6

Observe all warnings and safety precautions as

well as all local electrical codes and the National

Electrical Code (NEC).

WARNING

!

Bottom Access Panel Removal

The bottom access panel of the option enclosure must be

removed prior to installation to provide access to the

electrical cabling.The bottom panel is divided into sections.

Remove the desired panel sections, as required, by

removing the set screws holding the panel in place. Protect

theelectrical cables and connection wiringagainstdamage

duringinstallation.

Mounting Option Enclosure to Base

Align the holes on the bottom of the option enclosure with

thecorresponding holes on the mountingbase.Fastenthe

enclosuretothe base with the attaching hardwaresupplied

withtheoption enclosure.

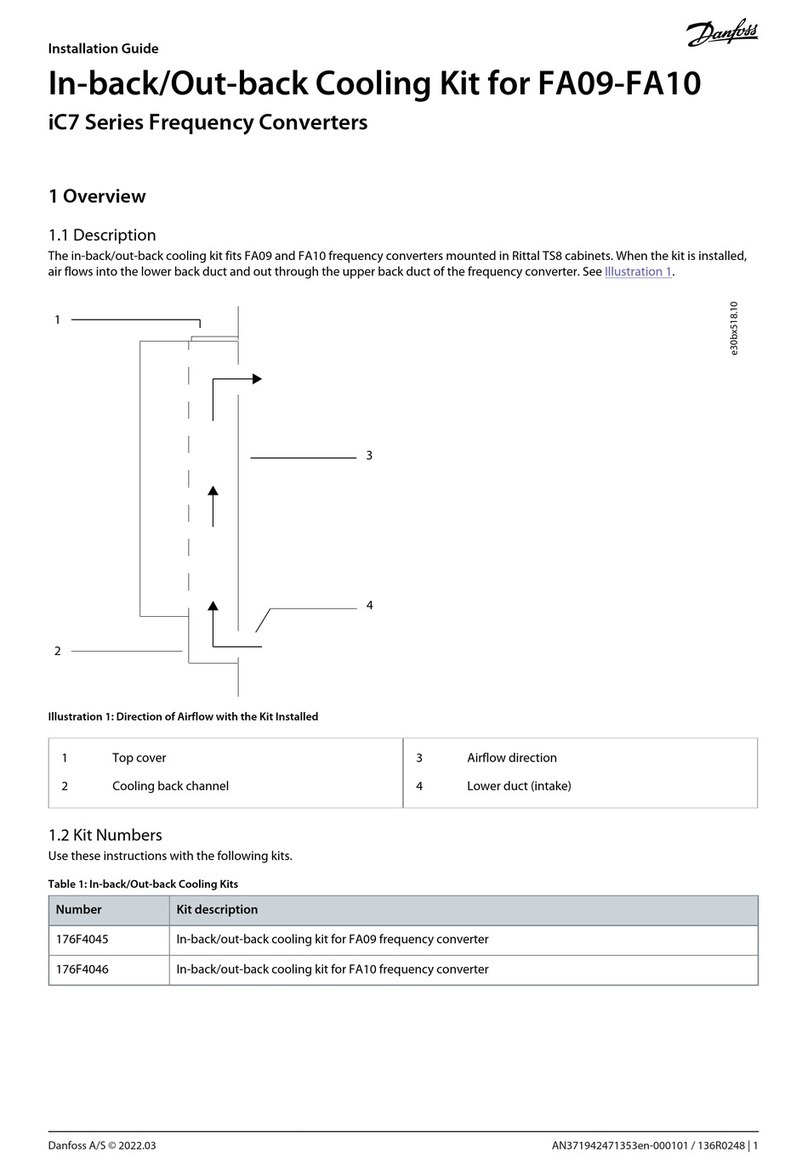

Electrical Connections

Wire the option enclosure to theVLT drive in accordance

withthefollowingprocedure.

1. Connectinputpowercables(typicallylabeled 5L1, 5L2,

and 5L3) to drive input power connections R/L1, S/L2,

andT/L3 (terminals 91, 92, and 93).Refer to customer

connectiondiagramfor details.

2. Connectoutputpowercables(typically labeled 2T1, 2T2,

and 2T3) from option to drive output connection U/T1,

V/T2, andW/T3 (terminals 96, 97, and 98).Refer to

customerconnection diagram for details.

3. Connectcontrolwires(providedloose in bottom of option

enclosure) toVLT drive control terminals in accordance

withschematic diagram provided with option.

Connect the drive and option assembly to the building

electrical system in accordance with the following procedure.

1. Connect3-phaseACinputpowertooptionenclosure

terminalsL1,L2,and L3. Connect ground wire to ground

terminalinside of option enclosure.

2. Connect3-phaseACmotorleadstooption enclosure

terminalsT1,T2,andT3.Connectmotor groundto

groundterminalinsideof option enclosure.

3. Connect external control wires to drive and option in

accordancewithcustomerconnectiondiagramprovided

with option.Note that terminal block TB1 (TB2, etc.) is

locatedin option enclosure.

Operating Instructions

Seethe

Installation,Operation and Maintenance Manual

(documentnumber23-6108-00) fortheVLT6000Adjustable

FrequencyDriveforoperatinginstructions.