1M60 Camera User’s Manual 3

DALSA C32-10010-01

1M60 USER’S MANUAL

Contents

1.0 INTRODUCTION TO THE 1M60 CAMERA .............................................................................. 5

CAMERA HIGHLIGHTS ................................................................................................................................5

Features.................................................................................................................................................. 5

Description ............................................................................................................................................. 5

Applications............................................................................................................................................ 5

1.2 IMAGE SENSOR ................................................................................................................................6

1.3 CAMERA PERFORMANCE SPECIFICATIONS....................................................................................... 7

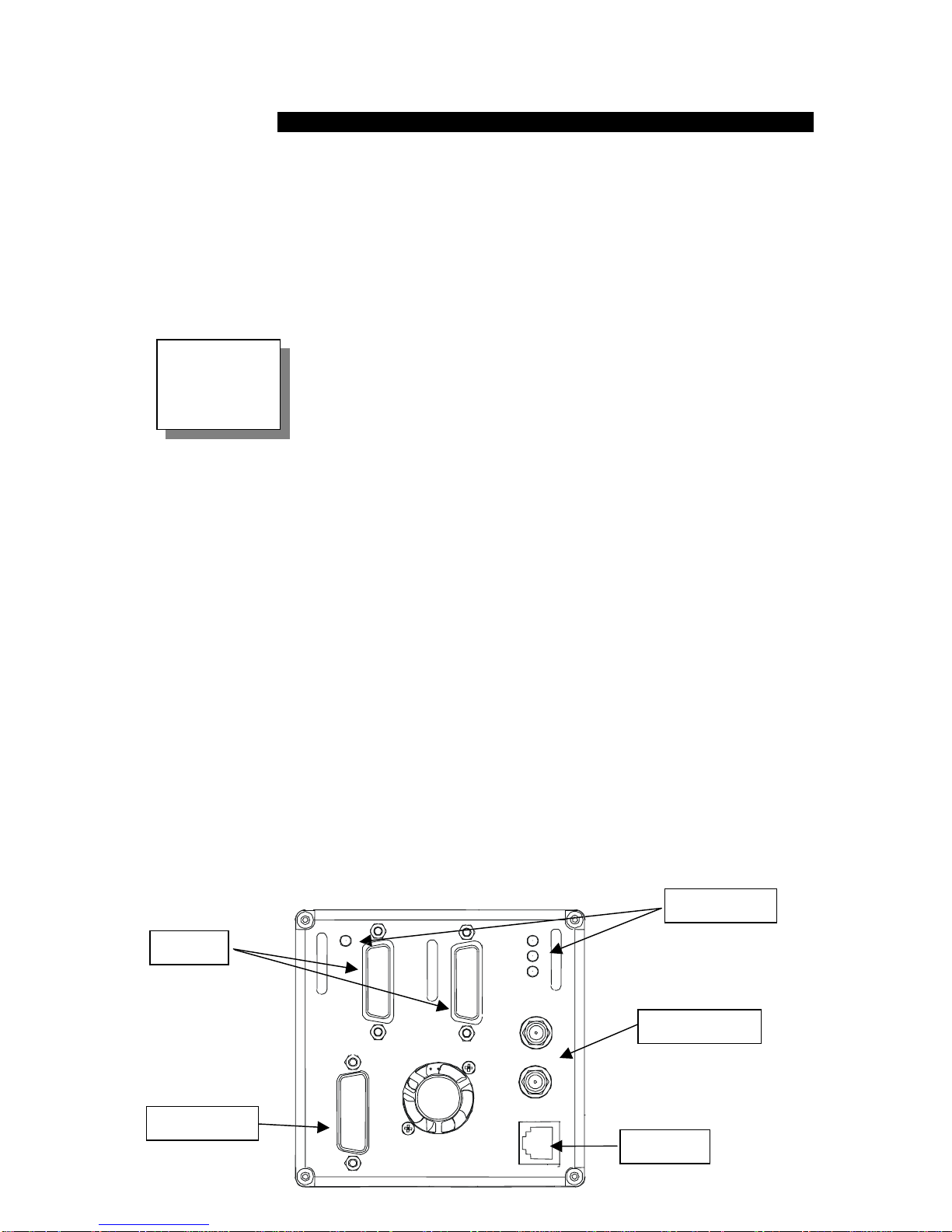

2.0 CAMERA HARDWARE INTERFACE......................................................................................... 8

2.1 INSTALLATION OVERVIEW .............................................................................................................. 8

2.2 INPUT/OUTPUT ................................................................................................................................8

2.3 LED STATUS INDICATORS............................................................................................................... 9

2.4 POWER INPUT .................................................................................................................................. 9

2.5 DATA OUTPUT............................................................................................................................... 10

