d.gen TELEIOS GRANDE H6 User manual

OPERATOR MANUAL

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

2

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

INDEX.

1. Important Safety Instructions ……………………………………………………………………………….

2. Notes on Usage and Storage ……………………………………………...………………………………..

3. Presenting the printer ………………………………………………………………………………………..

4. Turning ON and OFF the printer ……………………………………………………………..…………......

5. Loading ink ……………………………………………………………………………………………………

6. Loading the media …………………………………………………………………………….…………......

7. Nozzle check test print ………………………………………………………………………………………

8. Purge and Auto-cleaning ……………………………………………………………………………………

9. Global bidirectional adjustment ……………………………………………………………………………..

10. Feed Adjustment ………………………………………………………….………………………………..

11. Using the front dryer ………………………………………………………………………………………..

12. Using the fixation unit …..…………………………………………………………….…………………….

13. Using the fume buster ……………………………………………………………………………………...

14. Exchanging media ……………….………………………………………………………………………...

15. Removing the Take-up roll ……………………………………………………………………..…………..

16. Problem solver ……………………………………………………………………………………………...

17. Appendix …………………………………………………………………………………………………….

3

3

5

13

16

18

29

34

37

40

44

45

55

57

59

60

63

THANK YOU FOR CHOOSING d·gen

Be sure to read this document carefully for a correct use of this printer.

The contents of this document are subject to change without notice.

Please inform us if any misprint or error is found in this document.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of d∙gen Inc. International.

The information contained herein is designed only for use with this d∙gen printer. d∙gen is not

responsible for any use of this information as applied to other printers.

Neither d∙gen Inc. International nor its affiliates assumes no responsibility to the purchaser of this

product or third parties for damages, losses, costs, or expenses incurred by the purchaser or third

parties as a result of accident, misuse, or abuse of this product or unauthorized modifications, repairs,

or alterations to this product, or failure to strictly comply with d∙gen Inc. International’s operating and

maintenance instructions.

d∙gen Inc. International shall not be liable for any damages or problems arising from the use of any

options or any consumable products other than those designated as original d∙gen products or d∙gen

approved products.

d∙gen Inc. International shall not be held liable for any damage resulting from electromagnetic

interference that occurs from the use of any interface cables other than those designated as original

d∙gen products or d∙gen approved products.

d∙gen Inc. International

73, Bupyeong-daero 297 beon-gil

Bupyeong-gu, Incheon 21315

Republic of Korea

Phone: (+82) 32 510 3503

Web page: www.dgen.com

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

3

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

1. IMPORTANT SAFETY INSTRUCTIONS.

When using this product.

Take care not to spill liquid on this product.

Do not attempt to service this product yourself.

Do not block or cover the openings in the printer.

Unplug this product and refer servicing to qualified service personnel under the following conditions:

The power cord or plug is damaged; liquid has entered the product; the product has been dropped or

the cabinet damaged; the product does not operate normally or exhibits a distinct change in

performance.

Do not move the print head by hand; otherwise you may damage this product.

When handling the ink bottles.

Wear protective eyewear and gloves when refilling ink tanks or replacing the waste ink bottle.

Keep ink packs out of the reach of children and do not drink the ink.

If fluid adheres to your skin, immediately wash it off using large volumes of soapy water. Consult a

physician if the skin appears irritated or is discolored.

If fluid enters your eyes, rinse immediately with water. Failure to observe this precaution could result in

bloodshot eyes or mild inflammation.

If fluid enters your mouth, consult a physician immediately.

If fluid is swallowed, do not force the person to vomit, and consult with a physician immediately. If the

person is forced to vomit, fluid may get caught in the trachea, which can be dangerous.

2. NOTES ON USAGE AND STORAGE.

When using the printer.

Keep the printer running in a stable and controlled environment under these temperature and humidity

values: 20°C ~ 25°C (68°F ~ 41°F) and 45% ~ 65% of relative humidity.

Be sure the operating conditions suit the media. For more information, see the documentation supplied

with the media.

Also, when operating in dry areas, air-conditioned environment, or under direct sunlight, maintain the

appropriate humidity.

Do not bend or tug the waste ink tube. Ink could spill inside or around the printer.

Avoid using the printer in locations with heat sources or locations that are exposed to direct drafts from

ventilators or air conditioners. The print head nozzles could dry out and clog.

When the power is on, do not remove the power plug or cut the power at the breaker. The carriage may

not be capped properly. In this case, turn on the power and wait until capping is performed

automatically.

Be sure that the waste ink bottle is installed whenever the printer is on.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

4

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

When not using the printer.

If you do not print for a long time, the print head nozzles may become clogged. Turn the printer on at

least once a week to prevent the print head clogging.

Leaving the printer for too long without turning it on may result in a malfunction. Repair work for such

malfunction will be charged.

If you will not be using the printer for more than 2 weeks, maintenance must be performed by a service

engineer before and after this period. This maintenance work will be charged.

Note that even if proper maintenance has been done before a long period of non-use, repair may be

necessary when doing maintenance for reusing the printer, depending on the period and conditions of

storage. In such a case, the repair work will also be charged. Contact your local dealer or

[email protected] for more information.

The media may also become wavy or curled, causing jams or resulting in the media coming into contact

with the print head. Remove the media before storing the printer.

Store the printer after confirming that the print head has been capped. If the print head is left uncapped

for a long time, the print quality may decline.

Close all covers before placing the printer in storage. If you are not using the printer for a long time, put

the gray anti-static cover (provided with the printer) on the printer to prevent dust build-up. The print

head nozzles are very small, and they can become clogged easily if fine dust gets on the print head,

and you may not be able to print properly.

If you have not used the printer for a long time, check the print head for clogging before you start

printing. Perform head cleaning if the print head is clogged.

When storing the printer, be sure that it is level: do not store it on an angle, on end, or upside down.

When handling the ink bottles.

Store the ink bottles at room temperature out of direct sunlight.

To ensure print quality, use all the ink in the ink bottle before the expiry date. (One year after the

manufacture date).

If the ink bottle has been stored in a cold location for a long period of time, keep at room temperature

for at least 24 hours before using.

Be sure not to leave any ink in the ink bottle after refilling the Big Ink System.

Refill the Big Ink System as soon as possible after opening the ink bottle.

When handling the media before printing.

Do not fold the media or damage the printable surface.

Do not touch the printable surface. Moisture and oils from your hands can affect print quality.

When handling media, hold it by both edges. We recommend wearing cotton gloves.

Keep the media dry.

Packaging materials can be used to store media and should not be thrown away.

Avoid locations that are subject to direct sunlight, excessive heat, or humidity.

When not in use, media should be removed from the printer, rewound, and inserted in its original

packaging for storage. Leaving media in the printer for extended periods may cause it to deteriorate.

When handling the media just after being printed.

Do not rub or scratch the printed surface. If it is rubbed or scratched, the ink may peel off.

Do not touch the printed surface, as this may remove the ink.

Make sure printouts are completely dry before folding or stacking, as otherwise discoloration or other

marks may appear where the prints touch. These marks will disappear if the prints are immediately

separated and dried but will become permanent if the surfaces are not separated.

Avoid direct sunlight.

