a Ensure heat pump on site is as ordered, i.e. model, electrical supply and

factory fitted options.

b Inspect unit for damage, in particular inspect e evaporator (finned side)

to ensure at it is undamaged. (Minor indentations in e fins do not affect

performance). If severely damaged, endorse delivery note in presence of e

driver and send a recorded delivery letter to transport company giving details.

c Protect unit if installation is delayed.

d Provide a firm level base capable of supporting operational weight of unit;

spread load on timber floor.

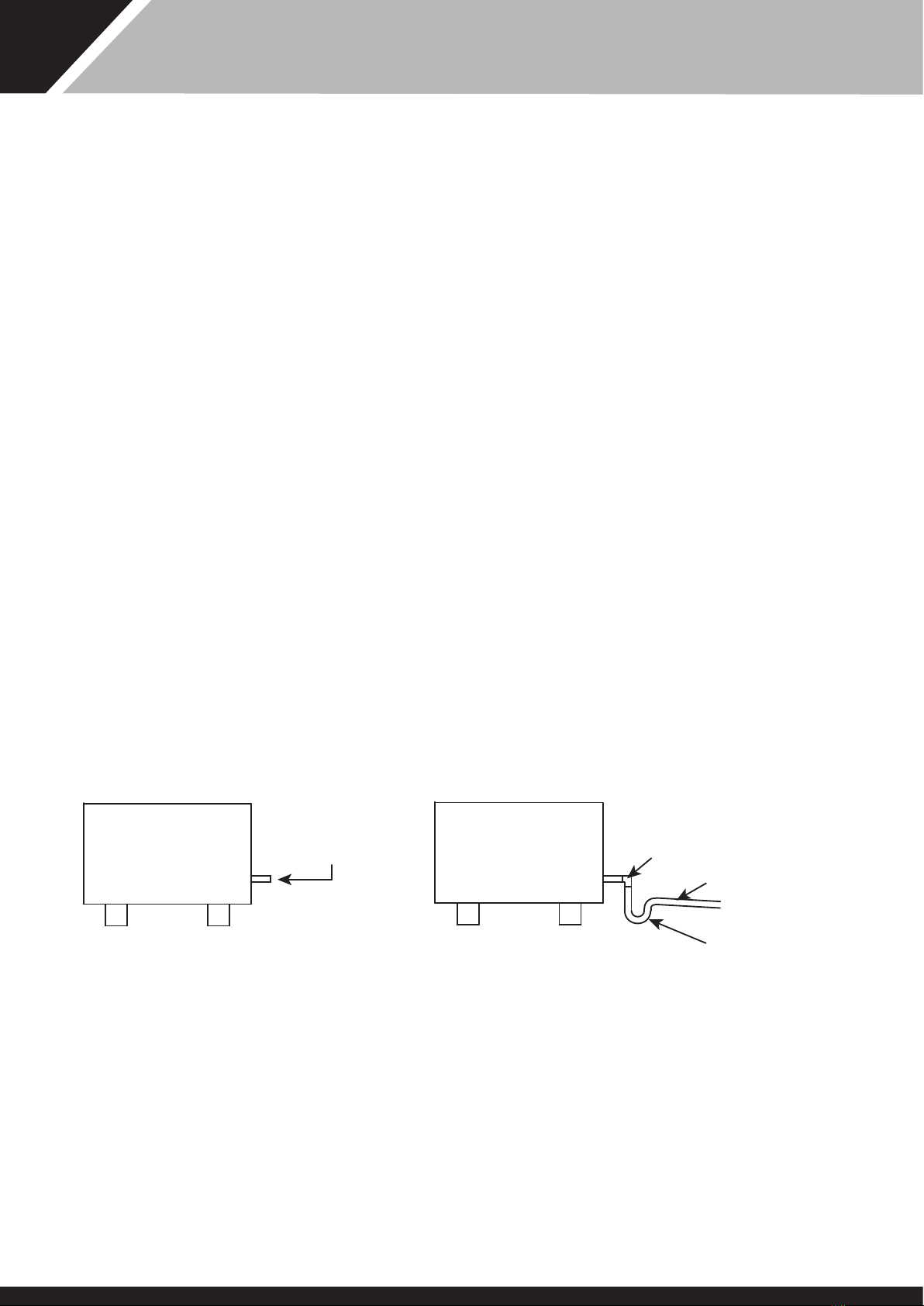

e Ensure water cannot collect under unit - recommend units are installed on

plins 100mm above finished floor level and to also aid condensate drainage.