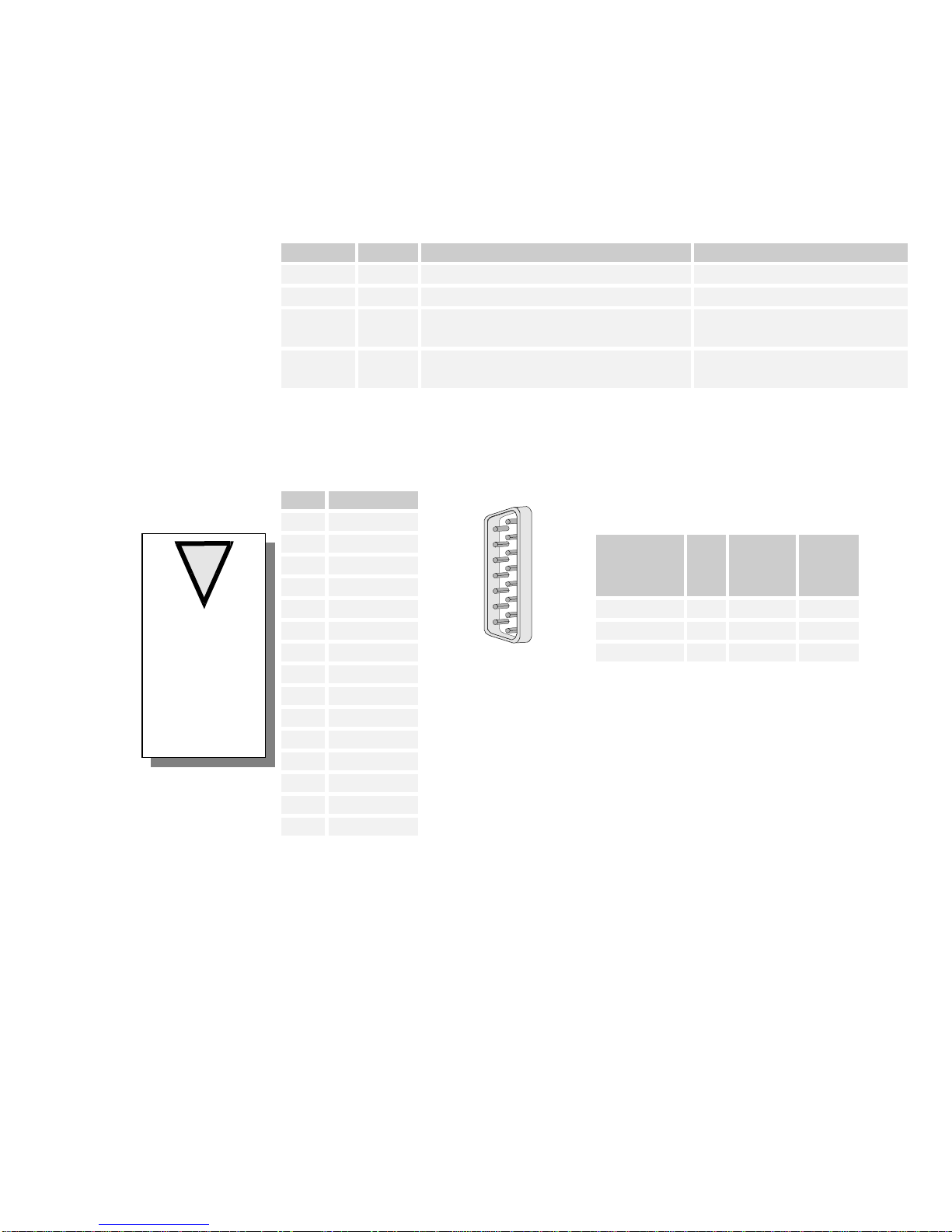

Connector and Pinout........................................................................................................................... 10

Data Signals ......................................................................................................................................... 11

Data Clocking Signals.......................................................................................................................... 12

2.6 SERIAL COMMUNICATION ............................................................................................................. 12

Connector and Pinout........................................................................................................................... 12

Serial Communication Settings ............................................................................................................ 13

