1 Introduction

1.1 Purpose of the Manual

The VLT®DeviceNet MCA 104 Programming Guide provides

information about conguring the system, controlling the

frequency converter, parameter access, programming,

troubleshooting, and some typical application examples.

The programming guide is intended for use by qualied

personnel who are familiar with the VLT®frequency

converter, with DeviceNet technology, and with the PC or

PLC that is used as a master in the system.

Read the instructions before programming and follow the

procedures in this manual.

VLT®is a registered trademark.

1.2 Additional Resources

Resources available for the VLT®frequency converter and

optional equipment:

•The VLT

®

Operating Instructions provide the

necessary information for getting the VLT®

frequency converter up and running.

•The VLT

®

Design Guide provides detailed

information about capabilities and functionality

to design motor control systems.

•The VLT

®

Programming Guide provides greater

detail on working with parameters and many

application examples.

•The VLT

®

DeviceNet MCA 104 Installation Guide

provides information about installing the

DeviceNet and troubleshooting.

•The VLT

®

DeviceNet MCA 104 Programming Guide

provides information about conguring the

system, controlling the VLT®frequency converter,

parameter access, programming, troubleshooting,

and some typical application examples.

Supplementary publications and manuals are available

from Danfoss. See vlt-drives.danfoss.com/Support/Technical-

Documentation/ for listings.

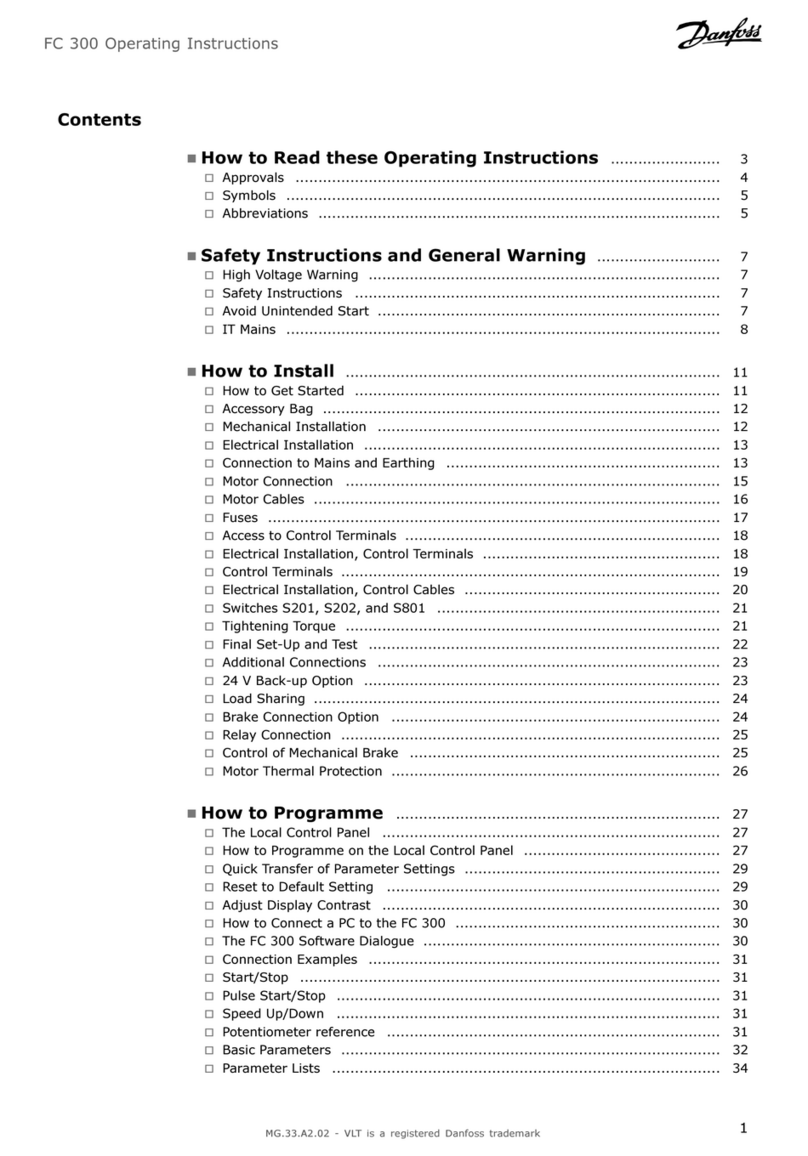

1.3 Document and Software Version

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding software

version.

Edition Remarks Software version

MG92F1xx First edition. 4.4x

Table 1.1 Document and Software Version

1.4 Product Overview

This programming guide relates to the DeviceNet interface.

