Electrical Retirements

IMPORTANT: The information below appNes only to free standing

units equipped for use in the U.S.A. and units with the self

rimming option.

It is the owner's responsibility to ensure that the electrical

connection of this appNance Jsperformed by a Ncensed

electrician. The electrical JnstaNatJon,including minimum supply

wire size and grounding, must be Jnaccordance with the National

Electric code ANSl/NFPA 70-1993" (or latest revision) and local

codes and ordinances. A copy of this standard may be obtained

from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

• The correct voltage, frequency and amperage must be

supplied to the appliance from a separate, grounded, circuit

that is protected by a properly sized circuit breaker or time

delay fuse. Refer to the ratings on the range rating label.

The ratings above are for reference only -

refer to the range rating label (see page 3)

• Consult local building codes for the type and minimum wire

gauge to use for the power requirements listed on the rating

label.

• Suggested wiring color code: Black, white, red and green.

• The wiring needs to be tong enough to allow the range

to be pulled out from the wall for service, while remaining

connected. See page 12 for further details.

• The wiring to the range must:

0 Have a minimum rating of 250 Volts @ 30 Amps

0 Include a strain relief

0 Be terminated by tinned leads, closed loop terminals or

open ended spade tugs with upturned ends

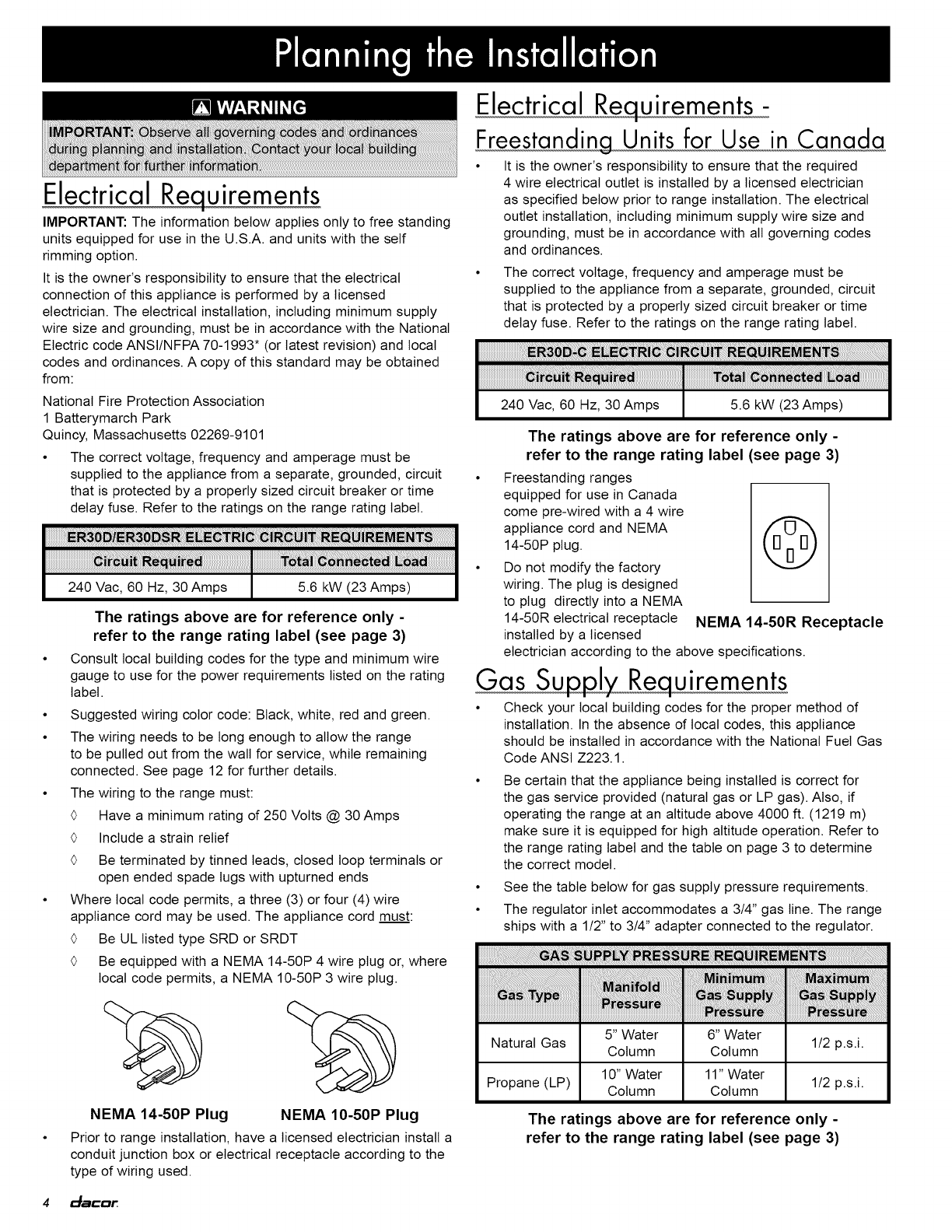

• Where local code permits, a three (3) or four (4) wire

appliance cord may be used. The appliance cord must:

0 Be UL listed type SRD or SRDT

0 Be equipped with a NEMA 14-50P 4 wire plug or, where

local code permits, a NEMA 10-50P 3 wire plug.

NEMA 14-50P Plug NEMA 10-50P Plug

Prior to range installation, have a licensed electrician install a

conduit junction box or electrical receptacle according to the

type of wiring used.

Electrical Retirements -

Freestanding Units for Use in Canada

• It Jsthe owner's responsibility to ensure that the required

4 wire electrical outlet Jsinstalled by a licensed electrician

as specified below prior to range installation. The electrical

outlet installation, including minimum supply wire size and

grounding, must be Jnaccordance with all governing codes

and ordinances.

The correct voltage, frequency and amperage must be

supplied to the appliance from a separate, grounded, circuit

that is protected by a properly sized circuit breaker or time

delay fuse. Refer to the ratings on the range rating label.

240 Vac, 60 Hz, 30 Amps 5.6 kW (23 Amps) I

The ratings above are for reference only -

refer to the range rating label (see page 3)

• Freestanding ranges

equipped for use in Canada

come pre-wired with a 4 wire

appliance cord and NEMA /f E] -"_

14-50P plug. ttgJ

Do not modify the factory

wiring. The plug is designed

to plug directly into a NEMA

14-50R electrical receptacle NEMA 14-50R Receptacle

installed by a licensed

electrician according to the above specifications.

Gas Su J_,w uirements

• Check your local building codes for the proper method of

installation. In the absence of local codes, this appliance

should be installed in accordance with the National Fuel Gas

Code ANSI Z223.1.

Be certain that the appliance being installed is correct for

the gas service provided (natural gas or LP gas). Also, if

operating the range at an altitude above 4000 ft. (1219 m)

make sure it is equipped for high altitude operation. Refer to

the range rating label and the table on page 3 to determine

the correct model.

• See the table below for gas supply pressure requirements.

• The regulator inlet accommodates a 314" gas line. The range

ships with a 112"to 314" adapter connected to the regulator.

iiiiiiiiiiiiii i' i ! !i i i ii i! i ;!i i ili i i ili,!ii!a777777777iilIi ! 7

5" Water 6" Water

Natural Gas Column Column 1/2 p.s.i.

10" Water 11" Water

Propane (LP) Column Column 1/2 p.s.i.

The ratings above are for reference only -

refer to the range rating label (see page 3)

4_acar