To prevent discoloration, display and store prints as instructed in the documentation supplied with the

media.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

5

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

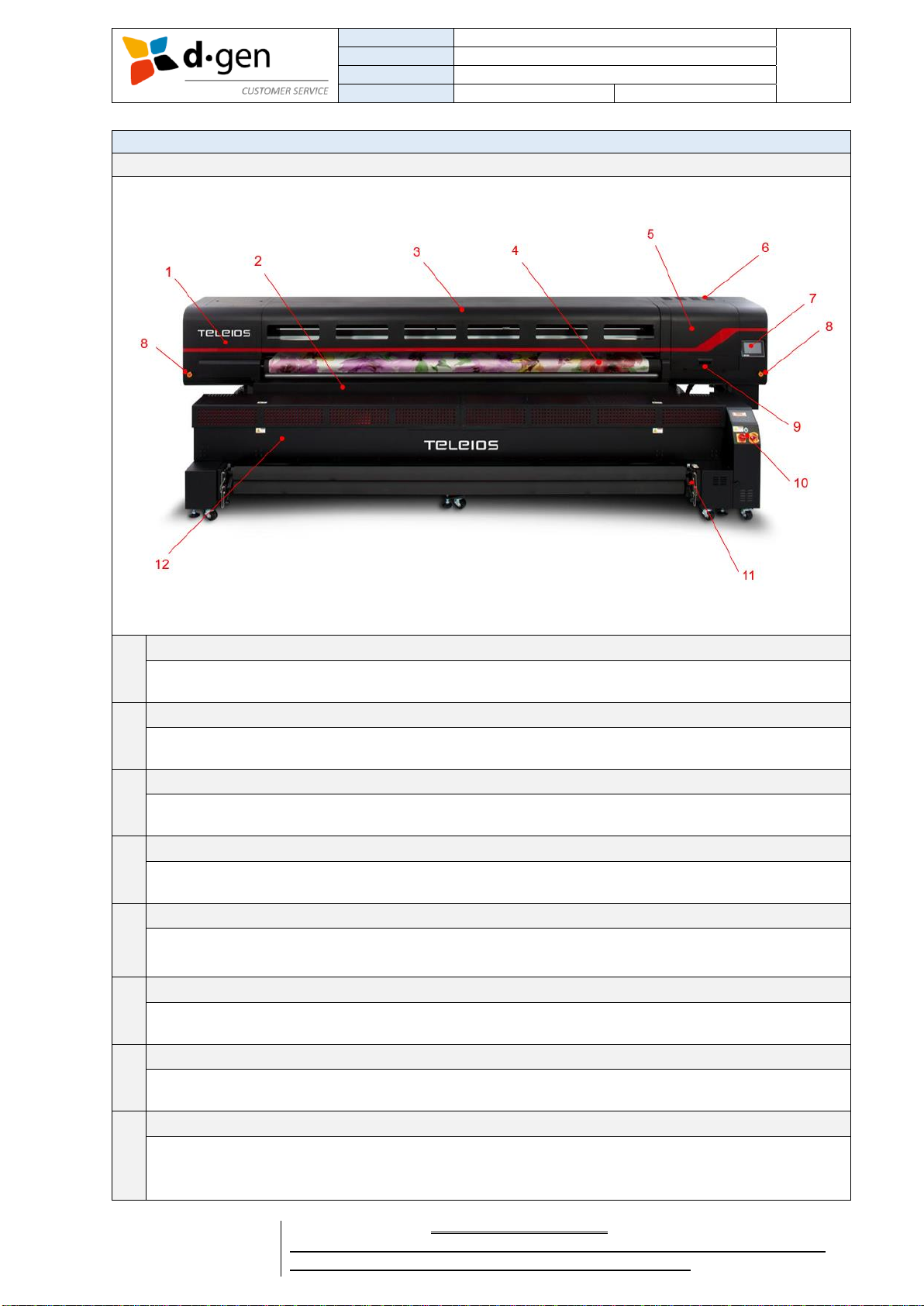

3. PRESENTING THE PRINTER.

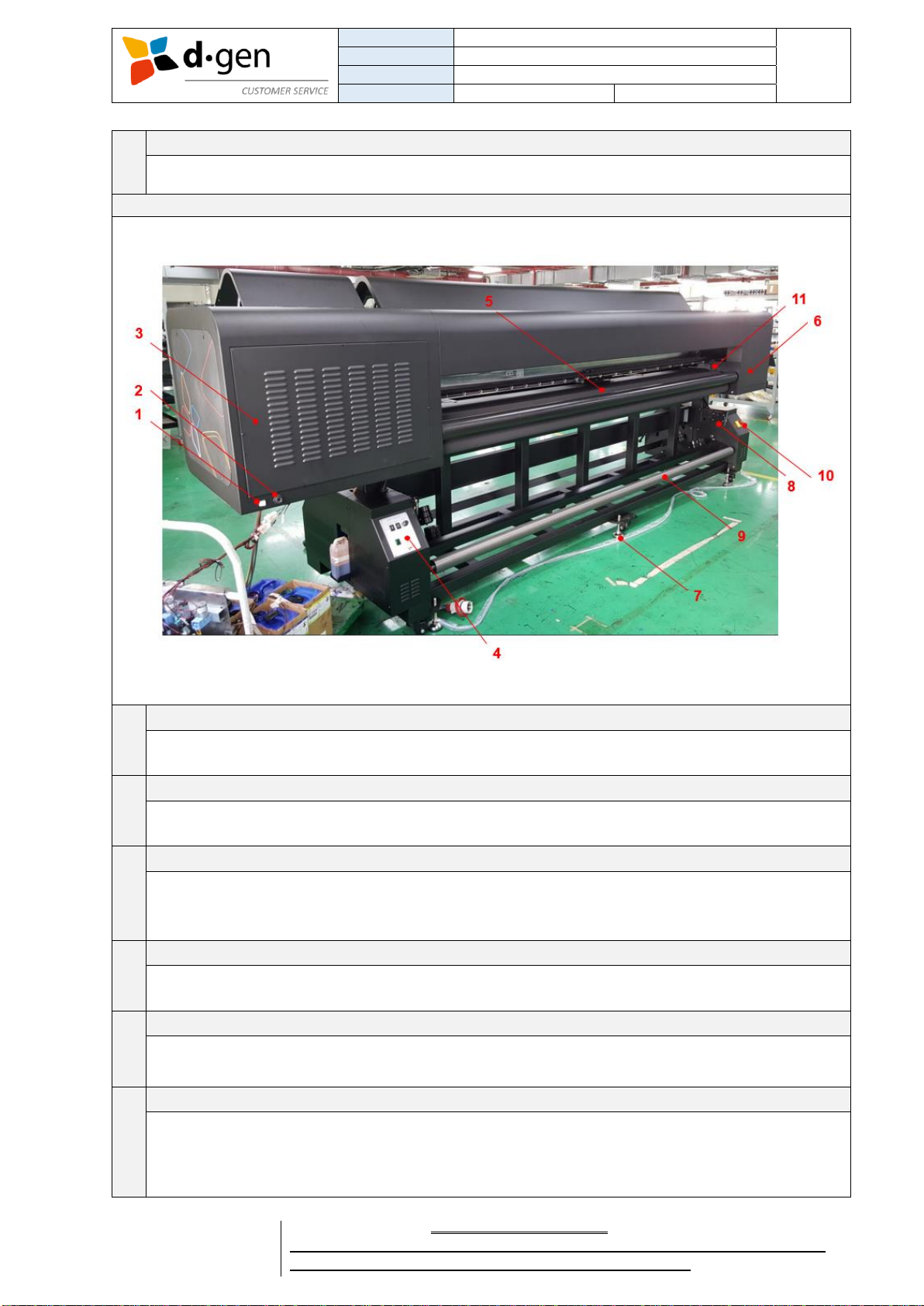

FRONT

1

Left side maintenance front cover.

Open this cover to clean the area around the print head. It is normally closed when the printer is in

use.

2

Drying unit.

This drying unit is to dry up the ink fast before the media touches the front rollers and enter the

fixation unit. Is equipped with 6 heating rods and 6 blowers.

3

Front cover.

Open when loading media, cleaning the inside of the printer, or removing jammed media. Normally

closed when using the printer.

4

Front rubber roller.

This roller and the rear rubber roller provides the sufficient traction to move the media forward in a

stable way.

5

Carriage cover.

This cover is opened for maintenance purposes, such as manual purge of the print heads, cleaning

of the wipers and the capping station, etc.… Normally closed when using the printer.

6

Upper carriage cover.