f Allow adequate clearance to service panels on unit; recommend 500mm

minimum (see installation drawings).

g All Calorex heat pumps are by design as quiet as is practical, however due

consideration should be given to siting in order to fully exploit is feature, i.e.

orientate inlet/outlet parallel to occupied premises.

h Ensure loose debris such as leaves, grass cuttings, etc will not block air inlet

grilles.

i Consider protection from extreme weaer conditions if installed externally, i.e.

lean-to-cover or building.

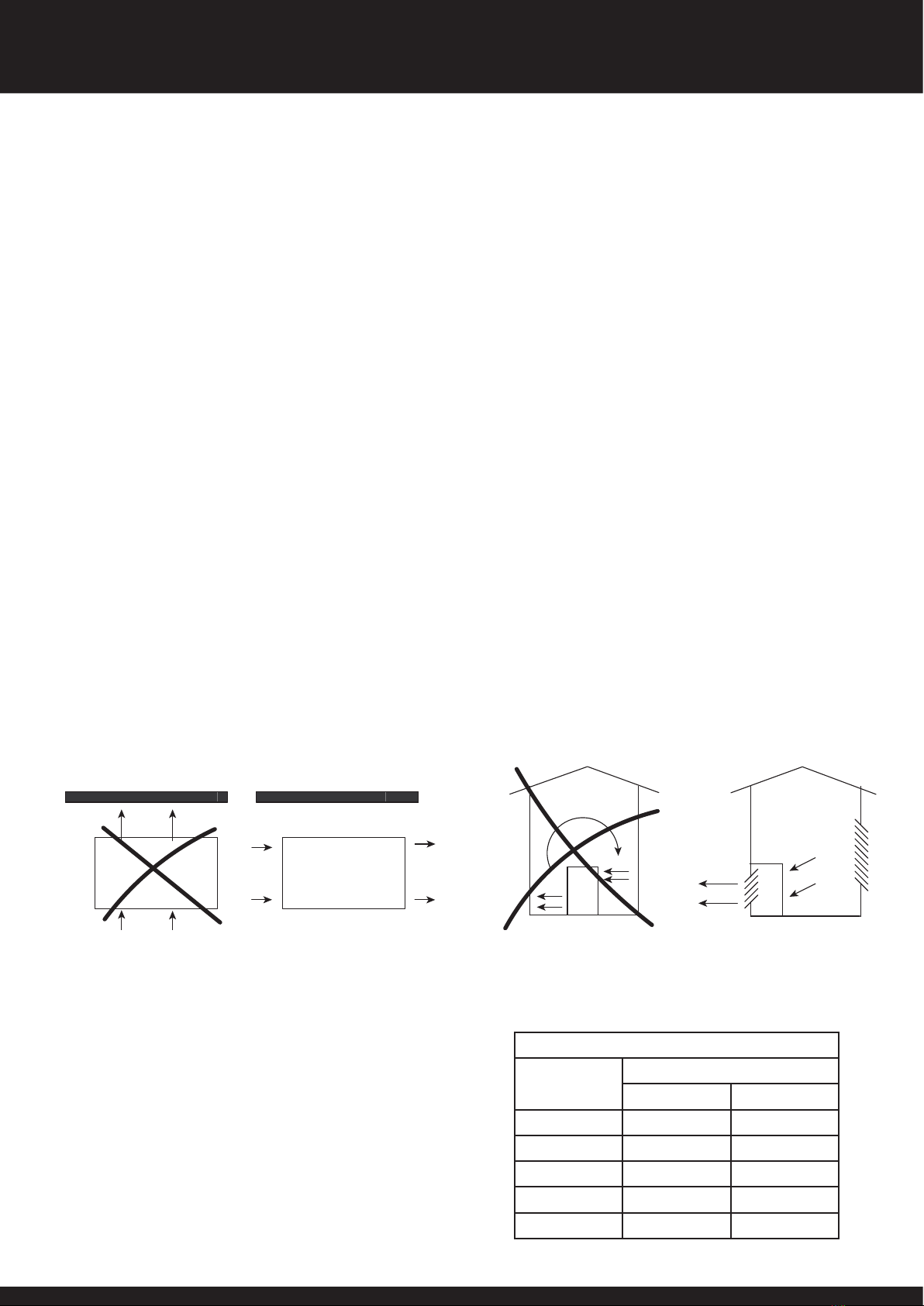

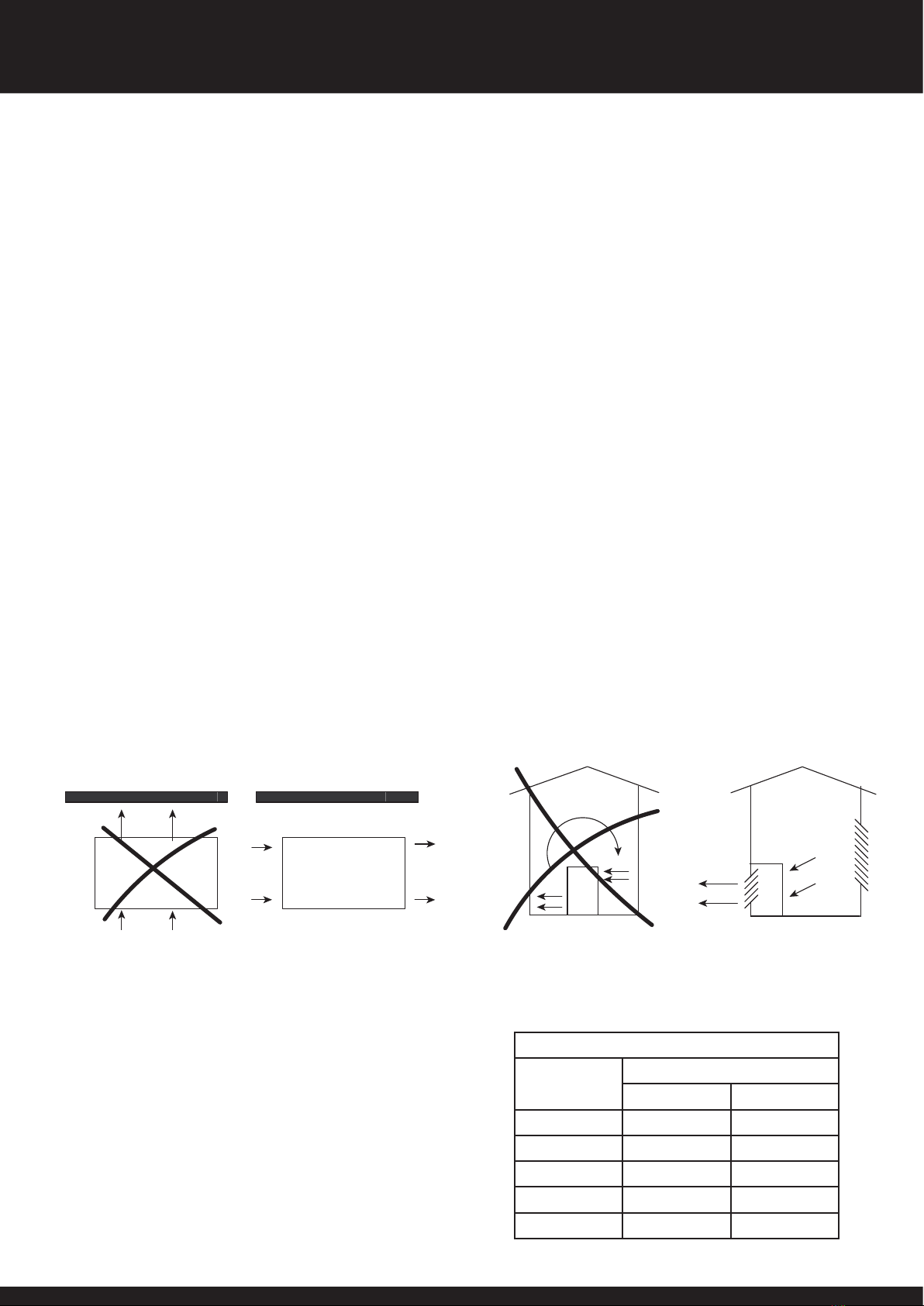

Due consideration must be given to air flow, i.e. do not obstruct inlet or outlet

and ensure discharge air cannot recirculate to inlet. (See figures 1 and 2)

Required Free Areas to provide air flow to and from heat pumps when

installed in an enclosed area or where required to pass air rough a

wall, etc.

