Dass DSP-123K5-OD Specification sheet

DASS Tech

Photovoltaic Grid-Connected Inverter

DSP-123K5-OD ver1.0

Operation and Installation Manual

1

NOTICE

1. Caution for safety.................................................................2

2. Product ...........................................................................5

2.1 General .....................................................................5

2.2 Specification................................................................8

3. Installation.......................................................................9

3.1 Configuration................................................................9

3.2 Installation place...........................................................9

3.3 Terminal connection diagram.................................................10

3.4 Wiring......................................................................11

3.5 Cautions for mounting the inverter to the wall ................................14

4. Operation.........................................................................15

4.1 Display.....................................................................15

4.2 Basic mode .................................................................15

4.3 Operation method............................................................17

5. Function..........................................................................17

5.1 Descriptions................................................................17

6. Maintenance & repair..............................................................19

6.1 Types of error .............................................................19

6.2 Customer service............................................................20

7. Quality assurance.................................................................21

7.1 Warranty letter.............................................................21

2

1. Cautions for safety

Cautions for safety must be kept under any circumstances in order to prevent accident or dangers for safe and

right use.

There are two types of caution in the manual, warning and attention, as below.

Warning

Attention

Symbols in the products and the operation and installation manual indicate as follows.

Indicates that you must be careful for possible danger under certain conditions

Indicates that you must be careful for electric shock under certain conditions.

After reading this operation and installation manual, keep the manual in place that anyone can read it anytime.

Read this operation and installation manual carefully in order to use the functions of DSP series sufficiently and

safely.

Warning

Do not operate when the cover is open.

It could cause electric shock as high voltage terminal or electric charging is exposed outside.

Do not adjust switch when your hands are wet.

It could cause electric shock.

Do not open cover when power is on or in operation.

It could cause electric shock.

Do not open cover even when the power is off except for regular check.

The inverter is still charged even if the power is off due to the long-time charging, which could cause electric

shock.

Shut off the power and wait more than 10 minutes to confirm complete discharging to VOM from

inverter when doing wiring work or regular check.

It could cause electric shock.

Do not use this inverter in the event of damaged wire.

It could cause electric shock.

Do not put any heavy items on the wire.

It could damage insulated wire due to damaged sheath.

It possibly causes serious injury or death when violated.

It possibly causes minor injury or product damages when violated.

3

Attention

Keep away from inflammables.

If installed on or near combustible material, it could cause fire. When there is fire or smell, stop operation

immediately and contact us right away.

Shut off input power (solar cell) and output power (AC power) immediately when the inverter

malfunctions.

Otherwise, it could lead to fire by subsequent accidents.

Do not touch the inverter for about 10 minutes even if the power is off or when the power is on.

The inverter is very hot and it could cause burn on your body.

Do not input power even if you finish installation when the inverter or a part is damaged.

It could cause electric shock.

Be careful not to get any screw, metals, water, oil, etc. inside inverter.

It could cause fire.

Directions forApplication

(1) Transportation

Please transport by proper means according to product weight.

Please check external conditions.

Do not pile up beyond the limited level or height.

Do not open the cover while transported.

Do not drop or damage with shock, as this device is a precision one.

(2) Applications

If auto-operation function is initially set up, it automatically operates when the voltage goes above the start-

up voltage.

You can operate or stop with run/stop key on key pad.

Reset troubled items, and then it automatically operates after waiting time.

Do not remodel at your convenience.

Reset to the required value when initialized, otherwise it automatically reset to the predefined value.

(3) Trouble-shooting

In the event that the inverter gets damaged so that it becomes uncontrollable, the device can be placed in a

dangerous state. In order to prevent such state, install additional safety device such as emergency brake.

(4) Maintenance and Repair

Don’t perform mega-test (for electric insulation and resistance) for inverter control circuit. It could cause

malfunctions or damages.

Refer chapter 6 for detailed Descriptions.

4

(5) Disposal

Dispose as a general industrial waste.

(6) Others

The pictures in this operation and installation manual occasionally drop the cover or breaker in order to

explain in detail, however, you must strictly follow the guidelines in this manual for operation after

installing the cover and breaker.

Directions for Installation

(7) Installation

Follow the instructions in this operation and installation manual.

This product must be installed indoor. or outdoor

Be careful not to install this device at wet, dusty, direct ray of sun light or high temperature place.

In the event of indoor installation, secure the space at least 20cm from the top, bottom, left and right side of

the inverter.

In the event of outdoor installation, secure the space at least 1m from the ground surface.

Installation must be carried out by a technical expert.

Do not place any heavy items on the product.

Do not spray or keep away from any inflammable materials.

Installation direction must be set followed by the guidelines in this manual.

Do not drop or add damage to the inverter, as this device is a précised one.

Do Class 3 grounding work (200V class) for the inverter.

Don’t place other home appliance near this device. Otherwise, a fault or noise of home appliance may

happen.

Always use T-type hanger, and be careful not to be damaged by a sharp part.

Install the circuit breaker of solar cell side (DC) and install the inverter. And then operate this device after

completing the installation and turning on the power of solar cell. If you operate the inverter when the

power of solar cell (DC) is “ON”, a serious damage may happen.

(8) Wiring

If you make wrong connection, damage may happen on the inverter.

Please be careful in the event of wrong connection in the polarities (+/-) of DC power, damage may happen

on the inverter or a serious accident may occur. Refer chapter 3 for detailed Descriptions.

Please be careful of sorting power and ground wire when connecting AC Connecter. Refer chapter 3 for

detailed Descriptions.

The technical expert should carry out the wiring work or check.

After install the inverter body, carry out the wiring work.

(9) Adjustment at the time of commissioning

5

Confirm all setting values prior to operation

2. Product

2.1 General

2.1.1 Contents you should know before using the appliance

If you misuse the inverter, it is operated abnormally or its performance may be depreciated. As the inverter

might be broken or damage might impair the body seriously, use the inverter after understanding the application

or installation manual enough in using the inverter.

2.1.2Appearance of the product

2.1.3 Confirmation of Products

After removing packing, check the regular nameplate on the front body. Also, make sure that the form and rating

power of the inverter correspond to the ordered inverter.

(1)Inverter type

(2) Accessories –Operation & installation manual / input(DC) & output(AC) connectors / T-type hanger

6

2.1.4 Preparation of devices or components for operation

As the preparation for operation may be changed dependent on the installation environment more or less,

prepare necessary materials and parts, i.e. –Multi Tester to check voltage and wiring, gearing tools to install T-

type hanger and etc.

2.1.5 Installation

To prevent the lifetime or performance of the inverter from being depreciated, install the device exactly,

considering its installed position or direction, or peripheral space.

