1

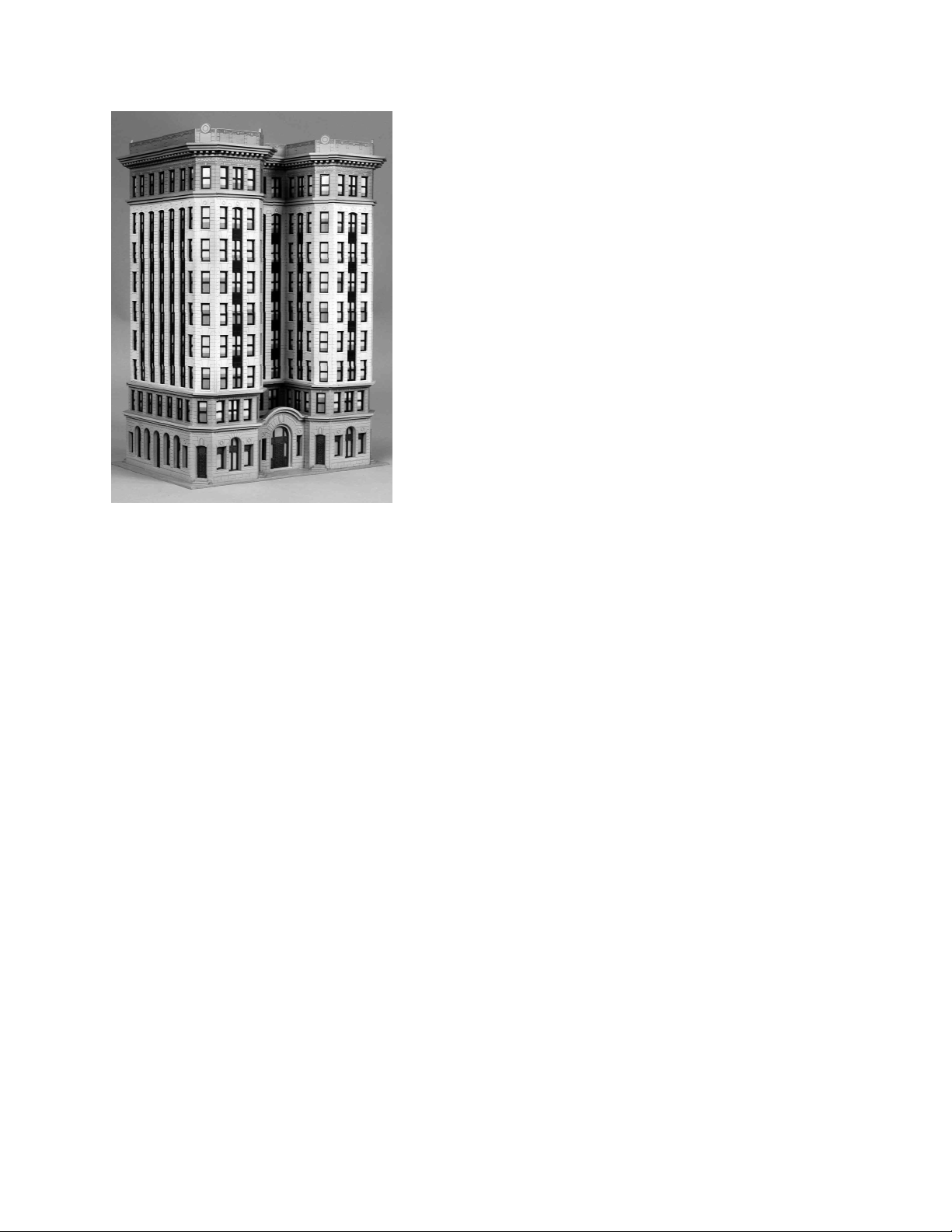

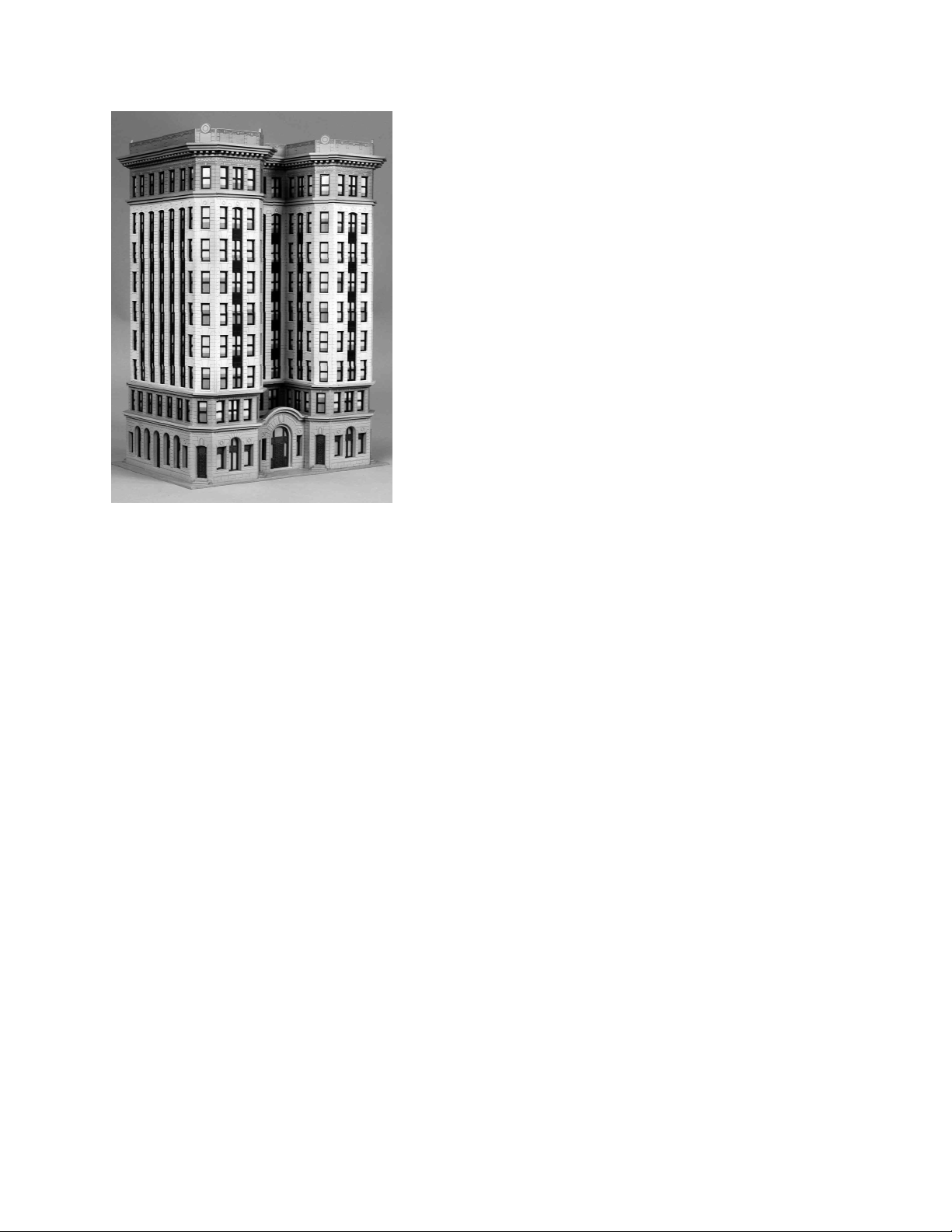

Railroad Headquarters Building

Instructions for Assembly of the HO scale kit.

v1.1

Kit Contents:

135 ea. laser cut .090" acrylic parts.

69 ea. laser cut .060" acrylic parts.

