-2-

TABLE OF CONTENTS

1SAFETY INFORMATION................................................................................................................. 3

2ARC WELDING SAFETY PRECAUTIONS .....................................................................................4

3CHECKING OF QUANTITY OF THE ACCESSORIES...................................................................9

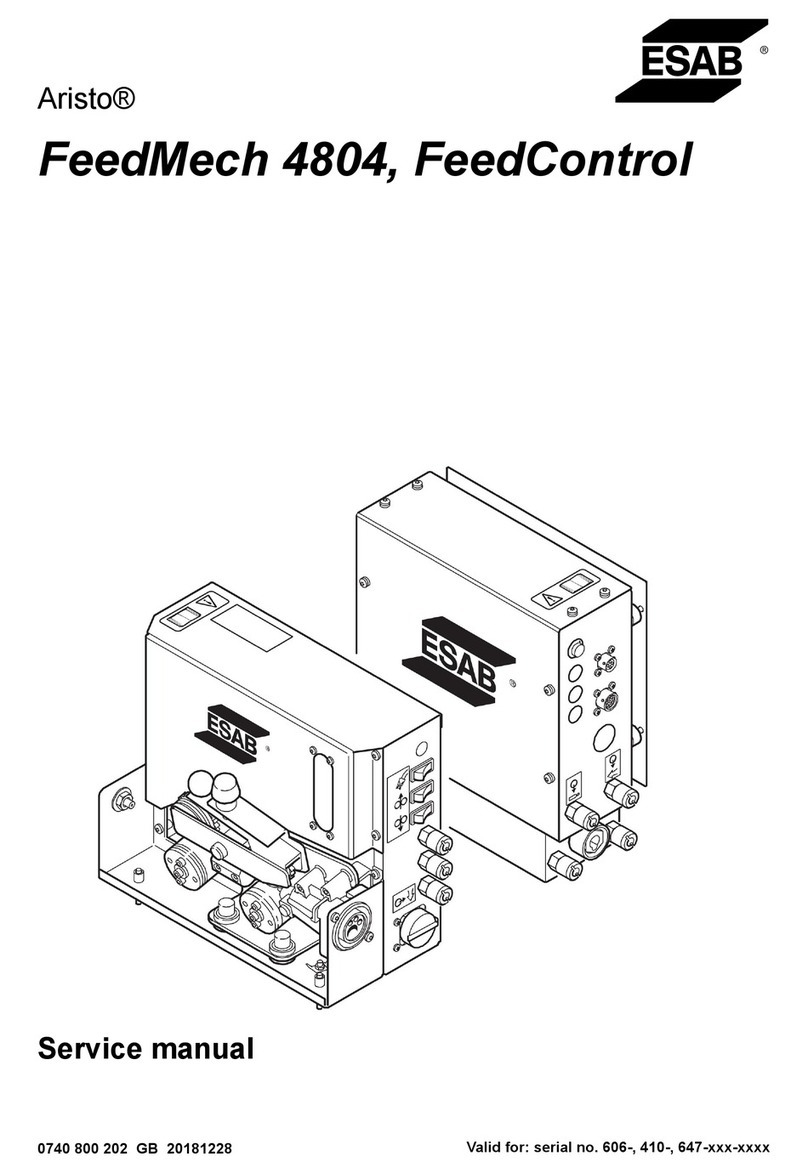

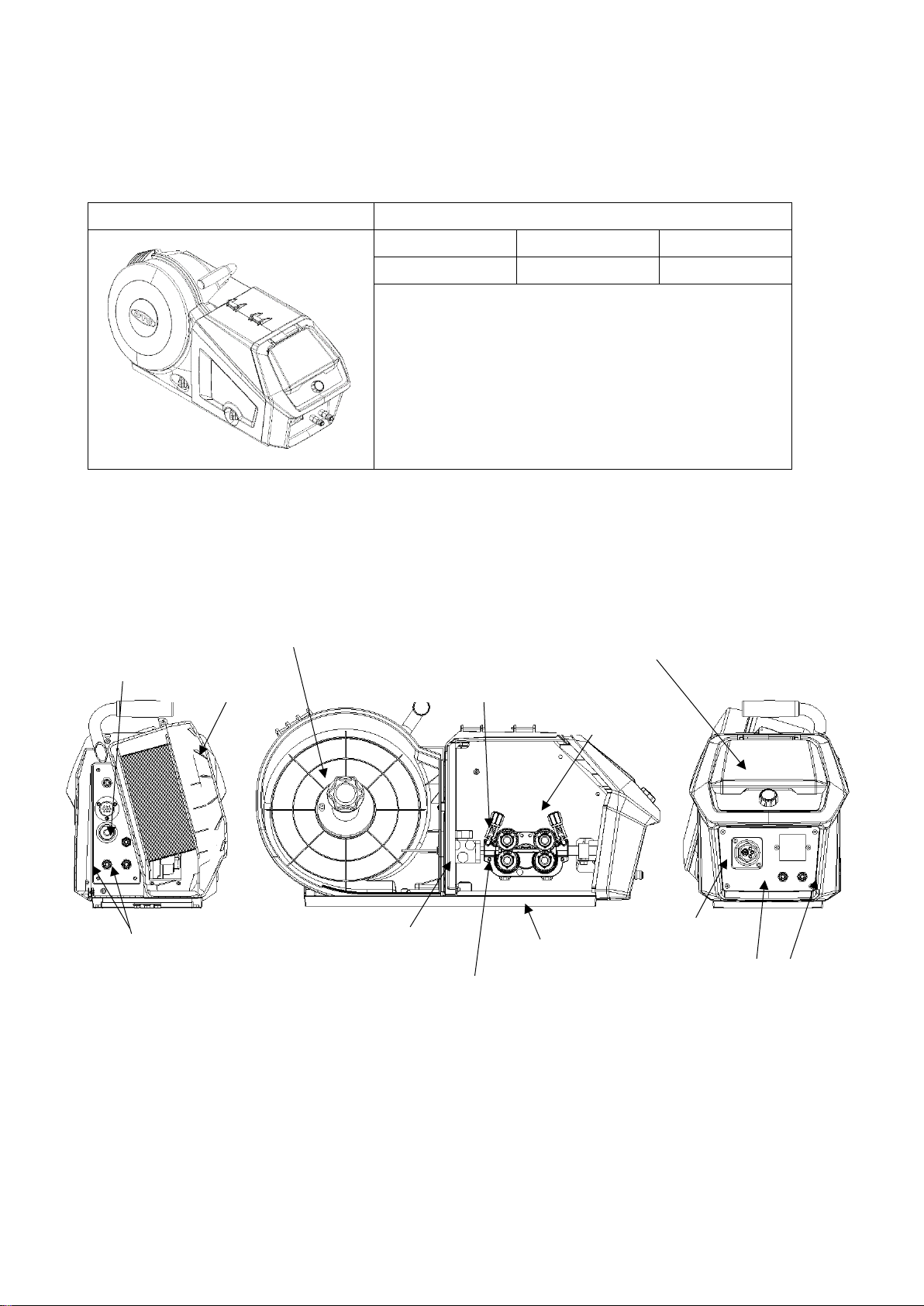

4NAMES OF PARTS.........................................................................................................................9

5CARRYING AND INSTALLING OF THE WIRE FEEDER.............................................................10

5.1 TRANSPORTATION......................................................................................................................10

5.2 INSTALLATION .............................................................................................................................10

6CONNECTION PROCEDURE.......................................................................................................11

6.1 CONNECTION FLOW CHART......................................................................................................12

6.2 CONNECTING OF THE WATER/GAS HOSE...............................................................................13

6.3 CONNECTING OF THE CONNECTION CABLE ..........................................................................14

6.4 CONNECTING OF THE POWER CABLE FOR WIRE FEEDER..................................................15

6.5 CONNECTING OF THE WELDING TORCH.................................................................................16

7WELDING PREPERATION ...........................................................................................................17

7.1 CHECKING OF WIRE SIZE / REPLACEMENT OF FEED ROLL .................................................17

7.2 FITTING OF WIRE.........................................................................................................................19

