I N S T A L L A T I O N M A N U A L B 0 9 U L F L I T H I U M B A T T E RY

R e v . 1 © 2 0 1 9 D a r f o n E l e c t r o n i c s Co r p . P a g e 2o f 28

TABLE OF CONTENTS

1Overview ......................................................................................................................................................................................................................3

2Safety Precautions.....................................................................................................................................................................................................4

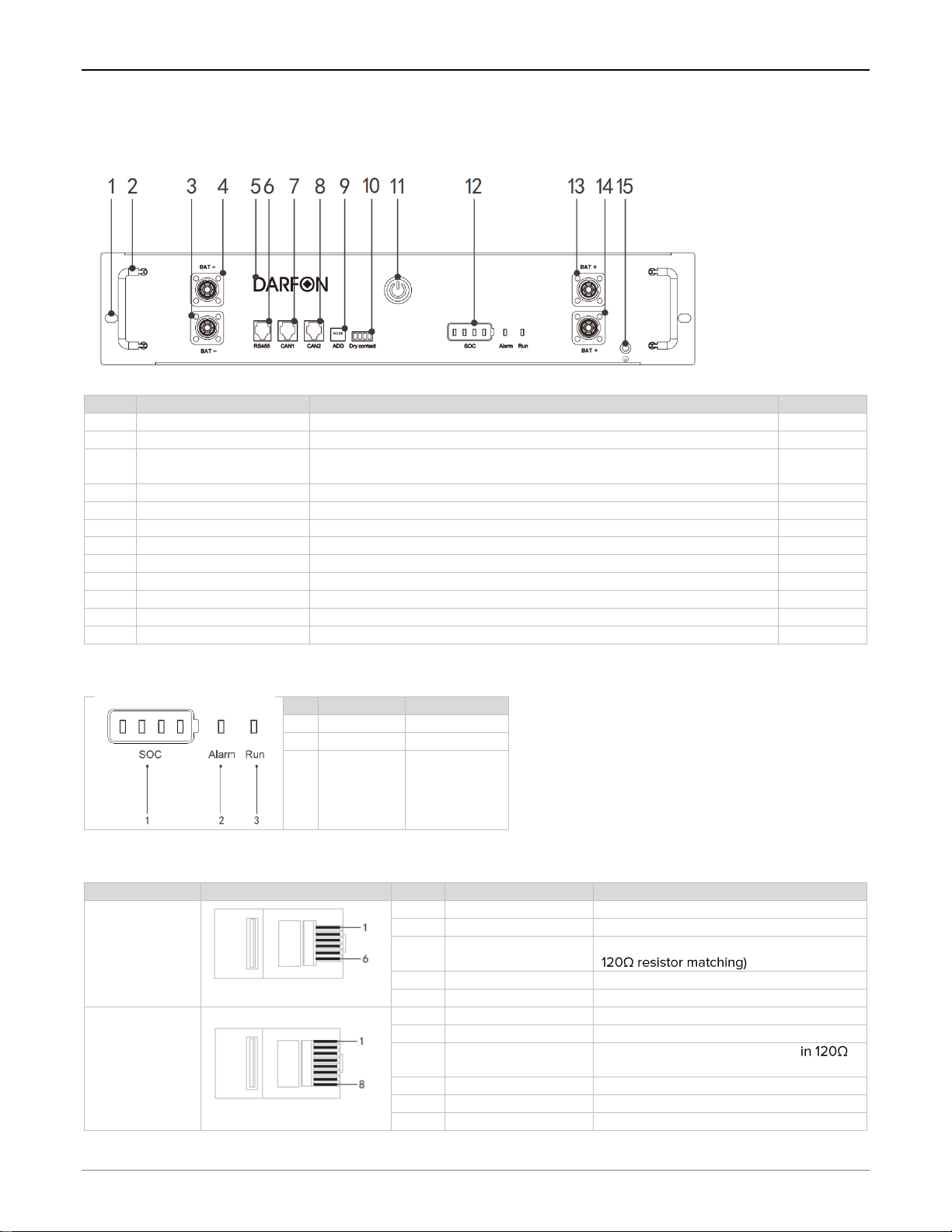

3Identifications..............................................................................................................................................................................................................5

