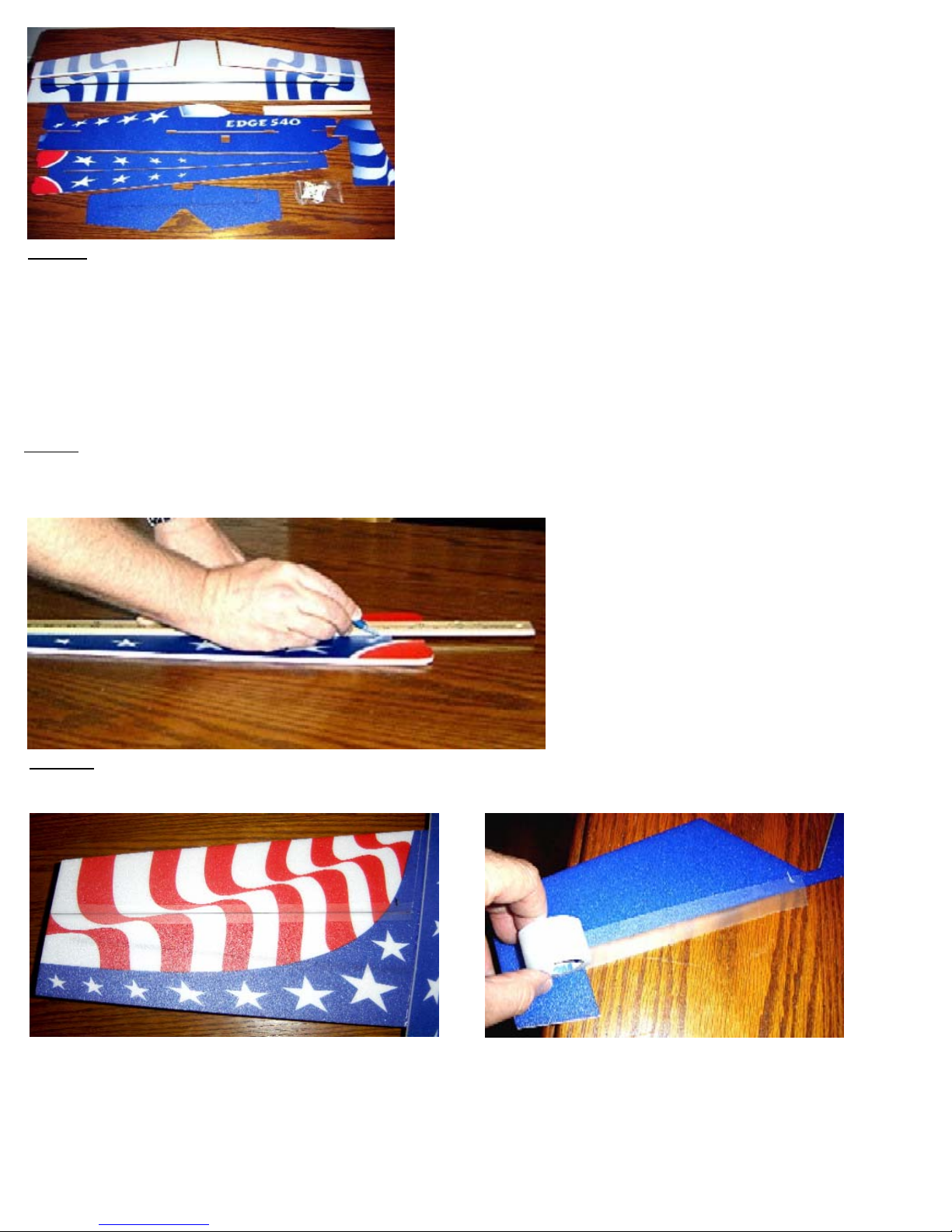

Connect the aileron, rudder and elevator servos to the micro receiver. Using Velcro, install the micro

receiver on the underside of the fuselage. Determine the length from the rudder and elevator control

horns to the servos and using the supplied .060 carbon rod, some heat shrink tubing and 4 pieces of

.032 music wire, make up the elevator and rudder pushrods as shown. Secure the .032 wire to the

.060 carbon rod with heat shrink, then wick some thin CA onto the heat shrink and “kick it” with CA to

strengthen the joint.

At this time, make two standoff pushrod supports from a Popsicle stick or a coffee stirrer, like the

ones at Starbucks and slip one over each .060 pushrod before you put the end on the pushrod. See

the picture at the top of page 5. Wait until you have the pushrods connected before you cut the

supports to the right length and Ca them in place."