7.3 ADJUSTING OF THE WIRE PRESSURE.....................................................................................21

7.4 ADJUSTING OF THE WIRE REEL HUB.......................................................................................22

7.5 WIRE FEEDING BY PERFORMING INCHING OPERATION.......................................................23

8DIGITAL CONTROL PANEL .........................................................................................................24

8.1 SETTING INTERNAL FUNCTIONS ..............................................................................................24

8.2 TROUBLESHOOTING...................................................................................................................25

8.2.1 ACTION IN CASE OF ERROR.....................................................................................................25

8.2.2 ACTION IN CASE OF TROUBLE.................................................................................................25

9MAINTENANCE AND TROUBLESHOOTING...............................................................................26

9.1 CARRYING OUT MAINTENANCE................................................................................................26

9.2 REPLACING OF THE OUTLET GUIDE ........................................................................................28

9.3 REPLACING OF THE FEED MOTOR...........................................................................................30

9.4 REPLACE THE CENTER GUIDE..................................................................................................31

10 INTERMEDIATE CABLE ...............................................................................................................32

10.1INTERMEDIATE CABLE –WATER COOLED..............................................................................32

10.2INTERMEDIATE CABLE - GAS COOLED ....................................................................................32

11 PARTS LIST ..................................................................................................................................33

11.1MAIN BODY...................................................................................................................................33

11.2FRAME ASSY................................................................................................................................34

11.3MODULE........................................................................................................................................35

11.4DRIVE UNIT...................................................................................................................................36

11.4.1DRIVE UNIT - MECHANISM.......................................................................................................37

11.4.2 TORCH CONNECTION..............................................................................................................39

11.5FRONT PANEL ASSY...................................................................................................................40

11.6REAR PANEL ASSY......................................................................................................................41

11.7DIGITAL PANEL ............................................................................................................................42

11.8WIRE REEL DRUM .......................................................................................................................43

