– i –

Table of Contents

1 Introduction���������������������������������������������������������������������������������������������������������������������������1

Important Contact Information ..........................................................................................................1

Display Identication............................................................................................................................1

Spare Parts.............................................................................................................................................1

Locate the Spare Parts Rack...............................................................................................................2

Open and Remove the Spare Parts Rack ��������������������������������������������������������������������������������������2

Remove a Module From Spare Parts Rack ������������������������������������������������������������������������������������2

Field-Replaceable Units .......................................................................................................................3

2 Display and Control Overview ��������������������������������������������������������������������������������������������4

Display Control System Flow Overview ..............................................................................................4

Display Power Overview ......................................................................................................................4

Display Signal Overview.......................................................................................................................4

3 Troubleshoot the Display������������������������������������������������������������������������������������������������������5

Remotely Cycle Power ........................................................................................................................5

Troubleshoot the Display......................................................................................................................5

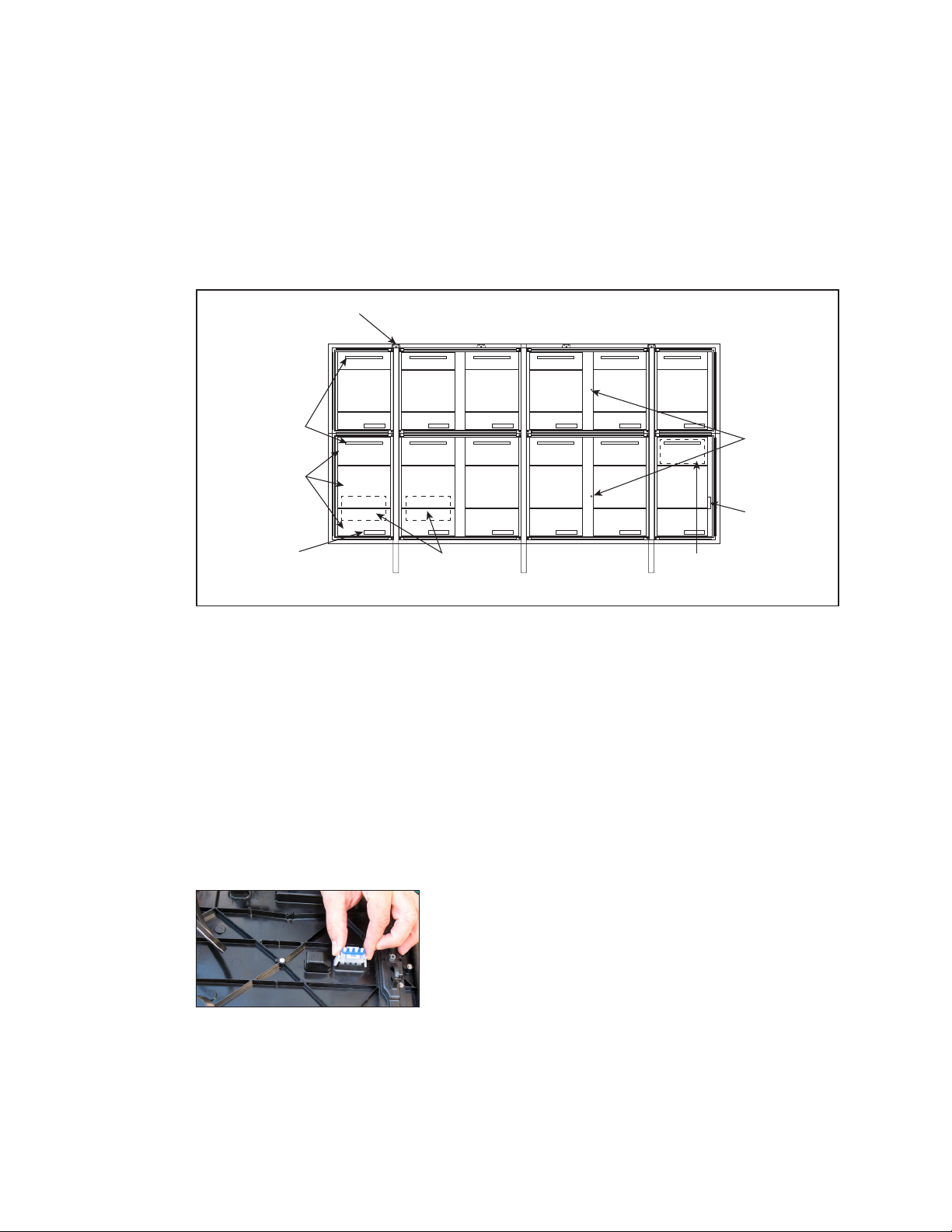

4 Access Internal Components����������������������������������������������������������������������������������������������9

Rear Access ..........................................................................................................................................9

Front Access..........................................................................................................................................9

5 Test and Remove Modules ������������������������������������������������������������������������������������������������10

Module Lanyard Attachment ...........................................................................................................10

Remove a Module (Front Access)....................................................................................................10

Reinstall the Module (Front Access) .................................................................................................10

Remove a Module (Rear Access) ....................................................................................................11

Remove Fan Plenum..........................................................................................................................11

Remove a Module from Behind an ISP Enclosure ..........................................................................12

Remove the Optional SmartLinkTM For Module Access..................................................................12

Reinstall a Module (Rear Access).....................................................................................................12

6 Test and Replace Display Components ���������������������������������������������������������������������������14

Test a Module......................................................................................................................................14

Module Status Indicators ���������������������������������������������������������������������������������������������������������������14

Perform a Module Self-Test������������������������������������������������������������������������������������������������������������14

Replace Module Power Supplies......................................................................................................14

Test and Replace a ProLink Router...................................................................................................15

Test a PLR �����������������������������������������������������������������������������������������������������������������������������������������15

Replace a ProLink Router���������������������������������������������������������������������������������������������������������������16

Replace PLR Power Supplies ���������������������������������������������������������������������������������������������������������16

Replace a Display Fan�������������������������������������������������������������������������������������������������������������������16

7 Control Equipment Overview, Service, and Replacement ��������������������������������������������17

Open the ISP Enclosure......................................................................................................................17

Control Equipment Overview............................................................................................................18

ISP Enclosure �����������������������������������������������������������������������������������������������������������������������������������18

DMP-8000 ����������������������������������������������������������������������������������������������������������������������������������������18