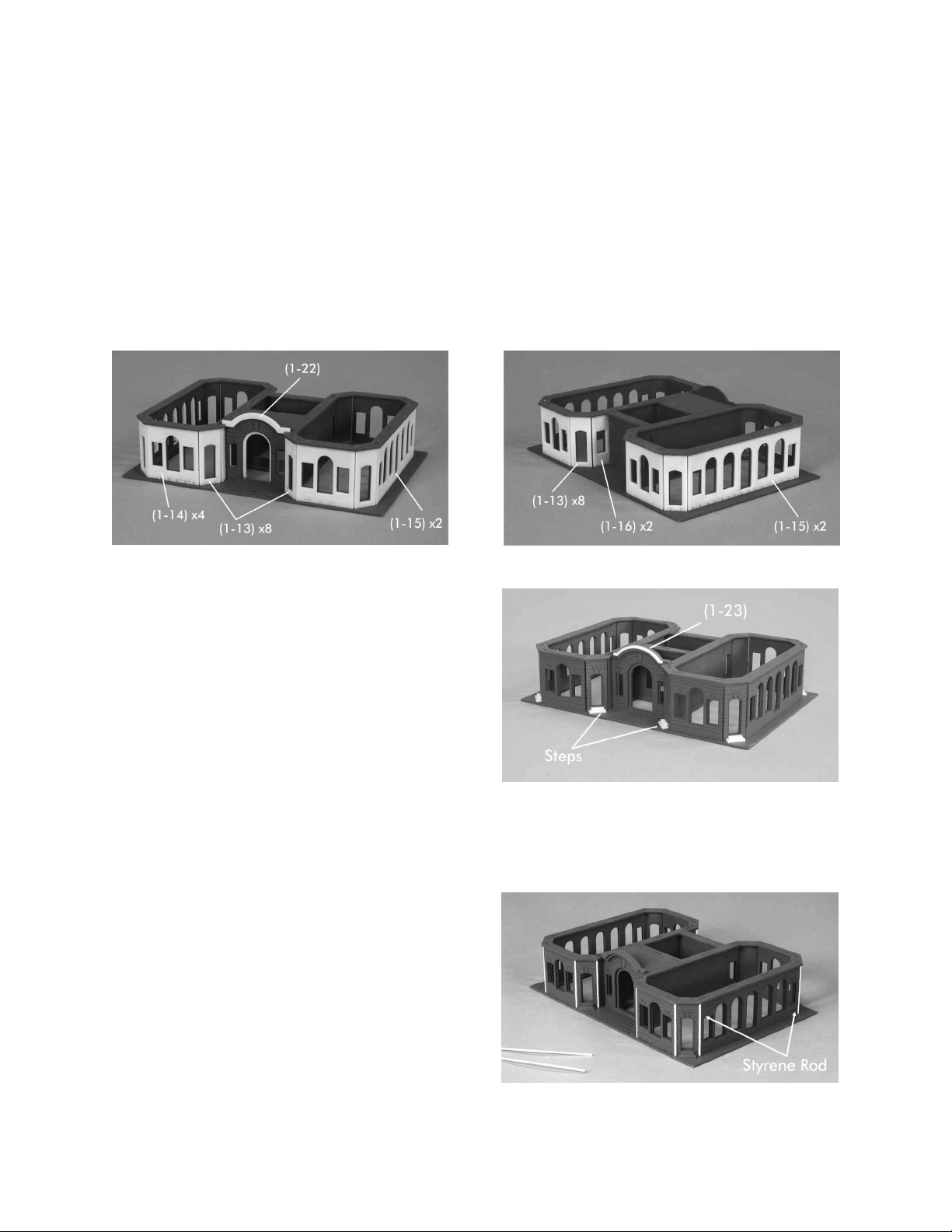

20 ea. .080" styrene rod.

9 ea. window glass templates

9 ea. window glazing

Instructions with diagrams

Thank you for purchasing this kit. Please read these

instructions completely before beginning and take your

time. Allow parts to dry after painting or gluing and do not

try to build this in one night.

Drawings of all the parts have been included for ease of part identification.

Practice gluing the acrylic together if you have never done it before. There is plenty of scrap in

your kit that you can use for this.

If by chance a part is missing or broken, please write us indicating the kit name and part number

and we will send you a replacement.

