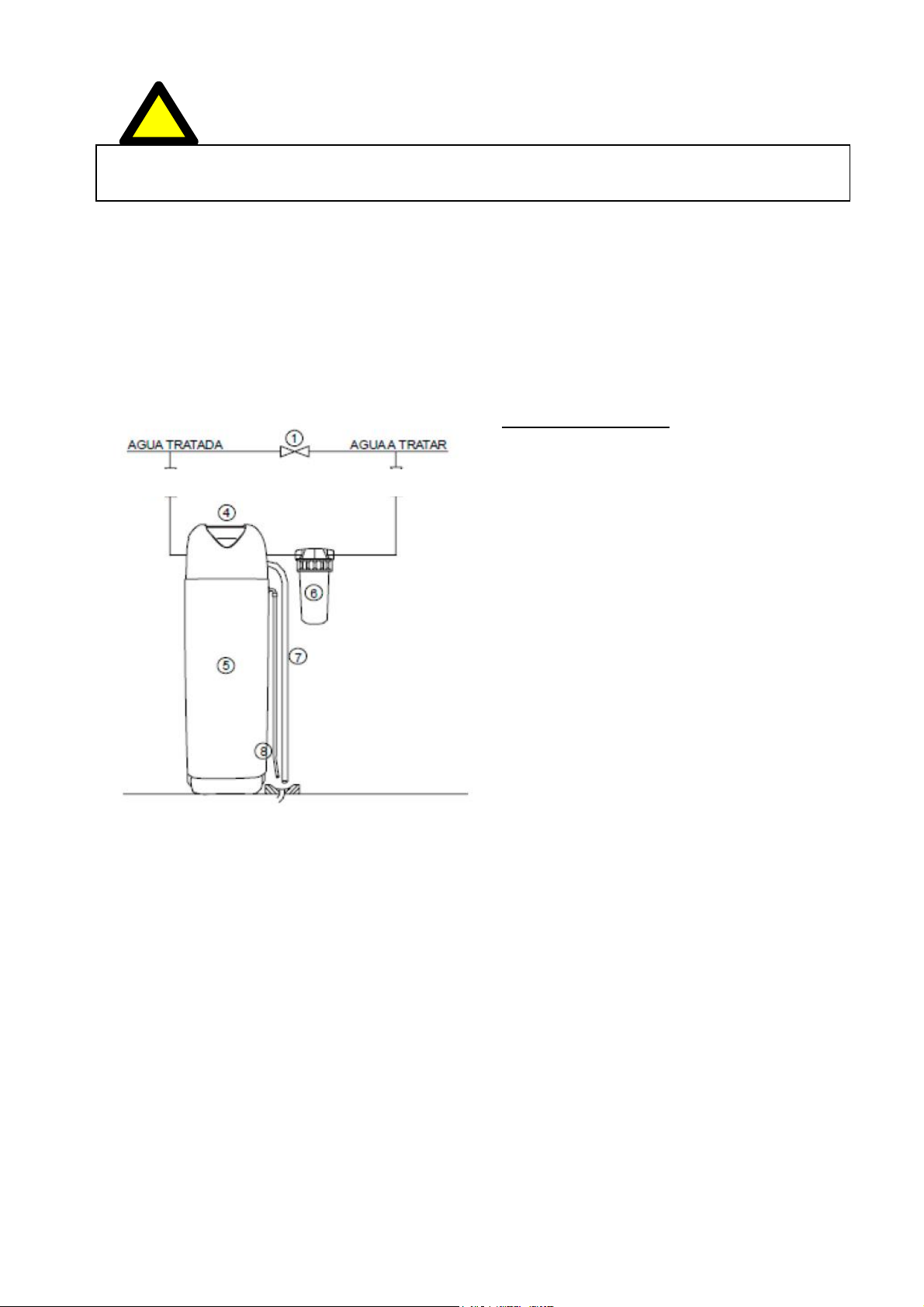

2.1. - SERVICE PHASE

During treatment the water enters the valve through the inlet, flows into the top of the bottle, flowing through the

resin bed in descending order thereby producing the ion exchange process.

The treated water is sent through the outlet connection to the service.

2.2. - REGENERATION PHASE.

Once the resin bed has retained all of the calcium and magnesium ions they must be regenerated for

a new cycle.