2.1.6 Wiring

Connect solar module input (DC) and grid power (AC) by using connectors . If an accurate connection is not

made, there can be problem in the inverter or peripheral devices and pls. wire carefully.

2.1.7 Construction of Solar Power System

The inverter requires the correction connection under the right selection of peripheral devices. Incorrect system

construction and connection may make the normal operation impossible or cause a serious declination in

lifetime. In the event of worst case, the inverter may be damaged by fire, and use this device in right manner in

accordance with the contents and notices in this manual.

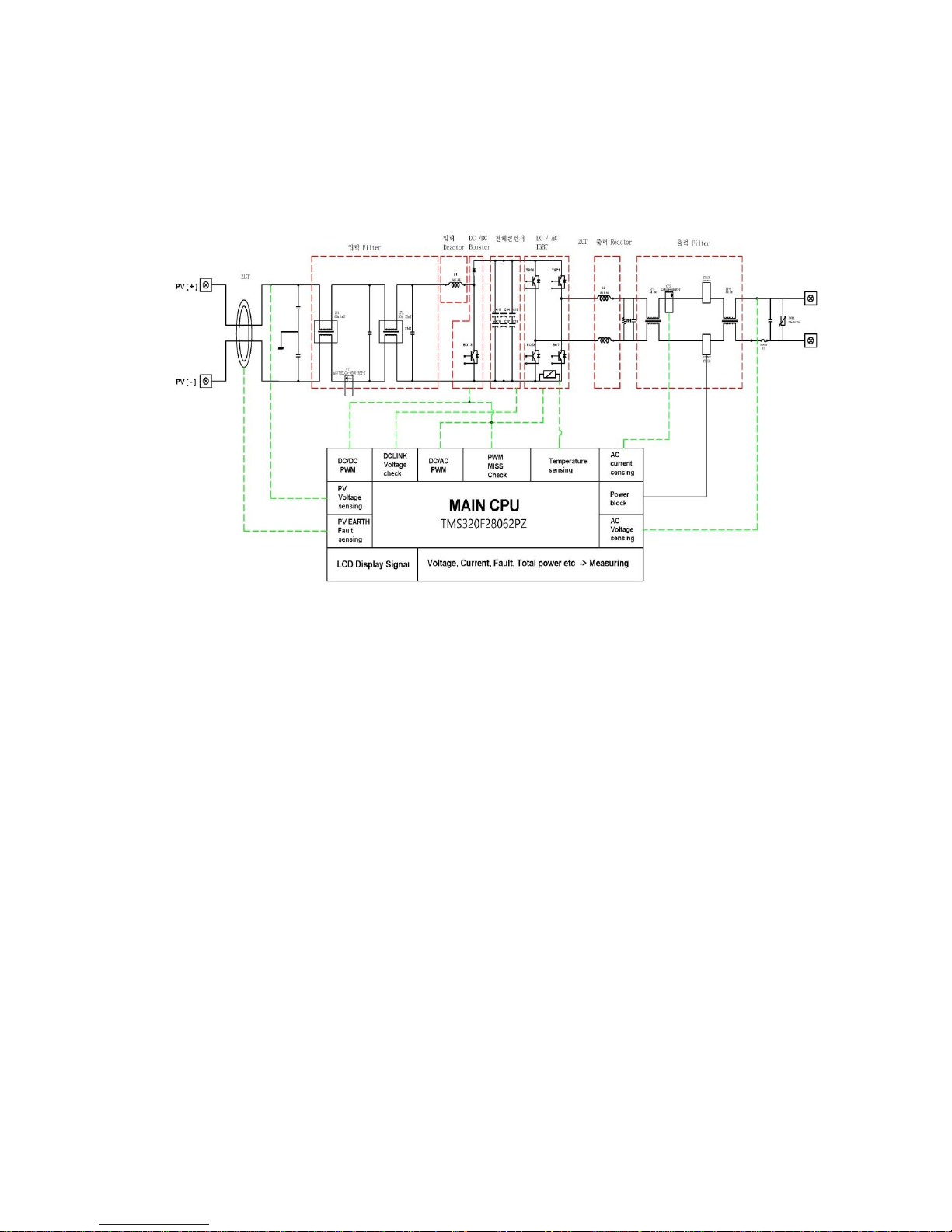

2.1.8 Specific Features of the Product

(1) High Efficiency Power Conversion

The inverter converts the power in a high efficiency using IGBT and has high an efficiency characteristic of

96% or more at rated power.

(2) Digital Control

It’s more convenient to control the system through digital control with high performance. You can check the

system through LCD keypad. LCD screen monitors and indicates the present condition of operation, input

and output and any abnormality of the inverter. And its operation stops in the event of any error. It detects

the voltage of solar cells to operate or stop automatically.

High voltage

distribution line

Low voltage

distribution line

Solar cell array

Interlocked protection device

Cabinet panel

Watt-hour meter

Outdoor switch

PCS(Inverter)

Washing machine

Refrigerator

Load

Air conditioner

Incoming line

Commercial

system

7

(3) Transformer-less circuit

DSP-123K5-OD inverter is of transformer-less type and is suitable for the decentralized power system

designed for industry, building and residential purpose.

(4) Decentralized Power System and Profitability

Photovoltaic power generation is a power generation type which can be installed wherever the sun shines

exists. The decentralized power by unit of building, housing complex and photovoltaic generating plant

enables to use the system economically.

(5) MPPT (Maximum Power Point Tracking)

As the uneven direct current is generated as per ambient temperature, humidity, climate, environment and

radiation for the characteristic of solar cells, the inverter controls the solar cells tracks to maintain the

maximum power point through MPPT.

(6) Easy Parallel Operation

If the capacity of solar cells increases, the inverter can be added and connected for extension of capacity

without any additional equipment.

(7) Convenient Installation and Operation

This product is designed for more easy and safe connection of the solar cells to the system power. Through

frontal LCD keypad, it is designed to display the present condition of converter and you can stop the

operation manually.

(8) High Reliability and Low Noise

The components of the inverter are optimized to reduce the causes for defaults. Especially, the inverter

cooling fan that has a limited mechanical life time is removed to realize high reliability and low noise.

(9) Electromagnetic Compatibility(EMC)

By optimizing Pattern Generation of inverter, inverter is manufactured to be suitable for EMC standard.

