d.gen TELEIOS GRANDE G5 Operating manual

MAINTENANCE GUIDE

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

2

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

We encourage our users to follow these maintenance procedures to reduce the number of breakdowns, print

with excellent results during a long period and increase its lifespan.

[PRINTER] Components to be cleaned or checked

Frequency

Component

Every day

Waste ink drain bottle (when starting the day)

Flushing stage

Front roller

Ink gutter and media guides

Capping unit and its surroundings

Wipers (when finishing the day)

Once a week

Head base plate

Machine’s exterior

Check the PALL ink filter’s level of ink

Once a month

Machine’s interior

Encoder strip

Limit sensors

Capping unit (deep cleaning)

Every six months or less

Vacuum filter replacement

Note

Bear in mind, that the following maintenance periods are basically suggestions. It mostly depends on how

much the unit is used and the type of fabrics handled. If the unit is strongly used (24 hours run for example),

or fabrics with heavy coatings, we would recommend the user to shorten the suggested maintenance

periods.

Components to be replaced

Component

Part number

Frequency

Wiper

C90010019-00

Every 6 months / worn out

Flushing stage’s sponge

NO PART NUMBER

Every 6 months / worn out

PALL Ink filter

D32060004-00

Every 6 months / changing ink chemistry or color

Air filter

D70010032-00

Every 6 months /

if color turned to black (exhausted filter)

