Getting Started 1-1

631 Digital Servo Drive 07-01-08-02-E-V0500

1GETTING STARTED

Introduction

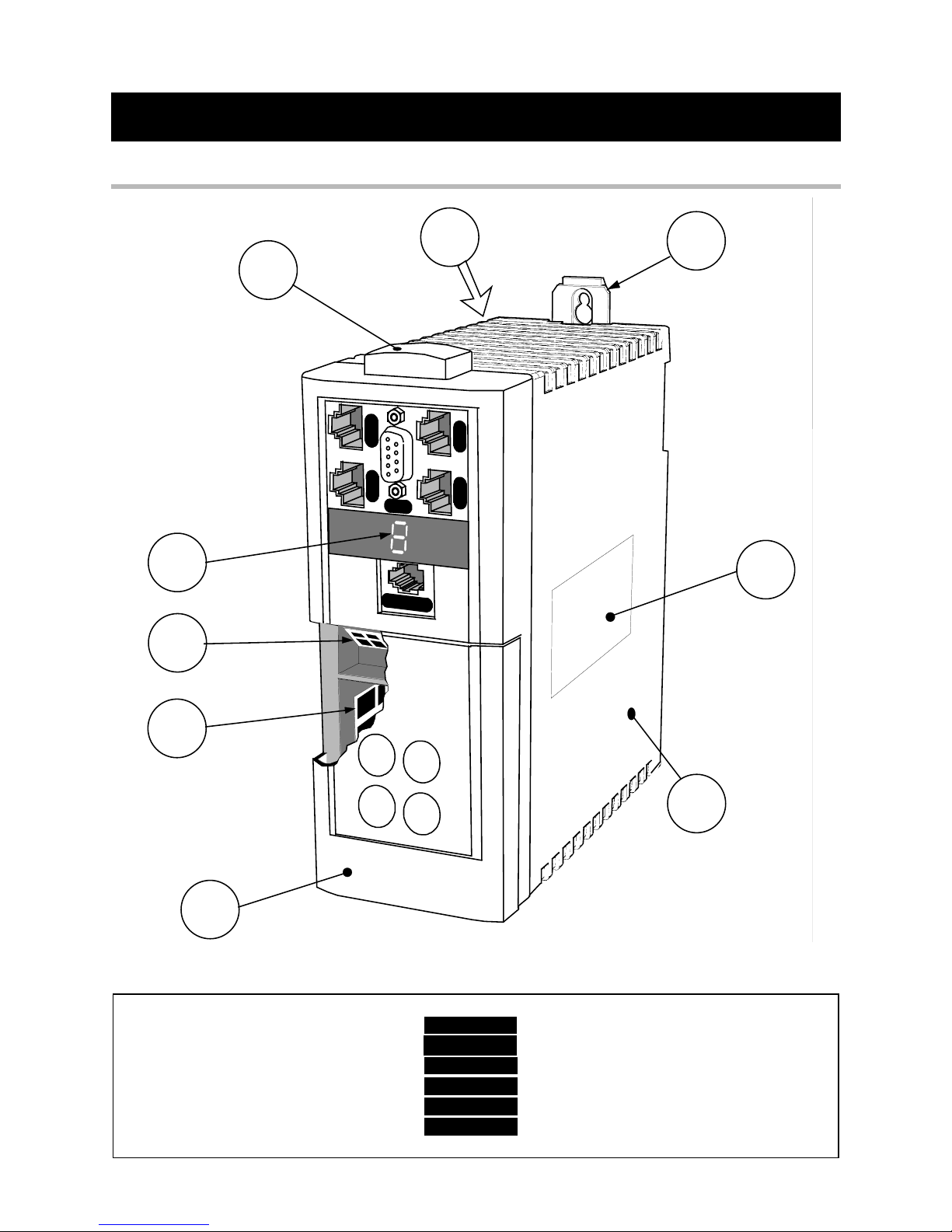

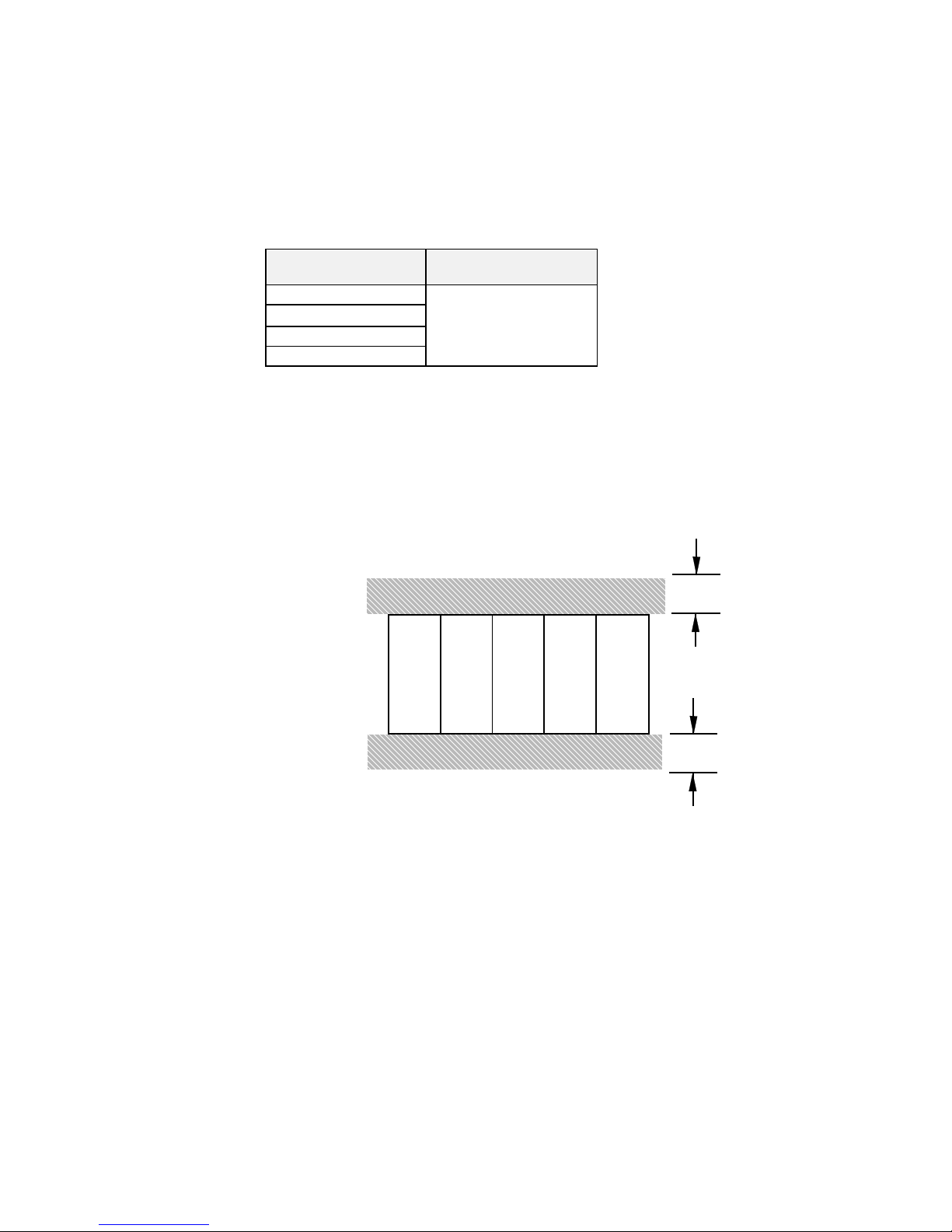

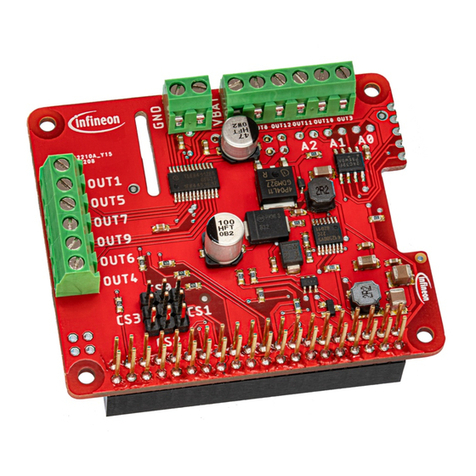

The 631 Digital Servo Drive is designed to control Eurotherm approved AC Brushless Servo

Motors. It is available in a range of current ratings from 1 to 6 Amps.