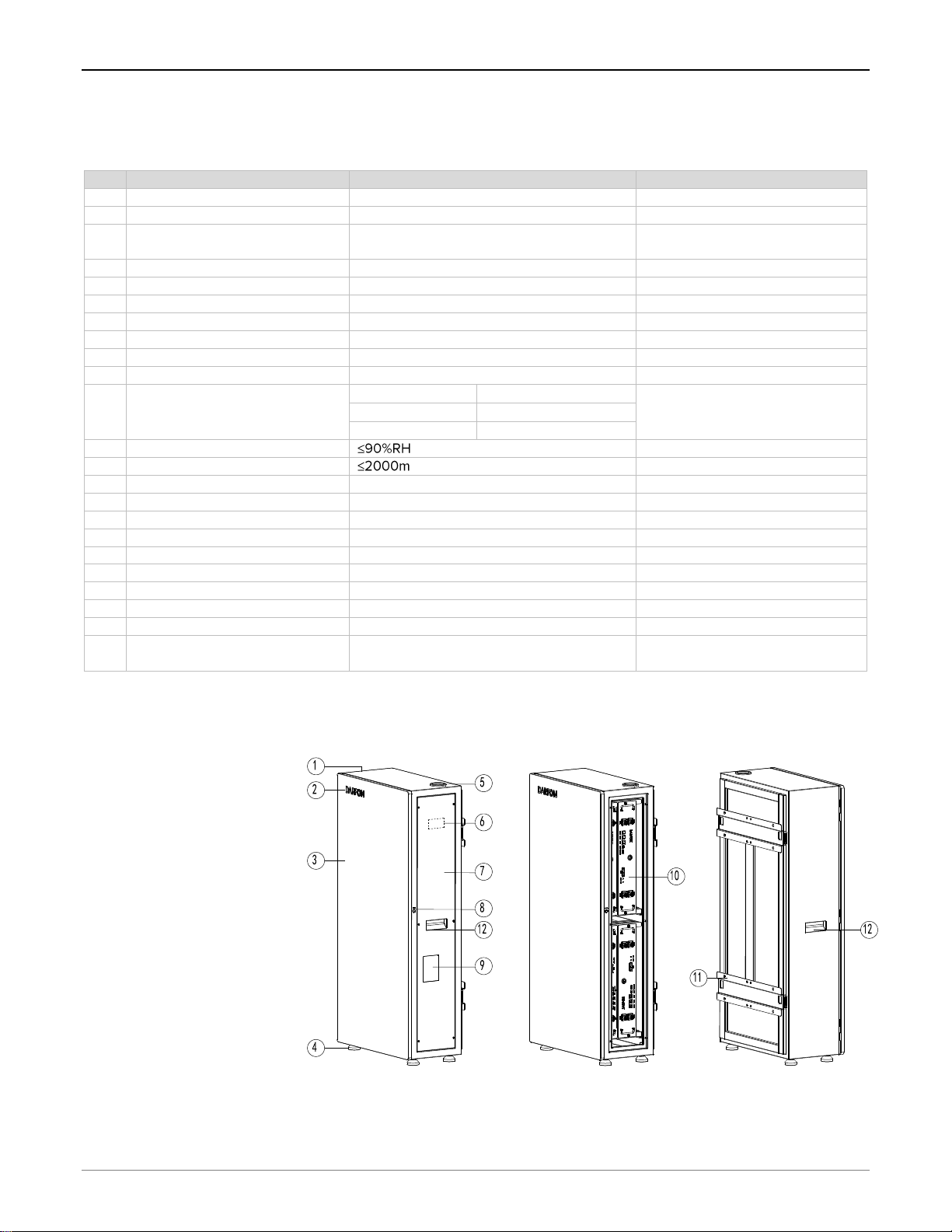

4Product Specifications..............................................................................................................................................................................................6

4.1 System Technical Parameters.....................................................................................................................................................................6

4.2Overall Dimensions and Construction ................................................................................................................................................6