This cover is opened for maintenance purposes taken in the upper part of the carriage. Also for

refrigeration. Normally closed when using the printer.

7

Touch operating panel.

For a full control of the printer without using a computer. See chapter 4 in this user’s manual for

more information.

8

Emergency push type switch.

Is provided one emergency push type switch on each side of the printer to be activated in case of an

emergency. If activated the carriage will become to a complete stop and return to the home position

located at the right side of the printer.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

6

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

9

Lower carriage cover.

This cover is opened for maintenance purposes taken in the capping station. Also, to switch on the

control PC by pressing the green led button. Normally closed when using the printer.

10

Fixation unit’s control panel.

Designed for a full control of the fixation unit to provide a uniform color fixation to the printed media.

11

Fixation’s take up unit.

Provides enough traction to move the media forward in a stable way. Towards a separate winder

(TU-4000) for example.

12

Fixation unit.

Even the upper part of the fixation unit is protected against high temperatures, there is still a risk to

get burned if exposed to this heat for a long period of time. Please maintain this area clear from

foreign objects.

INTERIOR (CARRIAGE)

1

Solenoid valves.

The solenoid valve is opened if the LED is turned on. Having the solenoid valve opened allows free

circulation of negative air pressure between the vacuum pump and the head. Making the heads to

bleed for long purging is possible by closing the solenoid valve (LED switched off) right after the

purge button is pressed in the touch panel.

2

Carriage.

The carriage prints by moving left and right while firing ink. Periodical cleaning is required.

3

Carriage height adjustment lever.

This lever regulates the carriage height in 3 positions. Low, medium and high. Depending the

thickness of the media. There is a difference of 1 mm between positions.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

7

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

4

Automated wiper unit.

If user executes Auto cleaning, this wiper will work automatically. To increase the wiper’s

performance, remove ink residue on wiper periodically.

5

Automated capping unit.

Except during printing, this capping station covers the print head nozzles to prevent them from

drying out. Cleaning may be required.

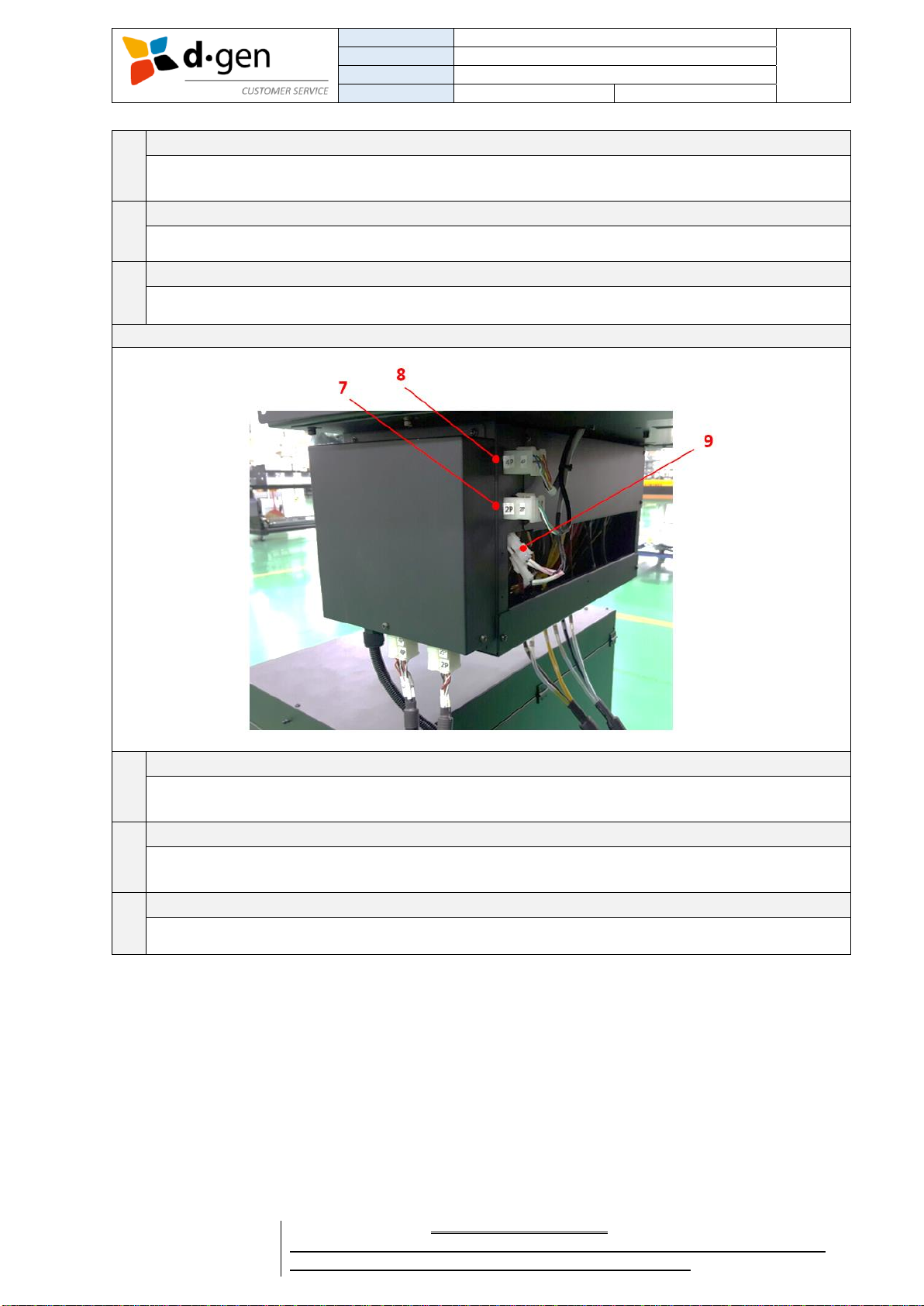

INTERIOR (CAPPING)

6

Home position sensor.

The carriage as soon as it gets to this sensor will adjust its speed to match its print heads with the

capping station’s location.

7

Right limit sensor.

For safety, this sensor brings the machine in an emergency state if the carriage crashes against the

right stopper.

8

Right stopper.

This machine is provided with 2 side stoppers to prevent the carriage damaging the side limit

sensors.

9

Flushing stage.

The flushing unit is used to keep the print heads unclogged. Every time the carriage leaves the

home position for printing right to left, the heads flush a very small quantity of ink in order to keep

the nozzles always unclogged.

10

Automated wiper unit’s front limit sensor.

Also, provided with a rear sensor. Brings the wipers to a complete stop reached this limit sensor.

11

Automated capping unit’s down limit sensor.

Brings the capping unit to a complete stop when reached its lowest point.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

8

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

12

PC control box’s main switch.

To turn ON/OFF the software side of the printer.

BACK

1

Printer’s main ON/OFF switch.

This switch turns ON/OFF the printer (not the other units like take-up unit…).

2

LAN port.

Connects the LAN cable. Use a shielded twisted pair cable (category 5 or higher).

3

Electric panel.

This electrical panel contains hazardous components. Risk of Electrical Shock. It is used for

maintenance purposes. Only qualified technicians can access this electric panel. Normally closed

when using the printer.

4

Feeder operating panel.

With the rear control panel is possible to switch it ON/OFF, regulate the feeder’s speed and mode.

5

Rear rubber roller.

This roller and the front rubber roller provides the sufficient traction to move the media forward in a

stable way.

6

Negative/Positive pressure system.

Behind this cover there are a series of pumps and valves to create enough negative pressure in the

heads for stable printing or enough positive pressure to purge the heads for cleaning its nozzles.

When printing, is normal to hear the pump functioning. Cover normally closed when using the

printer.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

9

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

7

Stopper.

There are 6 stoppers in this printer located in its base to fix and level up the machine to a permanent

and perfect horizontal position.

8

Pneumatic shaft (not in the picture).

