Operating & Installation Instructions EN HLF07-M/12-M/25-M/50-M Date 23.08.2023 Version 6.0 3–44

Table of contents

1General .................................................................................................................... 5

1.1 Contents and purpose of this manual........................................................... 5

1.2 Explanation of symbols................................................................................. 5

1.3 Additional symbols........................................................................................ 6

1.4 Warranty ....................................................................................................... 7

1.5 Liability.......................................................................................................... 7

2Safety instructions................................................................................................. 8

2.1 General ......................................................................................................... 8

2.2 Intended use ................................................................................................. 8

2.3 Foreseeable misuse ..................................................................................... 9

2.4 Obligations of the operator and the personnel ............................................. 9

2.4.1 Follow these operating instructions........................................................ 9

2.4.2 Obligations of the operating company.................................................... 9

2.4.3 Obligations of the personnel ................................................................ 10

2.5 Personnel requirements ............................................................................. 10

2.5.1 Personnel qualification ......................................................................... 10

2.6 Personal protective equipment (PPE) ........................................................ 11

2.7 Changes & Modifications............................................................................ 11

2.8 General hazards / residual risks................................................................. 11

2.8.1 General hazards at the workplace ....................................................... 11

2.8.2 Danger due to electricity ...................................................................... 12

2.8.3 Hazards due to strong alternating magnetic fields............................... 12

2.8.4 Mechanical hazards ............................................................................. 13

3Technical data ...................................................................................................... 14

3.1 Dimensional drawing HLF-M ...................................................................... 14

3.2 Technical data HLF-M ................................................................................ 15

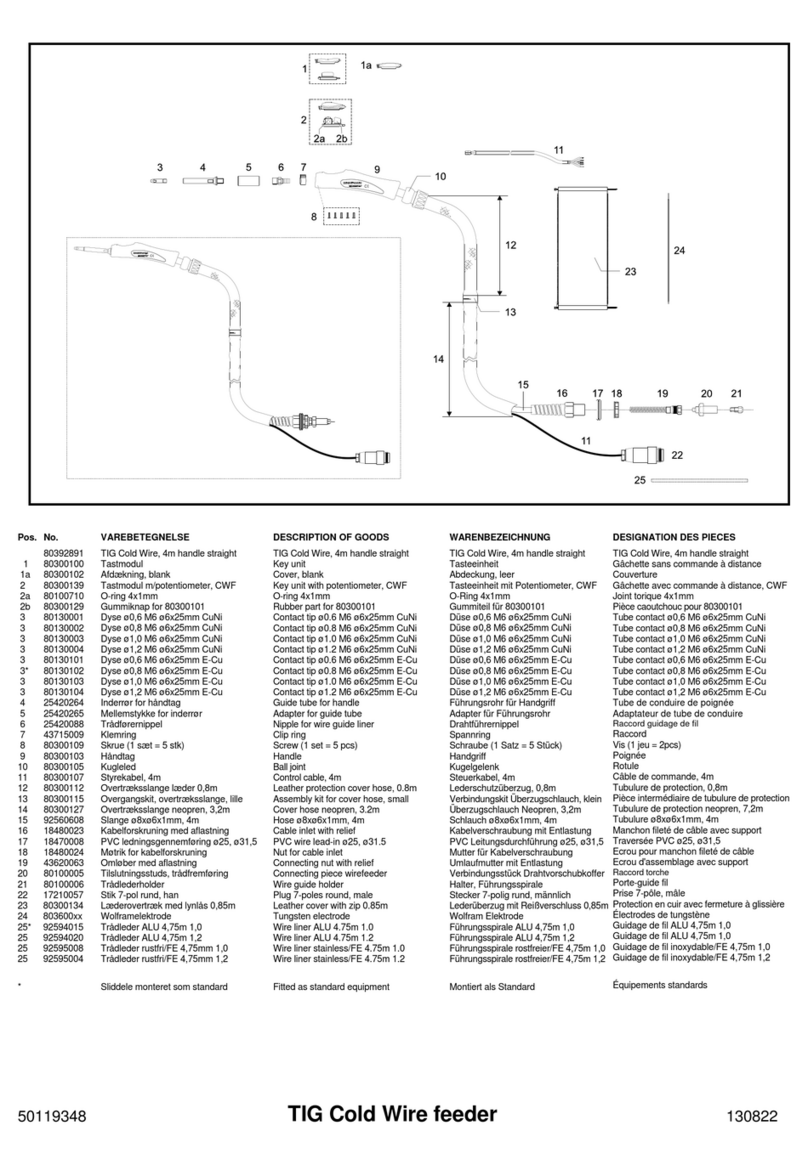

3.3 Accessories ................................................................................................ 16

3.3.1 Mounting parts...................................................................................... 16

3.3.2 Adjustment aids - Distance gauges...................................................... 16

3.3.3 Controller.............................................................................................. 16

4Transport, packaging and storage ..................................................................... 17

