1

TABLE OF CONTENTS

SAFETY&PRECAUTIONS ............................................................................................... 2

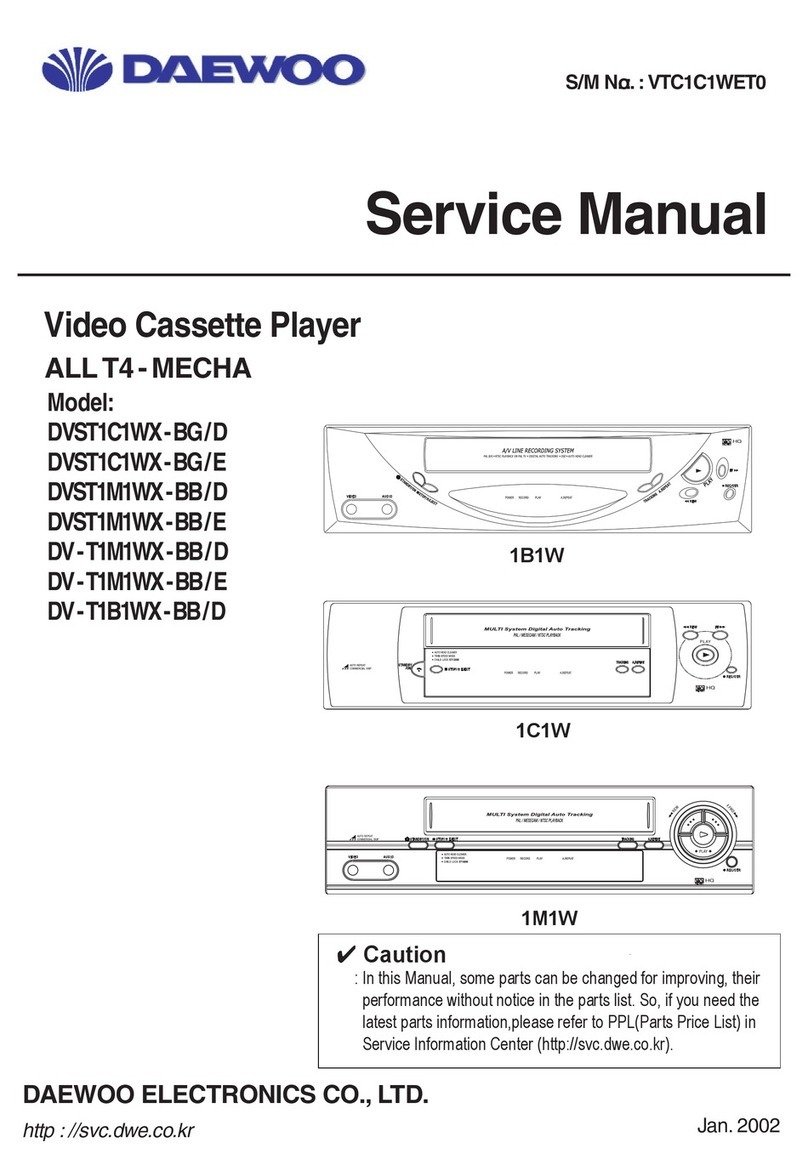

EXTERNAL VIEWS ........................................................................................................ 4

FRONT VIEWS FUNCTION ...................................................................................................................4

REAR VIEWS FUNCTION .....................................................................................................................5