The pneumatic shaft is inflated with an air compressor to secure the media’s core for a stable

feeding.

9

Dancing bar.

This printer comes with two dancing bars. One at the front and one at the back. The dancing bar

provides tension to the media for a solid feeding stability. You can regulate the weight of this dancing

bar by adding or subtracting its weights.

10

Machine’s main ON/OFF switch.

This switch turns ON/OFF the machine completely. Both printer and base.

11

Press roller (not in picture).

This free roller can be lowered and rest on the media to apply tension at the printing table.

RIGHT SIDE

1

Ink filter.

One ink filter for color to supply filtered ink to the print heads. This filter needs to be replaced

periodically or when changing the chemistry/color of the ink.

2

Ink LED indicator.

Two LED lights per color. The red LED turns on when the level of ink in the Big Ink System is

critically low. Green LED is turns on if refilled. Buzzer will sound to indicate low level of ink in one of

the ink cylinders.

3

Big Ink System K C M Y sensor level cables.

These cables come from the photo reflecting sensors located in the Big Ink System activating the

green LED indicator when full, and activating the red LED indicator when empty.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

10

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

4

Big Ink System SP1 SP2 sensor level cables.

These cables come from the photo reflecting sensors located in the Big Ink System activating the

green LED indicator when full, and activating the red LED indicator when empty.

5

Big Ink System’s white LED power supply cord.

To power up the white LED in the Big Ink System.

6

Ink inlets.

Ink hoses from the Big Ink System are connected to this side of the printer.

RIGHT SIDE (BACK)

7

Connector for SP1 and SP2 ink supply pumps.

This connector comes from the Ink Supply System board located in the rear electric panel. Activates

SP1 and SP2 ink pumps when the sub-tanks are needed to be refilled.

8

Connector for K C M Y ink supply pumps.

This connector comes from the Ink Supply System board located in the rear electric panel. Activates

K C M Y ink pumps when the sub-tanks are needed to be refilled.

9

White LED and Ink sensor level board DC 24 V power supply.

These cables power up both Ink sensor level board and the white LED lamp in the Big Ink System.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

11

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

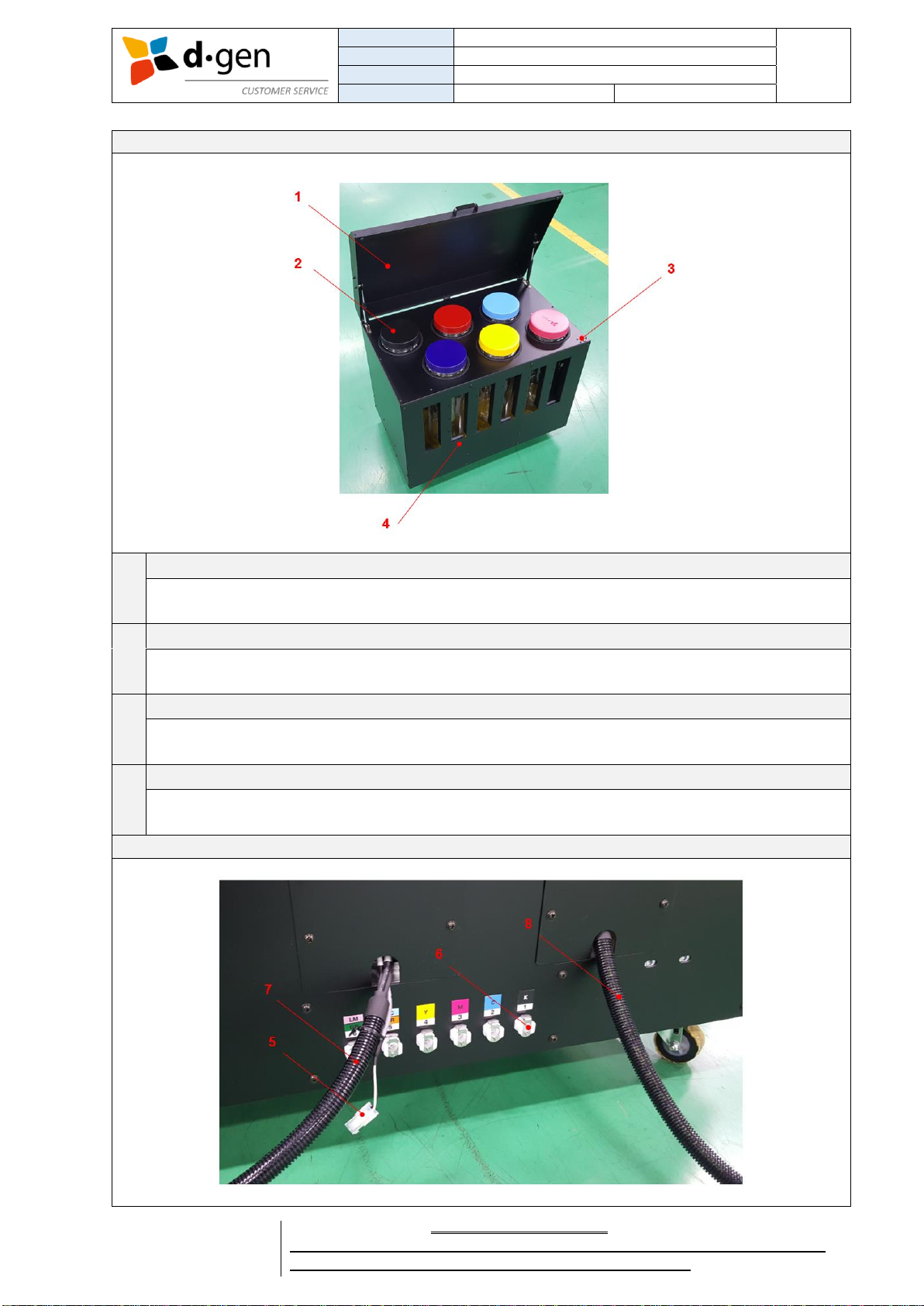

BIG INK SYSTEM

1

Cover.

Buzzer can be heard if this cover is opened. Cover normally closed when using the printer.

2

Lid and ink filter.

We suggest to pour the ink on the filter. Also, is suggested not to close the lid totally to let the air

flow in while the cylinder is getting empty.

3

Cover switch.

This device activated the buzzer when the cover is opened for refilling the inks.

4

Ink level photo sensor.

This photo sensor measures the ink level with a laser beam. Keep this area always free of ink.

BIG INK SYSTEM (BACK SIDE)

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

12

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

5

White LED bar’s power connector.

This cable powers up the white LED light bar in the Big Ink System.

6

Ink outlets.

By pushing down the silver fastening is possible to release or insert the ink line without spilling ink.

7

Sensor level connector (K C M Y inks).

This connector sends the signal from the photo-sensors located in the Big Ink System (to measure

the ink level in the cylinder) to the LED ink level indicators.

8

Sensor level connector (SP1 and SP2 inks).

This connector sends the signal from the photo-sensors located in the Big Ink System (to measure

the ink level in the cylinder) to the LED ink level indicators.

Important

Keep always the ink level’s photo sensor emitter and reflector free of ink and dust.