4.3 Battery Modules..........................................................................................................................................................................................7

5Product Installation....................................................................................................................................................................................................9

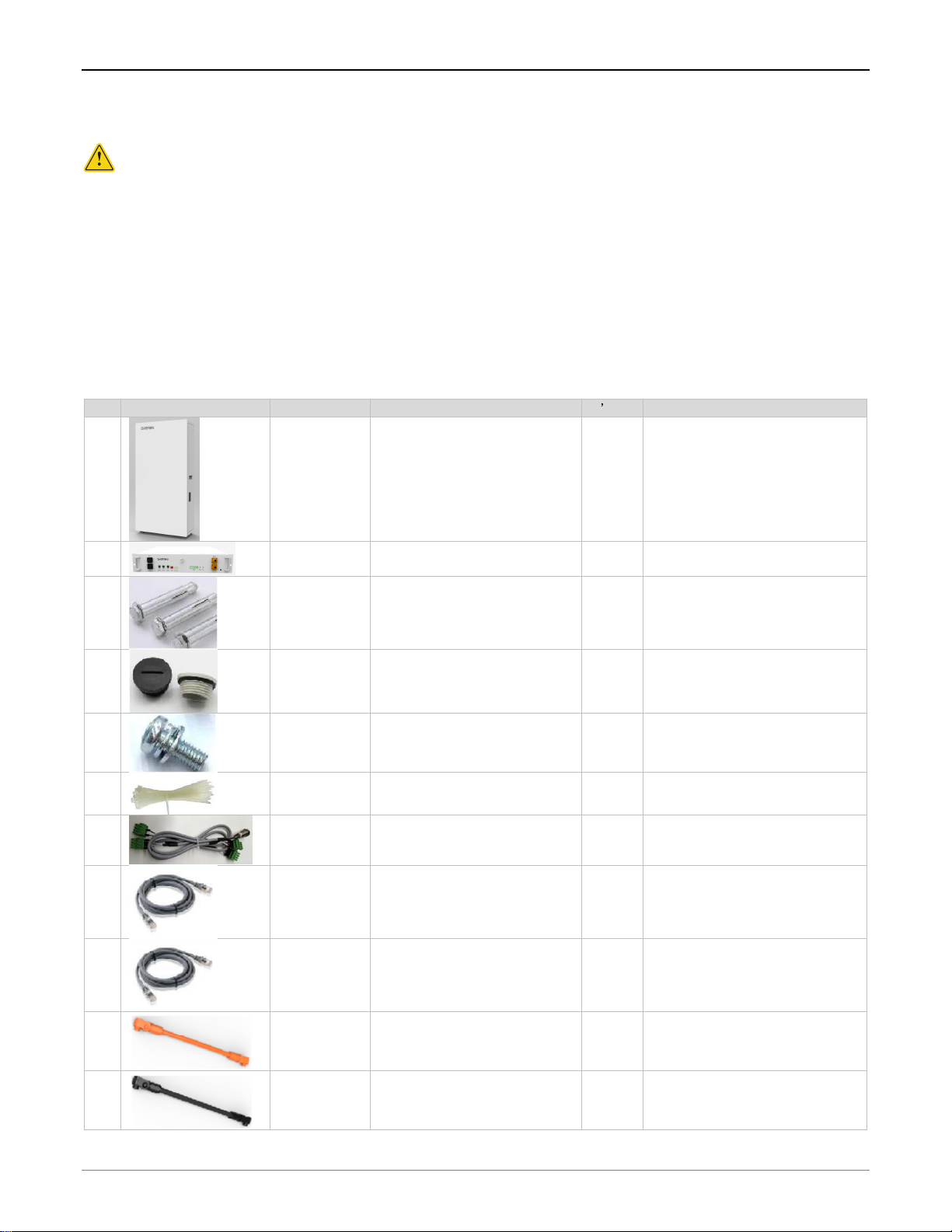

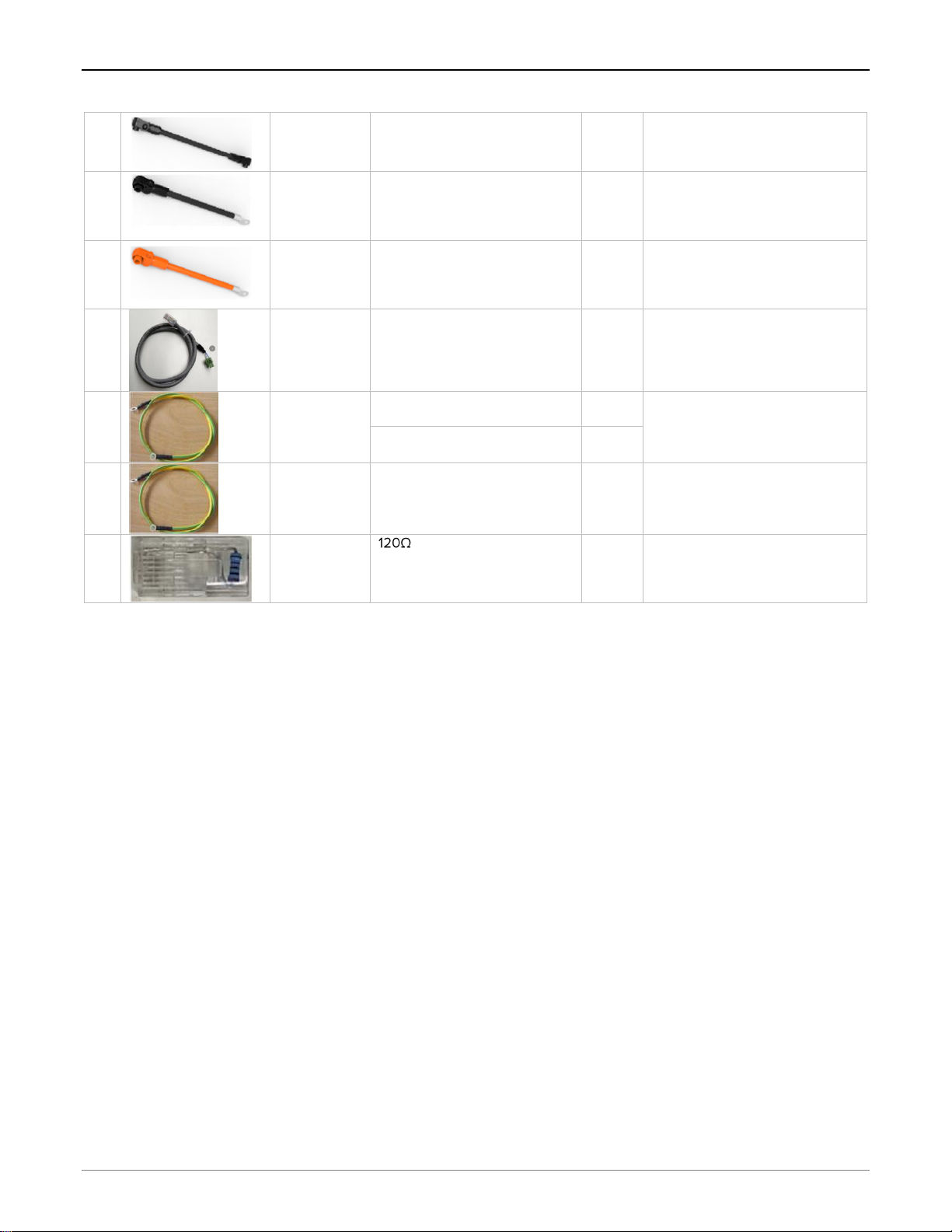

5.1 Device list..........................................................................................................................................................................................................9

5.2 Before installation.....................................................................................................................................................................................11

5.3 System installation...................................................................................................................................................................................12

6Electrical Connection...............................................................................................................................................................................................17

