1 Identification

Type marking: CCR 40

Manufacturer: Cyklos Choltice

533 61 Choltice

Czech Republic

2 Specifications

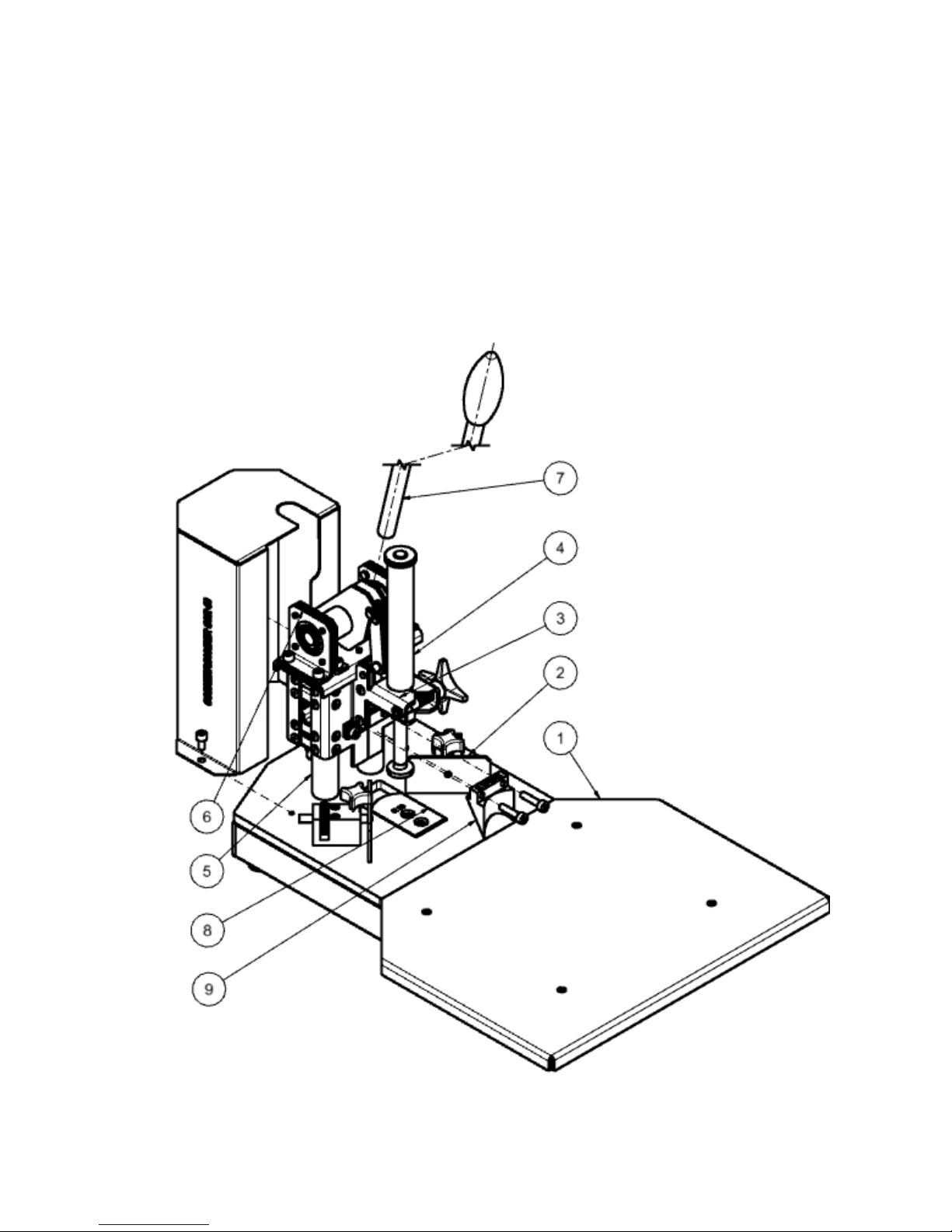

The machine is designed for the manual rounding of paper sheets of A3, A4, A5 and A6

size down to business card as a minimum dimension. Optional radius R4, 6, 9, 12 and 18

mm may be used. Another option is to cut paper corners with a direct tool at an angle of

45° and with a maximum length of 28 mm. The maximum height of inserted sheets to be

adjusted is 40 mm. The rounding machine is designed to cut standard office paper or

paper with similar physical-chemical properties.

3 Prohibited operations

a) The machine is designed only for the cutting of the paper specified in the parameters

section and of a plastic foil.

b) It is prohibited to cut metal foils, tin sheets or similar materials.

c) The machine can be operated only in closed, covered areas (e.g. offices, workshops).

It is prohibited to use the machine outdoors.

d) To reduce the risk of injuries, never use the machine near children.

e) If the machine’s operation gets interrupted or stuck, or if its operation requires

inappropriate efforts, stop working and check the technical condition of the machine.

f) The machine can be operated only if it is covered and none of its parts is missing. It is

prohibited to perform any work under the machine cover and to put one’s fingers

inside the thrust screw and blades area while the machine is working (paper cutting).

g) The machine can be attended only by a person familiar with its operation.

4 Parameters

a) Sheet size A3, A4, A5, A6 and smaller (business card)

b) Radius of tools R4, R6, R9, R12, R18 and straight tool 28 mm

c) Input capacity 40 mm

d) Space requirements length = 1007 mm

width = 375 mm

height = 834 mm

e) Transport size length = 535 mm

width = 380 mm

height = 400 mm

f) Machine weight 17 kg