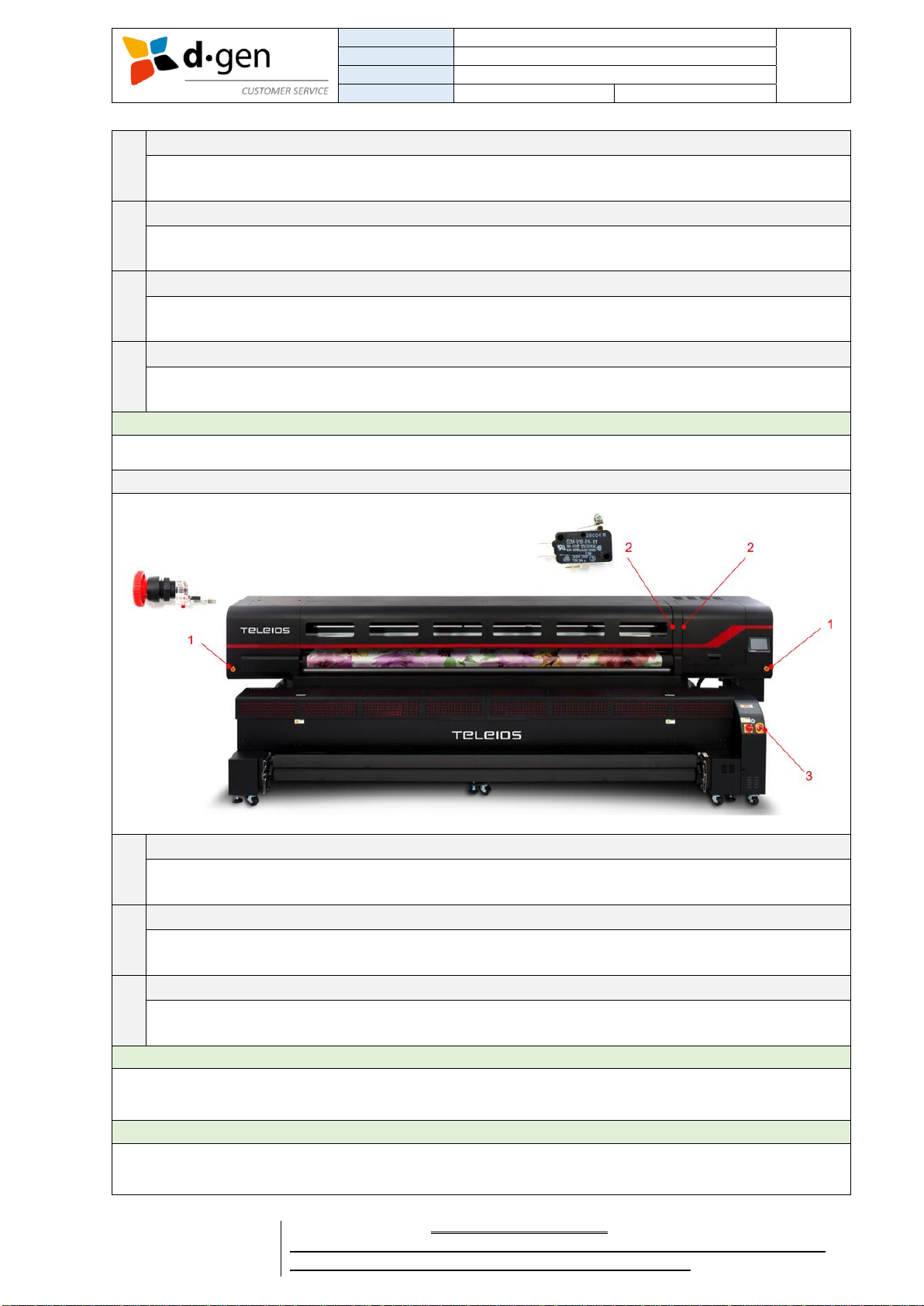

SAFETY DEVICES

1

Emergency push type switch for the printer.

Two at the front on each side. Pushing one of the switches will bring a total stop the carriage and

other moving elements.

2

Open cover switch.

Opening either the front or carriage cover will activate the emergency switch bringing the carriage to

a pause state returning to the home position.

3

Emergency push type switch for the fixation unit.

One located at the control panel. Pushing the switch will cut the electric supply to the heating rods

and both take up and up/down inductive motors.

Note

In case the printer exceeds its operation limits such as over-speed, operational temperature, etc., the

operator may use the emergency switches to bring the printer into an emergency stop.

Note

In case one of the safety devices is broken we strongly recommend the user to replace it with the help of

a qualified technician.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

13

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

4. TURNING ON AND OFF THE PRINTER.

Turning ON the printer.

The operator must follow the following steps to correctly turn ON the printer.

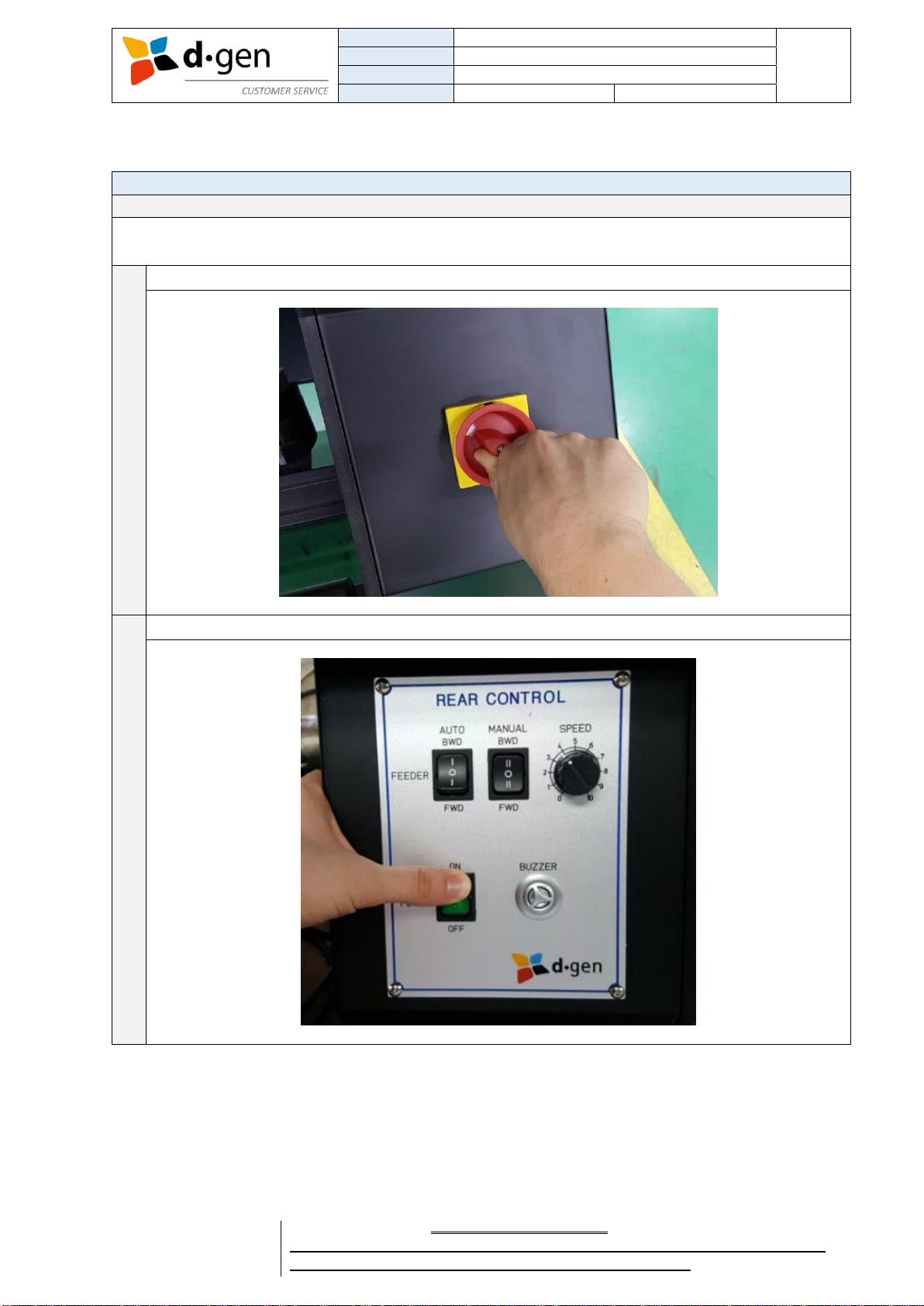

1

Turn clock-wise the red main switch at the back of the printer.