Set-up

The EASYRIDER software <is used to set-up the drive. An “Autopilot” set-up wizard can be

started when using the software.

Programming

The “BIAS” progamming language is contained in EASYRIDER <which provides for up to

1500 lines of program code.

Operation

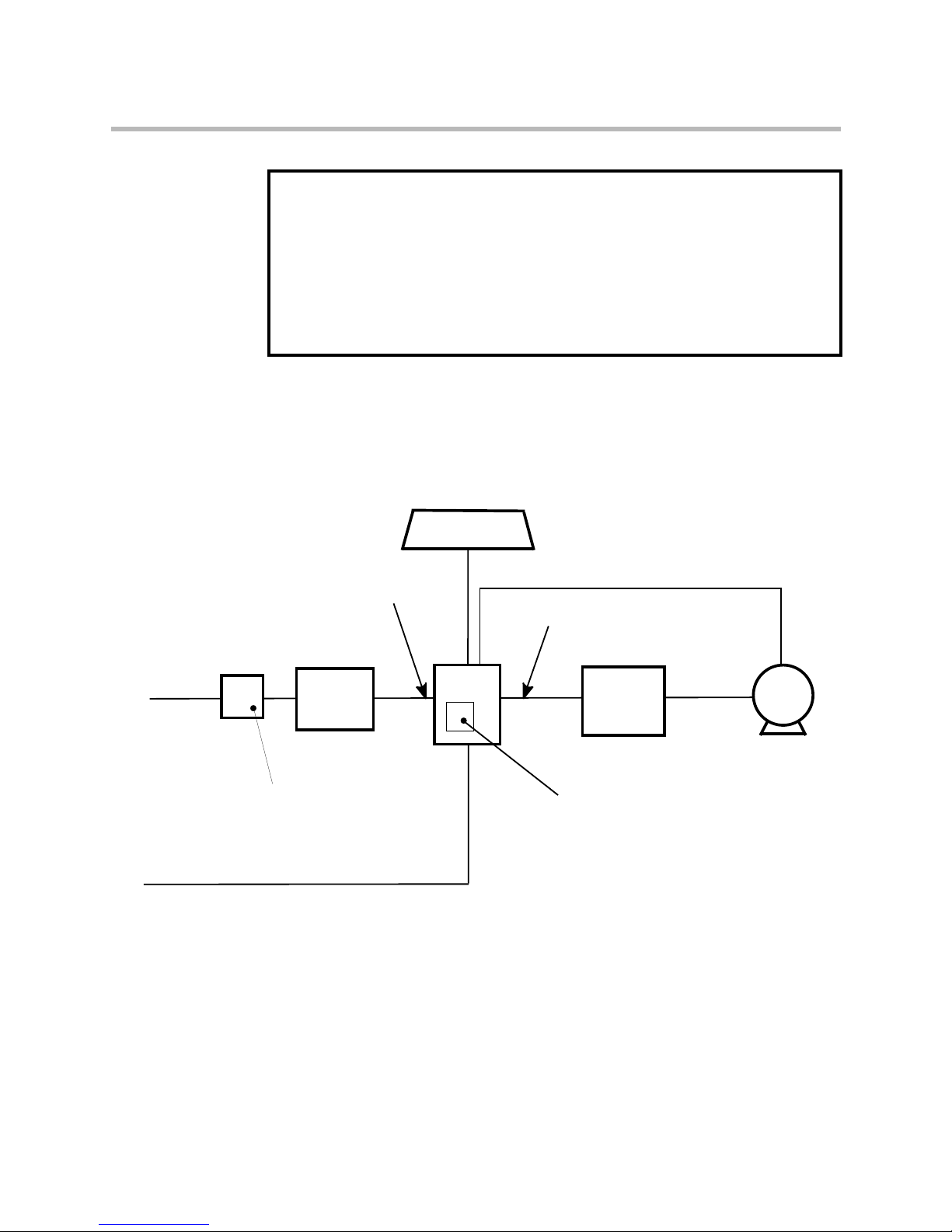

The unit is operated remotely using the analog/digital inputs and outputs via a PLC, for example.