Free area is e available area rough which air can pass rough a grille or

louvres.

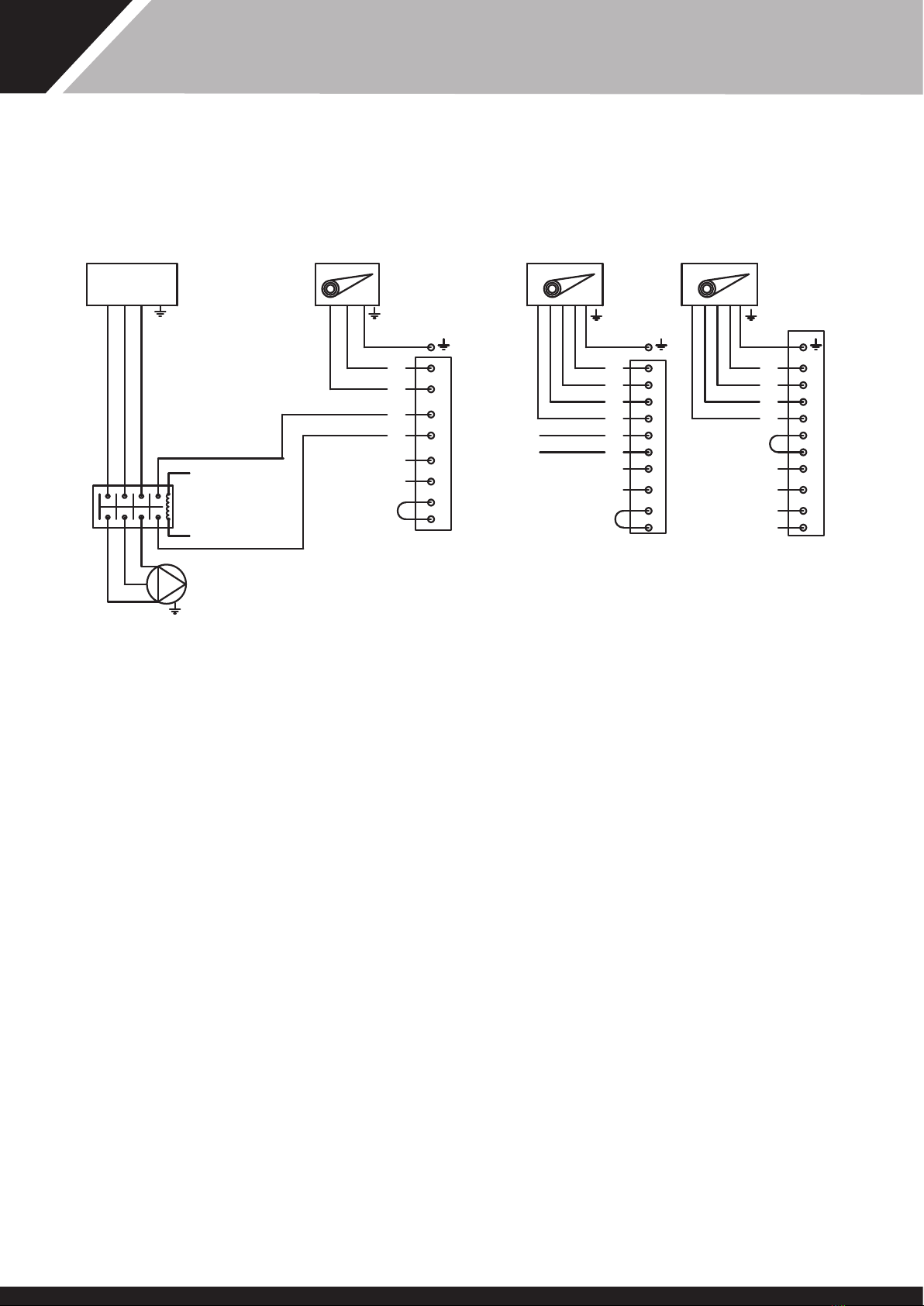

1. Note: If multiple units are installed in an enclosed area en e inlet free

areas required for each unit can be added togeer to form one inlet aperture.