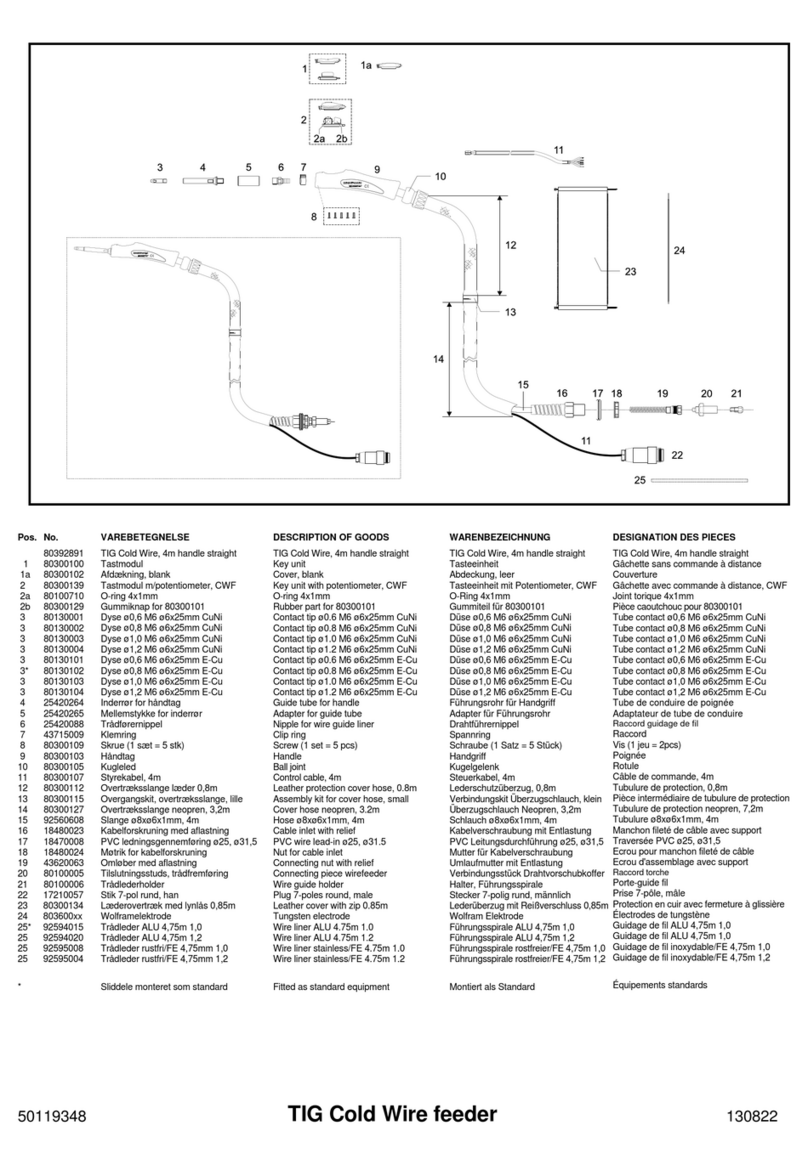

11.9OPTIONAL ACCESSORY.............................................................................................................44

11.9.1 WIRE STRAIHTENER................................................................................................................44

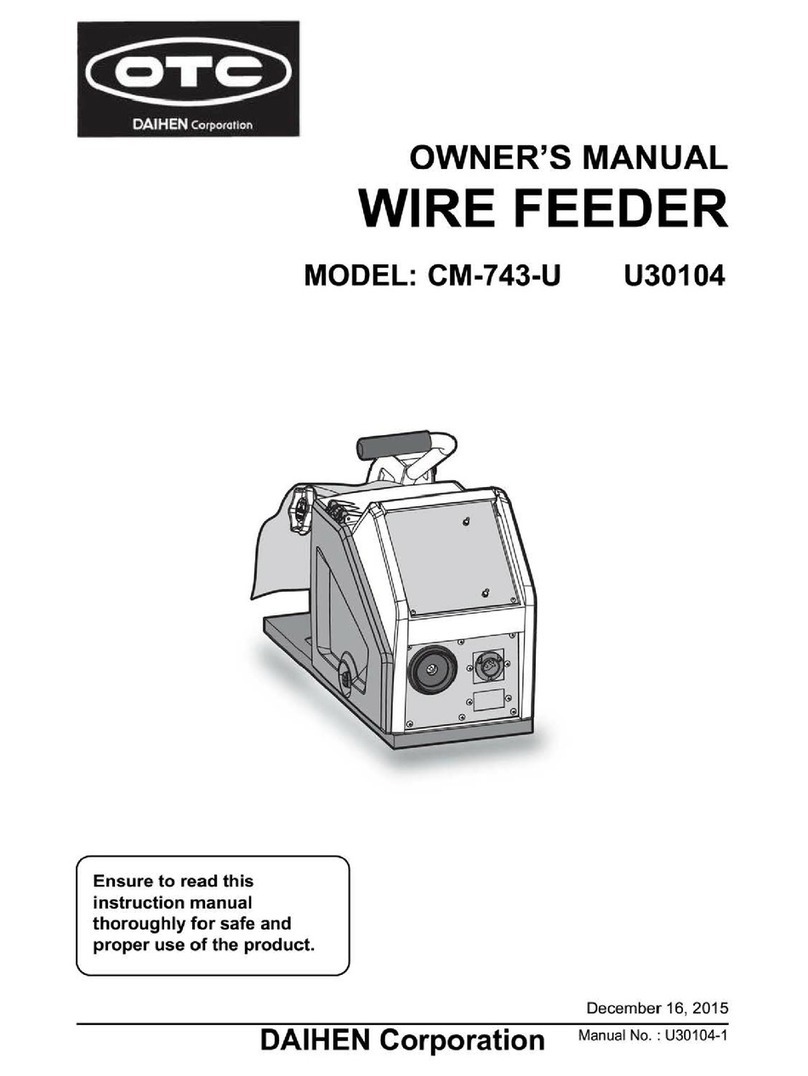

12. SPECIFICATIONS.........................................................................................................................45

12.1SPECIFICATIONS.........................................................................................................................45

12.2COMBINATION POWER SOURCES............................................................................................45

12.3EXTERNAL VIEW (mm) ................................................................................................................46