www.cuttermasters.com - Toll Free (800) 417 2171

CUTTERMASTER Professional JXT User’s Manual

Page 8

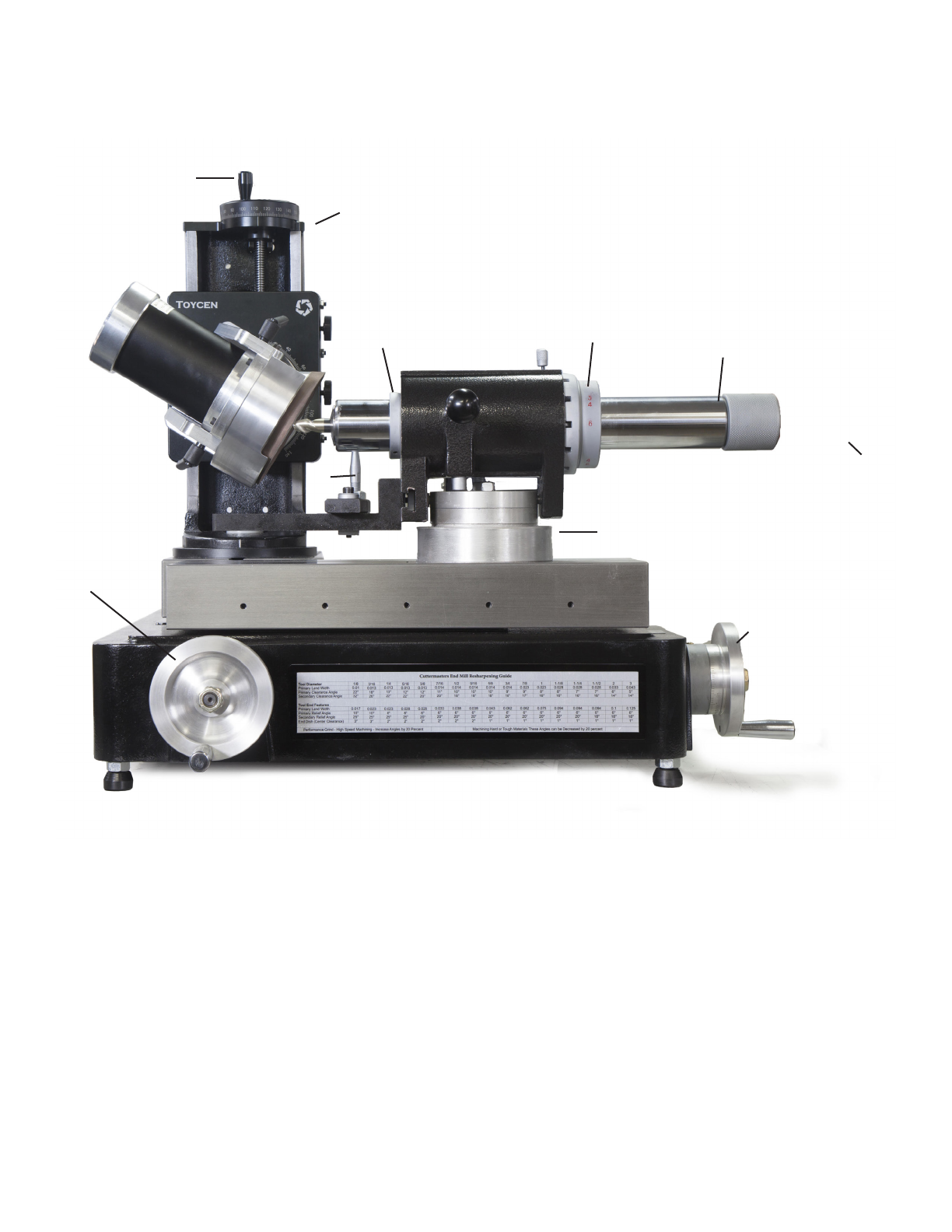

CUTTERMASTER Professional Products have been designed to accommodate a variety of needs.

This system has been designed to be easy to use and maintain. As with all machine tools care must

be taken to keep all working surfaces clean and in good repair. There are 5 movements to your

CUTTERMASTER Professional DC tower

• Up and down using Top dial lead screw

• Motor Tilt

• Motor Tip

• Base pivot

• VerticalIndexingwiththehandle(forquickliftoutofutes,Cornerrads)

The DC Motor comes with a single or twin spindle so motor/spindle assembly spindle to positive and

negative angles and rotates 360°. Cutting tool clearance angles can be tensioned so as to be quickly

adjusted as needed providing real angle result when setting angles without the use of tools.

Thereareninedierentaxestoworkwithforunlimitedversatility.YourJXSgrindsO.D.sandendsof

standardendmillsinonesetupwithinafewminutes.YoucansharpenendmilluteI.D.s,uteO.D.s

and ends (primary and secondary), as well as roughing end mills, carbide tools, reamers, end gash-

es,smallroundsorreamers(circumferentiallands),reducedneckgrinds,Weldonats,Carbideand

HSSCutos.

Most grinders have a single speed AC motor, designed to be inexpensive for the manufacturers to

produce. This is not conducive to a good tool grinding environment where conditions vary from tool to

tool. DC motors have more torque throughout their variable range of speeds allowing for deeper cuts

without heat damage to the tool, given that it is a dry grinding environment. The twin wheel head of

theJXSDCTowercanbeipped,reversedandspeedadjustedtosuitmostanygrindingrequire-

ment.

Ourgrindingwheelshavebeenspecicallydesignedfordrygrindingandgoodbalance.Onceyou

get your wheels dialed in, you can work from wheel to wheel without having to re-mount and dial in as

frequently.

The Toycen Radius Air Bearing has a 180° swivel base for radius grinding and takes standard 5C

collets with end mill holders available that can hold shank sizes up to 2”. The Toycen Motor Tower

provides easy and accurate positioning of the wheels to the tool being ground and allows two wheels

to be set and trued allowing for the indexing of one wheel to the next which is intended to reduce set

up times.

Journeyman JXT Overview and Theory