Dass Soleaf DSP-123JB-OD Instruction Manual

DASSTECH Photovoltaic

Grid-Connected Inverter/

Junction Box

DSP-123K6-OD ver1.3

DSP-123JB-OD ver1.1

Operation and Installation Manual

1

Table of Contents

1. Safety precautions .....................................................................................................................2

2. Product overview.........................................................................................................................5

2.1 Basic issues......................................................................................................................5

2.2 Product specifications.....................................................................................................8

3.

Installation.......................................................................................................................................9

3.1 Block diagram……………………......................................................................................9

3.2 Installation location..........................................................................................................9

3.3 Wiring diagram for connecting terminal......................................................................10

3.4 Wiring...............................................................................................................................11

4. Operation....................................................................................................................................14

4.1 Explanation on functions of display window ..............................................................14

4.2 Display mode for basic status ......................................................................................15

4.3 Operating method...........................................................................................................17

5. Functions...................................................................................................................................17

5.1 Explanations on functions.............................................................................................17

6. Explanations on junction box..................................................................................................19

6.1 Basic specifications.......................................................................................................19

6.2 Components block diagram and names......................................................................19

6.3 Precautions in wiring.....................................................................................................20

7. Maintenance...............................................................................................................................22

7.1 Symptoms of breakdown..............................................................................................22

7.2 Repairing breakdowns...................................................................................................22

8. Quality assurance ....................................................................................................................23

8.1 Warranty.........................................................................................................................23

8.2 Warranty.........................................................................................................................24

2

1. Safety precautions

Make sure to adhere to the safety precautions since they are aimed at safe and proper use of the product by

preventing accidents or hazards in advance.

Precautions are classified into ‘Warning’and ‘Caution’with the following meanings:

Warning: Situations with possibility of occurrence of serious injuries or death if

the instructions are violated

Caution: Situations with possibility of occurrence of minor injuries or product

damage if the instructions are violated

Meanings of pictograms use in the product, and User and Installation Manual are as follows:

is a sign to take precaution since there is concern for occurrence of risks under particular

conditions.

is a sign to take precaution since there is concern for occurrence of electrocution under

particular conditions.

After having read the User and Installation Manual, keep it at a location that can be accessed by all the

users at any time.

Make sure to sufficiently familiarize with the contents of User and Installation Manual in order to

sufficiently and safely use all the functions of DSP series inverter.

Warning

Do not operate while the front cover is opened.

It becomes a cause of electrocution due to the exposure of high voltage terminal or charging section.

Do not manipulate switch with wet hand.

It becomes a cause of electrocution.

Do not open the cover while power is turned on or during operation.

It becomes a cause of electrocution.

Even if power has not been turned on, do not open the front cover except in the event

of regular inspection.

It becomes a cause of electrocution since voltage has been charged over prolonged period of time

inside the inverter even if the power has been turned off.

Turn off the power at the time of wiring work or regular inspection, and make sure to

check that the DC voltage in the inverter has been fully discharged with measuring

device such as multi-tester (VOM), etc. after 10 minutes.

It becomes a cause of electrocution.

Do not use if the sheathing on cable has been damaged.

It becomes a cause of electrocution.

Do not use while heavy objects that impart excessive stress is placed on the electric

cable.

It becomes a cause of electrocution due to damages to the sheathing on cable.

3

Caution

Do not install in close vicinity of inflammable substance.

It becomes a cause of fire if installed onto or attached close to combustible material.

Cut off the inverter input (solar cell) and output (AC system) power in the event of

inverter breakdown.

If it is not cut off, fire can breakout due to secondary accident.

Do not touch inverter for several minutes while the power is connected or cut off.

It becomes a cause of burn if it comes in contact with human body since it is very hot.

Do not input power into inverter with damaged product and components even if

installation is completed.

It becomes a cause of electrocution.

Make sure foreign matters including screw, metallic substance, water and oil do not

enter inverter.

It becomes a cause of fire.

Precautions in use

(1) Transportation

Transfer in proper method in accordance with the weight of the product.

Check for any abnormalities in the outer appearance of the product.

Do not pile up in multiple layers in excess of the stipulated regulation.

Do not open the front cover during product transportation

Do not drop or impart strong impact to the inverter since it is a precision device.

(2) Application method

If the automatic operation functions is set at basic value, it operates automatically if the operating

voltage is exceeded and stops automatically if the voltage falls below the operating voltage.

It can be started and stopped with Operation/Stop key on the keypad.