ELECTRICAL ADJUSTMENT ........................................................................................... 6

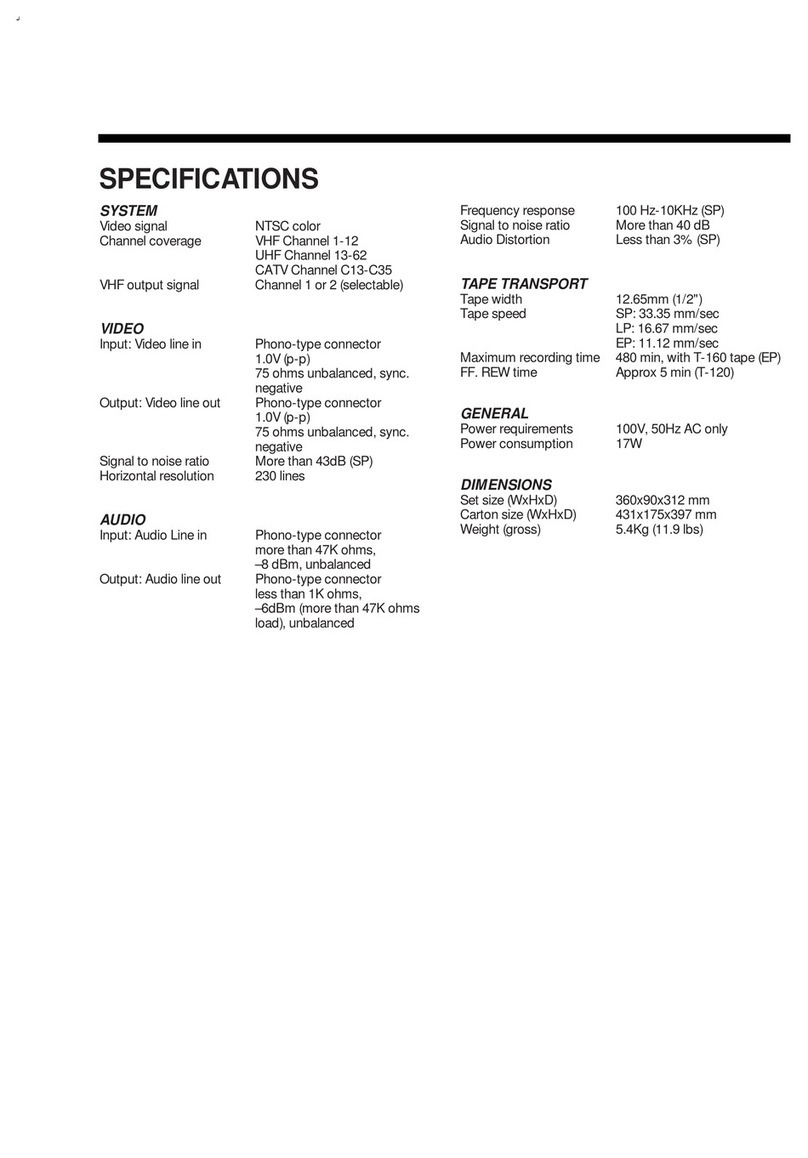

SPECIFICATIONS ....................................................................................................... 14

TIMELAPSE REC/PB SPEED CHART

................................................................................ 15

CIRCUIT OPERATION .................................................................................................. 16

TROUBLE SHOOTING FLOW CHART ............................................................................. 24

POWER CIRCUIT ................................................................................................................................24

SERVO-SYSCON CIRCUIT ...................................................................................................................26

VIDEO CIRCUIT .................................................................................................................................34

AUDIO CIRCUIT .................................................................................................................................38

