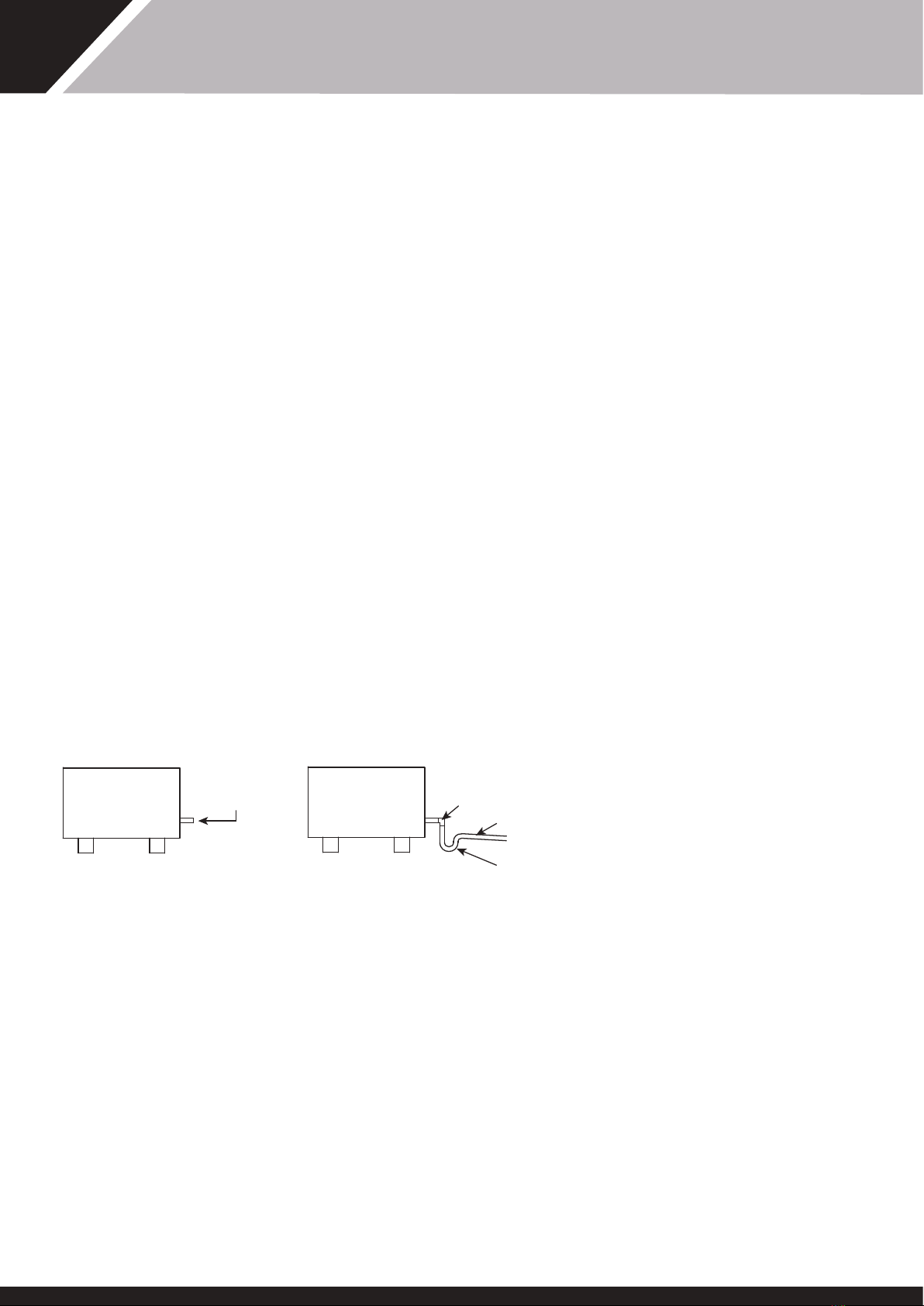

INCORRECT DRAINAGE

FOR CONDENSATE

CORRECT DRAINAGE

FOR CONDENSATE

THIS TYPE OF

INSTALLATION SHOULD

BE AVOIDED ELBOW

ADEQUATE FALL

U TRAP

a. Calorex ‘34’ range Heat Pumps have water inlet/outlet connections as

follows:

634/1234 models ¾ “ BSP parallel, male.(wi ¾” BSPF x 1½” ABS male

adaptors supplied loose).

1834 models 1½” BSP parallel, male.

PP22BC ¾” BSP parallel, male or 50mm

The machine is supplied wi bungs fitted in e water connection fittings.

These need to be removed before e unit is installed.

b. The Calorex Pool Heat Pump must be connected in bypass aer e filter in

e return pipe to e pool. If an existing heater is being retained, en e

Calorex Heat Pump should be connected between e filter and e oer

heater.

c. Suitable breakable couplings should be installed local to heat pump.

d. If heat pump installed at lower level an pool water en isolation valves

should be fitted.

e. Drain valve or plug should be fitted to lower pipe to facilitate drain down in

winter period.

f. Connections on all models are by parallel female fittings sealed by silicone

mastic ese should be hand tightened only, oerwise damage may result

to e reads of plastic fittings.

