1. Specifications -------------------------------------------------------------

1

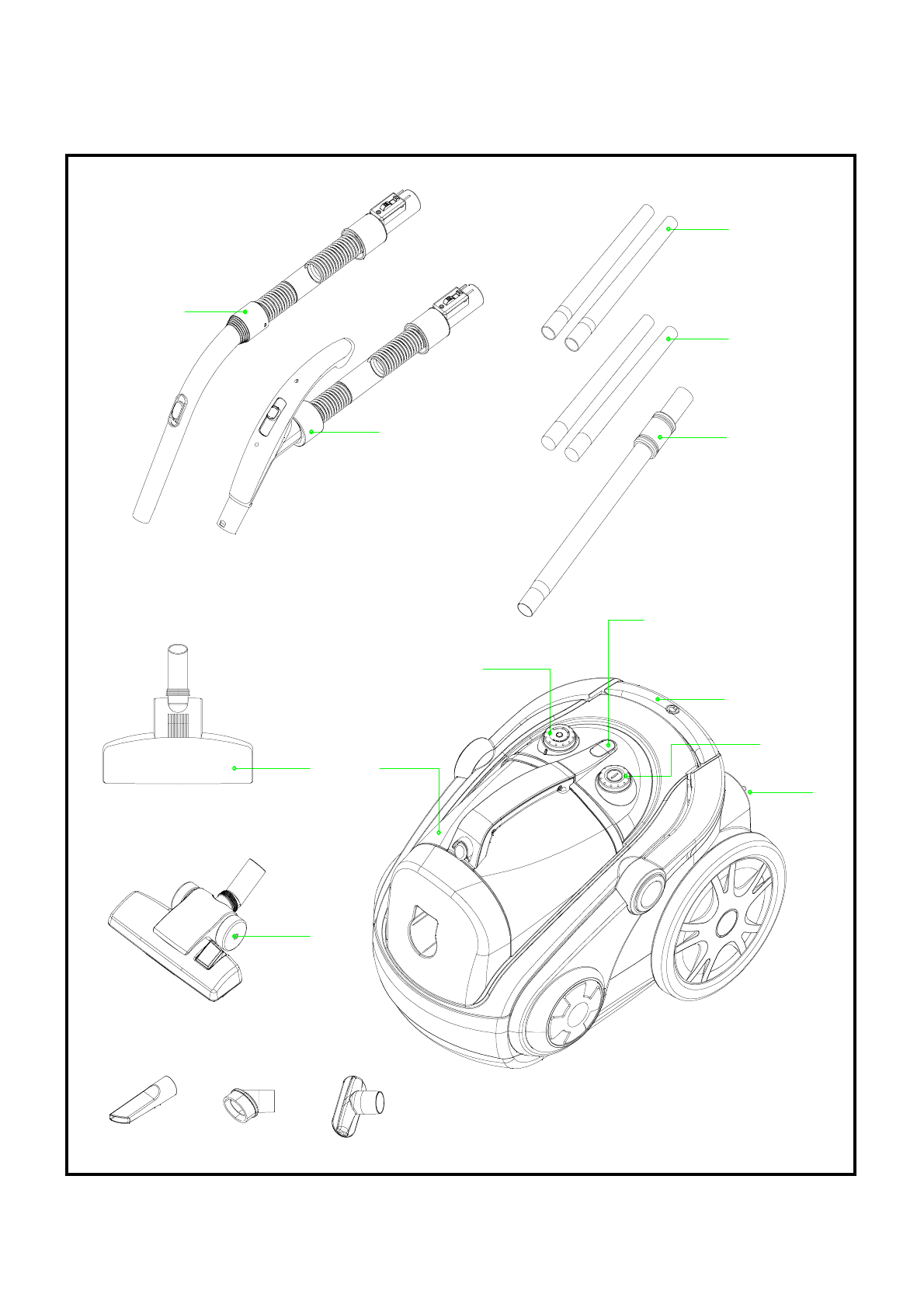

2. External Views ------------------------------------------------------------

2

2-1. External Components List ---------------------------------------------------