BUT discharge from each unit must be kept separate and must not be

incorporated into one common duct system.

2. If e unit is installed wiin a plantroom, connected to ductwork, Danerm

Ltd. can supply e unit wi an uprated fan motor.

Please consult Danerm Ltd. before ordering a unit.

INSTALLATION

1. SITING

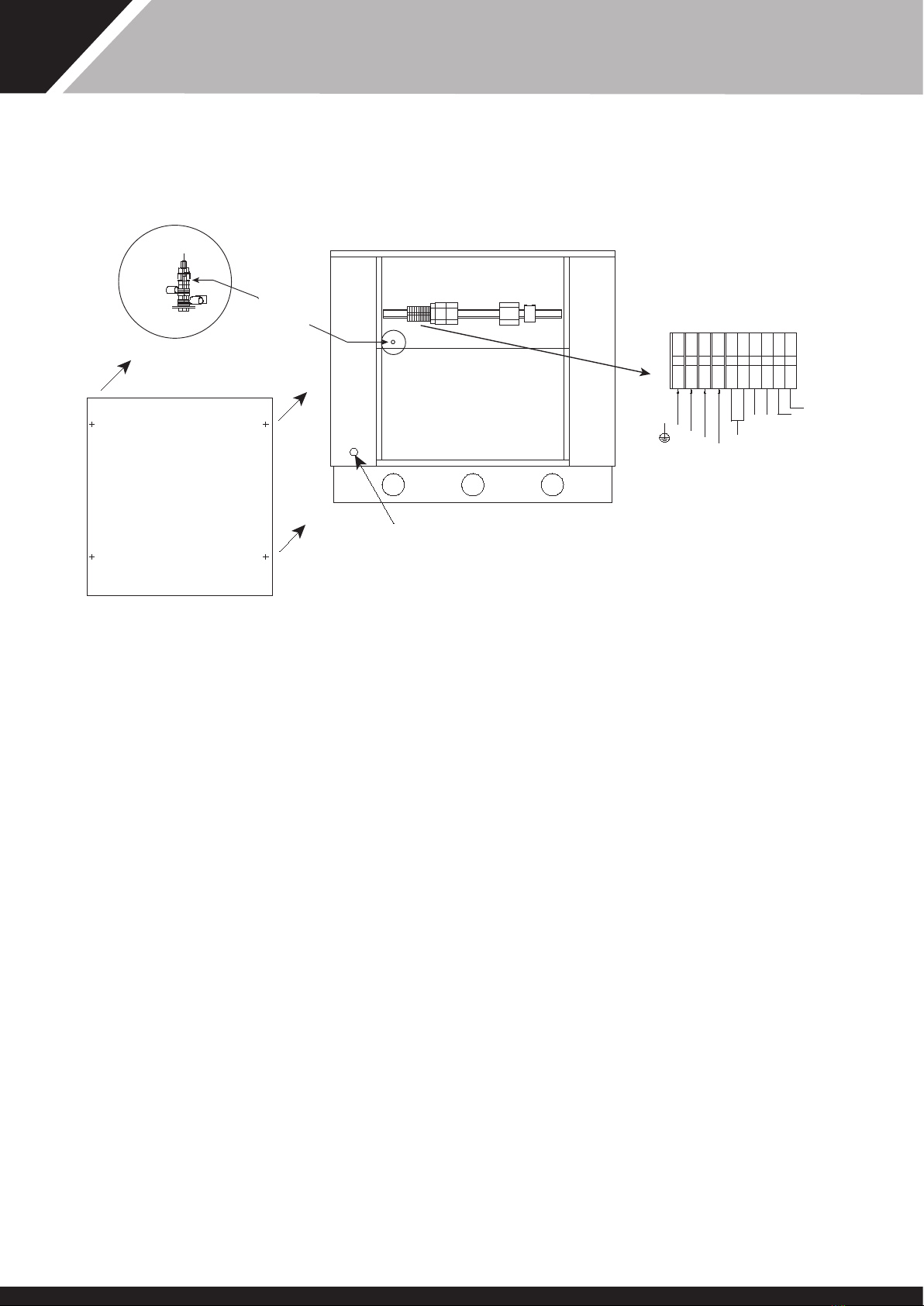

TYPICAL OUTSIDE INSTALLATION

FIGURE 1

WALL, FENCE OR HEDGE

TYPICAL INSIDE OR PLANTROOM INSTALLATION

FIGURE 2

WRONG RIGHT

Grill or apertures MUST comply wi figures (see Table 1)