Since the inverter will be reinitiated after prescribed standard by time if the breakdown contents

are reset, manipulate the breakdown reset switch after having assessed the cause.

Do not remodel the internal aspects of the product.

In the case of initializing the parameter, set the parameter necessary prior to operation again. If

the parameter is initialized, the parameter values will be changed to those set at the time of

shipment from factory.

(3) Measures to prevent occurrence of abnormality

If the inverter becomes destroyed and uncontrollable, there are cases in which the mechanical

device is left unattended in hazardous situation. In order to prevent such situation, install additional

safety device such as circuit breaker, etc.

(4) Repair inspection and component replacement

Do not conduct meg-test (measurement of insulation resistance) for the control circuit of inverter.

Refer to Chapter 6 for inspection.

(5) Discard

Discard as ordinary industrial waste.

4

(6) General issues

Although there are portions of explanation with missing front cover or circuit breaker in the

pictorial explanation indicated in this User and Installation Manual for more detailed explanation,

make sure to operate the product in accordance with the User and Installation Manual after

having installed the front cover and circuit breaker, etc. according to the relevant regulations.

Precautions in installation

(7) Installation

Install in accordance with the contents of the User and Installation Manual.

This product can be installed indoor and outdoor.

Install product within 30m from solar cell panel.

Install in location without humidity or dust, and away from direct sunlight and sections that

generate high heat.

At the time of indoor installation, make sure to secure space of more than 20cm above, left and

right of the inverter.

At the time of outdoor installation, make sure to secure space of more than 1m from the ground.

Installation work must be performed by specialist or technician.

Do not place heavy objects on top of the product.

Do not spray on or keep this product near inflammable substances.

Please comply with the standards indicated in the User Manual for the installation direction.

Do not drop or impart strong impact onto the inverter since it is a precision device.

Execute class 3 (200V class) grounding for inverter.

Do not use other household appliances in close vicinity of this product. Abnormality or noise can

be made in the household appliances.

Make sure to use the rack provided for exclusive use of the product and take precautions against

sharp parts in the rack.

Prior to installing the inverter, install solar cell power (DC) circuit breaker and install the inverter

while the solar cell power is turned OFF. After the installation, turn the solar cell power ON for

operation. If the inverter is installed while the solar cell power (DC) is ON, there is a concern that

inverter may be damaged or operate erroneously.

(8) Wiring

Erroneous terminal contact can become a cause of inverter breakage.

At the time of connecting the DC connector, pay attention to the (+/-) electrodes. Refer to the

installation method in Chapter 3.

At the time of connecting AC connector, pay attention to the distinction between power and

grounding cables. Refer to the installation method in Chapter 3.

Wiring and inspection must be performed by specialist or technician.

After having installed the main body of the inverter, execute wiring works (connect connectors).

(9) Adjustment at the time of trial run

Check various set values prior to operation.

5

2. Product overview

2.1 Basic issues

2.1.1 Contents you need to be aware prior to the use

If inverter is used erroneously, it may not operate normally or its lifespan may be shortened. In the

worst case, inverter can be broken or impart fatal injuries to human body. As such, sufficiently

understand the contents of this User and Installation Manual before using this product.