Limit sensor

D32040002-00

When damaged / impossible to clean

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

3

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

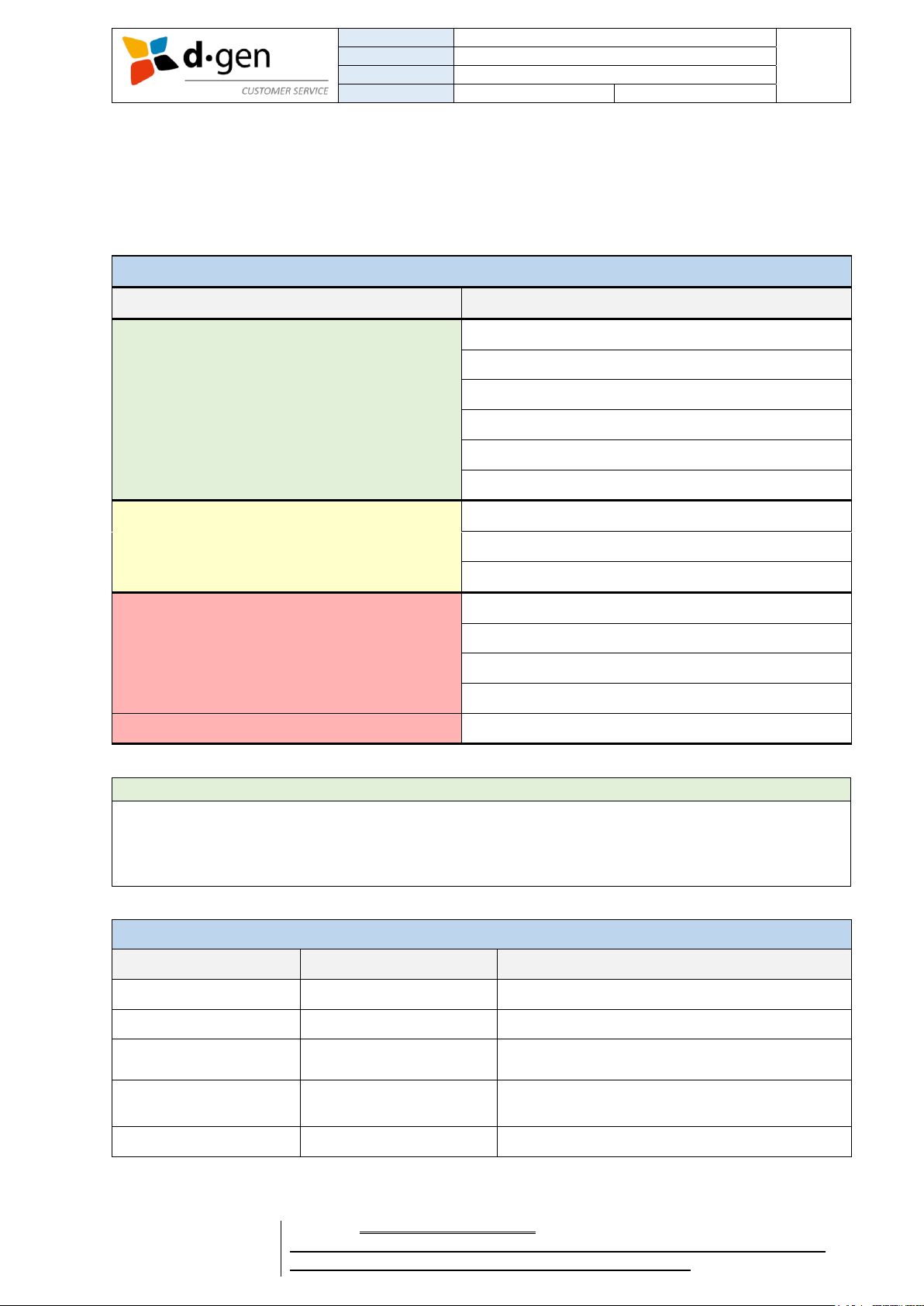

Every day

Waste ink drain bottle

It is recommended to empty and clean the drain

bottle every morning before starting to use the

printer.

Gloves and safety goggles are required for this

operation.

Pour the ink into a proper waste ink disposal

container according to your local environmental

law.

Flushing stage

We strongly recommend pouring some water on

the sponge to clean it. The water will also help to

reduce the ink mist all around the flushing sponge.

Replace the sponge in case starts to degrade

Front roller

We recommend the operator to clean the front

roller with a wet soft cloth every time before

starting to print in the morning and every time after

switching off the machine.

Careful not to scratch the front roller.

Ink gutter and media guides

We recommend the operator to clean the ink

gutter and media guides every time after

switching off the printer when finishing the day.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

4

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Capping unit and its surroundings

We suggest the user to do a regular cleaning

around the capping station and wiping unit to get

rid of any ink spilled while performing a head

cleaning.

Wipers

We recommend the user to clean the wiper blades

and wiping unit after switching off the printer when

finishing the day.

Avoid having dried ink on the wiper blades. The

dry ink may scratch the print heads when wiping.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

