Table of ConTenTs

Section 1 - Safe Servicing Practices............................. 1-1

Section 2 - Operation ...................................................2-1

Static Fill..............................................................................2-1

Dynamic Fill.........................................................................2-1

Wash System.......................................................................2-2

Soil Sensing........................................................................2-2

Main Wash/Temp Assure....................................................2-3

Temperature Controls.........................................................2-3

Rinse Phases .....................................................................2-4

Condensate Drying.............................................................2-4

Section 3 - Cycle, Systems & Components ...............3-1

Dishwasher Control............................................................3-1

Auto Wash.........................................................................3-1

Heavy Wash......................................................................3-1

Normal Wash ...................................................................3-1

Short Wash........................................................................3-1

Rinse Hold.........................................................................3-1

Component Function Test .................................................3-1

Water/Service Test............................................................3-1

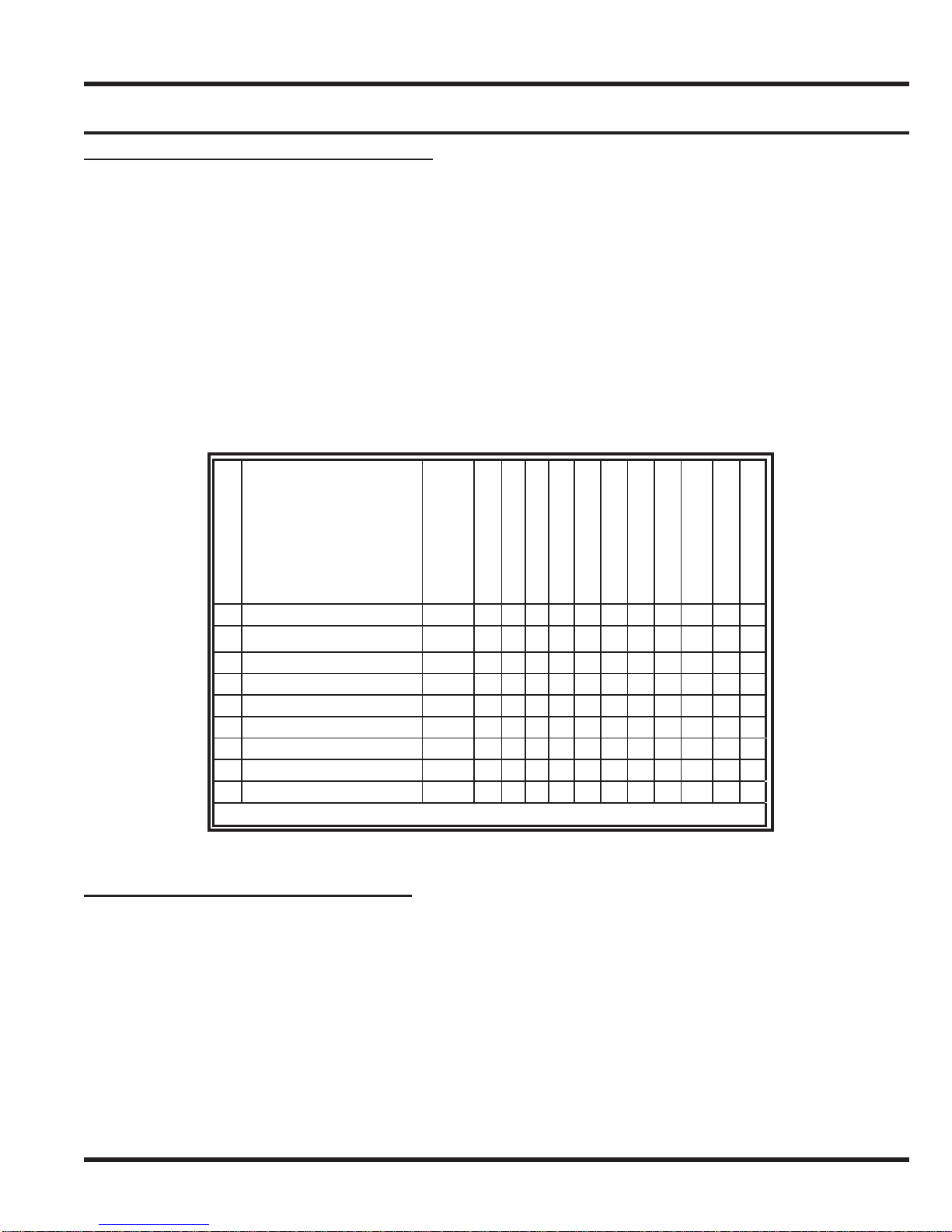

Entering the Water/Service Test........................................3-2

Water Temperature Test Mode..........................................3-2

Soil Sensor Test Mode......................................................3-3

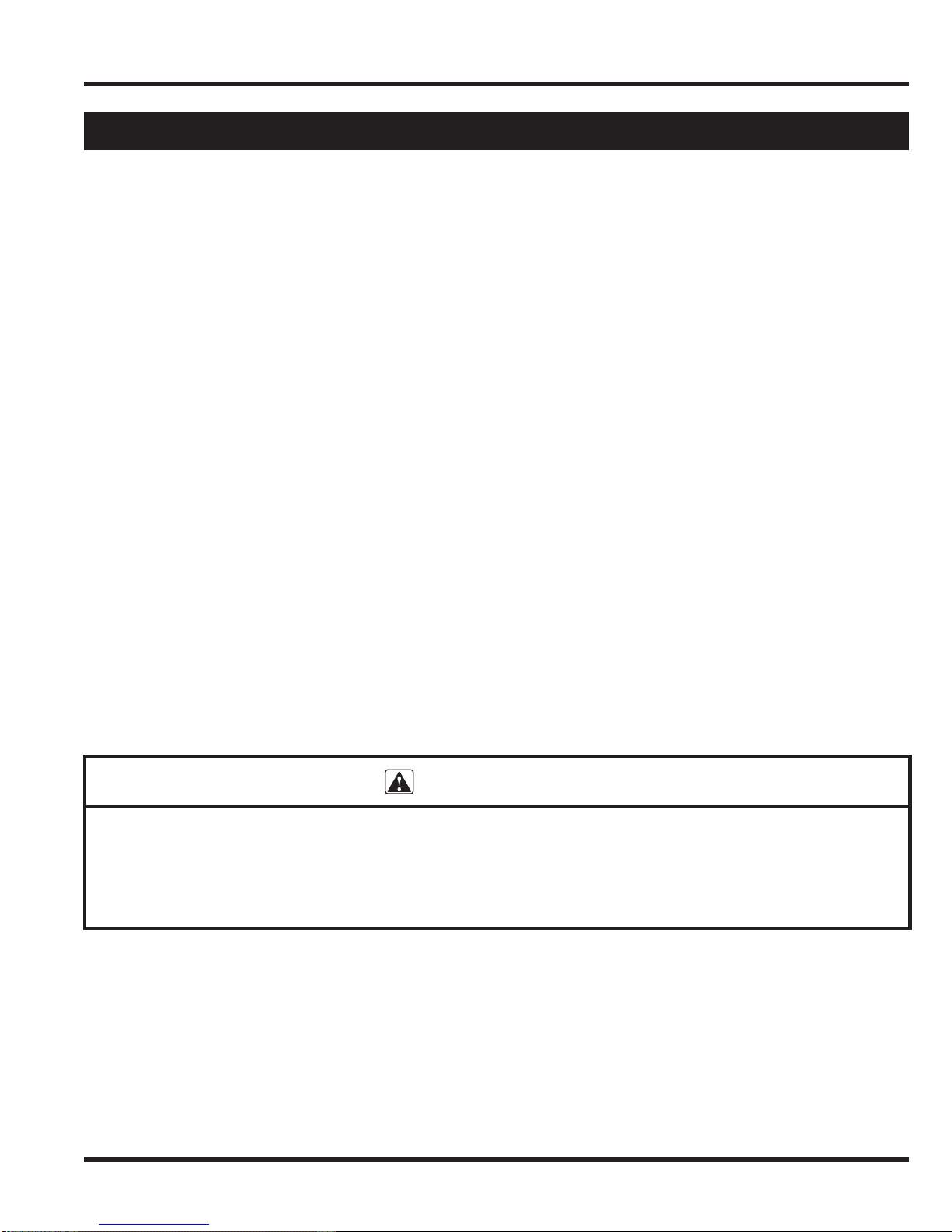

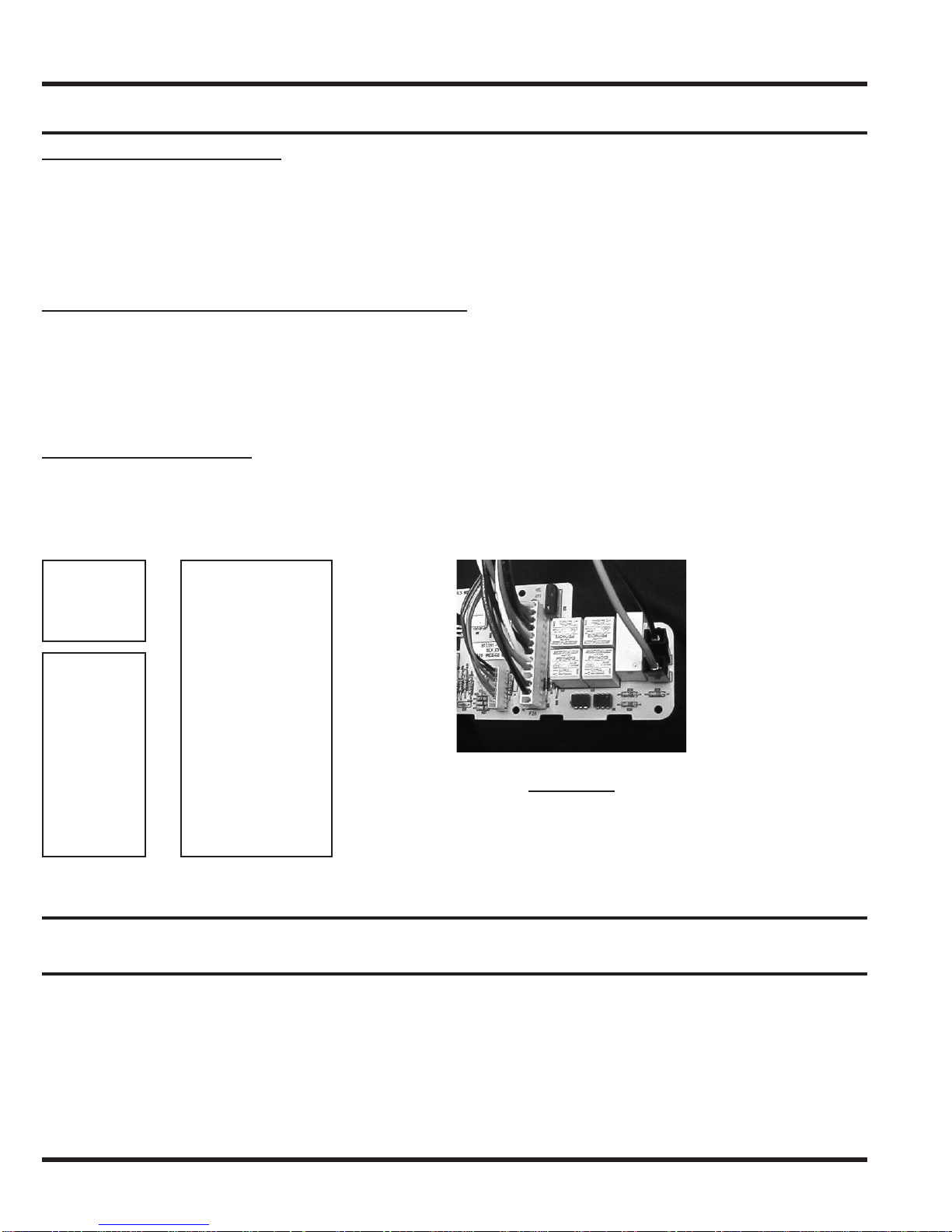

Electronic Control and Keypad Assembly.........................3-3

Control Board Plugs..........................................................3-3

Fill System...........................................................................3-3

Inlet Water Valve .................................................................3-3