4.1 Safety instructions ...................................................................................... 17

4.2 Scope of supply .......................................................................................... 18

4.3 Transport .................................................................................................... 19

4.4 Packaging ................................................................................................... 19

4.5 Storage ....................................................................................................... 19

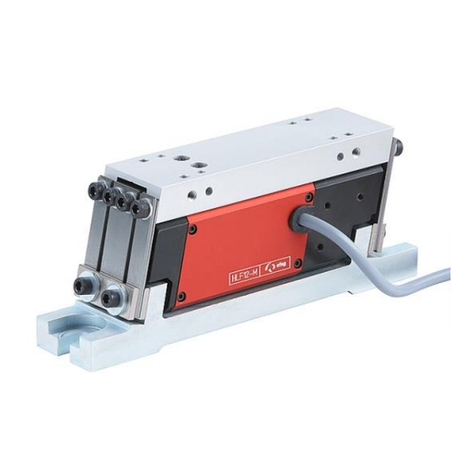

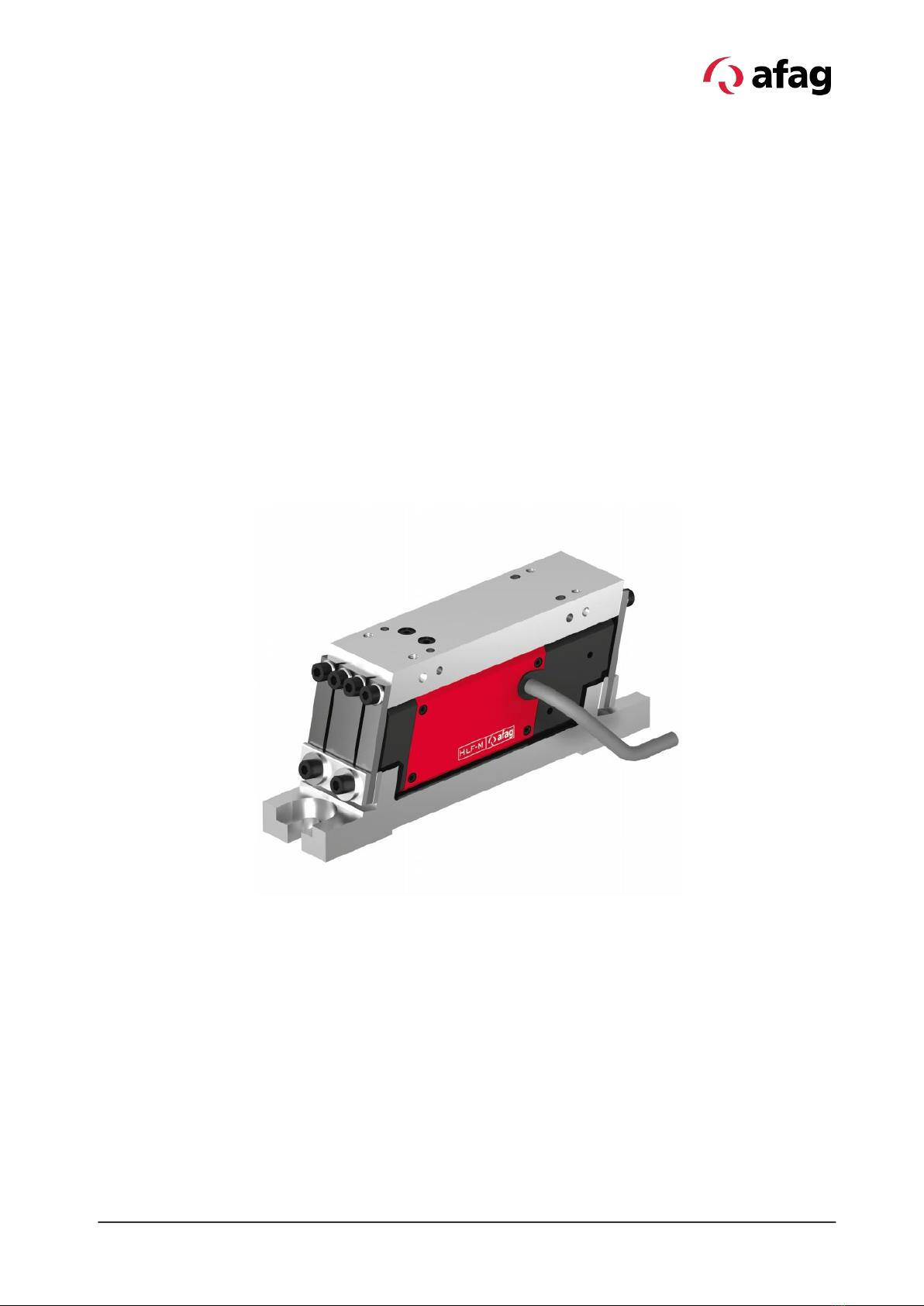

5Design and description ....................................................................................... 20

5.1 Design HLF-M linear feeder ....................................................................... 20

5.2 Description of the HLF-M linear feeder ...................................................... 20