5

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

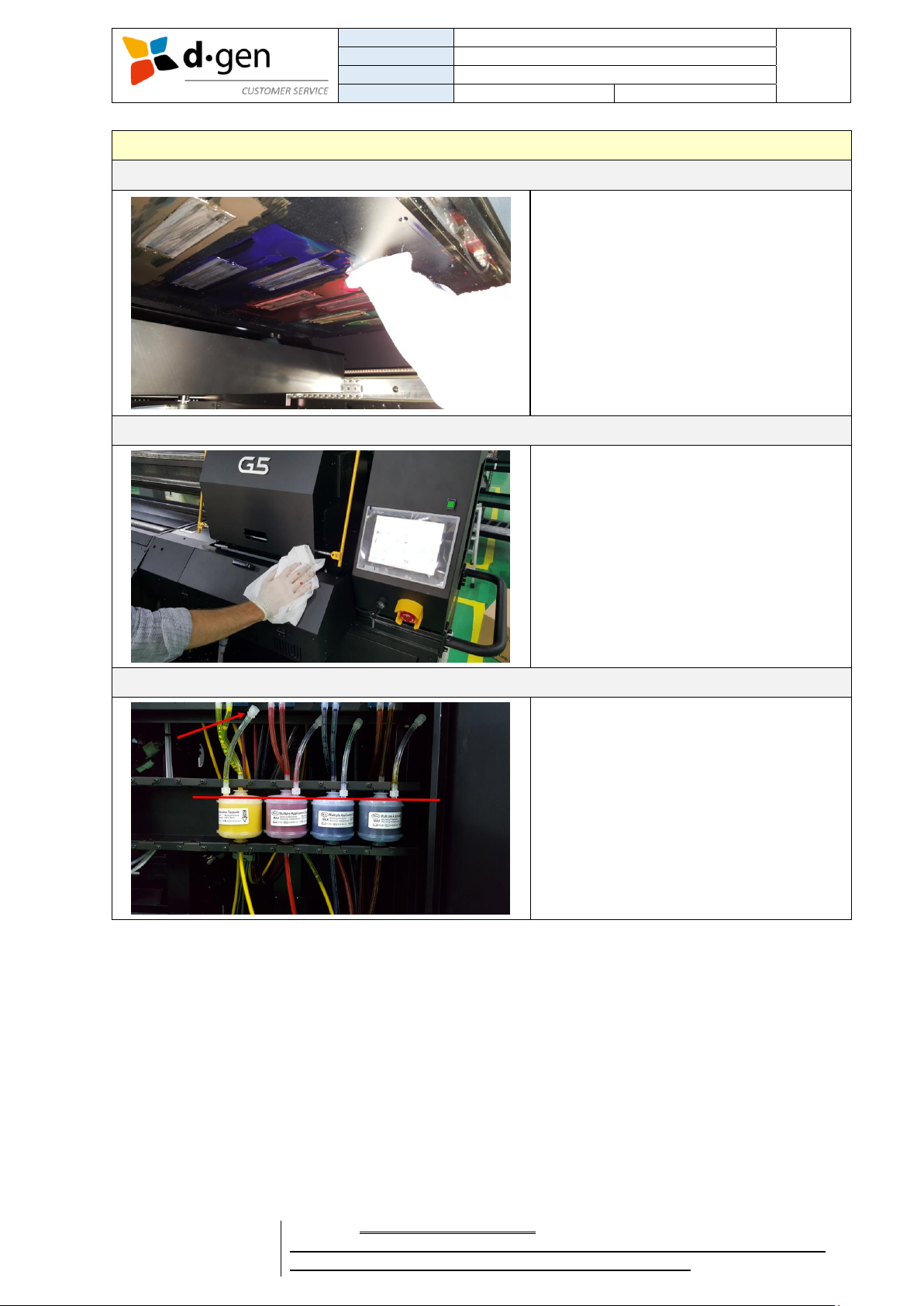

Once a week

Head base plate

With the help of a wet soft cloth clean the head

plate's surface. Once the job is done you may

close the cover and send the carriage back to the

home position by pressing the button “Home” in

the touch panel.

Machine’s exterior

Excessive dust is very harmful for the printer. It

can seriously affect negatively all the electronics

and print heads. We recommend removing the

accumulated dust with a piece of cloth.

Check the PALL ink filter’s level of ink

Check the ink level in the pall filters are close to

the red line as shown in the picture.

Keep the PALL ink filters free of air with the use of

a syringe.

We recommend replacing the filters every 6

months or when changing inks.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