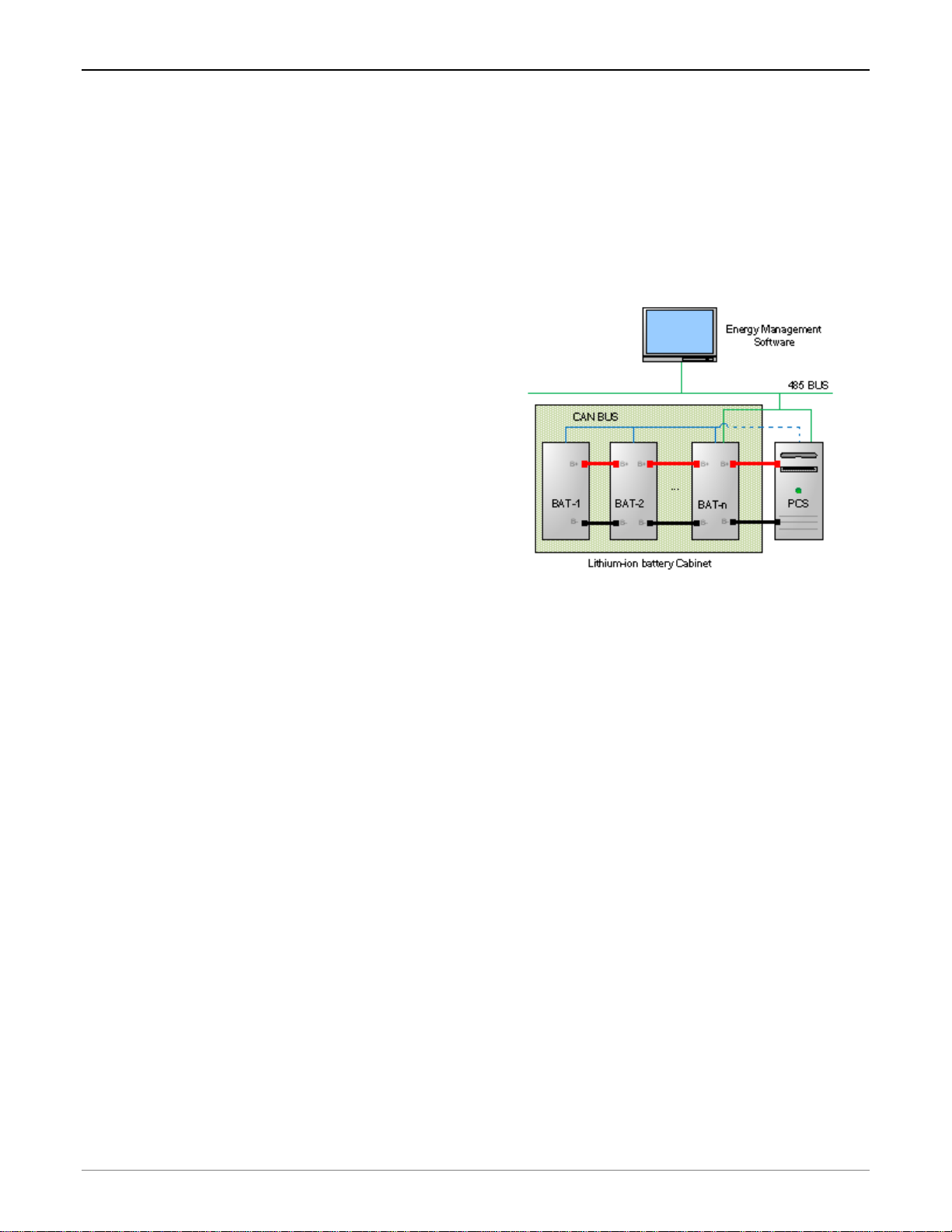

6.1 System Wiring.................................................................................................................................................................................................17

