GAS UNITS

KITS AND ACCESSORIES

@1997 Lennox Industries Inc, 503,289M

Dallas, Texas 2/97

Supersedes 7/96

_j_ Technical

_L Publications

Utho U.S.A,

HEAT CABLE KIT

INSTALLATION INSTRUCTIONS FOR HEAT CABLE KIT (LB--88643A, B & C) USED

WITH G21, GSR21, G26, GHR26 AND COMPLETEHEAT SERIES UNITS

Package 1 of 1contains:

1 - - Heat cable

Heat cable kit protects drip leg assembly, condensate

line, flue pipe and vent terminations when the unit is

installed in unconditioned spaces where freezing is

possible. When installed as outlined in manufacturer's

instructions, the heat cable will protect PVC and CPVC

lines from freezing without causing damage to pipes. The

heat cable is 120VAC pro-assembled self-regulating

electric cable. There are three heat cable kits available in

6 ft., 24 ft. and 50 ft. lengths (excluding 30" long cord set).

Fiberglass and aluminum tape are needed for each

installation. Table 1 lists all kits available from Lennox.

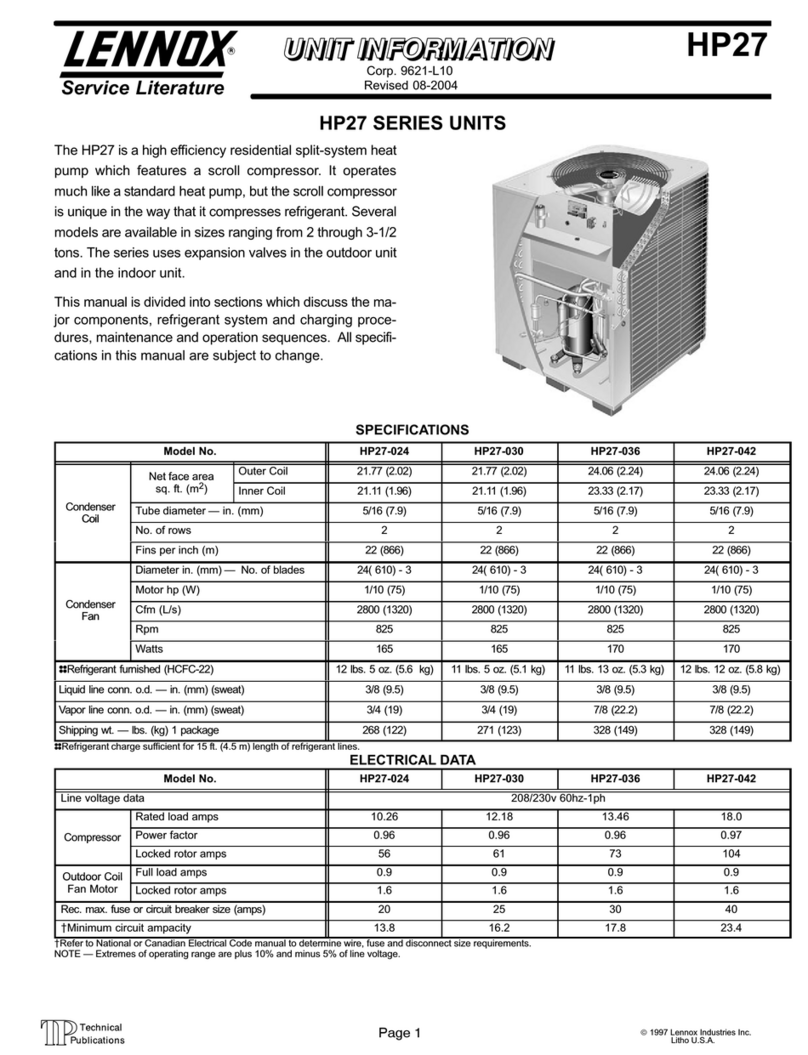

TABLE 1

DESCRIPTION LB--NUMBER CAT, NUMBER

6F]_ HEAT CABLE KIT LB- -88643A 26K68

24 FT HEAT CABLE KIT LB- -88643B 26K69

50 FT HEAT CABLE KIT LB- -88643C 26K70

66 FT FIBERGLASS TAPE KIT LB--56532DA 39G04

60 FT ALUMINUM FOILTAPE KIT LB--56534DA 39G03

NOTE - - Before installing heat cable kit, installer must

provide a 120V power source with cithara circuit breaker

or fuse suitable for handling required cable length. Do

not use an extension cord to reach the receptacle. For

additional safe_ a ground-fault pretection device should

be installed. See heat cable manufacturer's installation

instructions.

See table 2 to determine the length of heat cable needed

for specific run of PVC or CPVC pipe.

TABLE 2

LENGTH OF PIPE COVERED FOR

LENGTH OF HEAT CABLE

PIPE SIZE 6 FT. 12 F3_ 18 FT. 24 FT. 50 FT. 100 FT.