(KSC IEC 61000-6-1, KSC IEC 61000-6-3, KSC IEC 61000-6-4)

8

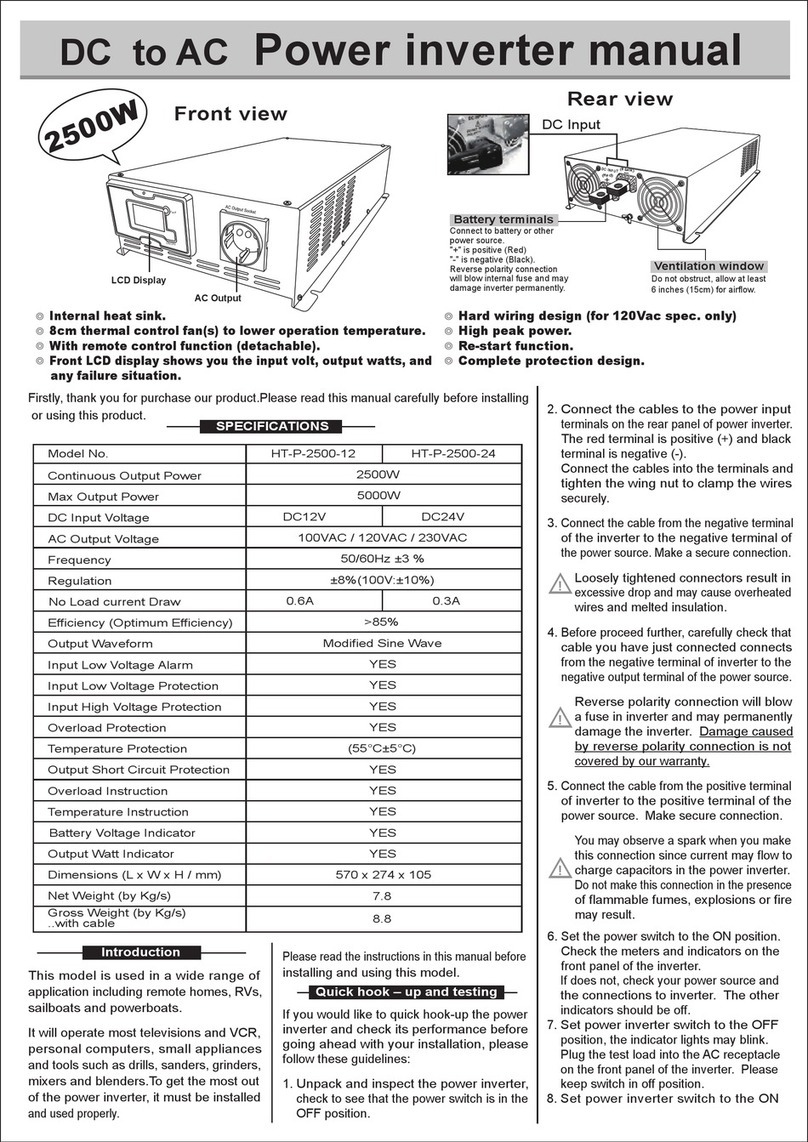

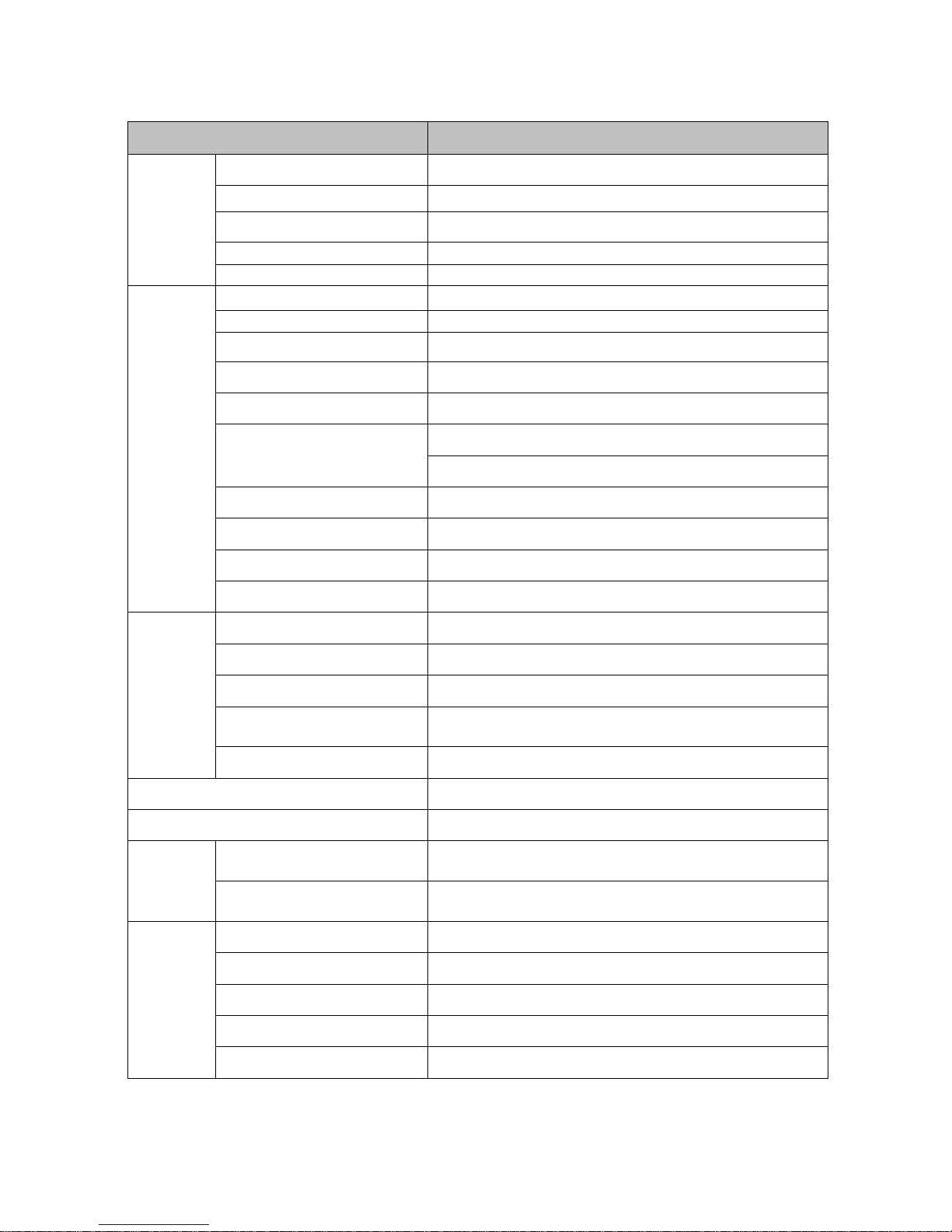

2.2 Specification

Model NO.