Ordering number:

•130B1102 (non-coated version).

•130B1210 (conformal coated version).

DeviceNet is a low-level network that standardizes

communications between industrial devices (sensors, limit

switches, motor controls) and high-level devices

(controllers). DeviceNet follows the Open Systems Intercon-

nection (OSI) model and is based on CAN technology for

media access control and physical signaling.

DeviceNet systems can be congured to operate in a

master/slave or a distributed control architecture using

peer-to-peer communication. Up to 63 nodes in a multi-

drop network topology are supported. By using the same

cable for communication, communication options can be

powered directly from the bus. Nodes can be removed or

inserted without powering down the network.

Each node on the network has its own unique media

access control identier (MAC ID) to distinguish it on the

network. The access control is based on the CSMA/CA

(carrier sense multiple access/collision avoidance) principle,

meaning that all nodes may have access to the network at

the same time. When 2 nodes attempt to get control of

the network bus simultaneously, the CAN protocol resolves

the issue by arbitration. In this way, collisions on the

network are avoided.

DeviceNet denes device proles for devices belonging to

specic classes. For other devices, dene a custom class to

make it DeviceNet compatible. All the above enhances the

interchangeability and interoperability of the network.

24 V

Trunk line

Power supply

Drop lines 1

RT=Termination resistors

RTRT

195NA228.10

1 1 1

1

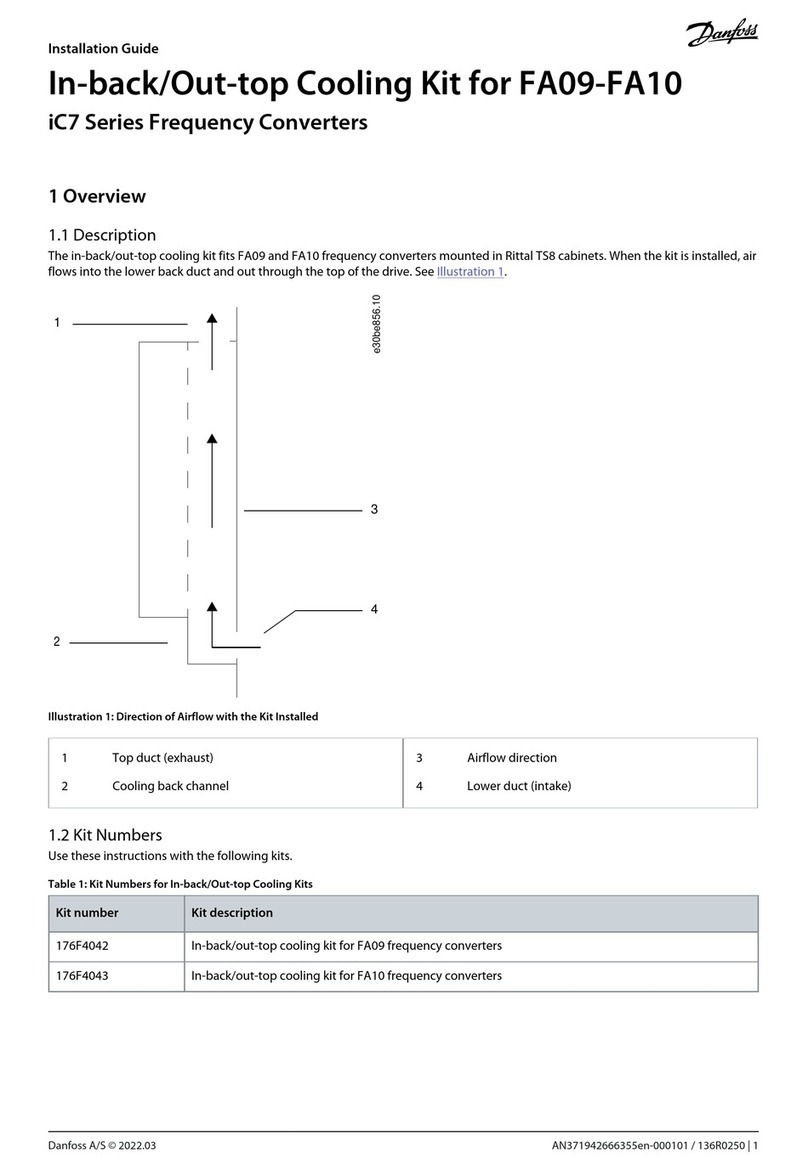

Illustration 1.1 Topology

Introduction Programming Guide

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 3

11