6

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

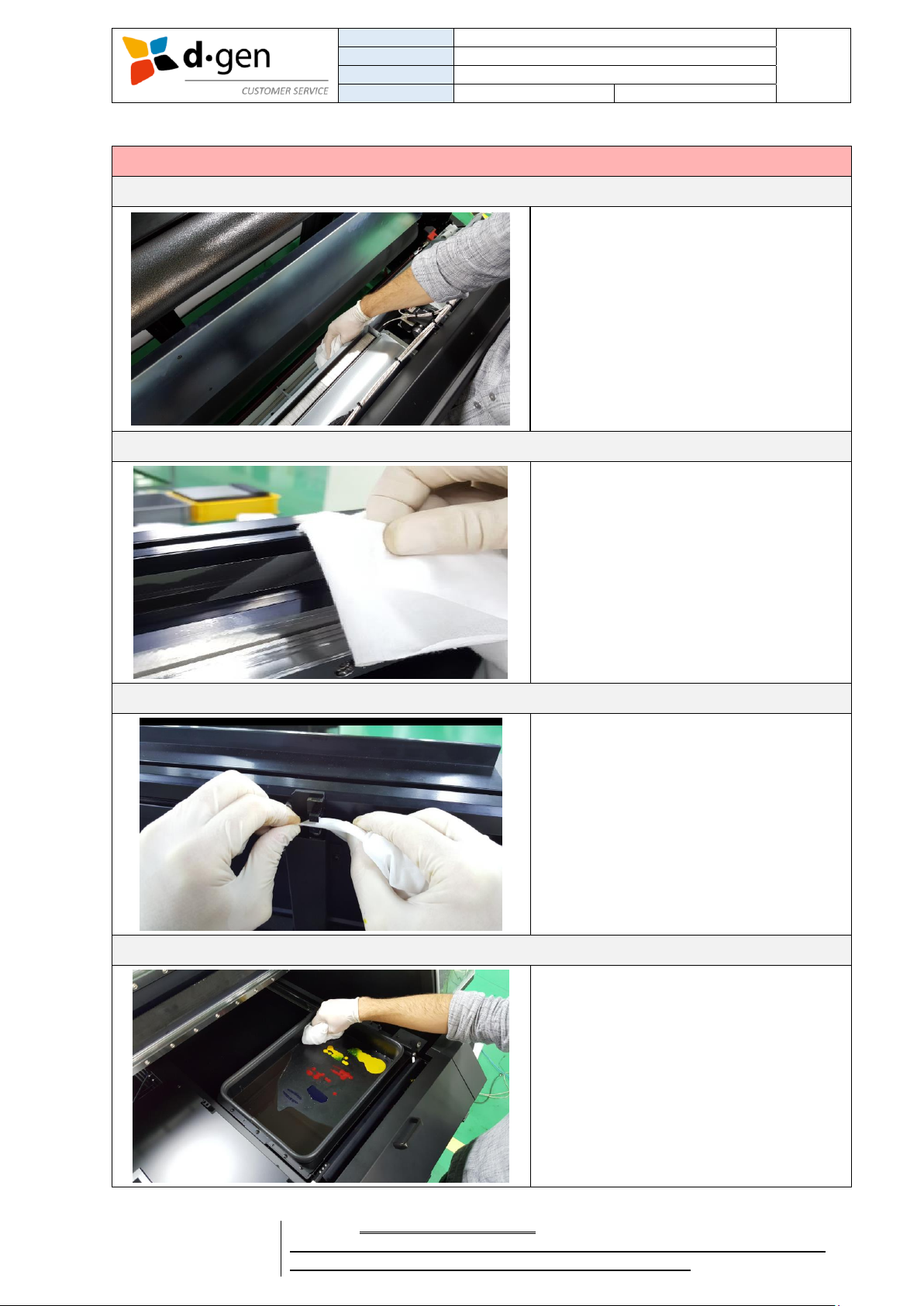

Once a month

Machine’s interior

It is strongly recommended to do some cleaning

in the machine’s interior since the dust and the ink

mist airborne in the environment can seriously

damage the printer’s internal devices such as

electric components, electronic boards, etc.

Switch off and unplug the machine from the power

source before cleaning the machine’s interior.

Risk of electric shock.

Encoder strip

Clean the encoder strip using a wet cloth with

distilled water.

Careful not to scratch the encoder strip.

Do not use alcohol for this operation.

Limit sensors

We recommend checking if some dust or ink mist

is deposited where the diode emitter and receiver

is.

Poorly maintained limit sensors can cause the

machine to behave erratically. Therefore, we

recommend cleaning these sensors with

compressed air once a month.

Capping unit (deep cleaning)

It is important to seal the print heads with a clean

and wet capping unit to preserve the heads

longer.

We recommend cleaning the capping unit deeply

to remove all the undesired waste ink. Once is

fully cleaned, then fill the bucket with clean water.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

7

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Every six months or less

Vacuum filter

A clogged vacuum filter (from white to light black)

may result in poor quality printings. Make sure this

filter is replaced every 6 months.

Note: Depending on how contaminated the

atmosphere is and the usage of the printer, the

vacuum filter may be replaced once every month.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

8

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

[FIXATION UNIT] Components to be cleaned or checked

Frequency

Component

Every day

Machine’s exterior

Check oil drain bottle

Take-up rollers and up/down roller

Once a week

Keep the machine free of waste oil

Once a month

Machine’s electric panel

Every six months

Chain

Every year

General inspection and deep cleaning

[FUME BUSTER] Components to be cleaned or checked

Frequency

Component

Once a week

Wash cashmere bag filters

Visual inspection of the filters

Wash lower module

Components to be replaced in the Fume Buster (From upper to lower module).

Component

Part number

Frequency

CARBON filter

D90010312-00

Every 6 months (not washable)

ULPA filter

D90010311-00

When damaged (not washable)

PRE filter

D90010310-00

Every 6 months (not washable)

GLASS MICROFIBER filter cartridge

D90010306-00

Every 6 months (not washable)

CASHMERE BAR filter

D90010305-00

Every year (wash everyday)

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

9

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Every day (Fixation unit)

Machine’s exterior

Strongly recommended to keep the machine’s

exterior covers always free of dust, fabric lint and

intrusive objects.

Leaving objects on the machine’s surface may

result in fire.

Perform this maintenance procedure once the

machine is cooled down. Risk of burns.

Check oil drain bottle

Keep the oil drain bottle’s level always low.

Dispose the waste oil in a container for a proper

disposal complying the local environmental laws.

Perform this maintenance procedure once the

machine is cooled down. Risk of burns.

Perform this maintenance procedure wearing

gloves and safety goggles.

Take-up rollers and up/down roller

We recommend the operator to clean the take-up

rollers and the up/down roller with a wet soft cloth

every time before starting to print in the morning

and every time after switching off the machine.

Careful not to scratch the front roller.

Perform this maintenance procedure once the

machine is cooled down. Risk of burns.

Perform this maintenance procedure wearing

gloves and safety goggles.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

10

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Once a week (Fixation unit)

Keep the machine free of waste oil

With the help of a wet soft cloth remove all the

condensed oil. Condensed oil tends to

accumulate in every corner of the machine.