To Check Inlet Water Valve...............................................3-4

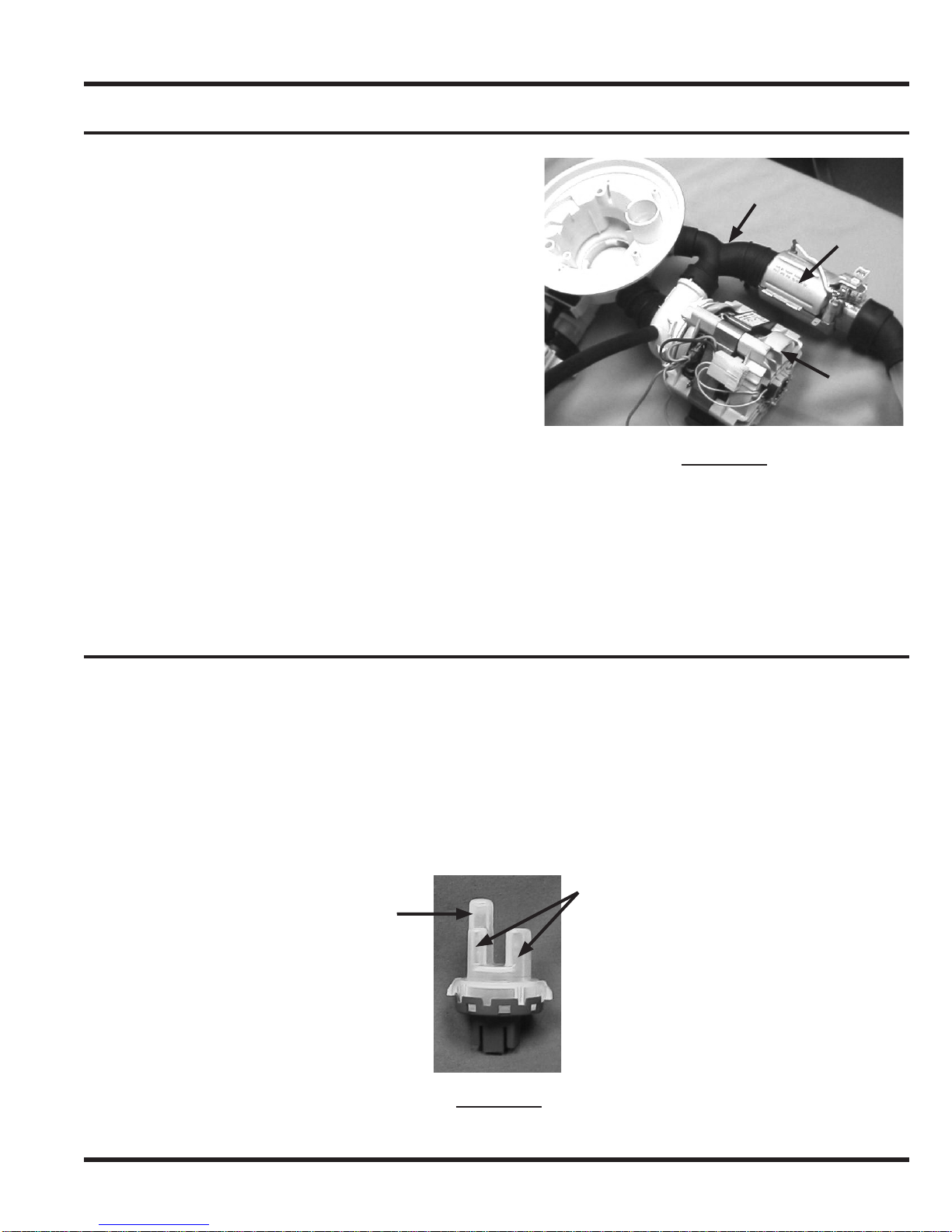

Pressure Switch Assembly................................................3-4

Low Water Level Switch.....................................................3-4

Checking Low Water Level Switch....................................3-5

High Water Level Switch....................................................3-5

Checking High Water Level Switch...................................3-6

Wash Motor .........................................................................3-6