O.SlN. I 6 I 12 I 18 I 24 I 50 I 100

RUN CABLE STRAIGHT tl FT OF CABLE TO 1 F_ OF PIPE_

_nIN I 3 I6IgI_I _s Isn

SPIRALCABLE(2 F]_OFCABLETO1FT OFPIPE.)

3nIN I _ I4IRIRI1_7 I:_33

SPIRALCABLE(3 FI_OFCABLETO1FT OFPIPE.)

Table 2 assumes lowest outside temperature of 0°F with

a minimum of 1/2" fiberglass insulation or equivalent (i.e.

Armaflex.) For protection to --20°F, use 1" fiberglass

insulation or equivalent. Multiple heat cable may be

needed for longer runs of pipe.

1 - -The first 30" from plug end of the heat cable is the

cord set. This section does not get hot and should

not be wound around the pipe. To prevent damage

to the cord set, provide a strain relief using plastic

cable ties, or three thicknesses of either, vinyl, glass

cloth or heavy duct tape.

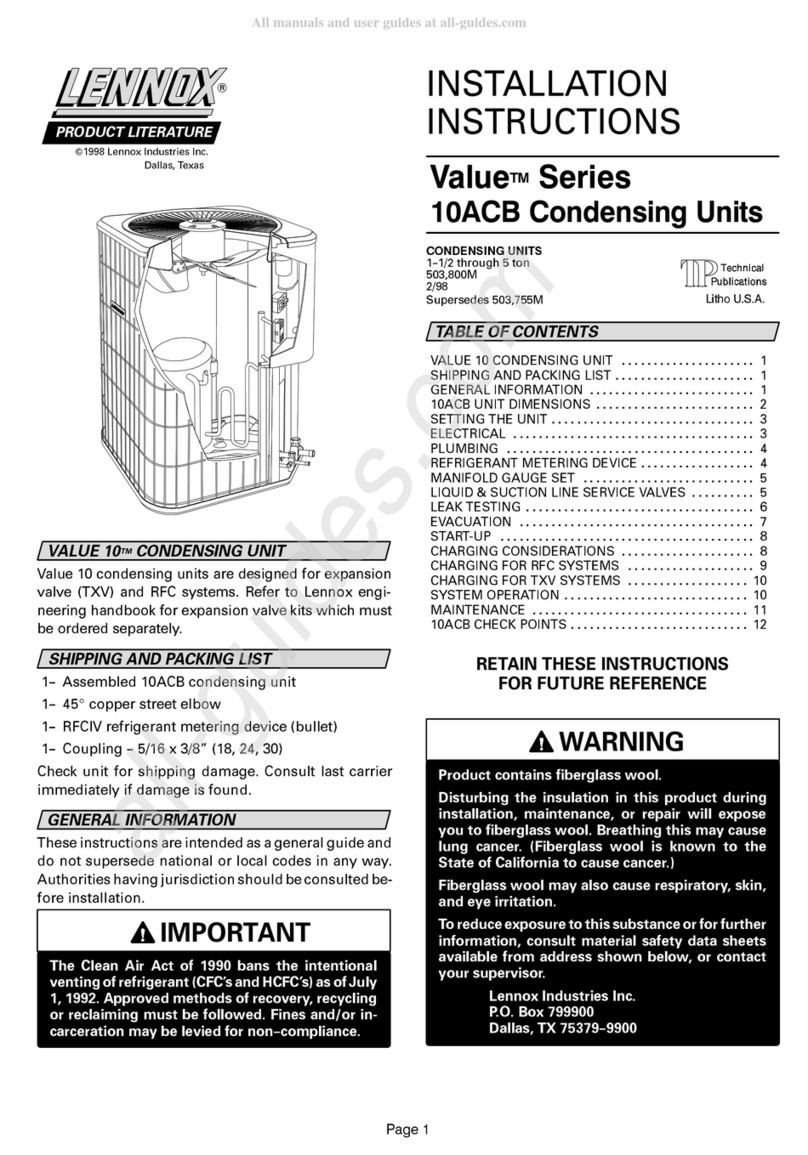

2--Wrap heat cable around pipe, condensate trap

assembly or vent termination, so that the cable is

pulled tight to ensure continuous contact between

the cable and the pipe. See figure 1.

Side View

If heat cable is longer than pipe, spiral

cable evenly along pipe and according toT able 2.

Side View End View

If pipe is 0.5" condensate pipe, cable of same length may be

run straight along pipe in either the 4 or 8 o'clock position.

FIGURE 1

3 - - After wrapping heat cable around pipe, secure cable

to the pipe using fiberglass tape. Wrap tape around

the pipe and cable using approximately 1-1/2 wraps

every foot. See figure 2. Do not use electrician's

tape, duct tape, vinyl tape, metal clamps or any

wire. Heat from the cable breaks down adhesive

properties of these tapes.

HEAT CABLE ALUMINUM FOIL TAPE

•,,'-',_1_ ' '/•......_I INSULATION

?,,J'

PVC or CPVC \

PIPE FIBERGLASS TAPE

(Wrap around pipe 1-1/2 times)

FIGURE 2

Page 1