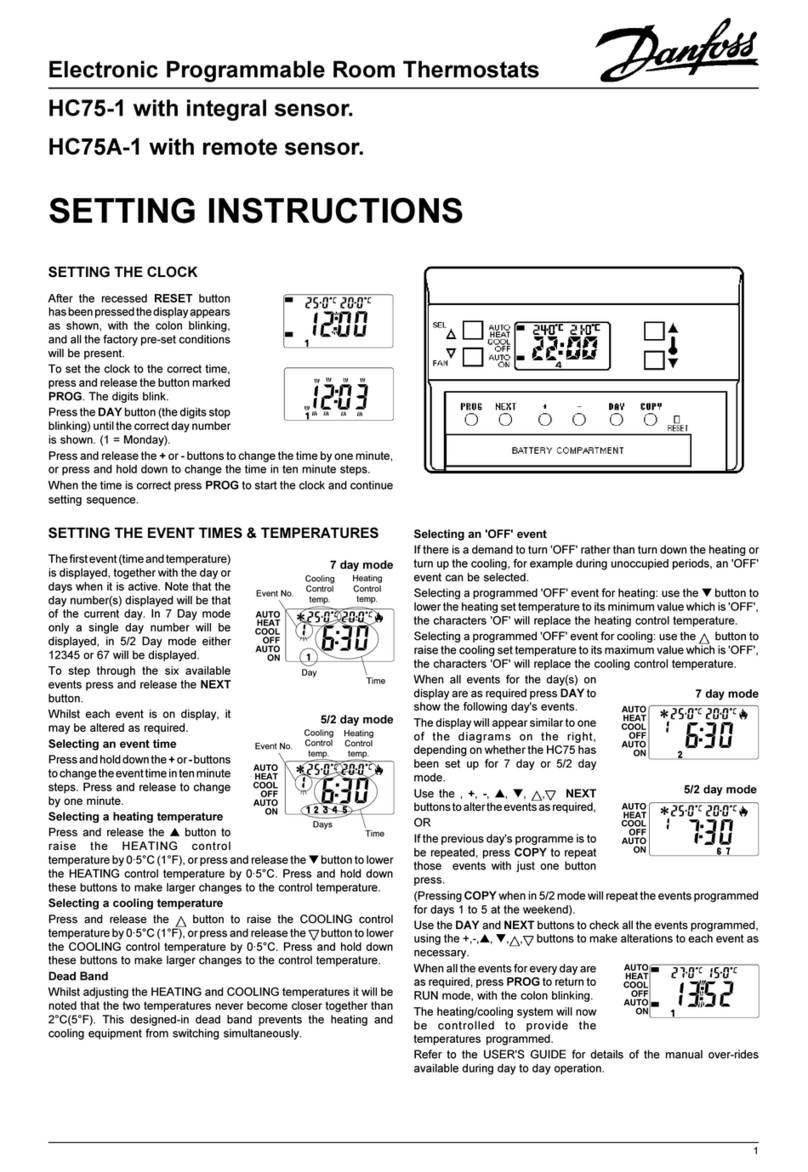

Screws for

bracket

mounting

Mounting holes

for at surfaces

2 DKRCC.PI.CD0.A3.22 / 520H8467 © Danfoss A/S (AC-MC / jmn), 2014-02

Installation

Select an accessible location, where the thermostat will not

be subject to damage. Mount the KPU on a bracket or on a

completely at surface. Mounting on an uneven surface may

cause incorrect thermostat operation. For bracket mounting,

use only the 10-32 x

3

/

16

in. screws furnished with the

thermostat. Other screws may interfere with the functioning of

the thermostat. In no case can screws protrude more than

1

/

8

in. into the thermostat. Use only the mounting holes provided.

Do not make additional holes.

IMPORTANT:

For vapor charged thermostats, ensure that the bulb

is installed in a colder location than the thermostat

housing and capillary tube. This prevents charge

migration from the bulb and ambient temperature

will have no eect on regulation accuracy.

For adsorption charged thermostats, the bulb can be placed

in a warmer or colder location than the thermostat housing

and capillary tube.

General recommendations for capillary tube

and bulb installation:

1. Protect the capillary tube from damage due to vibration.

a) When the thermostat unit is mounted directly on the

compressor, the capillary tube must be secured to the

compressor so that both vibrate together.

b) For mounting otherwise, form surplus capillary tube

into a loose loop, and secure the length of capillary tube

between the compressor and the loop to the compressor.

Secure the length from the loop to the thermostat to the

base on which the thermostat is mounted.

2. Leave a little slack in the capillary tube to help dampen

vibration.

3. Avoid sharp bends and bending the capillary tube at the

same point several times, as these actions can weaken the

material and increase the likelihood of the tube cracking.

4. Form and locate the capillary tube away from sharp or

abrasive objects that might damage it.

5.

Never allow the capillary tube of a vapor charged

thermostat to run alongside of a suction line in a wall entry.

6. Ensure minimal length of capillary tube exposed to

temperature for KPU with straight capillary bulb type:

− 16 in. for KPU tharmostats with 80 in.

capillary tube,

− 22 in. for KPU thermostats with 200 in.

capillary tube.

7. For thermostats with room sensor coils, make sure that

placement allows free airow around the coil and bulb.

At the same time, ensure that the bulb is not exposed to

drafts from doors, or to heat radiated from the evaporator

surface. Make sure that the bulb does not come into

contact with a wall surface. Never mount the thermostat

directly on a cold wall. Instead, mount the unit on an

insulating plate.

IMPORTANT:

Do not dent or deform the bulb of the thermostat, as

doing so could damage the bulb and cause charge

leakage.

Wiring

Electrical ratings according to UL regulations

120 V a.c. 24 FLA, 144 LRA - make only

240 V a.c. 24 FLA, 144 LRA - make only

240 V d.c. 12 W pilot duty

European electrical ratings according to EN 60947

AC1 AC3 AC15 LR DC13

16 A 16 A 10 A 112 A 12 W

400 V 220 V

CAUTION:

To avoid the possibility of electric shock and damage

to equipment, diconnect the power supply before any

wiring connections are made. Never touch current

conducting (LIVE) parts with your ngers or with tools.

NOTE:

All wiring should conform to the National Electrical

Code and to applicable local regulations. Use only

copper wire. Use only the terminal screws furnished in

the terminal block. Do not exceed tightening torque

of 20 inch pounds (2.3 Nm). Do not exceed the

thermostat’s specied electrical ratings.

The terminal block as well as grounding screw are accessible

after dismounting the front cover.