Perform this maintenance procedure once the

machine is cooled down. Risk of burns.

Perform this maintenance procedure wearing

gloves and safety goggles.

Once a month (Fixation unit)

Machine’s electric panel

It is strongly recommended to do some cleaning

in electric cabinet since the dust and the ink mist

airborne in the environment can seriously damage

the unit’s internal devices such as electric

components, electronic boards, etc.

Switch off and unplug the machine from the power

source before cleaning the electric cabinet. Risk

of electric shock.

Perform this maintenance procedure once the

machine is cooled down. Risk of burns.

Every 6 months (Fixation unit)

Chain (HEATMAN)

\

Check the grease in the ball screw or chain. Apply

more grease if needed. The grease must be

capable to withstand high temperatures.

Perform this maintenance procedure once the

machine is cooled down. Risk of burns.

Perform this maintenance procedure once the

machine is unplugged. Risk of electric shock.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

11

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Every year (Fixation unit)

General inspection and deep cleaning

The general yearly cleaning and revision involves:

- Deep cleaning of the heating rods.

- Deep cleaning of the unit’s interior.

- Cleaning & re-greasing of mechanical parts.

- Electrical inspection.

- Unit performance tests.

- Upgrades. (Optional)

This maintenance procedure must be performed

by a qualified and official d·gen technician.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

12

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Once a week (Fume buster)

Wash cashmere bag filters

Wash the cashmere bag filters with warm water

mixed with nonaggressive detergent. Make sure

its dried before placing the bag to its original

position.

Perform this maintenance procedure wearing

gloves and safety goggles.

Visual inspection of the filters

Check how clogged the filters are.

Clogged filters may result in:

- Poor exhaust of fumes in the fixation unit.

- Poor fixation process.

- Suction electric motor failure.

- Constant tripping of the magnetic contactor.

Perform this maintenance procedure wearing

gloves and safety goggles.

Wash lower module

Wash the fume buster’s lower module with warm

water mixed with nonaggressive detergent. Make

sure its dried before operating again the unit.

Perform this maintenance procedure wearing

gloves and safety goggles.

Perform this maintenance procedure once the

machine is unplugged. Risk of electric shock.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

13

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

OPERATING TEMPERATURE AND HUMIDITY RANGE.

When using the printer, make sure the environment is within the operating temperature and humidity range

described below.

Note

Desired results may not be achieved if the temperature and humidity are within the limits for the printer but

not within those for the media. Be sure the operating conditions suit the media. For more information, see

the documentation supplied with the media.

TITLE

MAINTENANCE GUIDE

PAGE

PRINTERS

TELEIOS GRANDE G5

14

VERSION

2017DEC04

OUT OF

REVISED BY

MUNOZ, ANTONIO

14

FOR THE USER

d·gen, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

DISPOSING OF WASTE INK.

Note

Since the waste ink bottle does not have a warning system to warn the user that the bottle reached the

limit, we strongly suggest keeping an eye on the bottle every time the heads are purged

Note

✓Never remove the waste ink bottle while the head is being cleaned or a head cleaning operation is in

progress. Failure to observe this precaution could cause ink to leak.

✓Have a piece of cloth ready to be placed under the funnel to avoid ink drops hit the bottle holder and

the floor.

✓Hold the waste ink bottle from them top. Then tilt a little bit until is possible to remove it from the bottle

holder.

✓Pour the ink into a proper waste ink disposal container.

✓Place the waste ink bottle carefully back again under the funnel.

✓Double check the waste ink bottle is under the funnel to avoid having ink all over the floor.

Caution

Store waste ink a location out of reach of children.

Caution

Wear protective eyewear and gloves when replacing waste ink bottle.

Caution

If waste ink contacts your skin or enter your eyes or mouth, immediately take the following actions:

✓If fluid adheres to your skin, immediately wash it off using large volumes of soapy water. Consult a

physician if the skin appears irritated or is discolored.

✓If fluid enters your eyes, rinse immediately with water. Failure to observe this precaution could result

in bloodshot eyes or mild inflammation. If problems persist, consult with a physician.

✓If fluid enters your mouth, consult with a physician as soon as possible.

✓If swallowed, do not induce vomiting. Consult with a physician as soon as possible. If vomiting is

induced, vomited material may enter the windpipe, which is dangerous.

Important

The waste ink from the printer is an industrial waste. Proper waste ink disposal in compliance with the

industrial waste disposal laws and ordinances of your local government is required. Consign disposal of

waste inks to an industrial waste disposer.

Table of contents

Other d.gen Printer manuals