DSP-123K5-OD

Input

Voltage range(25 ℃)

100V ~ 500V

MPPT Voltage range(25 ℃)

100V ~ 400V

Rated voltage(25 ℃)

350V

Start voltage(25 ℃)

150V

Control method

Max. Power Point Tracking control(MPPT)

Output

Rated output

3.1 kW

Rated voltage

Grid Voltage (AC 220V +10%/-12%)

Frequency change rate

Grid Frequency (60Hz +0.5Hz/-0.7Hz)

Grid connection

Single Phase 2 Wire

Power factor

0.95 or above

Current distortions

Total below 5%

Individual Harmonics 3% or under

Control method

PWM Method

Anti-islanding

Within 0.5 sec

Overload

110%

Efficiency

97.21% (Maximum) / 96.76% (Euro)

Structure

Cooling method

Natural air cooling

Protection structure

IP 65, Outdoor

Equipment noise

50 dB or less

External dimension

(W x L x H)

305 * 380 * 135.5 mm

Full weight

9.9kg

External interface

RS 485

Monitoring Device(Option)

DSP-WR5/DSP-ZR5(Wire/Wireless, RS485/232)

Protection

Function

Inverter

Input overvoltage, short circuit of output, over-load, overheating,

short of fuse and preventing DC output leakage

System

Anti-islanding(IEEE1547), Over/Under voltage of grid,Over/Under

frequency of grid

Environment

for

Operation

Ambient temperature

-20 ℃~ 50 ℃

Preserving temperature

-20 ℃~ 65 ℃

Ambient humidity

Below 90% RH (Under no Dewfall)

Altitude & vibration

1,000 m or less ·5.9m/sec²(=0.6g) or less

Ambient temperature

Shall be no corrosive gas, flammable gas, oil mist and dust

※Specifications ofthis product may be changed withoutprior notice for qualityimprovement, etc. Please inquiryat the time ofpurchase..

9

3. Installation

3.1 Configuration

1) DSP-123K5-OD

3.2 Installation place

Install the Solar Inverter at the place satisfying following conditions.

1) Do not install the inverter at the place where the vibration exists.

2) As the lifetime of inverter is affected by surrounding temperature, make sure that the surrounding temperature

around the place where the inverter is installed is lower than the allowable temperature (-10 ~ 50℃).

3) Avoid hot and humid place (Relative humidity should be less than 90%. No dewfall).

4) Install the inverter at the place with no direct sun shine.

5) As the inverter is a high temperature unit which generates the heat, it should be installed at the face of non-

flammable material.

6) Secure the sufficient space around the inverter so as to install it for efficient dissipation of the heat.

7) Avoid the place where oil mist, flammable gas, fabric mote, dust and moisture do not exist.

8) Install the inverter by tightening the screws firmly.

9) Install the inverter at the place where no salt exists.

10

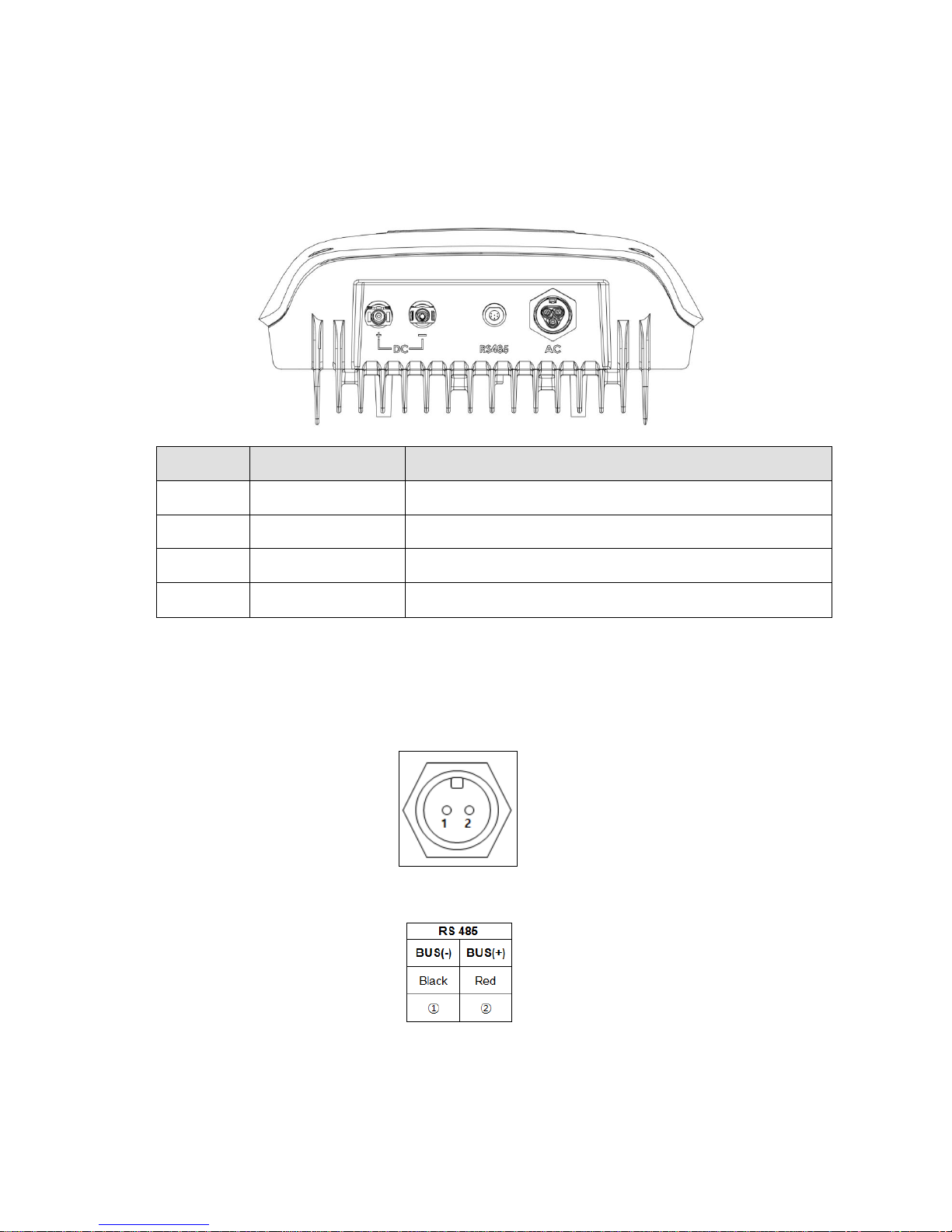

3.3 Terminal connection diagram

If you uncover the cover in front on the lower part of inverter, you can find the terminal blocks as below.

Read carefully this terminal connection diagram for wiring.

1) Description on main circuit terminal

Terminal

symbol

Terminal name

Description on terminals

DC [+]

Solar input power (+)

Connected with (+) of Solar cell power

DC [-]

Solar input power (-)

Connected with (-) of Solar cell power

RS485

Communication

terminal

Connect to signal line of the monitoring system

AC

Grid power connection

terminal

Inverter output is connected to grid power & ground lines

2) Description on RS 485C Communication terminal and connectors.