Checking the Wash Motor.................................................3-6

Checking the Tachometer .................................................3-6

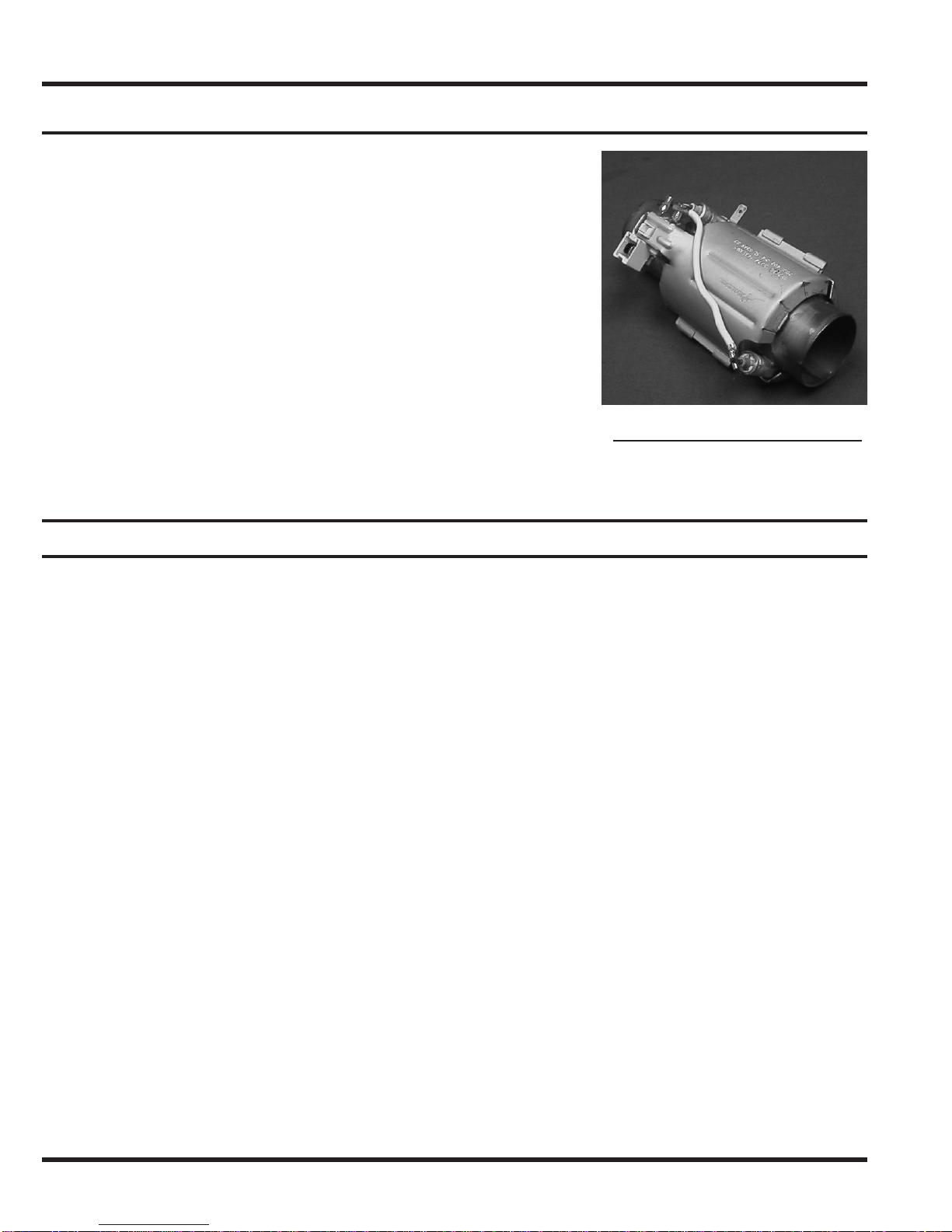

Heater...................................................................................3-7

Temperature Sensor and Soil Sensor...............................3-7

Checking the Thermistor...................................................3-7

Checking the Soil Sensor..................................................3-8

Drain Pump..........................................................................3-8

Checking the Drain Pump.................................................3-8

Dispenser.............................................................................3-9

Checking the Dispenser....................................................3-9

Fan Dry Unit ......................................................................3-10

Checking Fan Dry Motor.................................................3-10

Section 4 - Service & Disassembly.............................4-1

Safety Precautions .............................................................4-1

Door Panel...........................................................................4-1

Control.................................................................................4-1

Dispenser.............................................................................4-2