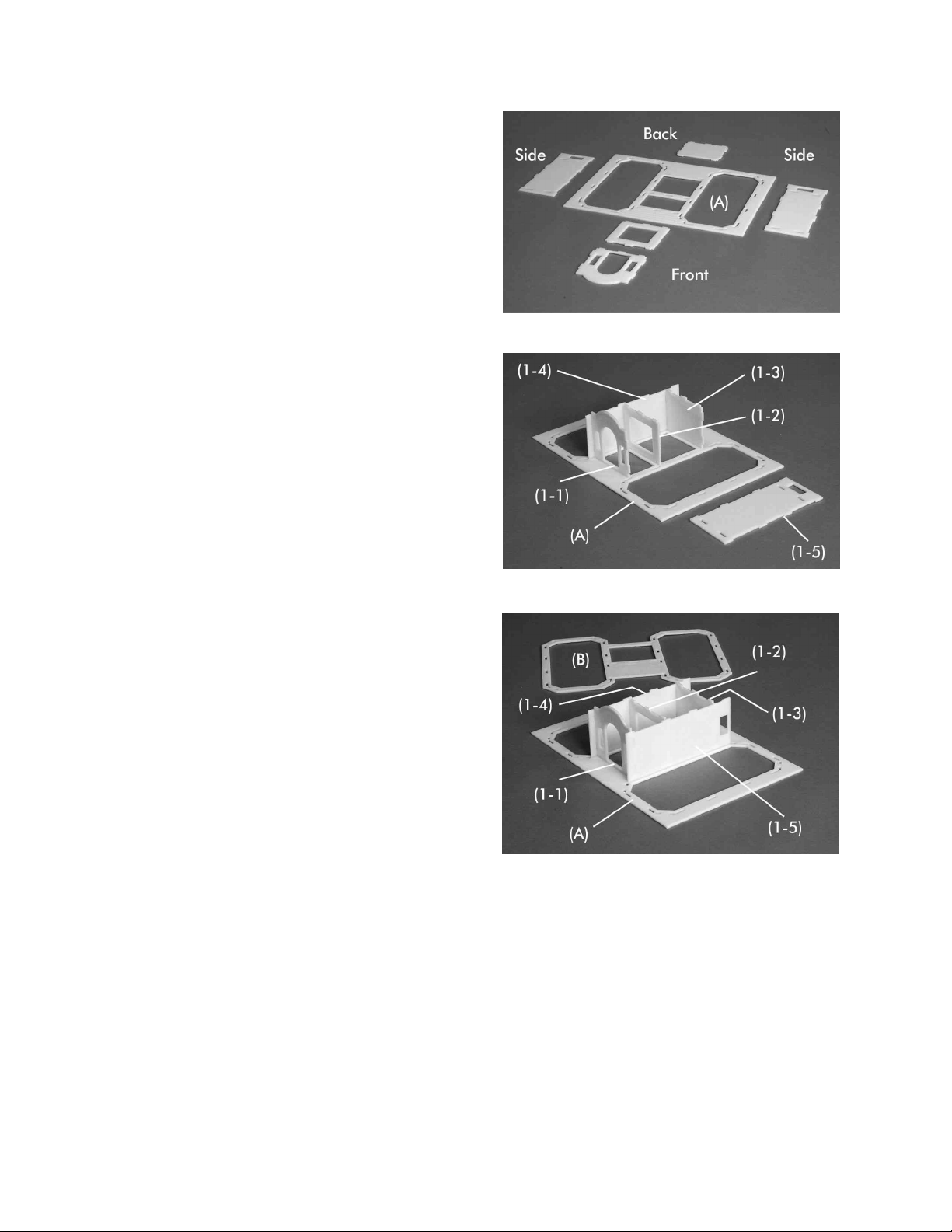

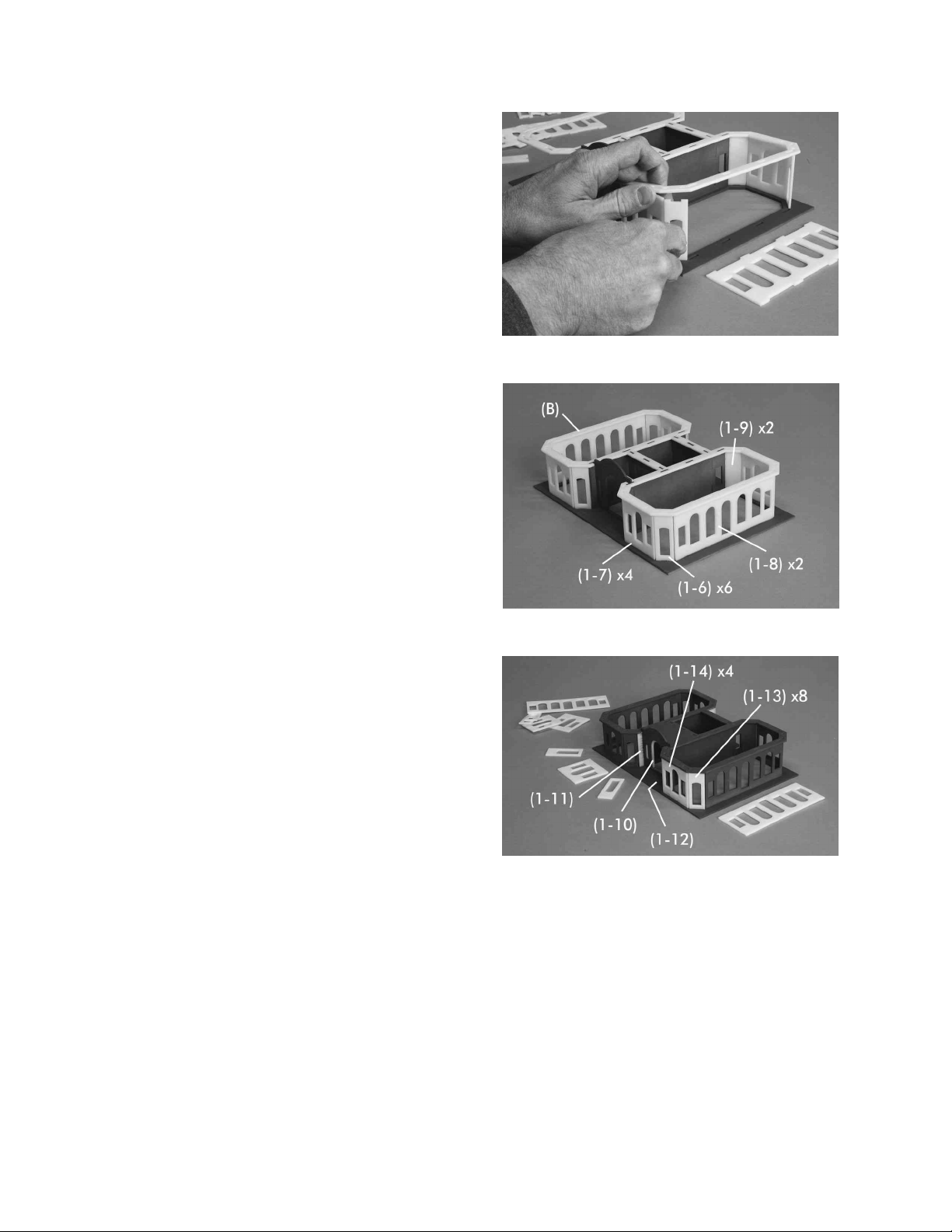

Please note that parts of the kit have been painted gray in the assembly photos so that new parts

can easily be seen and identified. This is only for ease of identifying parts and seeing them

clearly in the photos. We recommend gluing all parts together prior to painting unless otherwise

noted.

Pre-production models were used in these instructions, your parts may vary slightly.

You will need the following items to assemble your model: Hobby knife, fine sand paper, file,

paint (see “Painting Your Model”), paint brushes, glue (see “Gluing Acrylic”), modeling putty.

About the Kit

Our kit is based on a thirteen-story high rise built in 1906 to replace its predecessor which was

destroyed by fire. It has a steel frame and stone clad exterior. Inside, it hosts lavish details, a

marble-clad lobby and ornate stairs. When completed, it clearly made a statement as to the

railroad’s confidence moving forward. The building housed railroad headquarters for seventy-

five years. Currently it is a high end hotel. Our model has nine floors and can be increased in

height by the addition of an “Add-On Kit” sold separately.