Installation and Maintenance Manual IM 1017-1

Group: Applied Air Systems

Part Number: 910102992

Date: January 2017

MT 168 0-10 VDC/4-20mA Thermostat

Installation

DANGER

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING

TO INSTALL, OPERATE OR SERVICE THIS THERMOSTAT.

Failure to observe safety information and comply with instructions

could result in PERSONAL INJURY, DEATH AND/ OR PROPERTY

DAMAGE.

To avoid electrical shock or damage to equipment, disconnect power

before installing or servicing. Use only wiring with insulation rated for

full thermostat operating voltage. Use copper wire only. Insulate or

wire-nut all un-used leads. Any wiring, including the remote probe, may

carry the full operating voltage of the thermostat.

To avoid potential re and/ or explosion do not use in potentially

ammable or explosive atmospheres.

Retain these instructions for future reference. You must review your

application and national and local codes to ensure that your installation

will be functional and safe.

CAUTION

Care should be used to avoid electrostatic discharge to the

microprocessor.

This unit has conguration dip switches and jumpers. You may need to

recongure the thermostat for your application.

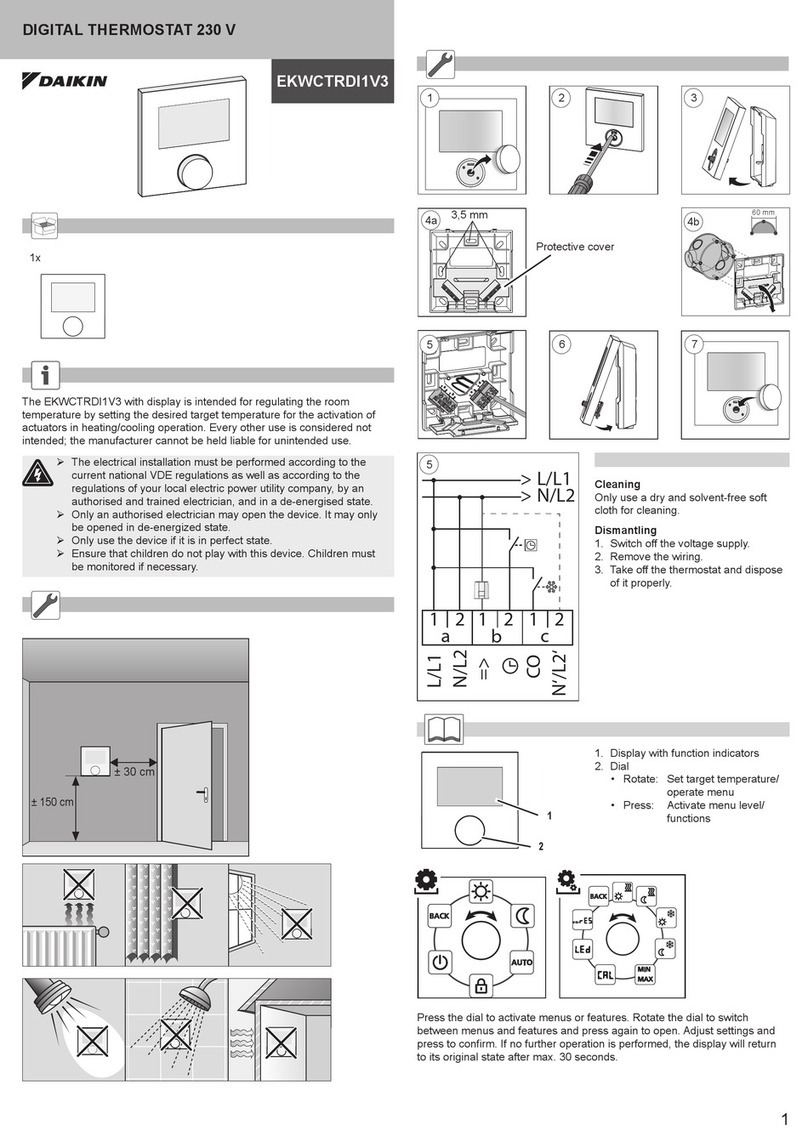

1. Install the thermostat with the two furnished mounting

screws to a standard 4-1/16" × 2-1/8" square device

box with a 2" × 4" adapter ring.

2. For wall installations, mount the thermostat on an

inside wall approximately 5 feet above the oor. The

location should provide circulation at average room

temperature. Avoid direct sunlight or sources of hot or

cold air in the room or wall.

3. Remove the cover. Mount thermostat base assembly

to the outlet box using screws provided. Tighten the

screws evenly but do not overtighten. Connect wires

per wiring diagram.

4. To use a remote sensor on units with local sensing

capability, remove jumper JP-1 to disable local

sensing. Failure to remove JP-1 will cause improper

operation of thermostat.

5. Connecting a jumper between terminals 16 and 17

will disable the secondary output and change the

main output to heat mode.

6. Connection of a 24 VAC set-back signal will force

the control into unoccupied mode (see diagram).

Pressing an arrow key or the mode buttons on the

thermostat cover will disable the setback input for

one hour.

7. Remove the LCD plastic protective lm to complete

the installation. Reinstall the cover assembly. Install

cover locking screw provided.

8. Checkout: After wiring and installation are complete,

energize the system and check the operation. Adjust

the thermostat as necessary to complete at least one

cycle. Be sure the thermostat and all other equipment

are functioning correctly.