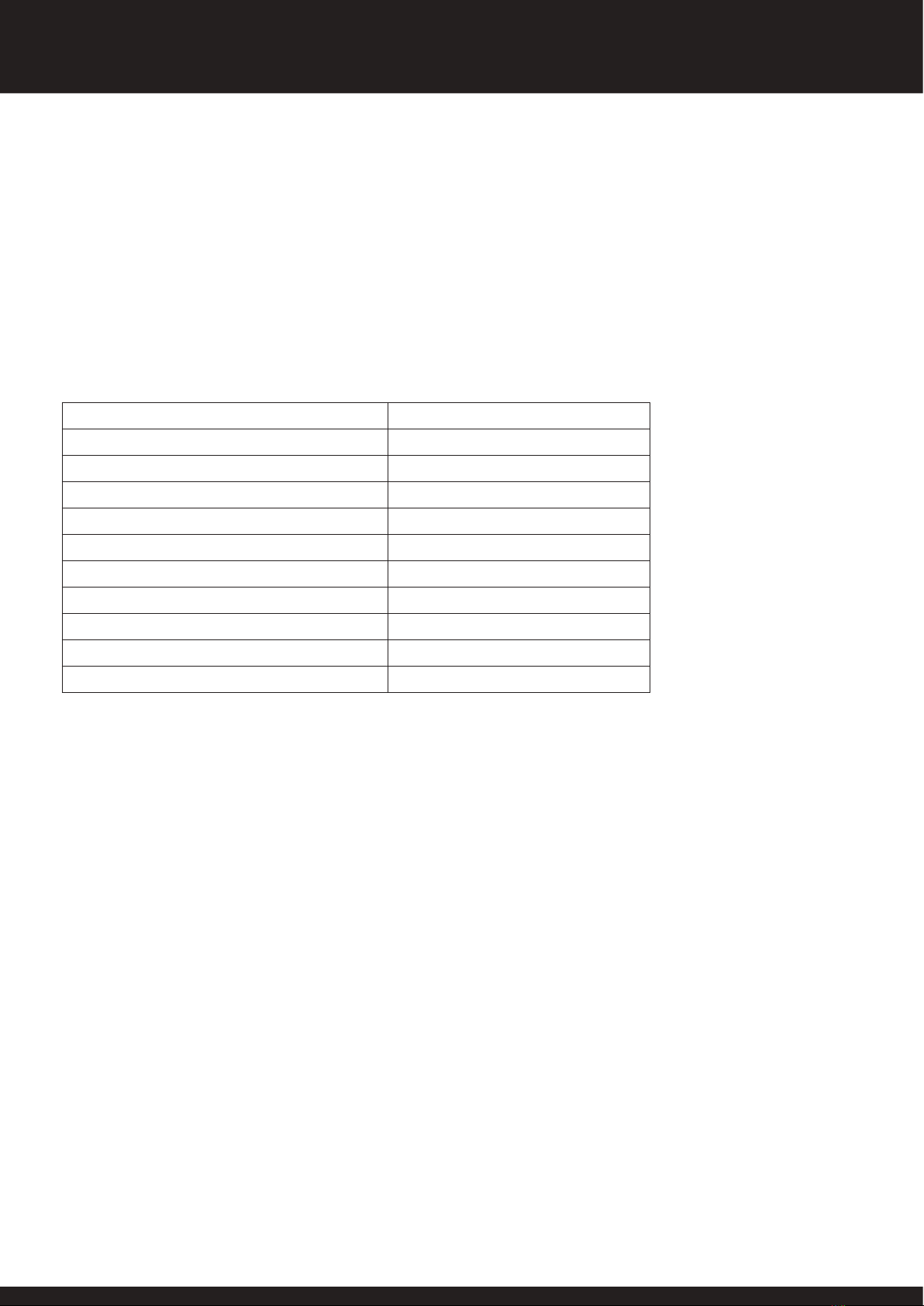

g. The condensate drain at e base of e unit collects e condensation

from e evaporator fins. On 634/1234 and PP22 is should be run away

to waste via ¾” domestic waste piping using connector supplied. On

1834 models e waste piping needs to be 1½”. It is erefore necessary

to ensure at e Calorex unit is placed on a level plin so at e

condensate water can run away wi adequate fall to waste ie. ½” per foot

min and must incorporate a ‘u’ trap as to not overflow e edges of e

drip-tray inside e machine.

h. When e pipework installation is complete e pool pump should be

switched on and e system tested for leaks. Also check e filter gauge to

see at ere is not an excessive increase in back pressure. If everying is

en working normally e water circulating system is ready to use.

i. Water circuit to and from unit to be capable of maintaining wiin specified

limits e rate of flow required by heat pump (see data sheet).

j. All pipework must be adequately supported wi allowance for expansion/

contraction especially wi plastic pipework.

k. It is recommended at when installing water systems e last connections

to be made in e system should be e breakable connections to avoid

any stresses on to e unit connections.

3. PLUMBING

9

SD331852 ISSUE 7