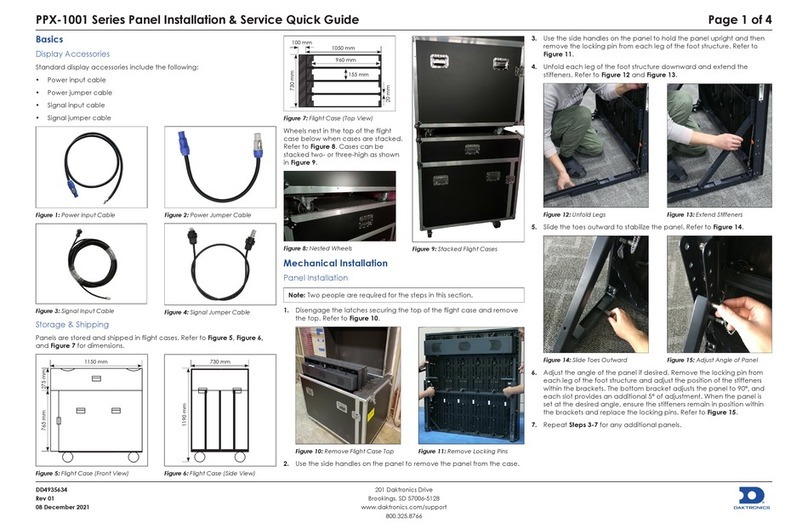

PPX-1050 Series Panel Installation & Service Quick Guide Page 2 of 3

DD5004860

Rev 00

05 January 2022

201 Daktronics Drive

Brookings, SD 57006-5128

www.daktronics.com/support

800.325.8766

Panel-to-Panel Connection

1. Place two panels side-by-side on the wall and secure the panels

together with M10 screws and nuts at three xing points on the side of

each panel. Refer to Figure 16 and Figure 17.

Figure 16: Secure Panels Together

2. Route power and signal cables

between panels directly from the top.

Electrical Installation

Signal Connection

A DVI cable connects a computer located in the control room to a

sending box. Some sending boxes may have additional signal input

options, such as HDMI and SDI. The sending box passes signal via a

Cat 5e/Cat 6 cable into the receiver card located inside the rst panel.

Each panel has a receiver card, and Cat 5e/Cat 6 cables daisy-chain the

receiver cards together. The last panel can connect back to the sending

box for redundant data to the receiver cards if desired.

1. Connect the sending box to the computer with a DVI cable. Refer to

Figure 18 and Figure 19.

Figure 18: Sending Box (Front)

Figure 19: Sending Box (Rear)

2. Connect a Cat 5e/Cat 6 cable from the sending box RJ45 output jack

to the RJ45 quick-connect jack in the rst panel. Refer to the

contract-specic Riser Diagram.

Figure 17: M10 Fastener (Front View

with Module Removed)

Note: The maximum cable distance from the sending box to the rst receiver

card is 328.08' [100 m]. For installations exceeding this distance, use

a ber converter to convert the Cat 5e/Cat 6 cable to a ber cable,

which offers an additional 984.25' [300 m] with multi-mode ber or up

to 9.32 mi [15 km] with single-mode ber. Two ber converters can be

used to convert the cable to a ber cable and then back to a

Cat 5e/Cat 6 cable. The cable can connect to the rst panel. Use

additional cables to connect to the next panel. Refer to Figure 20 and

Figure 21.

Figure 20: Fiber Cable

3. Route the Cat 5e/Cat 6 cable from

the signal output jack to the signal

input jack on the next panel. Refer

to Figure 22 and the Riser Diagram.

Figure 22: Route Cables

Sending box Fiber converter Fiber

Cat 5e/Cat 6 Fiber converter

Cat 5e/Cat 6

Note: Routing may vary based on converter type.

4. Connect the last panel back to the sending box for redundant signal

connection if desired.

5. Refer to the NovaStar®LED Display Control System M3 User’s Manual for

details on how to congure the system and run the display.

Refer to Figure 23 for an example of six panels connected together.

Sending box

Primary

Redundant (optional)

Figure 23: Connect Signal

Power Connection

Most standard panels come with power quick connects with

pre-terminated connectors at each end.

The gender is different for the power input and output ends. Power

interconnect cables are shipped with the displays. Typically, every six

panels needs a new power input cable. Refer to the contract-specic Riser

Diagram for more details.

Figure 21: Fiber Converter

The main power input cable has a pre-terminated connector at one

end and bare wires at the other end. Only horizontal interconnects are

available. Refer to Figure 24.

To main CIR #1

Figure 24: Route Power Cables

Service

Note: Avoid exposing the contents of the power/signal box to moisture,

as the components are not sealed for water exposure.

Module Removal

1. Disconnect power to the display.

2. Unlock the top locks and slide the cover back to remove the top cover.

Refer to Figure 12 and Figure 13.

3. Use the handle at the top of the module to slide the module up and

out of the panel. Refer to Figure 25 and Figure 26.

Figure 25: Slide Module Up

4. Use a screwdriver to remove the four screws connecting the module

cable and then disconnect the cable. Refer to Figure 27 and Figure 28.

Figure 27: Remove Module Cable

Screws

Figure 28: Disconnect Module

Cable

Figure 26: Slide Module Out