2

Turn on the rear control panel by pressing the green switch.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

14

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

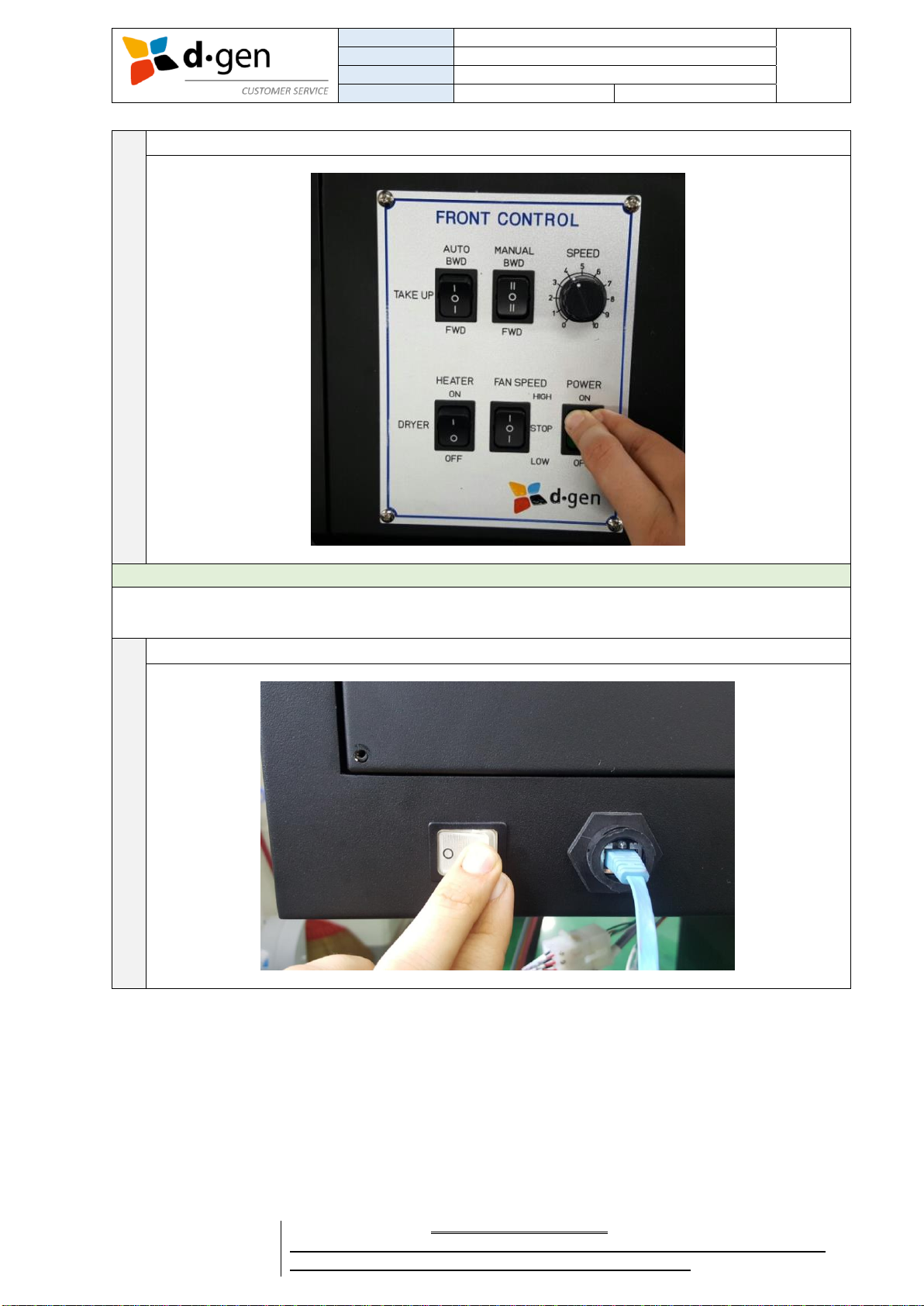

3

Turn on the front control panel by pressing the green switch.

Note

The buzzer located at the REAR CONTROL panel will be activated if one or both FEEDER and TAKE UP

units are in AUTO OFF (AUTO button in idle).

4

Turn on the printer by pressing the white switch at the back of it.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

15

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

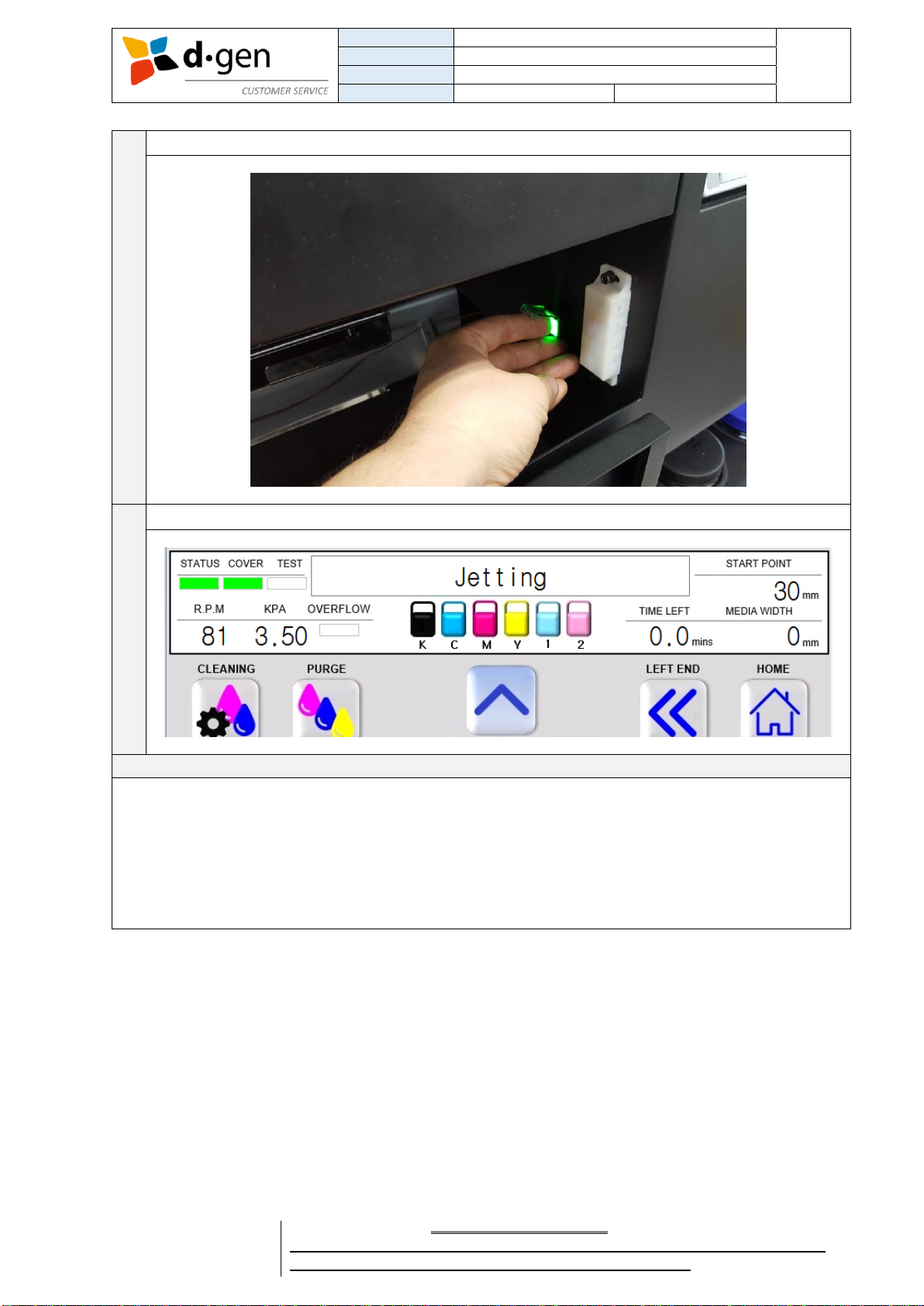

5

Turn on the PC control box by pressing the green switch.