Multiple units can be controlled using RS232, CAN-Bus or Incremental Bus.

Four operating modes offer various speed, torque and position controls.

There is a seven-segment diagnostic display for trip and fault finding information.

The internal RFI filter offers enhanced EMC compliance without the need for additional external

components.

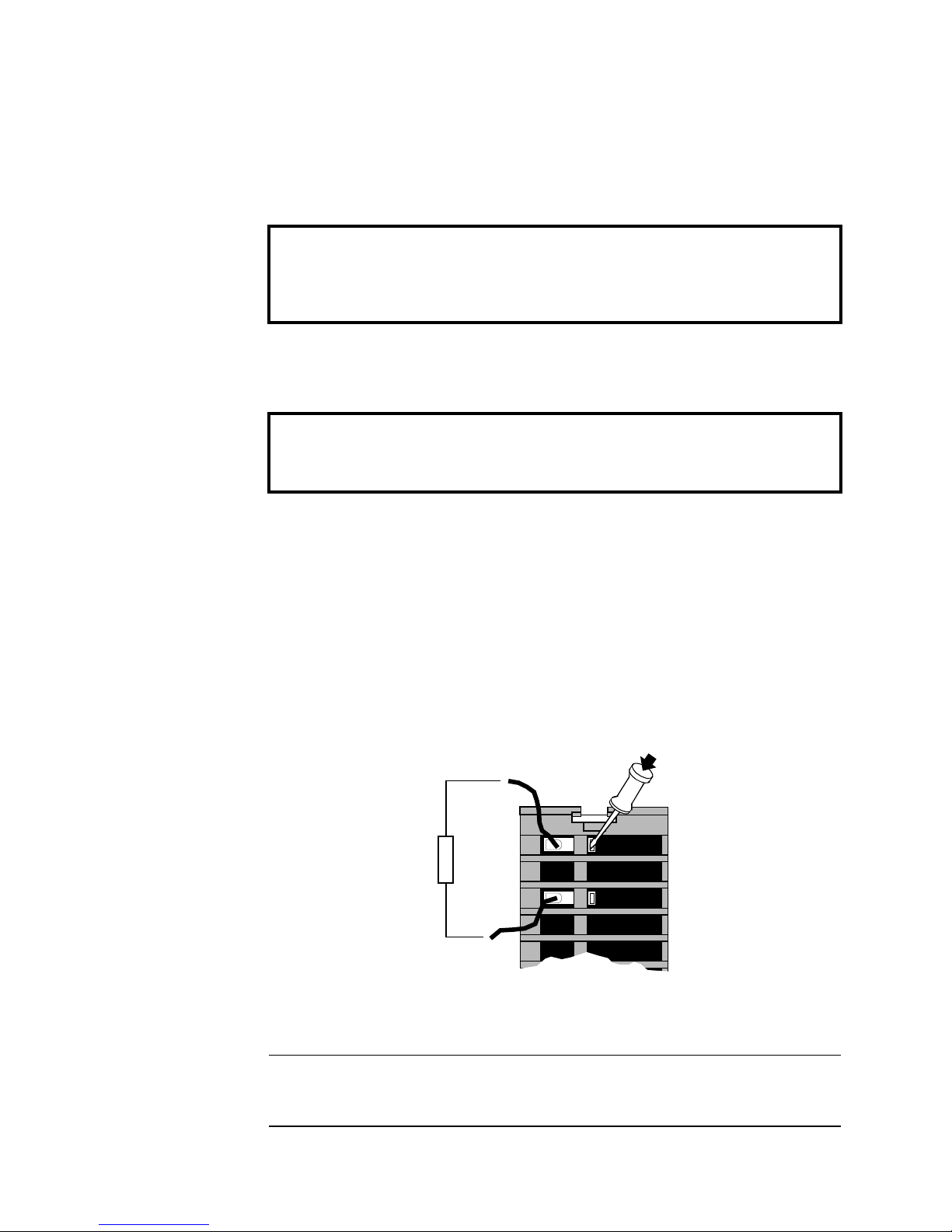

An internal dynamic brake resistor is provided.

