2

CONTENTS

3.10.1 Chart indication mode ........................3-57

3.10.2 P code (Pull down time indication) .....3-59

3.10.3 Chartless code display function..........3-60

3.10.3.1 List of chartless codes.................3-60

3.10.3.2 H-code.........................................3-61

3.10.3.3 d-code: ........................................3-63

3.11 Communication modem ............................3-64

4. Service and Maintenance .................................4-1

4.1 Maintenance service .....................................4-1

4.1.1 Collection of refrigerant ..........................4-1

4.1.2 Gauge manifold ......................................4-1

4.1.3 Automatic pump down............................4-3

4.1.4 Refrigerant recovery and charge............4-5

4.2 Main components and maintenance .............4-9

4.2.1 Scroll compressor...................................4-9

4.2.2 Fan and fan motor ................................4-15

4.2.3 PT and CT board (EC9756) .................4-16

4.2.4 Electronic expansion valve...................4-17

4.2.5 Thermostatic expansion valve..............4-18

4.2.6 Suction modulation valve .....................4-19

4.2.7 Drier......................................................4-20

4.2.8 Solenoid valve ......................................4-21

4.2.9 Discharge pressure regulating valve ....4-22

4.2.10 Check valve........................................4-22

4.2.11 High-pressure switch (HPS) ...............4-23

4.2.12 Low pressure transducer (LPT)..........4-23

4.2.13 High pressure transducer (HPT) ........4-24

4.2.14 Water pressure switch (WPS) ............4-24

4.2.15 Humidity sensor..................................4-24

4.2.16 Ventilation port opening degree sensor

(FA sensor) ........................................4-25

4.2.17

Air-cooled condenser and evaporator

...4-25

4.2.18 Water cooled condenser ....................4-26

4.2.19 Fusible plug ........................................4-26

4.2.20 Liquid/moisture indicator ....................4-26

4.2.21 Evacuation and dehydrating...............4-27

5. Additional Devices............................................5-1

5.1 USDA transportation .....................................5-1

5.1.1 Type of USDA sensor/receptacle ...........5-1

5.1.2 Initial setting ...........................................5-1

5.1.3 USDA sensor calibration ........................5-1

5.1.4 USDA transportation requirement ..........5-1

5.1.5 USDA report ...........................................5-1

6. Troubleshooting................................................6-1

6.1 Refrigeration system and electrical system...6-1

6.2 Alarm codes on electronic controller .............6-5

6.3

Troubleshooting for automatic PTI (J-code)

