A440-010

December, 2005

2.0INSTRUCTION FORSAFEUSE

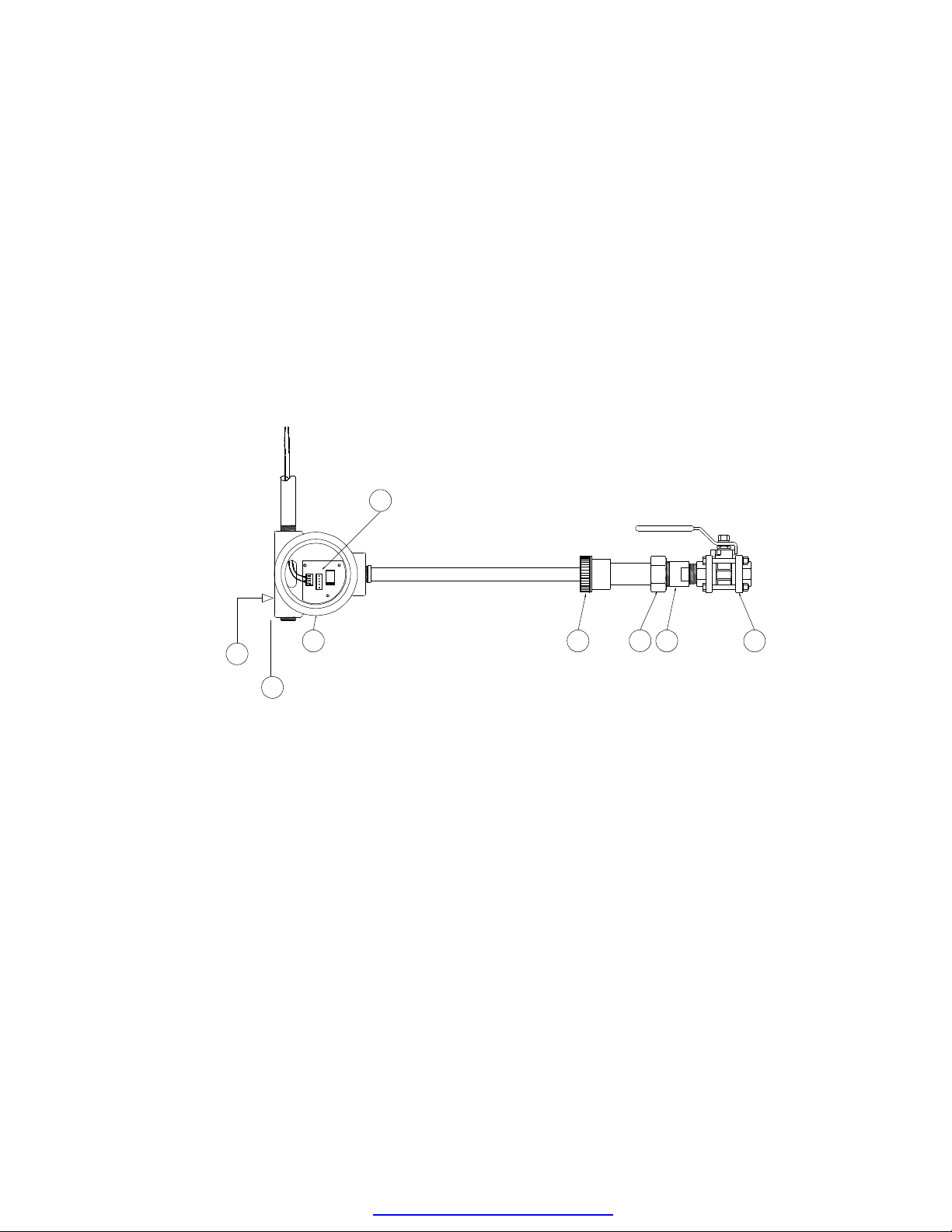

TheD-2JF-1AConductivityMeterreadsconductivityinpicosiemens/meter,fuel

temperatureinITS-90 degrees C,andfullycompensatedConductivityinpicosiemens/

meterperASTMD2624,AppendixX2inliquidfuelsandsolvents.Thesensorcanbe

usedina2wire4-20mA industrialcontrollooporinconjunctionwithaserialinput

deviceusingRS-232 IEEE StandardASCII SerialInputData.Optionallya2wire(4-20

mA)temperatureinterfacecanbeaddedtoallow remotemonitoringoffuel

temperature.

WARNING:

Immediately switch

off

the sensorin the

case

of

emergency!

Until thesensorisfully installedin afilledproductlinedo

notenergizesensor.

When

using

the sensor

to

measure combustible media,

obser

ve

the r

egulations

concerning transport and

storage

of combustible liquids

.

Observe

applicable

national

r

egulations

for installation abroad.

Only Exdapprovedcableentry devices(e.g.cablegland)shall

beused, withtheapparatus.

Sensorisintendedforuseinproductlineswheretheabsolute

maximumphysicalconditionsdonotexceedthespecifications

listedin Section6.0.

CAUTION: Sensors must be

accessible

at

all

times

to

facilitate operation

and

maintenance.

Do not obstruct or block clear

access.

Only

specially

trainedand

authorized

persons

are

permitted

to

maintain

and

repair

JF-1A Sensorsandtheir

peripheral

equipment.

Always

depr

essurize

the liquid end first befor

e

carr

ying

out

any

PDFcreated withpdfFactorytrialversion www.software-partners.co.uk