2

2-2. External Components View -------------------------------------------------

3

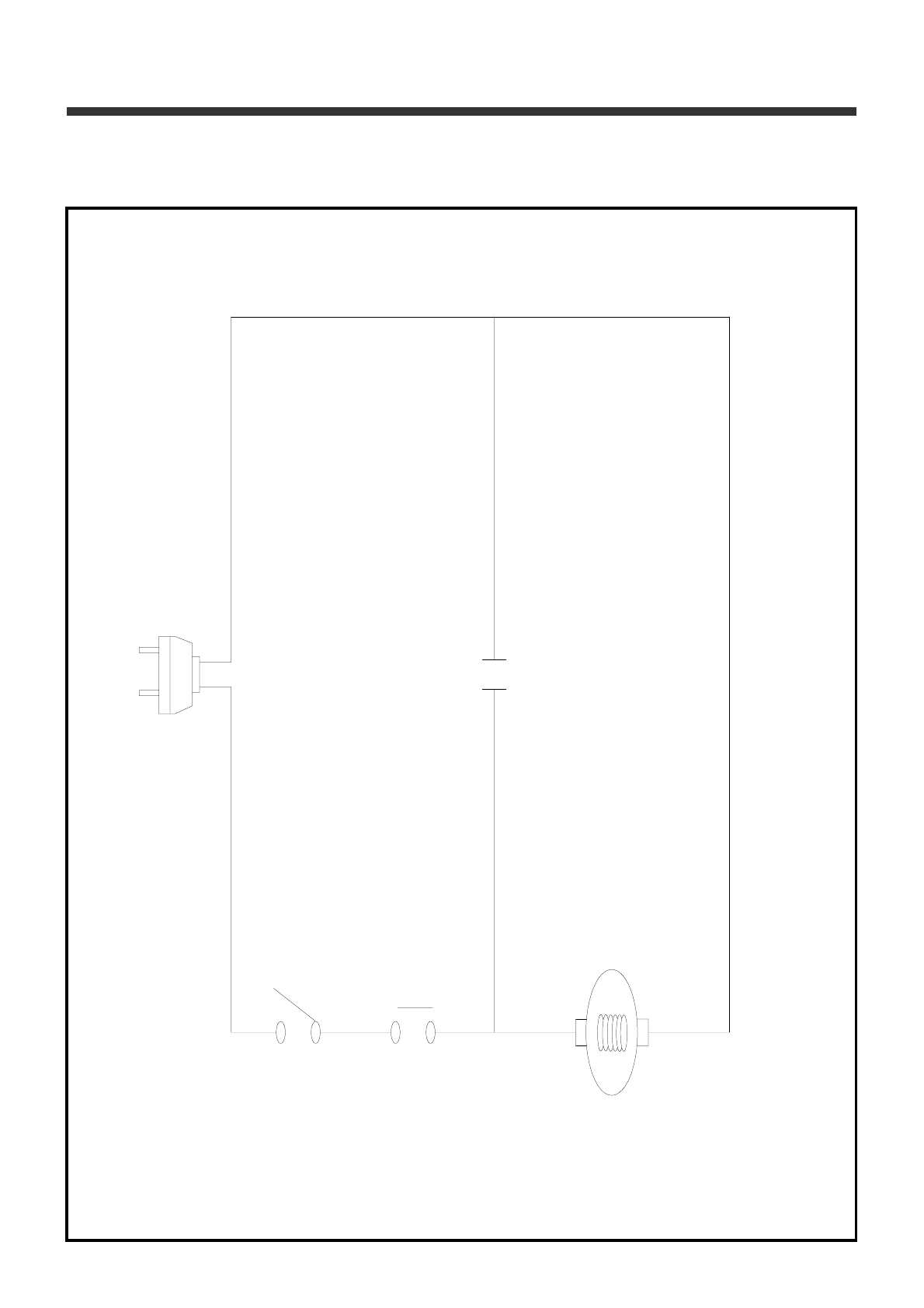

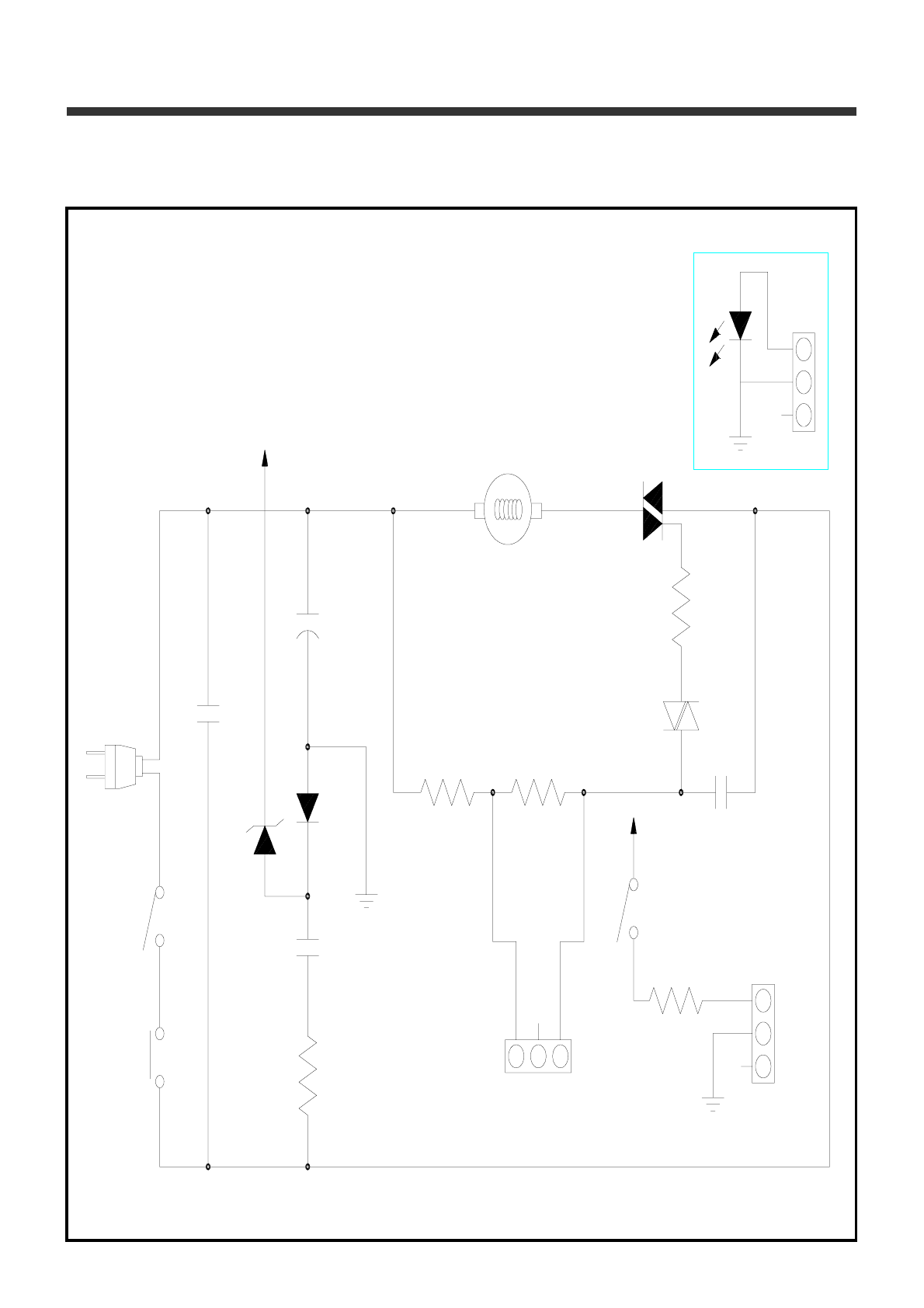

3. Electrical Description (Diagram) ------------------------------------ 4

3-1. Wiring Diagram ----------------------------------------------------------------