...6-10

6.4 Emergency operation ..................................6-12

6.4.1 Emergency operation of controller .......6-12

6.4.2 Short circuit operation of controller.......6-13

6.4.3 Opening adjustment of electronic

expansion valve....................................6-14

6.4.4 Emergency operation of suction

modulating valve ..................................6-15

6.4.5 Automatic Back up for supply / return air

temperature sensors ............................6-16

7. Appendix............................................................7-1

7.1 Standard tightening torques for bolts ............7-1

7.2 Standard tightening torques for flare nuts .....7-1

7.3 Standard tightening torque for stop valve .....7-1

7.4

Resistance of motor coil and solenoid valve coil

...7-2

7.5 Standard tightening torque for electronic

expansion valve coil (EV coil) .......................7-2

7.6 HFC134a, temperature-vapor pressure

characteristics table ......................................7-3

7.7 Temperature sensor characteristics table .....7-4

7.8

Temperature sensor characteristics table DCHS

...7-5

7.9

High pressure transducer characteristics table

...7-5

7.10

Low pressure transducer characteristics table

.7-5

7.11 Piping diagram ............................................7-6

7.12 Pilot lamps...................................................7-7

7.13 Fuse protection table...................................7-8

7.14 Schematic wiring diagram .........................7-10

7.15 Stereoscopic wiring diagram .....................7-11

Safety Precautions

• Danger .................................................................3

• Warning................................................................4

• Caution.................................................................5

1. Introduction .......................................................1-1

1.1 Operation range ............................................1-1

1.2 Basic Names of components ........................1-1

1.3 Basic operation of refrigeration unit ..............1-2

1.3.1 Operation preparation ............................1-2

1.3.2 Starting operation ...................................1-3

1.3.3 Checking during operation .....................1-4

1.3.4 Procedure after operation.......................1-4

1.3.5 Adjust the ventilation ..............................1-5

2. General description ..........................................2-1

2.1 Main specifications........................................2-1

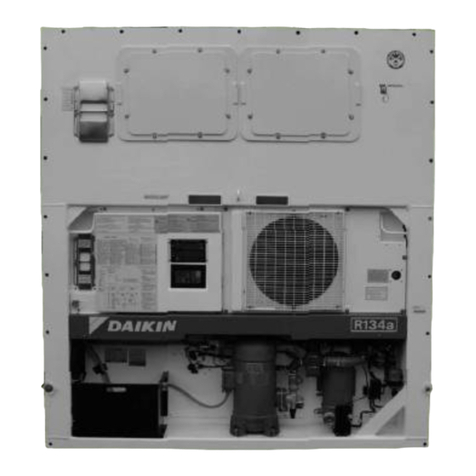

2.2 Names of components ..................................2-2

2.2.1 Outside ...................................................2-2

2.2.2 Inside......................................................2-4

2.2.3 Control box .............................................2-6

2.3

Set point of functional parts and protection devices

...2-9

2.4 Operating pressure and running current .....2-10

2.5 Operation modes and control......................2-14

2.5.1 Frozen mode ........................................2-15

2.5.2 Chilled mode ........................................2-17

2.5.3 Defrosting mode ...................................2-19

2.5.4 Dehumidification...................................2-22

2.5.5 Common control ...................................2-23

3. Electronic Controller.........................................3-1

3.1 Function table................................................3-1

3.2 Basic operation of electronic controller .........3-3

3.2.1 Control panel ..........................................3-3

3.2.2 Operation mode and control...................3-5

3.3 Operation procedure .....................................3-6

3.3.1 Operation procedure flow chart ..............3-6

3.3.2 Mode operation procedure .....................3-9

1. Current indication mode .........................3-9

2. Operation setting mode ........................3-10

3. Battery mode ........................................3-11

4. Mode operation ....................................3-12

5. LED display light-OFF mode ................3-15

6. Sensor indication mode........................3-16

7. Temperature record scroll mode ..........3-19

8. Alarm record scroll mode .....................3-22

3.3.3 Setting flow chart..................................3-24

10. Optional function setting mode...........3-26

11. Basic function setting mode ...............3-27

12. Optional condition setting mode .........3-29

13. Input data mode .................................3-31

14. Controller software download mode...3-32

3.4 Alarm display and back-up function ............3-33

3.4.1 Alarm list...............................................3-33

3.4.2 Back-up operation at sensor

malfunction ...........................................3-34

3.5 Battery.........................................................3-36

3.5.1 Specifications .......................................3-36

3.5.2 Function................................................3-36

3.5.3 Battery check........................................3-36

3.5.4

Battery replacement (Rechargeable battery)

...3-37

3.6

Information interchange with personal computer

...3-38

3.6.1 Data logging .........................................3-39

3.6.2 Software configuration..........................3-40

3.7

Inspection procedure for the electronic controller

...3-42

3.8 Controller replacement and initial setting ....3-43

3.8.1 Controller replacement .........................3-43

3.8.2 Initial setting & operation procedure.....3-44

3.9

PTI (Pre-Trip Inspection) and periodic inspection

...3-45

3.9.1 Inspection item .....................................3-46

3.9.2 Automatic PTI (Pre-Trip Inspection) .....3-49

3.9.2.1 PTI selection mode........................3-50

3.9.2.2 Short PTI (S.PTI)...........................3-51

3.9.2.3 Full PTI (F.PTI)..............................3-52

3.9.2.4

Alarm list during PTI (Pre-Trip Inspection)

...3-54

3.9.2.5 Manual check (M.CHECK) ............3-55

3.10 Chartless function .....................................3-57

☆

☆☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

001-030E-SM(LXE10E-1E)A42007.04.2713:29ページ2