6

Wait for the touch panel to display “Jetting”.

Turning OFF the printer.

The operator must follow the following steps to correctly turn OFF the printer.

1. Turn off the PC control box by pressing the green switch.

2. As soon as a beep is heard turn off the printer by pressing the white switch at the back of it.

3. Turn off the front control panel by pressing the green switch.

4. Turn off the rear control panel by pressing the green switch.

5. Turn counter clock-wise the red main switch at the back of the printer

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

16

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

5. LOADING INK.

The operator must follow the following steps to correctly load with ink the Big Ink System.

1

Open the Big Ink System’s cover. Buzzer will be activated.

2

Open the lid. Make sure the filter is present and correctly positioned.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

17

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

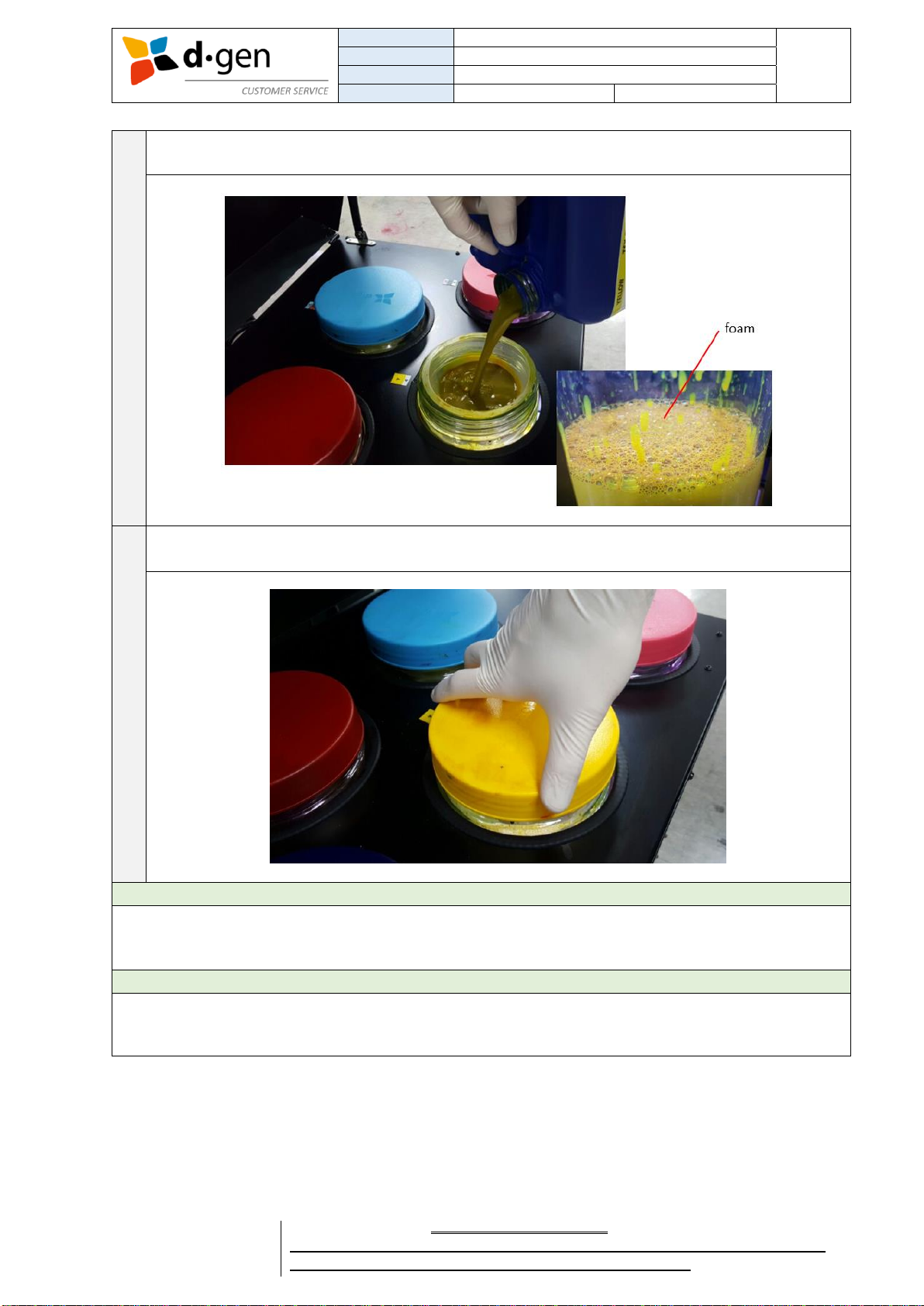

3

Pour gently to avoid spilling ink outside the cylinder. Do not pour the ink too fast. Leave some time

to let the ink go through the filter before pouring some more.

4

Close the lid. Do not close the lid too tight to let the air go into the cylinder as it gets empty when

printing.

Important

Do not wait until the cylinder gets completely empty. Risk of clogging the ink filter / damaging the heads

with the deposited ink sediments at the bottom. We strongly suggest to refill the tank as soon as the

buzzer is heard.

Important

When pouring ink, foam will be created. Do not let the foam get into the printer. This may negatively

affect the quality of your printings. Therefore, we suggest to refill the tank as soon as the buzzer is heard.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