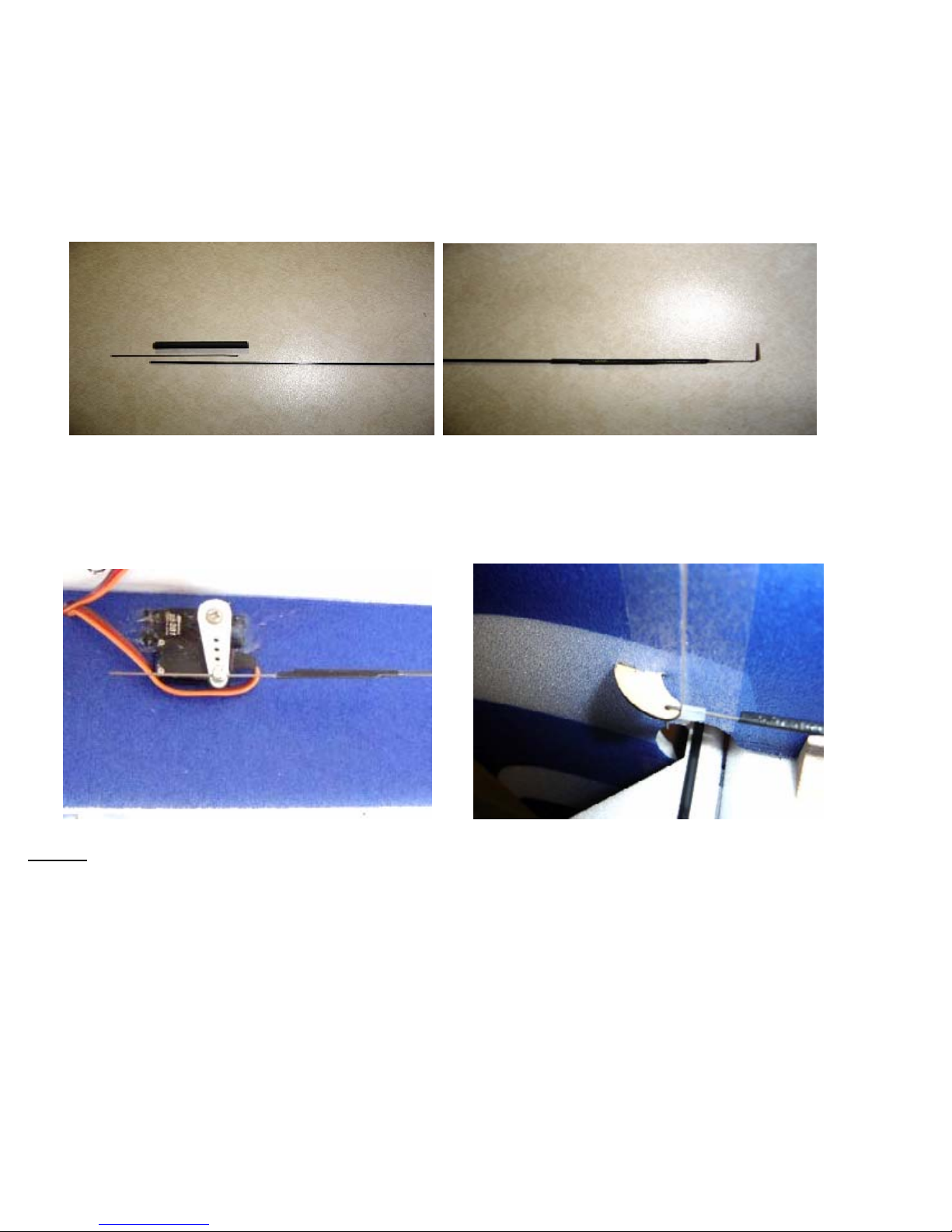

Insert the rudder and elevator servos into the square hole underneath the wing. The servos should

lay on top of each other and face away from each other when installed. Secure them with CA. Attach

the rudder and elevator pushrods to the servos, using either z-bends at the control horns or L-bends

with Dubro micro E-Z links (pictured).

Step 7: Counter sink the four holes on the front of the firewall. This can be done easily with a Dremel

tool with a round ball cutter attachment. Insert the motor shaft underneath the fuselage behind the

firewall (the slotted hole in the firewall allows the motor shaft to be move into position more easily).

Secure the motor to the firewall with the 4 flat head screws included in the motor package.

6