Communication Output Port:

Communication Connector terminal:

(RS232/485 Communication terminals are connected as shown on the figure above and do not touch the metal part of the connector

(conductor part). It may cause electric shock.)

11

For parallel operation(more than 2 inverters) and using monitoring, 485 communication terminal resistancedddd

ON/OFF switch

3.4 Wiring

3.4.1 Main circuit wiring

1) Cautions for main circuit wiring

For input power, connect the inverter’s inside connector [+] to the inverter’s outside connector [+] and the

inverter inside connector’s [-] to the inverter outside connector [-], then supply power. The inverter might be

damaged by wrong connection.

Do not disconnect the connecter while at power.

Keep in mind that the internal capacitor of the inverter is charged even if the power is off.

To prevent electric shock, the inverter must be earthed. Make sure that the resistance of earth is 100 mΩ or less.

Connect the terminal of the inverter to the exclusive terminal block. Do not use a case or sash screw as an

earth terminal.

For earth wire, use exclusive earth wire complying with the standard. Connect the earth terminal to the spot

adjacent to the inverter. The earth cable must be 4.0mm²or more.

Confirm the maximum input voltage of inverter and output voltage of solar panel. If the output voltage of solar

panel exceeds the maximum input voltage of inverter, the critical damage can occur to the product.

Power

Size of earth cable( mm²)

1.5 ~ 3 kW

4.0

5 kW

6.0

Confirm the maximum input voltage of inverter and output voltage of solar panel. If the output voltage of solar

panel exceeds the maximum input voltage of inverter, the critical damage can occur to the product.

For the wiring of solar panel, check the temperature coefficient to set the output voltage. Otherwise, input

over-voltage or low-voltage of inverter can occur due to the ambient temperature.

