Operating Instructions | GPM 450 verSA

4

If the GPM 450 verSA is used correctly, it is a very safe machine. However, if used incorrectly, it can

be dangerous. When operating the machine, the operator is responsible for their own personal

safety. The manufacturer may not be held liable for any personal injury or damage to the machine

caused by use or operation at variance with these Operating Instructions. The owner of the machine

is responsible for the machine being operated, maintained and serviced only by qualified personnel.

The machine design is in compliance with international standards and regulations for the

construction of machine tools. For the machines exported to the European Economic Area (EEA), the

customer will obtain a "Declaration of Conformity" together with the accompanying technical

documentation for the machine - Operating Instructions. Also, the machine bears the CE marking.

The CE marking on the machinery signifies that the product complies with the technical requirements

specified in all the legal regulations that apply to the machinery and that require or allow this

marking. This marking also signifies that a specified procedure was followed during the assessment of

the stated conformity.

The manufacturer certifies by means of the “Declaration of Conformity” that the machinery

concerned complies with the requirements of Directive 98/37/CE of the European Parliament and of

the Council and those of the harmonized technical standards. Directive 98/37/CE of the European

Parliament and of the Council is a document defining the generally applicable basic requirements for

health protection and safety of machinery operated at the user’s facility within the EEA.

Directive 98/37/CE of the European Parliament and of the Council does not apply to the machinery

exported to countries outside the EEA.

The customer will receive the accompanying technical documentation for the machine –Operating

Instructions. The manufacturer hereby requests that the user trains its staff accordingly in order to

ensure comprehensive safety as directed by the relevant laws, standards and regulations, these

Operating Instructions and other documents.

The machine is intended for work in automatic cycles.

The machine operator monitors the process and the operating mode of the machine, replacing

material and checking the dimensions. The Operator's position by the machine is not defined.

3. WARNINGS AND RECOMMENDATIONS

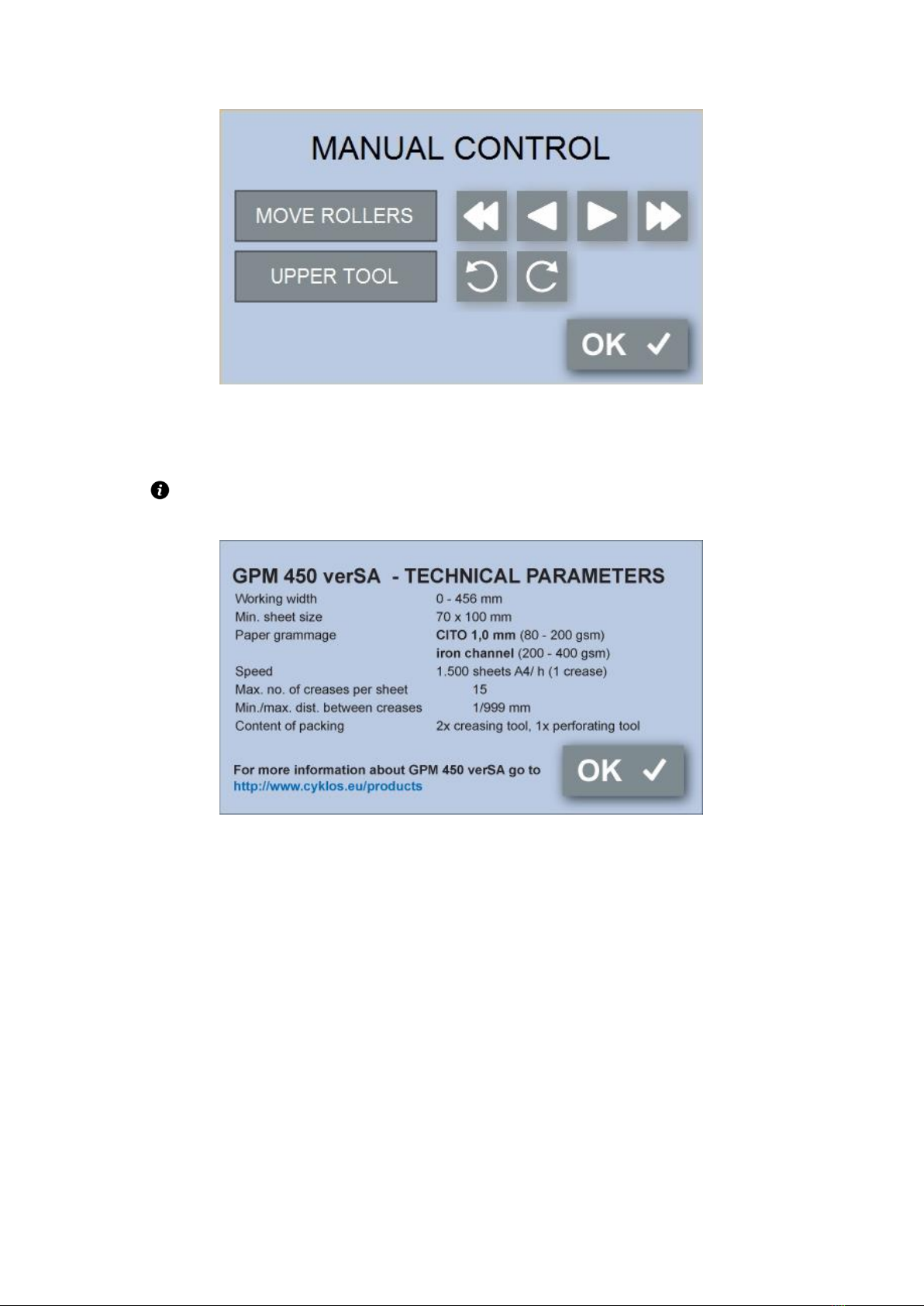

Only sheets of the size listed in the parameters can be creased, perforated and punched by GPM 450

verSA.

a) The operator or the individual appointed for operation cannot use the machine unless they

have been trained.

b) Only sheets of the size listed in the parameters can be creased, perforated and punched by

GPM 450 verSA.

c) It is forbidden to crease and perforate foils, sheet metal or other similar materials.

d) The machine can be only used in interior spaces (e.g. offices, shops), it is not allowed to use

the machine outdoors.