ROBOT.HEADtoTOE

ProductUser’sManual–MDS160A

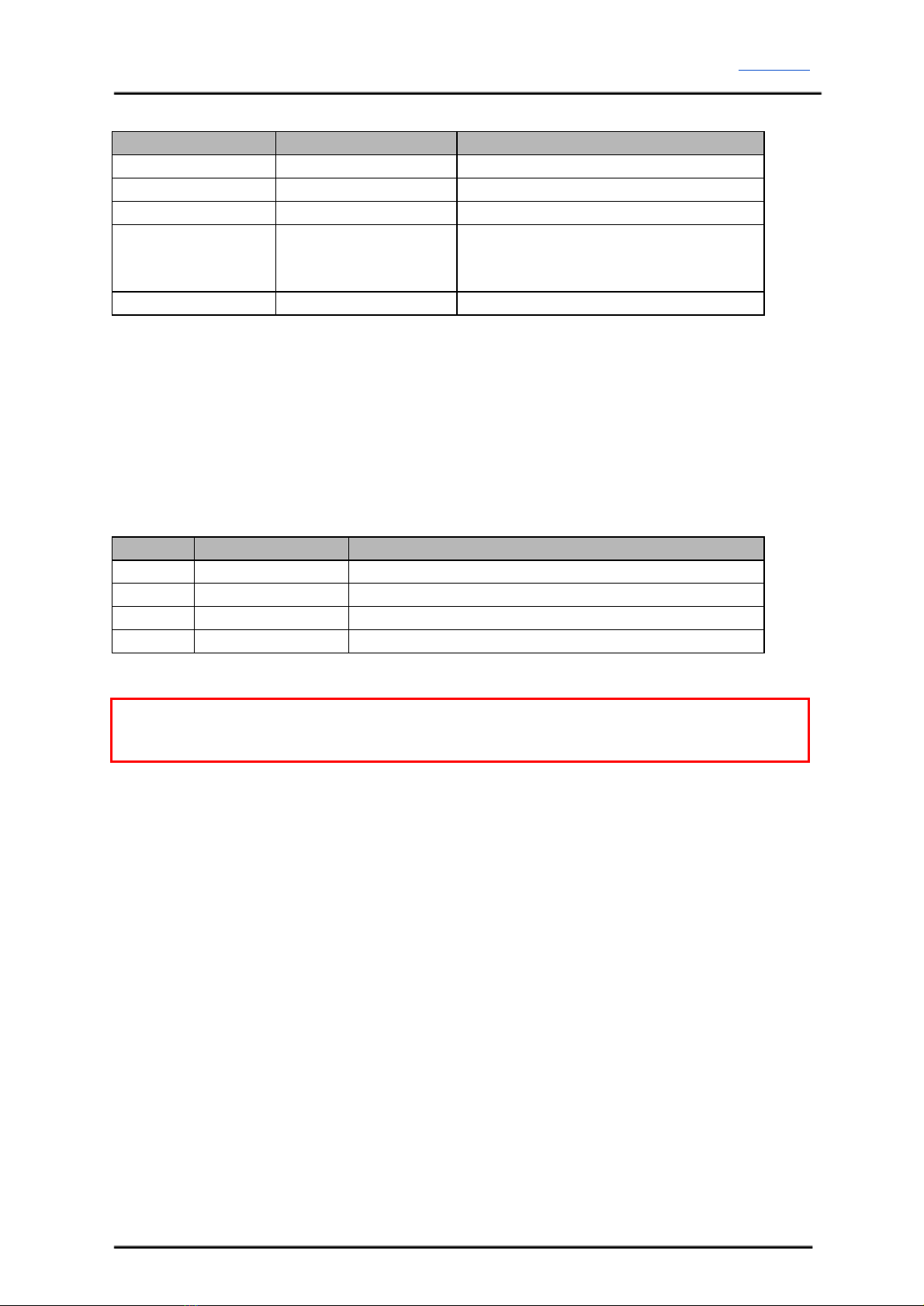

6.0SAFETYFEATURES

SmartDrive160 incorporates some safety features which make it a robust and reliable motor

driver.Belowarethedetaileddescriptionsforeachfeature.

a. LiPoUnderVoltageWarning(ErrorLEDblinks3times)

Upon power on, SmartDrive160 will automatically detect the number of cells for the

LiPo battery. If the input voltage falls below 3.3V per cell during operation, the error

LED will blink to warn the user. However, the power to the motor will be maintained

and will not be cut out. Thus, it is the user’s responsibility to stop the motor and

replacethebatterytoavoidfurtherdamagetothebattery.

If the other type of battery is used to power the board, the LiPo under voltage warning

will still be shown. In this case, user may ignore the warning and he/she needs to

estimatewhentoreplacethebatterybyhim/herself.

b. OvervoltageProtection(ErrorLEDblinks4times)

When the motor is slowing down, current will be generated and flow back to charge

the battery. However, if the power source cannot absorb the current generated by the

motor, the voltage will rise. If the motor driver detects the rise in voltage, it will slow

down the deceleration of the motor. If the voltage rises to a dangerous level, the motor

will be braked immediately by shorting the 2 motor terminal to prevent any damage to

themotordriver.

c. OvercurrentProtection(OCLEDturnson)

Whenovercurrentoccurs,thecurrentwillbelimitedbyeachPWMcycle.

Theactualovercurrentthresholdisdependingonthetemperatureoftheboard.

d. OverTemperatureProtection(ErrorLEDblinks5times)

SmartDrive160 is equipped with a temperature sensor to monitor its operating

temperature. It will gradually lower down the current limiting threshold base on the

temperature.