4

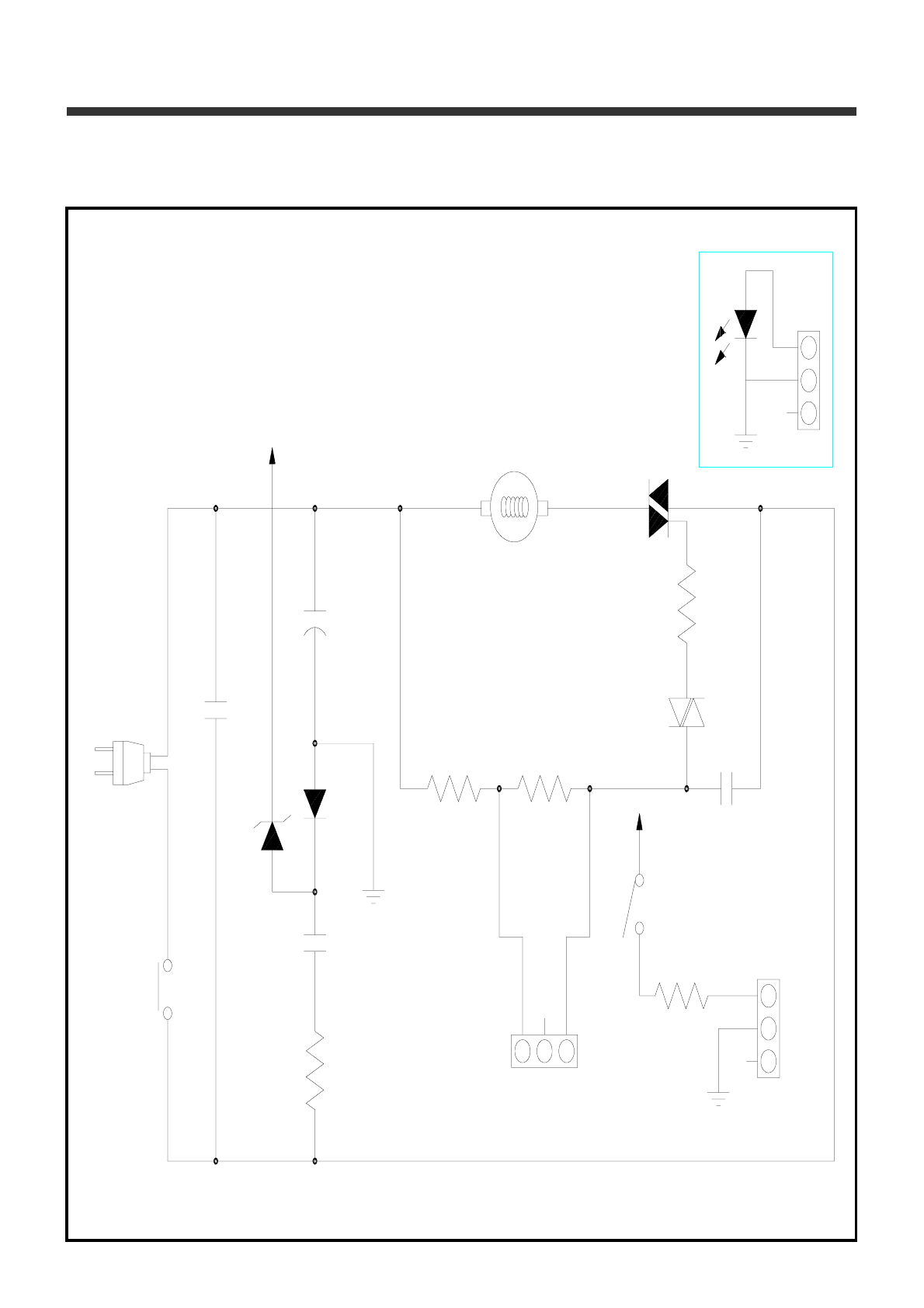

3-2. Circuit Diagram ----------------------------------------------------------------

6

4. Trouble Shooting Guide -----------------------------------------------

9

5. Disassembling and Treatment --------------------------------------

11

5-1. Cleaner Assembly -------------------------------------------------------------

11

5-2. Motor Assembly ---------------------------------------------------------------- 12

5-3. Cordreel Assembly ------------------------------------------------------------

13

5-4. Cover Assembly ---------------------------------------------------------------

15

5-5. Hose Assembly ----------------------------------------------------------------

16

5-6. Brush Assembly ---------------------------------------------------------------

17

6. Exploded View and Part List -----------------------------------------

18

6-1. Cleaner Assembly -------------------------------------------------------------

18

6-2. Body Assembly ----------------------------------------------------------------

24

6-3. Cover Assembly ---------------------------------------------------------------

28

6-4. Cover Top Assembly ---------------------------------------------------------

34

6-5. Motor Case Assembly --------------------------------------------------------

37

6-6. Cordreel Assembly ------------------------------------------------------------

39

6-7. Cover Side Assembly --------------------------------------------------------

41

6-8. Dustbox Assembly ------------------------------------------------------------

42

6-9. Hose Assembly ----------------------------------------------------------------

46

6-10. Pipe Assembly ---------------------------------------------------------------- 50

6-11. Brush Assembly --------------------------------------------------------------

51

Page

Table of Contents