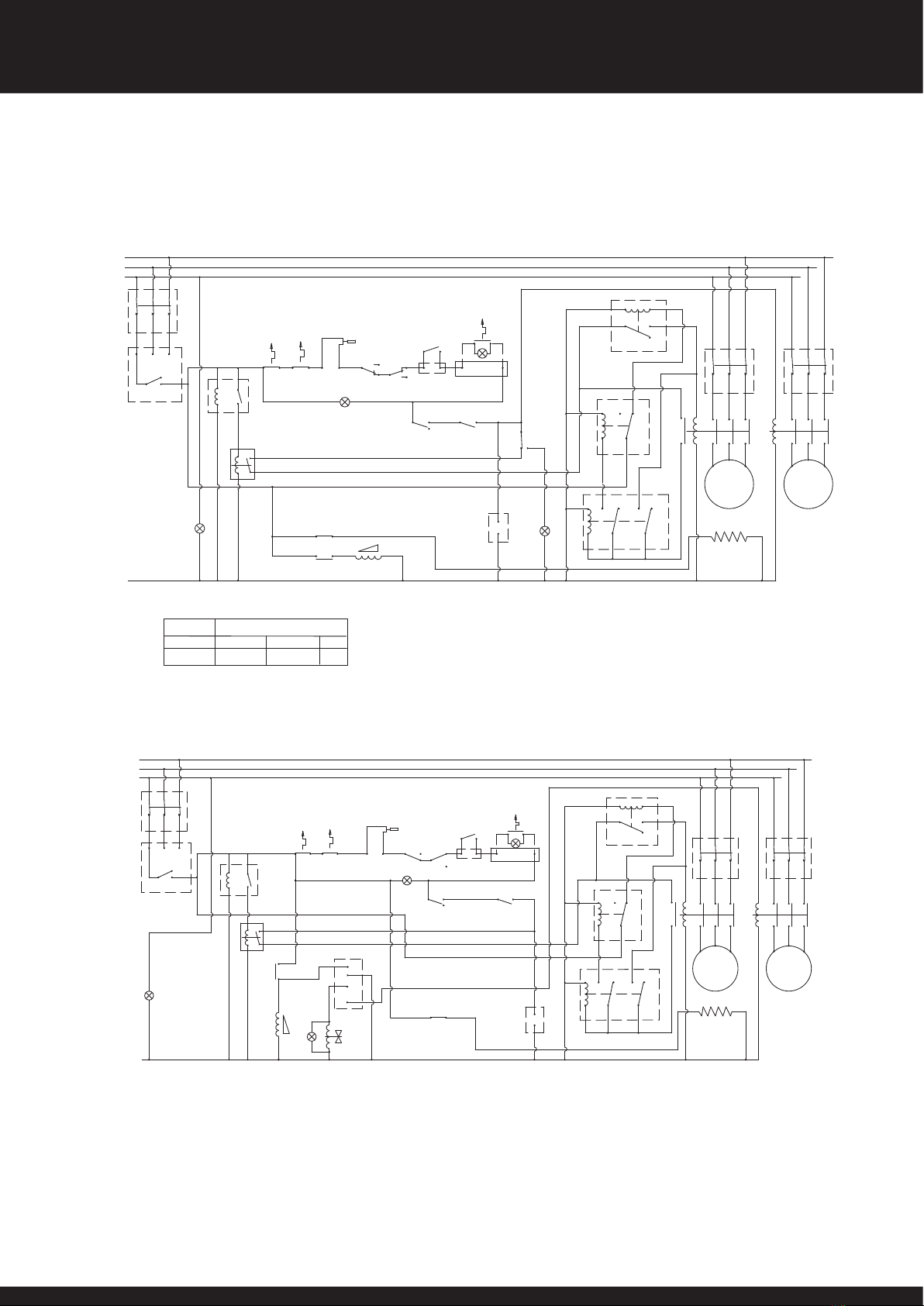

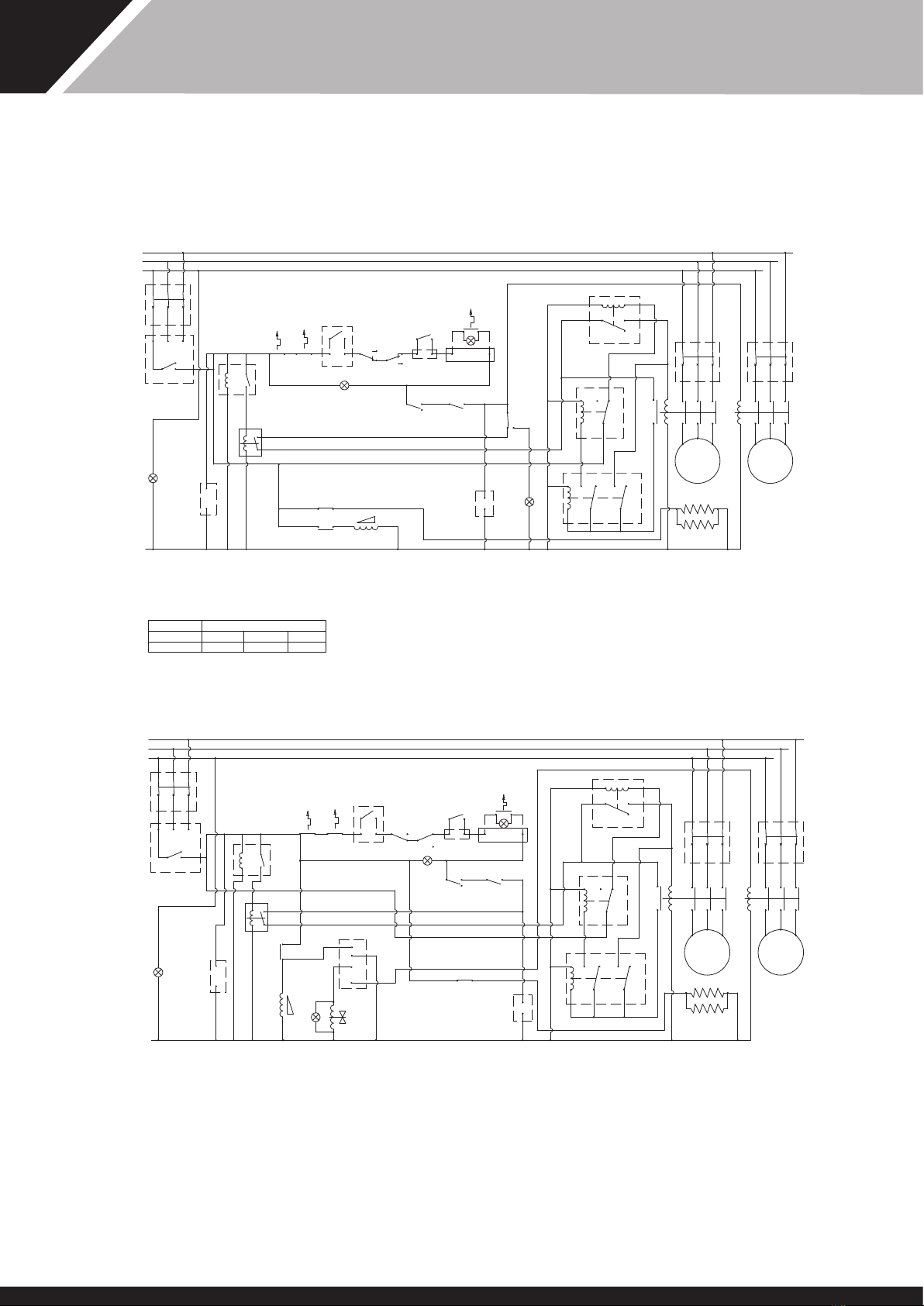

TABLE 1

MODEL MINIMUM FREE AREA M2

INLET DISCHARGE

AW834 0.46 0.06

AW1234 0.46 0.07

AW1534 0.54 0.10

AW3034 1.2 0.18

AW7034 1.5 0.2

2. AIR FLOW

6 SD331851 ISSUE 28

AW834,1234AH/BH,1534BH AW 3034,7034H/HY OWNER INSTALLATION MANUAL