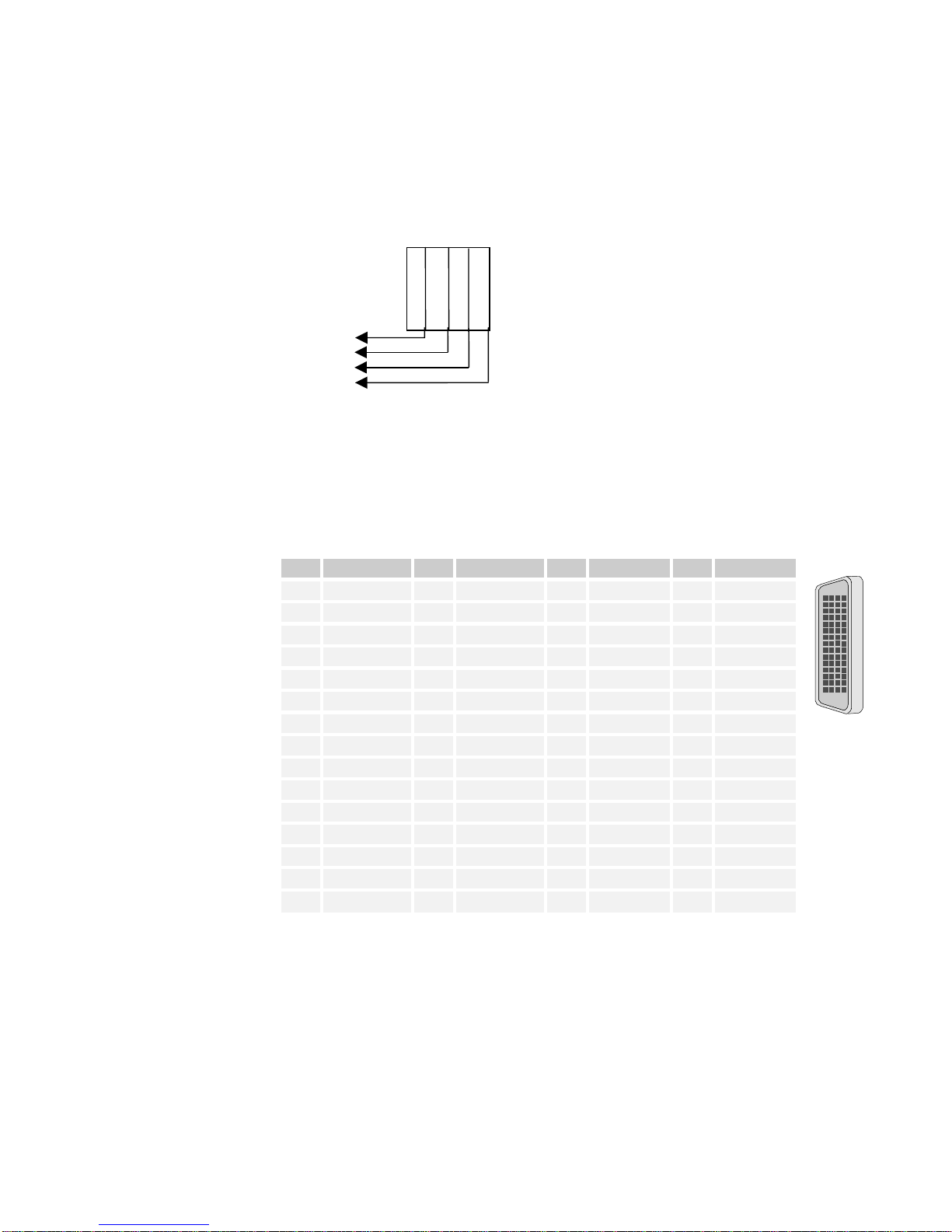

2.7 TTL TRIGGER INPUT AND OUTPUT ............................................................................................... 14

Connector ............................................................................................................................................. 14

2.8 INTEGRATION TIME ....................................................................................................................... 14

2.9 TIMING .......................................................................................................................................... 15

Programmed Integration ...................................................................................................................... 15

3.0 CAMERA OPERATION ............................................................................................................... 16

3.1 HOW TO CONTROL THE CAMERA................................................................................................... 16

Command Protocol Overview .............................................................................................................. 16

3.2 CONTROL REGISTER REFERENCE .................................................................................................. 17

3.3 READING THE CAMERA TYPE ........................................................................................................ 18

3.4 READING THE FIRMWARE REVISION.............................................................................................. 18

3.5 RESETTING THE CAMERA .............................................................................................................. 18

3.6 ADJUSTING GAIN........................................................................................................................... 19

3.7 ADJUSTING ANTI-BLOOMING ........................................................................................................ 19

3.8 CONTROLLING BINNING ................................................................................................................ 19

3.9 ADJUSTING USER OFFSET.............................................................................................................. 20

Reading Offset from the Camera .......................................................................................................... 21

3.10 TRIGGERING, INTEGRATION, AND FRAME RATE OVERVIEW ......................................................... 21

3.11 CONTROLLING INTEGRATION (SHUTTER TIME) ............................................................................. 22

Free Running (Programmed Integration): ........................................................................................... 23

Programmed Integration/SMA Trigger ................................................................................................ 23

Programmed Integration/Serial Trigger .............................................................................................. 24

External Integration/SMA Connector................................................................................................... 24

External Integration/Serial Connector ................................................................................................. 24

3.12 CONTROLLING FRAME RATE ......................................................................................................... 25

Free Running (Programmed Fame Rate) .............................................................................................25

External Trigger/SMA Connector......................................................................................................... 25

External Trigger/Serial Connector....................................................................................................... 25