The regeneration process consists of 4 steps aiming at the regeneration of the resin bed and its

preparation for the new cycle.

Softeners from the CURVE, D-UF and D-DF series automatically switch between operating and

regeneration phases without the user having to manipulate the system.

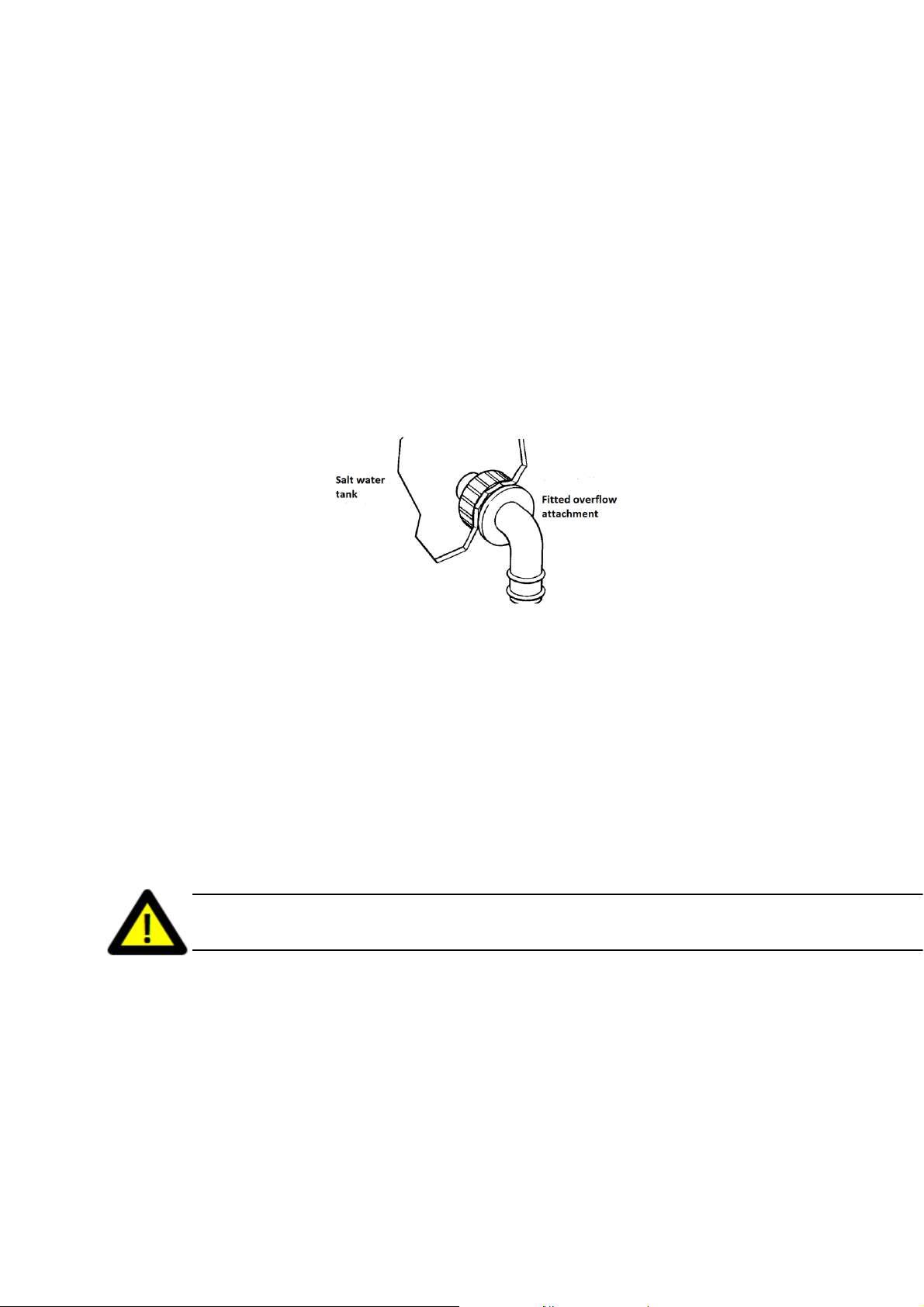

The final user should only keep the brine tank full of salt for softeners.