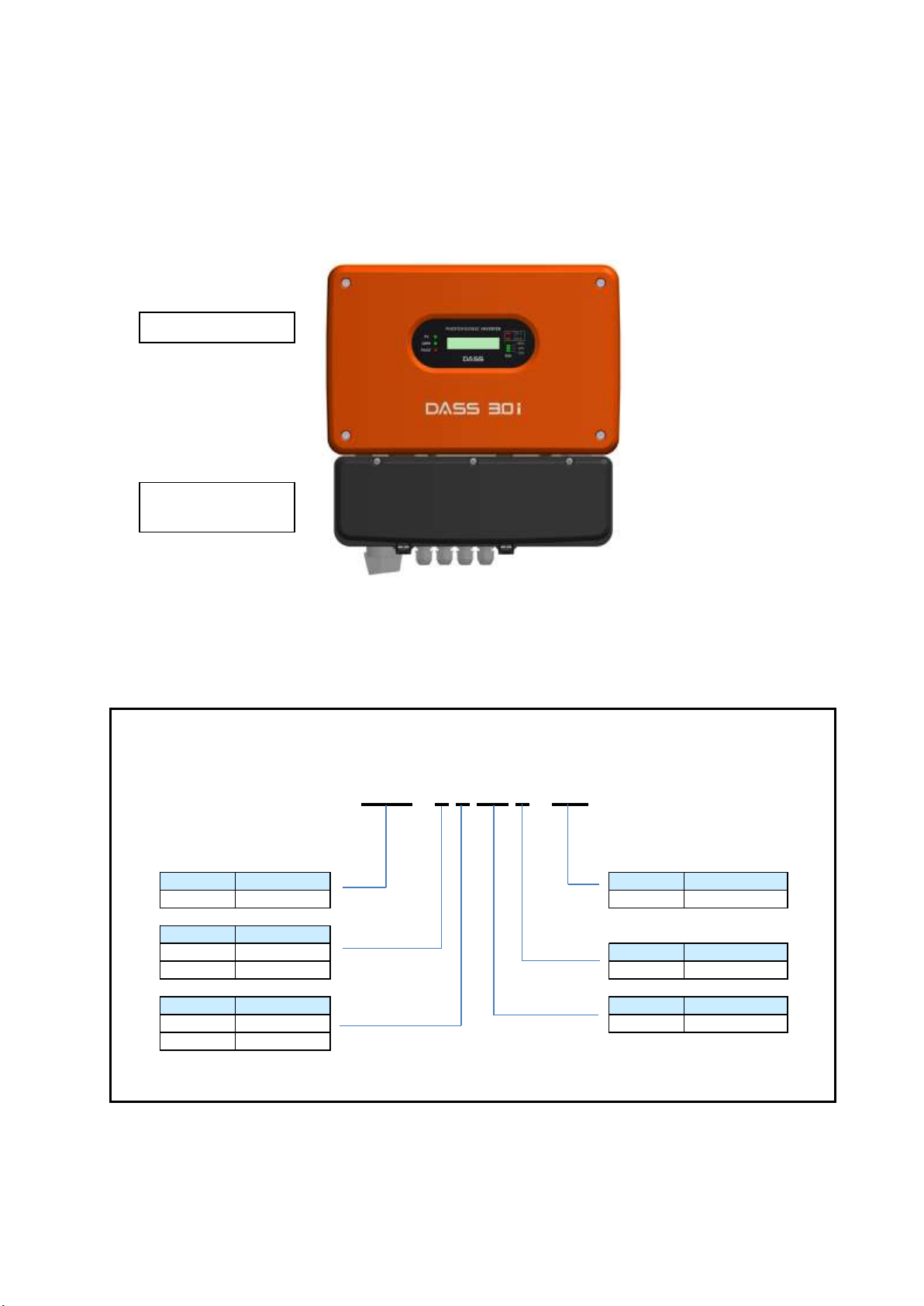

2.1.2 External appearance of the product

2.1.3 Check the product

After having taken the inverter out of the packaging box, inspect the nameplate on the lateral side of

the main body to check the format and rated output of the inverter is the same as those of the product

you ordered. In addition, check for any breakage during delivery.

(1) Inverter types

(2) Components –Please contact our company if there are any components missing including User

and Installation Manual, output (AC) connector, installation rack and components for

fixation at the time of installation, etc., and if there is any breakage in the product.

Code

Name

Type

DSP

DASS Tech.

OD

Outdoor type

Phase

1

Single phase

Type

2

Three phase

6

Series No.

AC voltage

AC voltage

2

220V

3K

3kW

3

380V

DSP

-

1

2

3K

6

-

OD

Code

Code

Code

Code

Code

Inverter section

Junction box

section

6

2.1.4 Preparation of device and components necessary for operation

Since there are some differences in the items to be prepared for operation, prepare components

according to the need (example: multi-tester for checking voltage and wiring, and motorized tools for

installation rack installation, etc.)

2.1.5 Installation

Accurately install the inverter in a location without direct sunlight with considerations for the location

and direction of the installation as well as the surrounding spaces in order to prevent degradation of

the lifespan or performances of the inverter.

2.1.6 Wiring

Connect the solar cell power (DC) and system power (AC) by using terminal block and connector. If

not connected accurately, inverter and surrounding devices can suffer breakage. As such, wire with

caution.

2.1.7 Photovoltaic system composition

Proper contact is needed for the inverter under proper setting of the peripheral devices. Erroneous

system composition and contact can make normal operation impossible or result in substantial

degradation of lifespan. In the worst case, inverter can be damaged due to fire. As such, use the

inverter properly in accordance with the instructions of this Manual and precautions.