18

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

6. LOADING THE MEDIA.

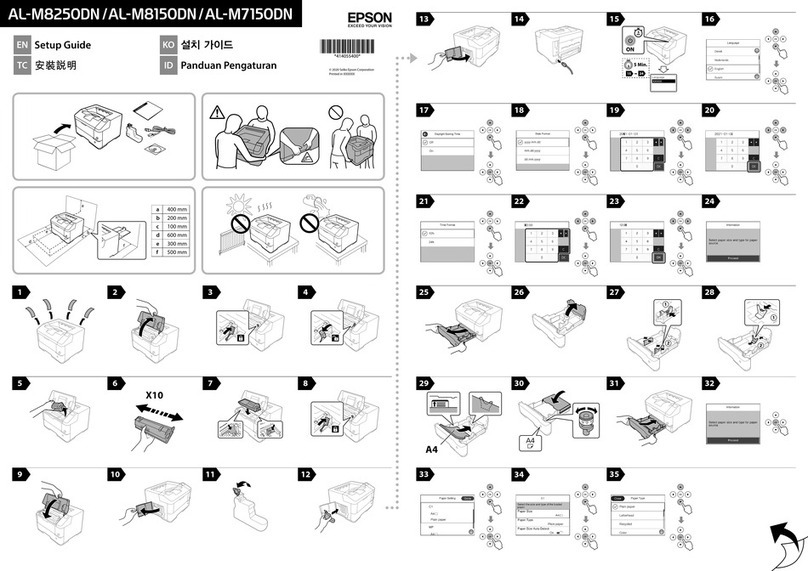

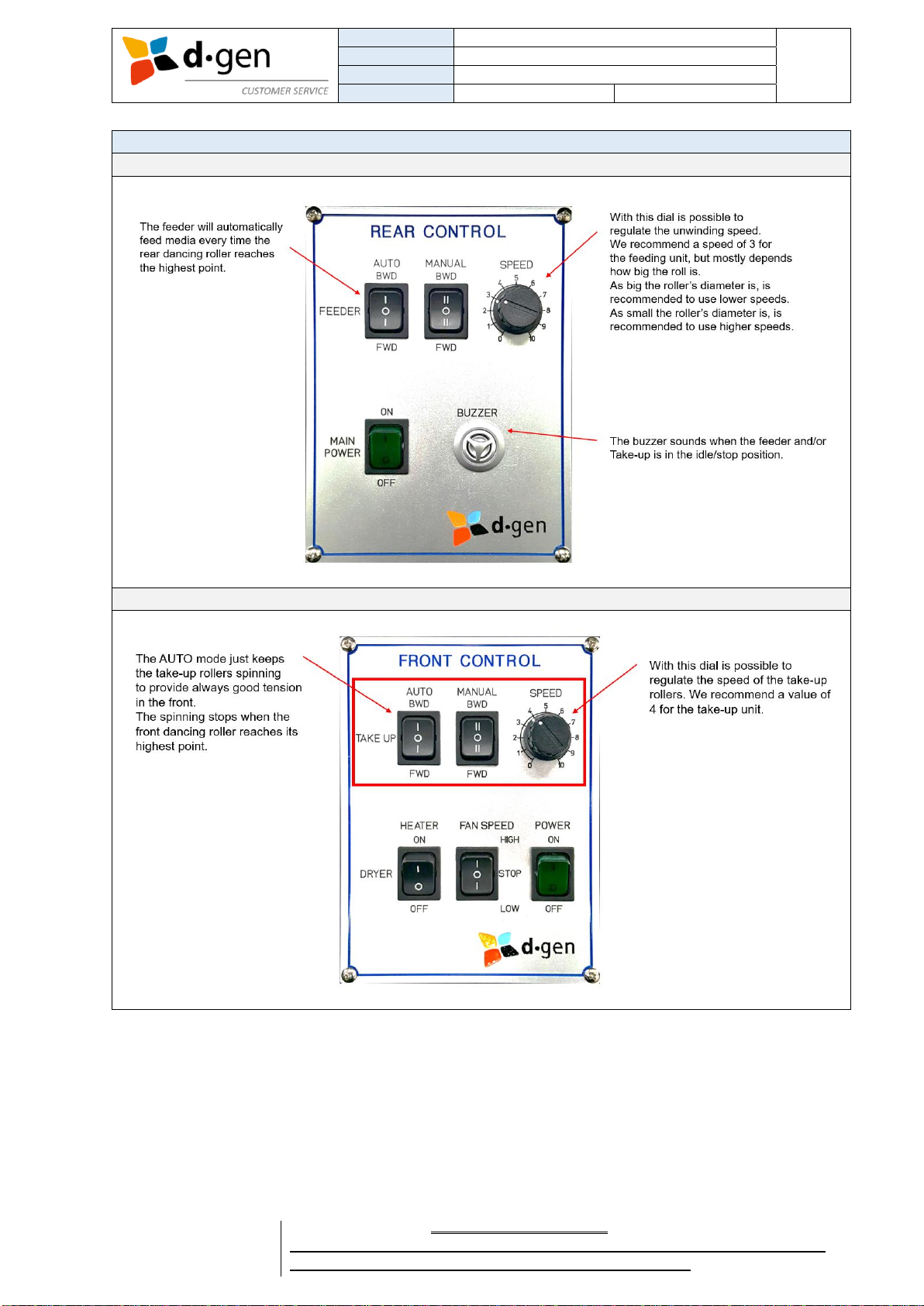

Introducing the printer’s rear control panel.

Introducing the printer’s front control panel.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

19

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

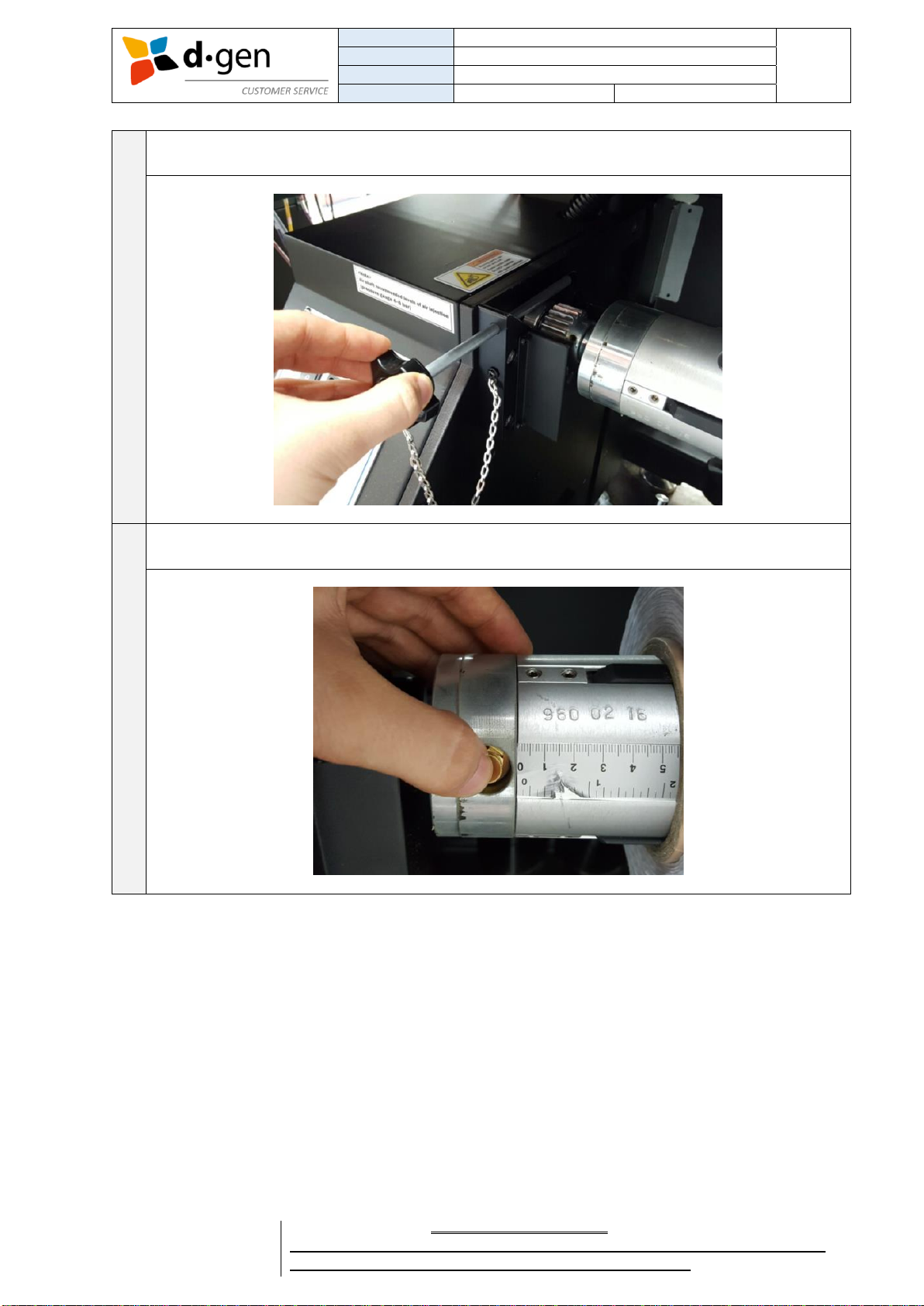

1

Release the latches at both side of the feeding unit to remove the pneumatic shaft.

2

Press the golden valve to release all the air inside the pneumatic tube.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

TELEIOS GRANDE H6

20

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

64

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

3

Place the pneumatic shaft in the media’s core oriented to make the printable side facing upwards

when going through the printing table. Make sure the roll is centered using the measuring tape as a

reference.

4

With the help of an air compressor (only the air gun is provided) stick the gun to the golden valve

and apply compressed air until an approximate value of 5 bars is reached.

5

Lift the pneumatic shaft with the roll fastened and place it carefully in the feeder unit. Insert back the

latches at both sides of the feeder unit to safely secure the pneumatic shaft. Using the rear control

panel unwind a certain length of media to make it go through the rear dancing bar. Depending on

how the media’s core is oriented push the MANUAL BWD or FWD to unwind media.

Other manuals for TELEIOS GRANDE H6

1

Table of contents

Other d.gen Printer manuals