485communication

Terminal resistance connection : ON

Terminal resistance release : OFF

12

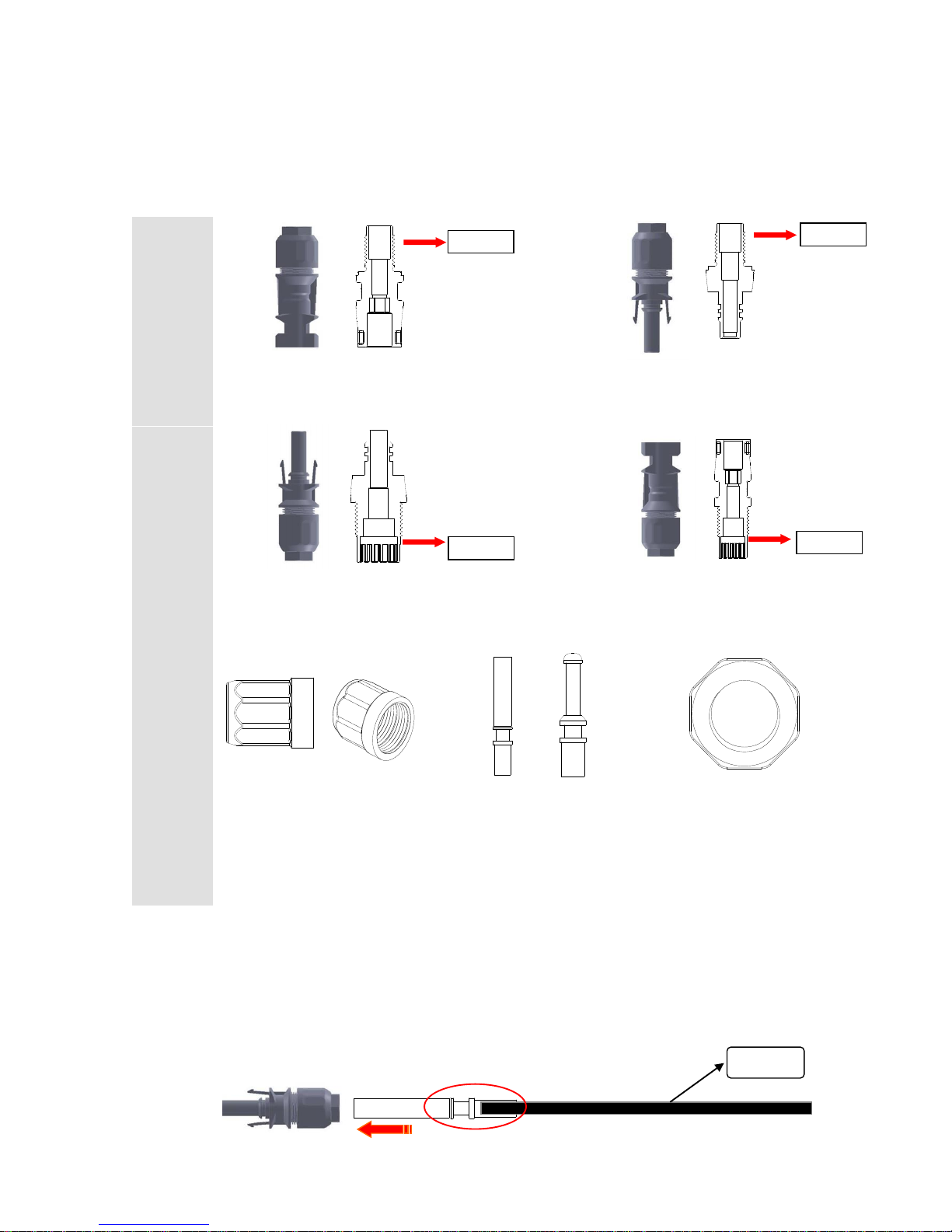

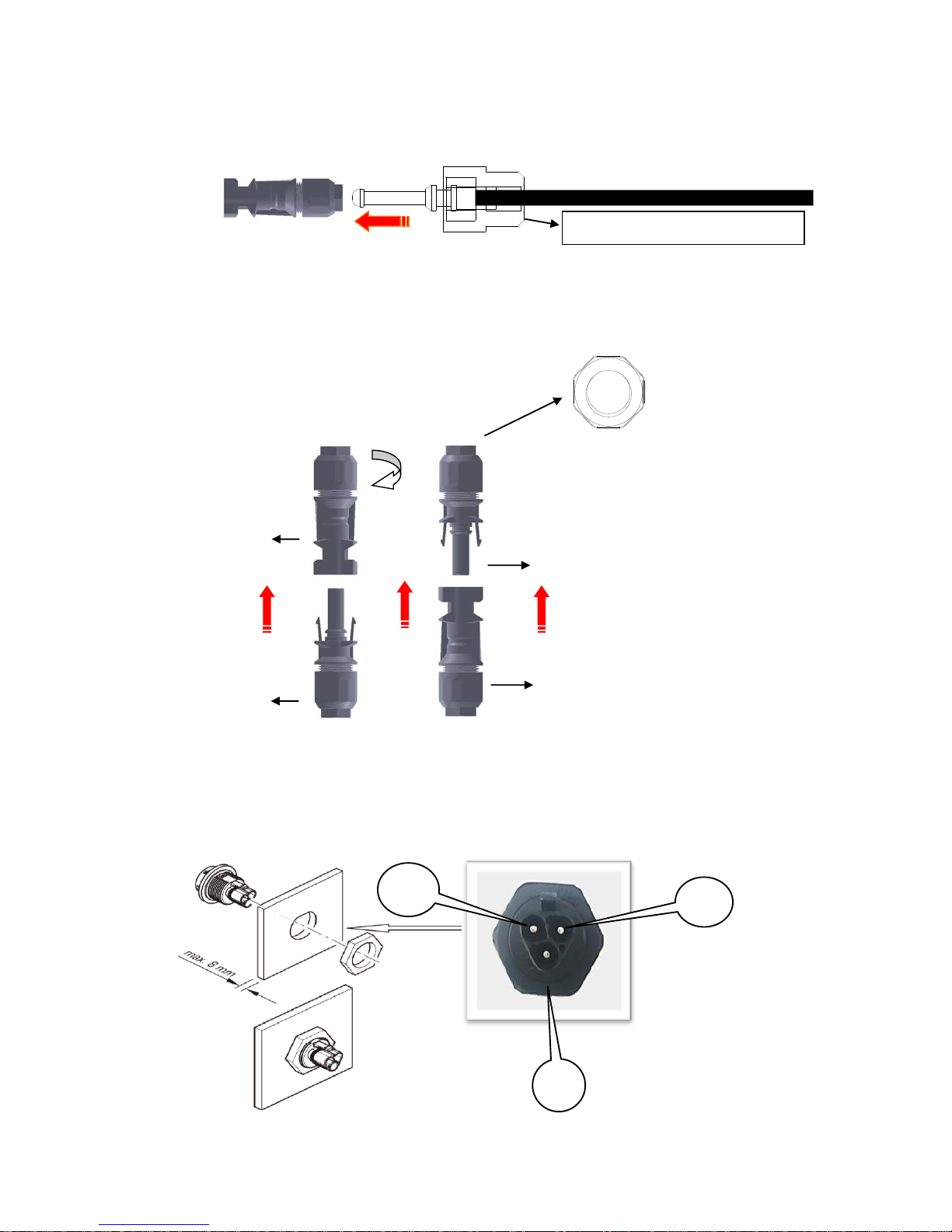

2) Configuration and installation for DC connector

Configuration

Inverter

Inside

Connecter

[ + ] Pole / Inner diagram

[ - ] Pole / Inner diagram

Inverter

Outside

Connecter

( + ) Pole / Inner diagram

( - ) Pole / Inner diagram

①CAP : tightening form when

connecting cable and terminal

④Terminal used when

connecting cable and

connector

⑤Nut to fix the connecter

inside the inverter

※To easily classify Inside Connector and Outside Connector is to check the difference in connection part of rear

cap. When tightening, tighten the same pole shown in the connector.

Installation

Step 1. Coupling method of cable terminal and connector

①Compress cable and terminal

Cable

Terminal

Terminal

Terminal

Terminal

[+]

13

※Terminal coupling method is only connectable with terminal and connector shown above

Step 2. Connection method of connector and inverter

※Notice : Connect only the same polarity shown above [[+] ↔ [+] , [-] ↔ [-]]

2) AC Connector wiring

Connector [+] Terminal

Connector [+] Terminal

Connector [-] Terminal

Turn the nut to be fixed

Nut

Connector [-] Terminal

②Connect the connector to the cable which is connected to terminal

CAP is only used for PV connector

[-]

FG

N

L

14

3.4.2 Communication circuit wiring

1) Notice of the communication circuit wiring

Wiring of Control circuit terminal is to be used for communication connector. See the wiring diagram 3.3.

