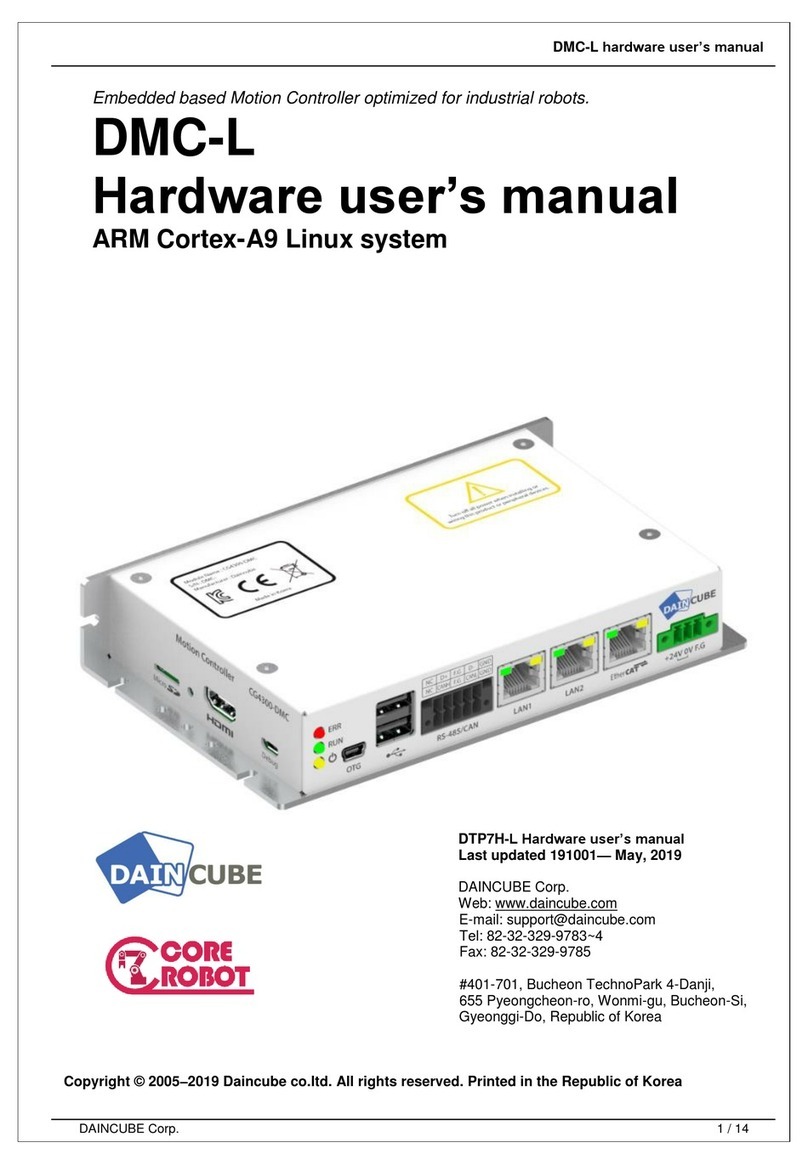

CG4300-DMC hardware user’s manual

DAINCUBE Corp. 5 / 28

1. Introduction

Thank you very much for purchasing our product.

Improper usage or mishandling may result in a product not only being unable to deliver full functions but also

produce unexpected troubles or shorten the product’s life.

Please read this manual carefully, and operate the product properly by paying attention to its handling. When

operating the product, always keep this manual at hand and read the relevant items as required.

1.1.General precautions

Be sure to read this Instruction Manual for proper use of this product.

Part or all of this Instruction Manual may not be used or reproduced without permission.

Please take note that we shall not be liable for any effects resulting from using this Instruction manual.

This manual may be modified when necessary because of improvement of the product, modification or

changes in specifications.

Some drawings in this manual are shown as a typical example and may differ from the shipped product.

2. Safety information

Before unpacking and installing the product or adding devices on it, carefully read all the manuals that

came with the package.

Avoid using product in extreme dust, humidity and temperature conditions. Do not place the product in

wet area.

Before carrying out assembly and adjustment work or maintenance and inspection work of the machine,

be sure to disconnect the power cord. Otherwise, electric shock may result.

After turning OFF power, wait at least five minutes before servicing the product. Otherwise, residual

electric charges may result in electric shock.

⚠Warning

Be sure to check grounding before you use the unit. Danger of personal injury due to electric shock!

Be sure to use the unit within the voltage range indicated.

The operator must have a sufficient educational level and must know details of intended use described in

the user’s manual.

Be sure to check the wiring to the main unit.

When the user (customer) extends wiring, malfunction may occur due to faulty wiring. In this case,

inspect wiring thoroughly and check it for properness before turning on the power.

Before operating the unit, be sure to check that there is no danger in or around the operating range.

Do not allow water or oil to get on the unit and the power cord.

Install the unit in a place which can endure its weight and conditions while running.

Take care not to squeeze and thus damage the cable with any object.

Do not lay the cable over sharp edges to avoid damaging the cable sheath.

Check the mounting screws regularly so that they are always firmly tightened.

Never touch terminals directly or internal parts of controller.

Do not disassemble or modify the product.

Before carrying out assembly and adjustment work or maintenance and inspection work of the machine,

be sure to disconnect the power cord.

Connect the power supply after completing the adjustment of all the cables and switches.

⚠Caution

After the shutdown window, turn off the power supply. Otherwise the components could be destroyed or

undefined signals could occur.

To prevent the equipment from falling to the ground.

Never lay the device onto unstable surfaces. It could fall to ground and thus be damaged.

It is recommended to use the unit in an environment where no electrical noise is present.

In noisy environments, use a filter fitted.

Never lay the device close to heat sources or into direct sunlight.