High Voltage

distribution line

Commercial System

Low Voltage

distribution line

Lead-in line

Solar cell arrey

Watt-hour

meter

Outdoor

switch

PCS

(Inverter)

Grid

Protection

device

Load

Load

Load

Distribution

panel

7

2.1.8 Product features

(1) High efficiency power conversion

It achieves highly efficient power conversion in PWM format by using IGBT semiconductor device

with high efficiency of more than 96% of the rated output.

(2) Digital control

System control is more convenient through the use of high-performance digital controller that

allows confirmation through LCD keypad. Moreover, operation, input and output status, and

abnormality of inverter are monitored and indicated, and inverter will be stopped in the event of

occurrence of abnormality. It also gets operated and stopped automatically by detecting the

voltage of solar cell module.

(3) Transformerless inverter

DSP-123K6-OD inverter is a transformerless type solar cell inverter appropriate for dispersion

type power system designed to be appropriate for industrial, building and household uses.

(4) Dispersion power system and economic value

Since solar power generation uses power generation format that can be installed at anywhere with

sunlight, it is a format that can achieve economic use due to its ability to establish dispersed

power in the units of building or residence and solar power generation plant.

(5) Maximum Power Point Tracking (MPPT) control

Since occurrence of direct current that is not uniform in accordance with the temperature, humidity,

climate, environment and insolation given the output characteristics of solar cells, inverter controls

the solar cell modules to maintain the maximum power point through MPPT control.

(6) Ease of parallel operation

If the capacity of solar cell module increases, it is possible to easily connect additional inverter in

parallel to increase the capacity without the need of separate additional equipment.

(7) Convenience of installation and operation

It is designed to allow easy and safe connection between solar cell and system power by using

dedicated connector. It is also designed to indicate the status of inverter through the frontal LCD

keypad in real time. In addition, installation is more convenient than the separate connection-board

installation method since it is in integrated junction box format.

(8) High reliability and low noise

Factors that induce defectiveness were reduced by optimizing the inverter components and, in

particular, high reliability and low noise were realized by removing inverter-cooling fan with

mechanical lifespan.

(9) Electromagnetic conformity (EMC)

It was manufactured to be appropriate for household electromagnetic conformity (EMC) by

optimizing the inverter power circuit design (KSC IEC 61000-6-1, KSC IEC 61000-6-3, KSC IEC

61000-6-4).

8

2.2 Product specifications

Model name

DSP - 123K6-OD

Input

Range of operating

voltage (25℃)

100V ~ 500V

Operating MPPT

voltage range (25℃)

200V ~ 400V

Rated voltage (25℃)

360V

Operation initiation

voltage (25℃)

150V

Maximum input

current (25℃)

18A

Output

Rated output capacity

3.5 kW

Rated voltage

System voltage (AC 220/230V +10%/-12%)

Frequency modulation

rate

System frequency (50/60Hz +0.5Hz/-0.7Hz)

Constant

Single phase and 2 lines

Power factor

0.95 abnormality

Current distortion

power (current THD)

Less than 5% of total

Less than 3% of each difference

Control format

PWM format

Prevention of single

operation

Within 0.5 seconds

Efficiency

96% abnormality

Structure

Cooling method

Natural air cooling

Protection structure

IP 65

Device noise

Less than 50 dB

External dimension

358*376*150 mm

Total weight

9kg

External interface

RS485

Monitoring terminal unit (Option)

DSP-WR5/DSP-ZR5/CM-04A001 (wired/wireless, RS485)

Protection

functions

Inverter

Excessive input voltage, output short circuit, overload, inverter

overheating protection, and prevention of DC output discharge

System

Single operation protection, system over-voltage and under-

voltage protection, and system over-frequency and under-

frequency protection

Application

environment

Ambient temperature

-20℃~ 50℃

Preservation

temperature

-20℃~ 65℃

Ambient humidity

Relative humidity (RH) of less than 90% (absence of dew

formation)

Vibration at elevation

Less than 5.9m/sec²(=0.6g) at under 1,000m

Ambient environment

There must be no corrosive gas, inflammable gas, oil mist and

dust, etc.

※Specifications of this product can change without prior notice for reasons such as improvement of quality. Please

inquire at the time of product purchase.