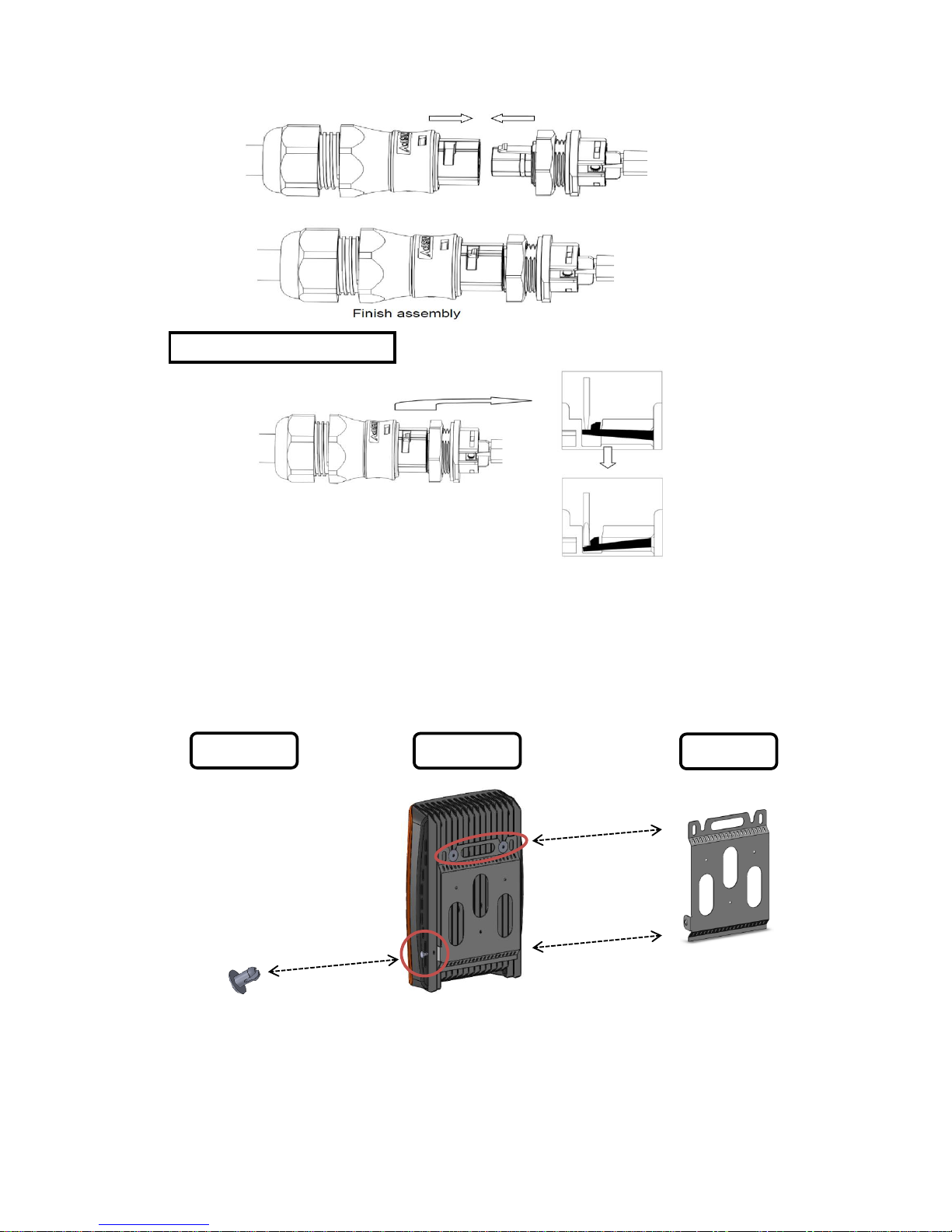

3.5 Cautions for mounting the inverter to the wall

▶Installation ①Remove (press fit) spanner for the inverter by using a tool(like long nose plier)

②Remove Wall BKT from the inverter and mount Wall BKT to the wall

③Install the inverter to Wall BKT and fix it by the (press fit) spanner

Unlocking & Separating

(Press fit)

Spanner

Inverter

Wall BKT

15

4. Operation

4.1 Display

4.1.1Appearance

4.1.2Functions of display

LED Status

Description

Input (입력)

Indicates the input status from solar modules.

(Green light: solar module is in normal operation)

Grid (한전)

Indicates the grid power system status. (Green light : grid power system is normal)

Operation (운전)

Indicates the operation status of the inverter.

(Green light : inverter generation is normal, Red flickering : ‘Fault’)

4.2 Basic mode (2 lines 16 characters LCD)

When the inverter power is ON, information on the LCD is updated every 10 second.

4.2.1 Input power (DC)

Display Input voltage Input current

PV: solar module D.C voltage D.C current

▶▶▶▶▶▶▶▶▶▶ Present power generated

4.2.2 Grid power input

Display Grid frequency Grid current

Line : grid frequency grid current

▶▶▶▶▶▶▶▶▶▶ Grid voltage

→PV 412V 7.7 A

▶▶▶▶▶▶▶▶▶▶ 3.1 kW

→LINE 50Hz 14.1A

▶▶▶▶▶▶▶▶▶▶ 230.0 V

16

4.2.3 Total generated power

Display Unit

Total : total generated power kWh

▶▶▶▶▶▶▶▶▶▶ Present power generated

4.2.4 Maximum(Peak) generated power

Display Unit

Peak : maximum generation kW

▶▶▶▶▶▶▶▶▶▶ Present power generated

4.2.5 Daily(today) generated power

Display Unit

Today : today’s generated power Wh

▶▶▶▶▶▶▶▶▶▶ Present power generated

4.2.6 Daily (previous day) generated power

Display Unit

DAY-1 : previous day’s generated power Wh

▶▶▶▶▶▶▶▶▶▶ Present power generated

4.2.7 Present power generated

Display Unit

RUN : operation status kW

▶▶▶▶▶▶▶▶▶▶ Generated power(%)

→Total 500 kWh

▶▶▶▶▶▶▶▶▶▶ 3.1 kW

→Peak 3.1 kW

▶▶▶▶▶▶▶▶▶▶ 3.0 kW

→TODAY 1000 Wh

▶▶▶▶▶▶▶▶▶▶ 3.1 kW

→DAY-1 1500 Wh

▶▶▶▶▶▶▶▶▶▶ 3.1 kW

→RUN 3.1kW

▶▶▶▶▶▶▶▶▶▶ 97.2%

17

4.2.8 Fault status (Displayed for 5 seconds)

Display Type of error

Fault number : number of times

Fault status

4.3 Operation method

4.3.1 Check points prior to operation

-. Check the wiring and installation status of the inverter.

-. Especially, check that input polarity of solar module has been connected correctly and the line to grid has

been connected correctly.

-. Direct power of solar panel is supplied to the inverter and AC power status is checked, then the inverter

operates automatically after 300 seconds

(If necessary, a DC circuit breaker can be installed outside the inverter)

4.3.2 Automatic operation

The inverter is set to auto-operation mode as default setting when shipped from the factory.

The inverter operates automatically when the voltage of the solar panel is over setting value after sunrise and the

inverter stops automatically when voltage of the solar panel is under setting value after sunset.

The inverter always monitors the grid power and it stops automatically in abnormal status.

5. Function

5.1 Descriptions

5.1.1 Grid monitoring

Whether the system voltage is normal or abnormal is determined by the difference from the normal voltage (Fault

high voltage, Fault low voltage), and if this value is higher or lower than the specified value, it stops the inverter.

If the frequency of system voltage is off the line frequency by line fault frequency, it stops the inverter’s operation.

In order to start the generation at the normal system status, it operates with the system after the line transition time

elapses. Frequency of used system voltage can be set in accordance with the frequency band.

5.1.2 MPPT control and total power generation

As the output of solar panel varies on surrounding temperature, humidity and solar ray intensity, MPPT

(Maximum Power Point Tracking) algorithm should be carried out smoothly. The method applied to this product

does not show the fluctuation in current, and it stops the inverter when the solar cells reach the PV stop voltage

and the inverter cannot be operated anymore.

[001] E008

Under Voltage

18

As the accumulated total power is stored, total generation power can be checked.

5.1.3 Initialization and action for abnormality

In case the inverter stops due to any errors, error indication is shown on the screen. At this time, examine the

reason why any error occurs, remove the fault cause and then re-run the inverter. When the same problem

happens or the inverter does not re-run, you should contact Dass tech or Installer.

Fault scan is stored 100 in the order in which they were generated in the past from 0 to 99 and the most recent

one is No. 0. By using the Up/Down key on the keypad inside the inverter, it is able to find out the situations of

the fault occurrences from the past or variables.

When the inverter is stopped, it is able to change the parametric value by using the inner keypad.

There are two initializations, which is Parameter initialization and Fault initialization. Parameter initialization

sets every parameter or selection function to the Factory Default, and Fault initialization deletes the fault records

occurred in the past and sets to ‘ready’mode.

Controlling the inner keypad randomly shall cause malfunction of the inverter. You should contact DASS tech..