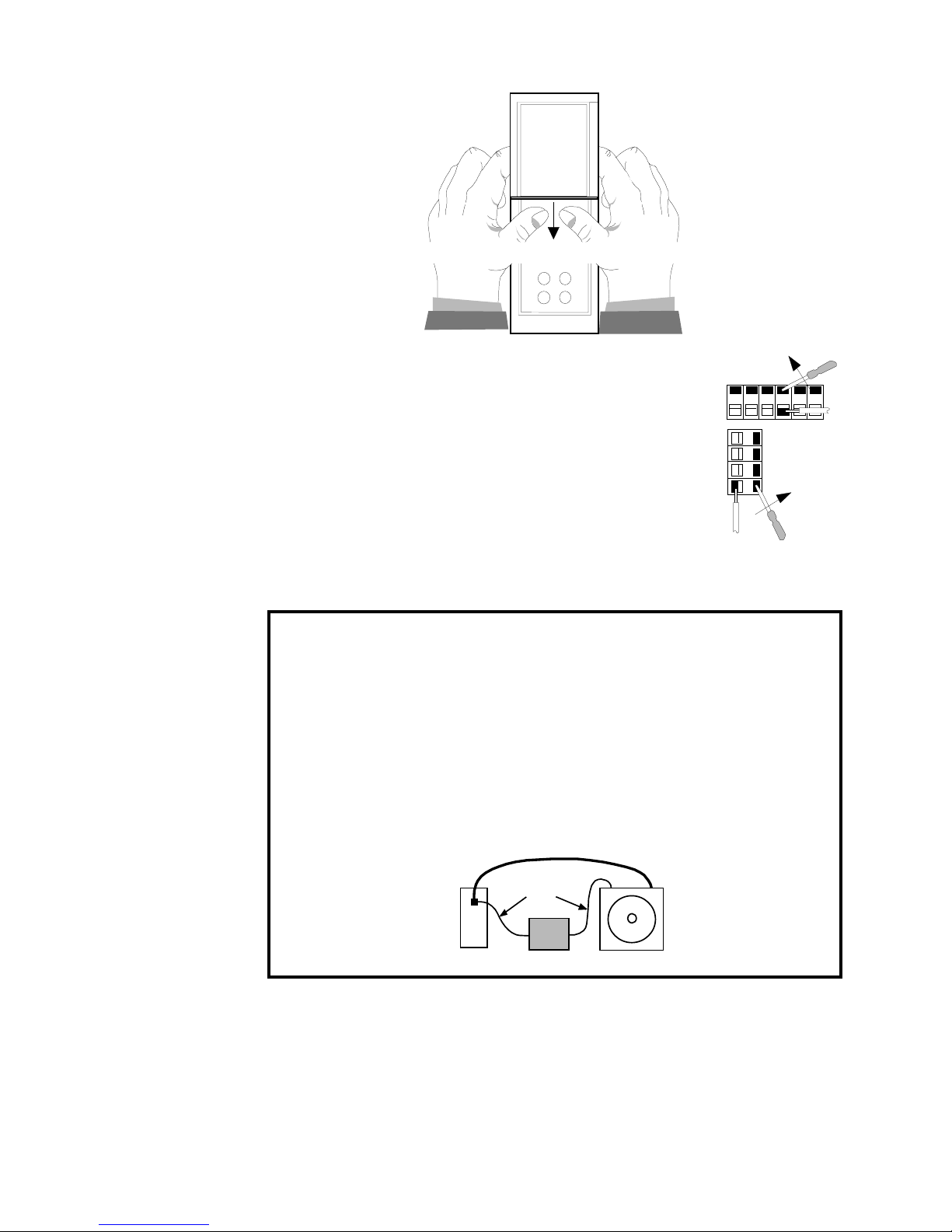

Equipment Inspection

•Check for signs of transit damage

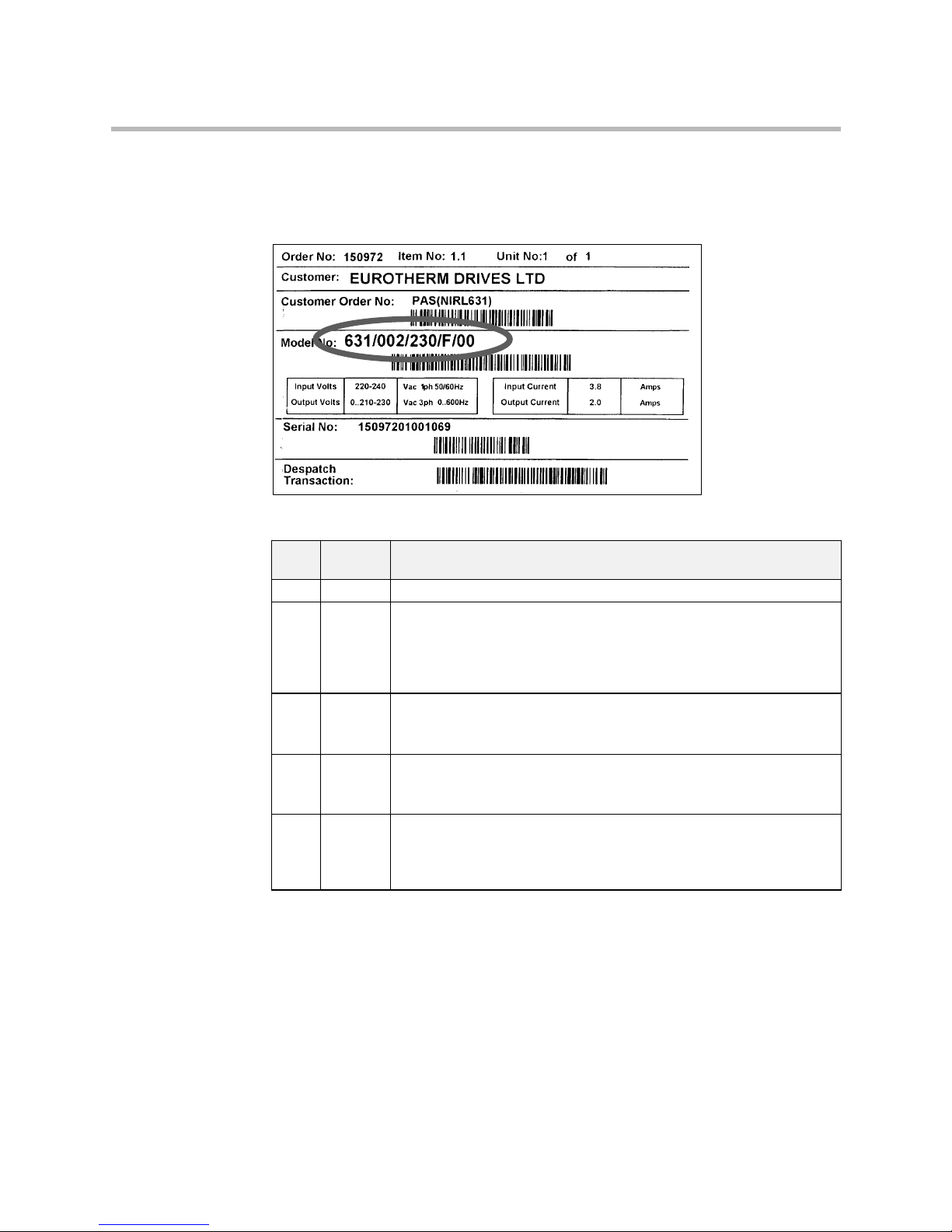

•Check the product code on the rating label conforms to your requirement.

If the unit is not being installed immediately, store the unit in a well-ventilated place away from

high temperatures, humidity, dust, or metal particles.

Refer to Chapter 2: “An Overview of the Servo Drive” to check the rating label/product code.

Refer to Chapter 8: “Routine Maintenance and Repair” for information on returning damaged

goods.

Refer to Chapter 9: “Accessories” to check for the correct items.

About this Manual

This manual is intended for use by the installer, user and programmer of the 631 Servo Drive. It

assumes a reasonable level of understanding in these three disciplines.