Lower Access Panel...........................................................4-2

Door Latch/Door Switch.....................................................4-2

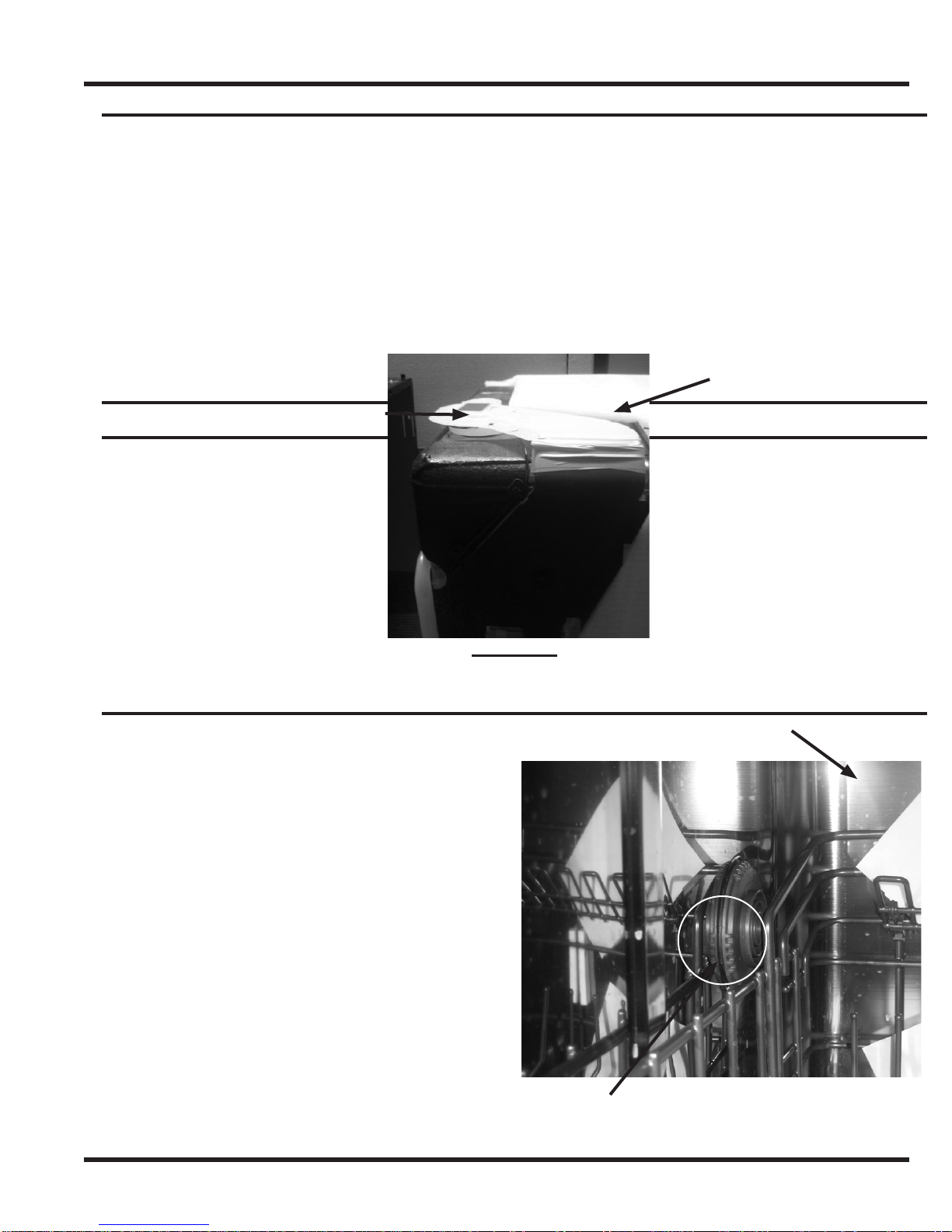

Upper Spray Arm ................................................................4-3

Lower Spray Arm................................................................4-3

Center Spray Arm and Upper Rack Manifold...................4-4

Main Delivery Tube.............................................................4-4

Upper Spray Arm Mount ....................................................4-5

Bottom Door Seal ...............................................................4-5

Door Seal.............................................................................4-5

Water Valve..........................................................................4-6

Cabinet Removal.................................................................4-6

Door Spring.........................................................................4-7

Hinge “C” Arm ....................................................................4-7

Door Seal Retainer..............................................................4-8

Pressure Switch Assembly................................................4-8

Thermistor/Soil Sensor......................................................4-9

Inline Heater .......................................................................4-9

Drain Pump........................................................................4-10

Wash Motor .......................................................................4-10

Capacitor ...........................................................................4-11

Blower Assembly..............................................................4-12

Sump..................................................................................4-12

Side Vent and Fill Hose....................................................4-13

Section 5 - Troubleshooting Tips................................5-1

Section 6 - Parts Breakdown.......................................6-1

Section 7 - Electrical Diagram.....................................7-1