5.1.4 Fault

1) Fault

Input Overvoltage (DC OV)

In case the voltage of solar cells is higher than the specified value, stop the system to protect the inverter.

Output Over-current (Over current)

In case the output current of the inverter is over-current due to abnormal load status, stop the system to protect

the inverter.

Inverter Overheat (Over heat)

In case the temperature inside the inverter is higher than 95℃, stop the system to prevent overheat. If the

temperature inside the inverter returns to normal, operate the inverter normally after reset.

Earth fault

In case the current leaks due to abnormal earth, stop the system.

Line failure (Over/Under frequency, Over/Under voltage)

When abnormality occurs in the grid power, stop the system. (Anti-islanding, protection of system over/under-

voltage, protection of system low voltage, protection of system over/under-frequency, protection of system low-

frequency)

Abnormal PWM control (Over current 2)

If there is abnormal status found in PWM control inside the inverter, stop the system

19

6. Maintenance & repair

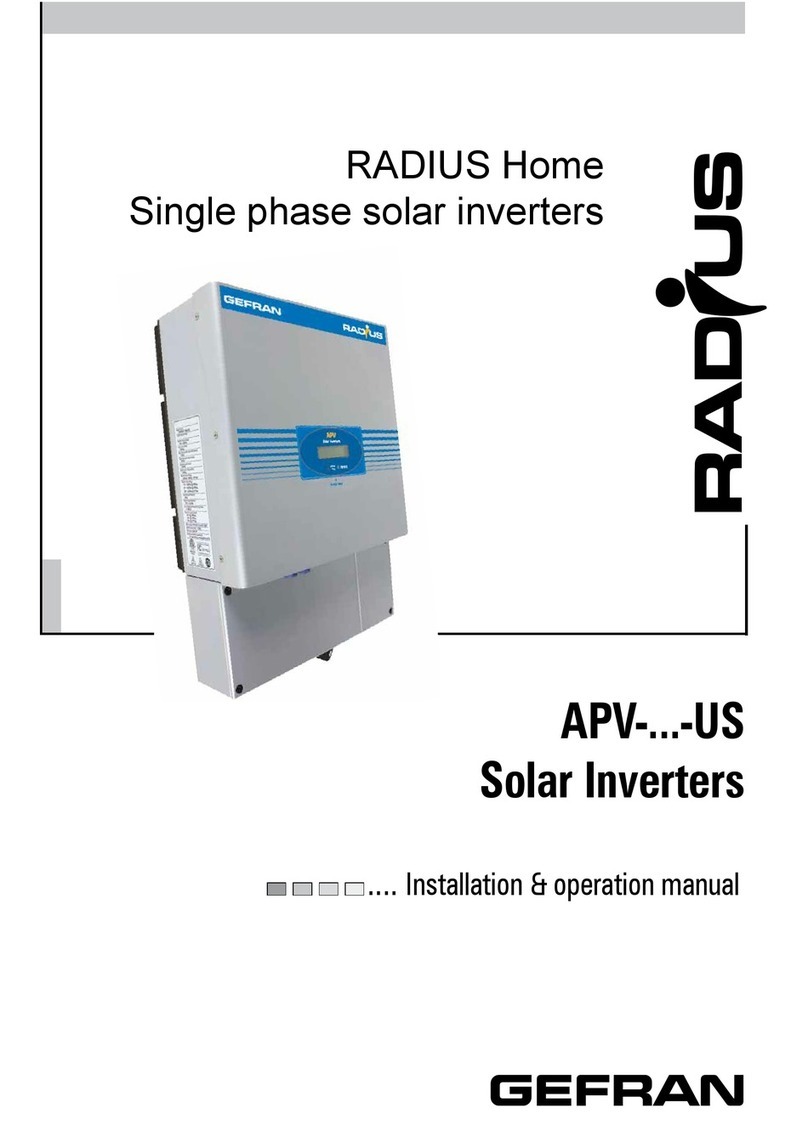

6.1 Types of error

If any error occurs, it indicates such error and stops operation.

When abnormal, its contents are displayed on the window of the keypad.

Causes of faults and corrective actions

Fault

Code

Type

Indication

Causes of errors

Corrective actions

E001

Input

Over-current

PV Error

Over current from solar module

Check the solar module then operate the inverter.

If the problem isn’t solved, contact us.

E002

Input

Over-voltage

DC OV

Over voltage from solar module

Check the solar module then operate the inverter.

If the problem isn’t solved, contact us.

E004

Input

DC-LINK

Over-voltage

DC-Link OV

Over voltage from DC-LINK of

the inverter

Check the solar module then operate the inverter.

If the problem isn’t solved, contact us.

E005

Input

DC-LINK

Under-voltage

DC-Link UV

Under voltage from DC-LINK

of the inverter

Check the solar module then operate the inverter.

If the problem isn’t solved, contact us.

E006

Grid

Over-current

Over Current

Over current in grid output

Check grid status and contact your electricity authority.

Then if the problem isn’t solved, contact us

E007

Grid

Over-voltage

Over voltage

Abnormal grid voltage

Check grid status and contact your electricity authority.

Then if the problem isn’t solved, contact us

E008

Grid

Under-voltage

Under voltage

Abnormal grid voltage

Check grid status and contact your electricity authority.

Then if the problem isn’t solved, contact us

E010

Grid

Over-frequency

Over

frequency

Abnormal grid frequency

Check grid status and contact your electricity authority.

Then if the problem isn’t solved, contact us

E011

Grid

Under-frequency

Under

frequency

Abnormal grid frequency

Check grid status and contact your electricity authority.

Then if the problem isn’t solved, contact us

E019

PWM fault

(Input)

Over

Current 2

Inverter’s internal problem

Contact us immediately

E020

PWM fault

(Output)

Over

Current 2

Inverter’s internal problem

Contact us immediately

E022

Over heating

Over

heat

Inverter’s over heating

Pls. try to operate inverter and if the problem isn’t solved,

pls. contact us immediately

E023

Earth fault

(DC)

Earth fault

Leakage of current

(Short circuit status)

Check earth and insulation status then, if the problem isn’t

solved, contact us.

E030

Consecutive fault

Cont. fault

Same fault happens

consecutively

Pls. try to operate inverter and if the problem isn’t solved,

pls. contact us immediately

Table of contents

Other Dass Inverter manuals

Popular Inverter manuals by other brands

gefran

gefran RADIUS APV 1700-2M-TL-US Installation & operation manual

Deye

Deye SUN-6K-SG03LP1-EU user manual

Western

Western Leonardo Off-Grid 4kW-5000-48 MG user manual

Wagan

Wagan Smart AC user manual

Rinnai

Rinnai EVT20A Operation & installation manual

Black & Decker

Black & Decker MAXX SST instruction manual