u-COM PORT DESCRIPTION ....................................................................................... 41

VOLTAGE CHART ....................................................................................................... 44

CIRCUIT DIAGRAM ..................................................................................................... 50

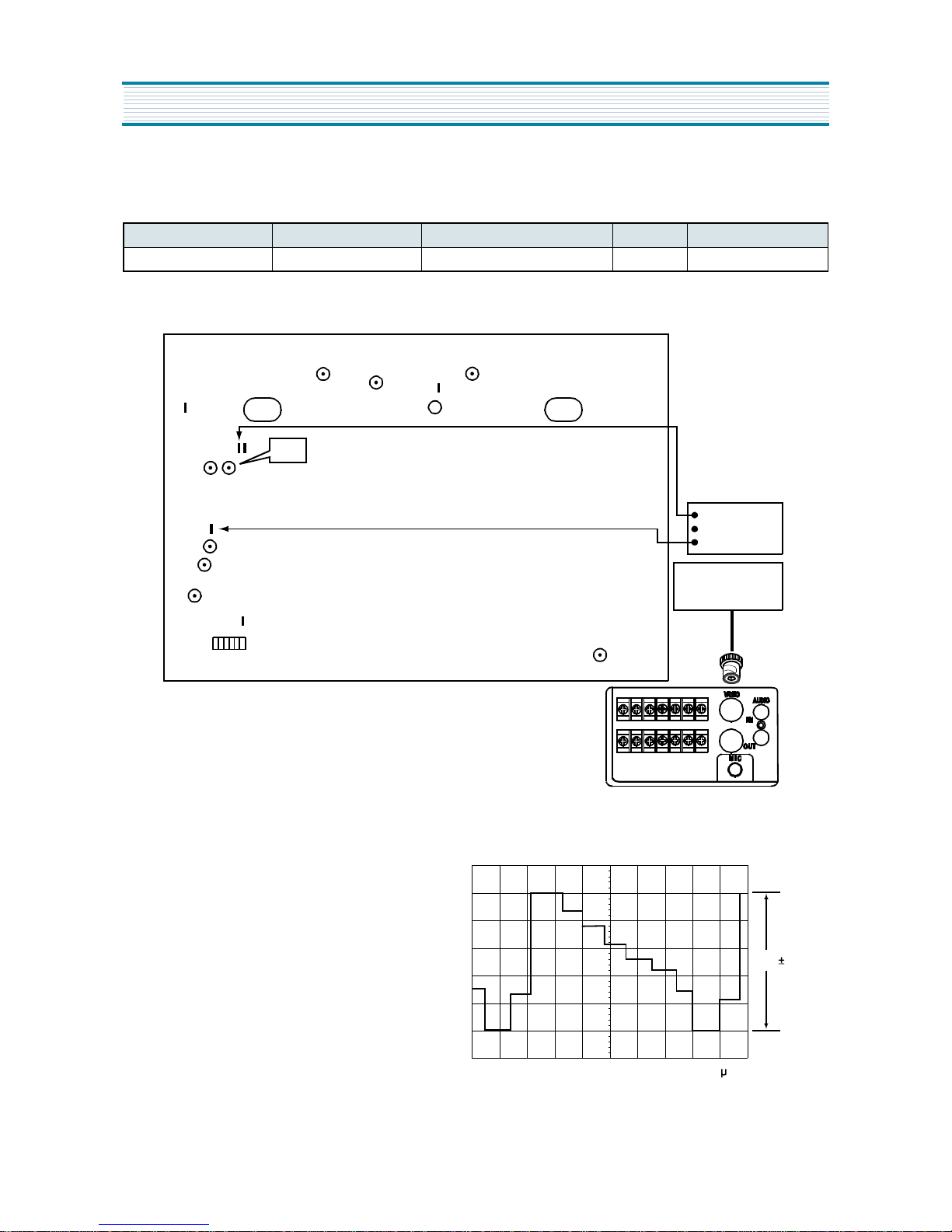

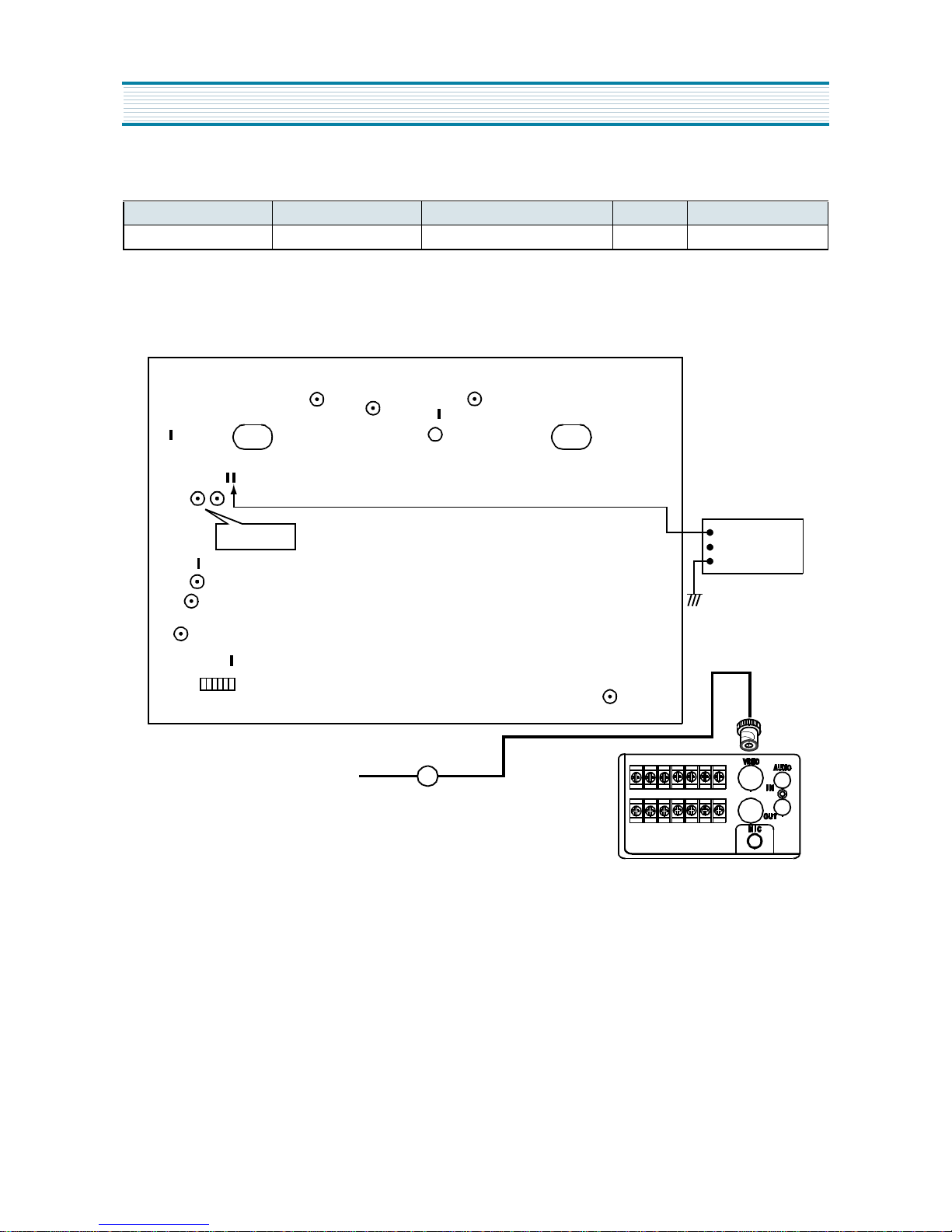

CONNECTION DIAGRAM ..................................................................................................................50

POWER CIRCUIT DIAGRAM ................................................................................................................51

SYSCON CIRCUIT DIAGRAM ..............................................................................................................52

VIDEO CIRCUIT DIAGRAM .................................................................................................................53

HEADAMP CIRCUIT DIAGRAM ............................................................................................................54

OSD CIRCUIT DIAGRAM ....................................................................................................................55

Y/C SEPARATION CIRCUIT DIAGRAM ..................................................................................................56

AUDIO CIRCUIT DIAGRAM .................................................................................................................57

LOGIC CIRCUIT DIAGRAM .................................................................................................................58

TERMINAL CIRCUIT DIAGRAM ............................................................................................................59

COMPONENTS LOCATION GUIDE ON PCB BOTTOM VIEW ........................................... 60

PCB MAIN .........................................................................................................................................60

PCB UNION .......................................................................................................................................61

DISASSEMBLY ............................................................................................................. 62

PANEL FRONT ASS’Y ...........................................................................................................................62

SET TOTAL ASS’Y .................................................................................................................................63

PACKING ASS’Y .................................................................................................................................64

ELECTRICAL PARTS LIST ............................................................................................... 65