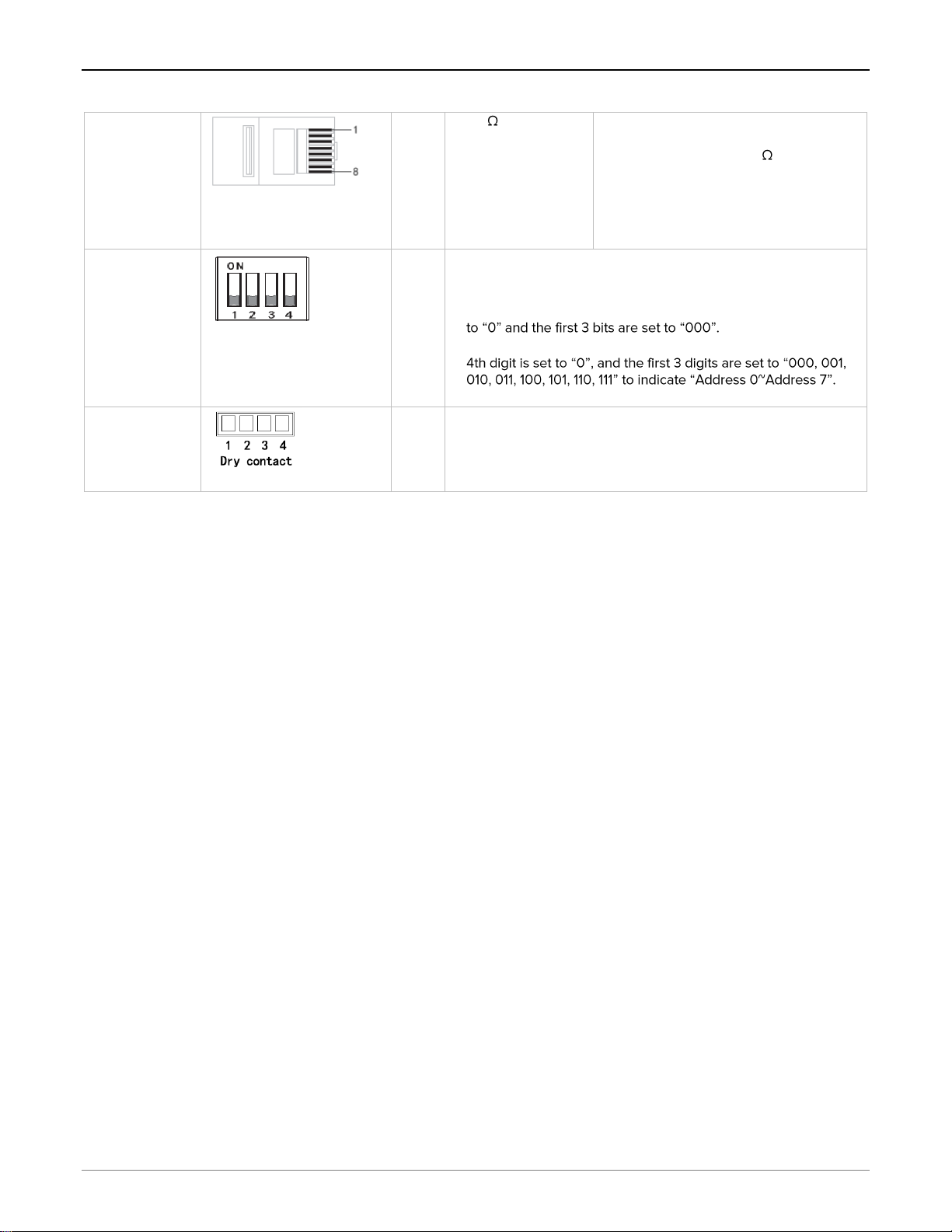

6.2 DIP switch settings..................................................................................................................................................................................20

6.3 Grounding...................................................................................................................................................................................................21

7OperationS.................................................................................................................................................................................................................22

7.1 Power On or Off............................................................................................................................................................................................22

7.2 Display state .............................................................................................................................................................................................22

7.3 Host computer description...................................................................................................................................................................23

8Maintenance and Common Troubleshooting..................................................................................................................................................26

8.1 Daily maintenance........................................................................................................................................................................................26

8.2 Common troubleshooting table..........................................................................................................................................................26

9Packaging, Transportation, and Storage...........................................................................................................................................................27

9.1 System packaging........................................................................................................................................................................................27

9.2 System handling and transportation..................................................................................................................................................27

9.3 System storage........................................................................................................................................................................................27