Note:

Please read all Safety Information before proceeding with the installation and operation

of this unit.

Enter the “Model No” from the rating label into the table at the front of this manual. It is

important that you pass this manual on to any new user of this unit.

Initial Steps

Use the manual to help you plan the following:

Installation

Know your requirements:

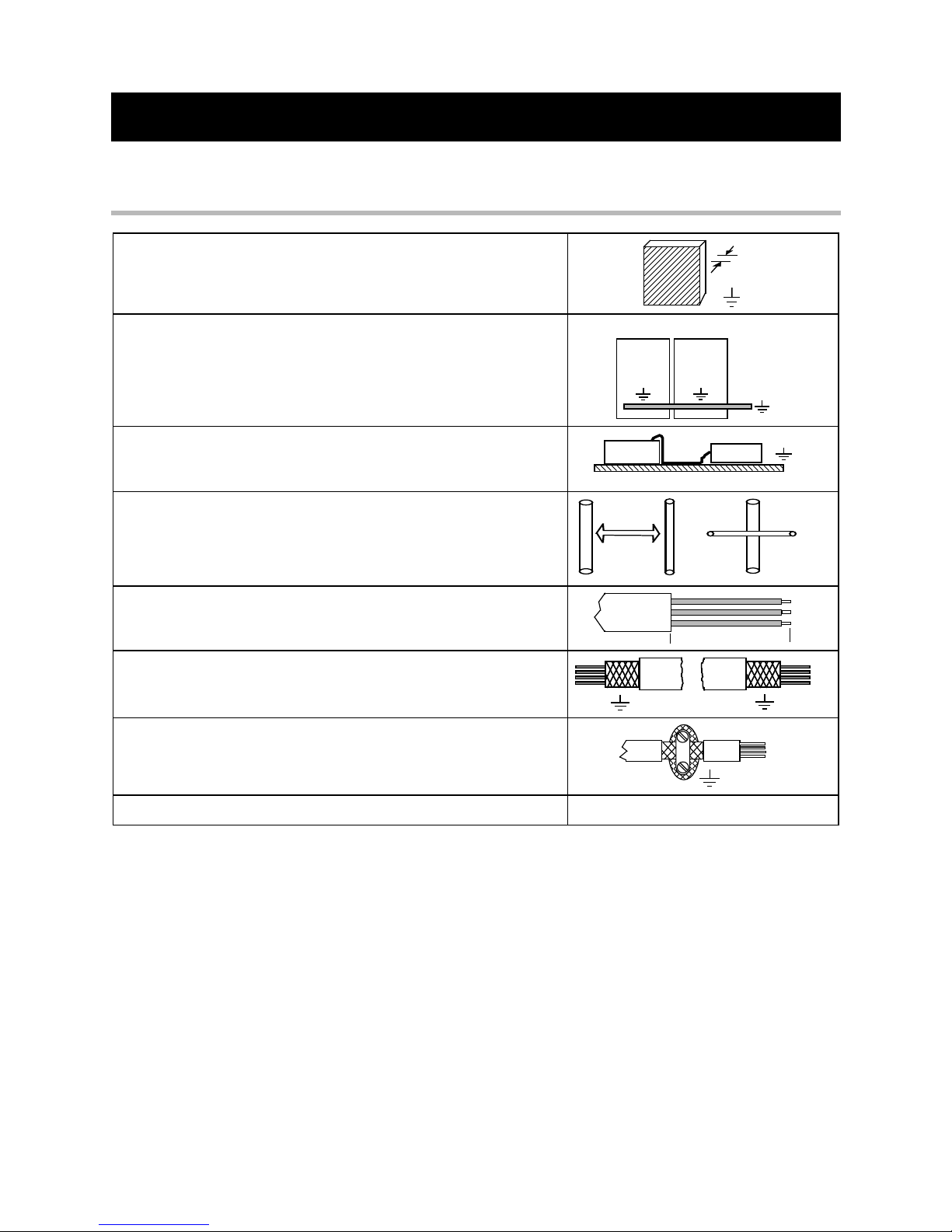

•certification requirements, CE/UL/CUL conformance

•conformance with local installation requirements

•supply and cabling requirements