9

3. Installation

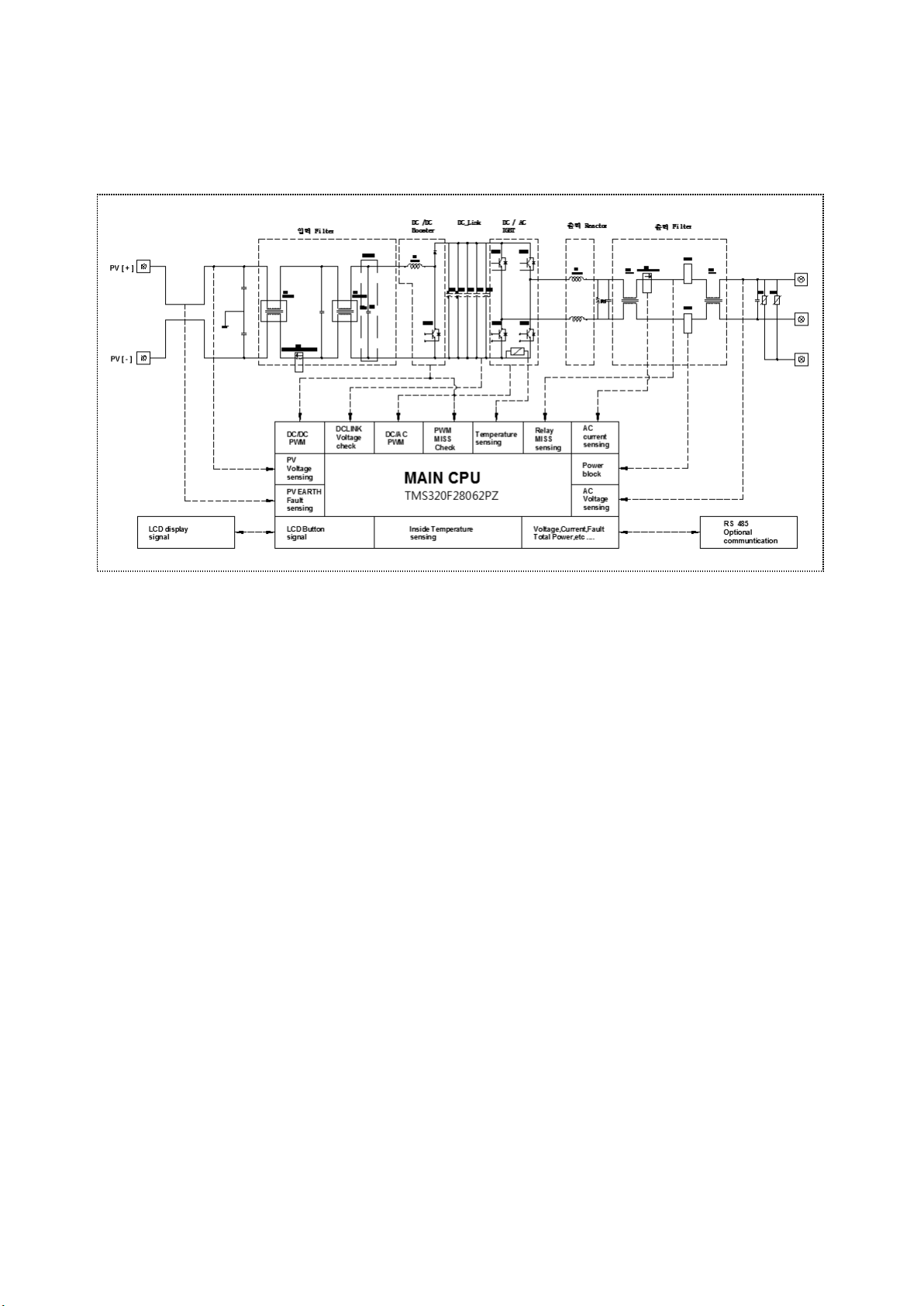

3.1 Block diagram

1) DSP-123K6-OD

※Sections marked with broken line indicate the inner aspect of the inverter.

3.2 Installation location

Please install at a location that satisfied the following conditions.

1) Please install at a location without direct sunlight.

2) Do not install at a location with vibration.

3) Since the inverter lifespan is greatly affected by the surrounding temperature, make sure that the

temperature in the area of installation does not exceed the allowed temperature range (-20 ~ 50℃).

4) Avoid location with high temperature and humidity (less than relative humidity of 90% and absence of

dew formation).

5) Since inverter generates high level of heat, make sure to install it on surface with non-flammable

material.

6) Install the inverter by securing sufficient space around it to allow harmonious dispersion of heat.

7) Avoid location with oil mist, inflammable gas, fibrous dust, dust and moisture, etc.

8) Install it erect by firmly securing with bolts.

9) Install at a location without salinity. (In particular, if it is installed in seacoast, corrosion of the product

can occur. As such, avoid the product coming in contact with salinity in the methods such as use of

separate casing or indoor installation, etc.)

10

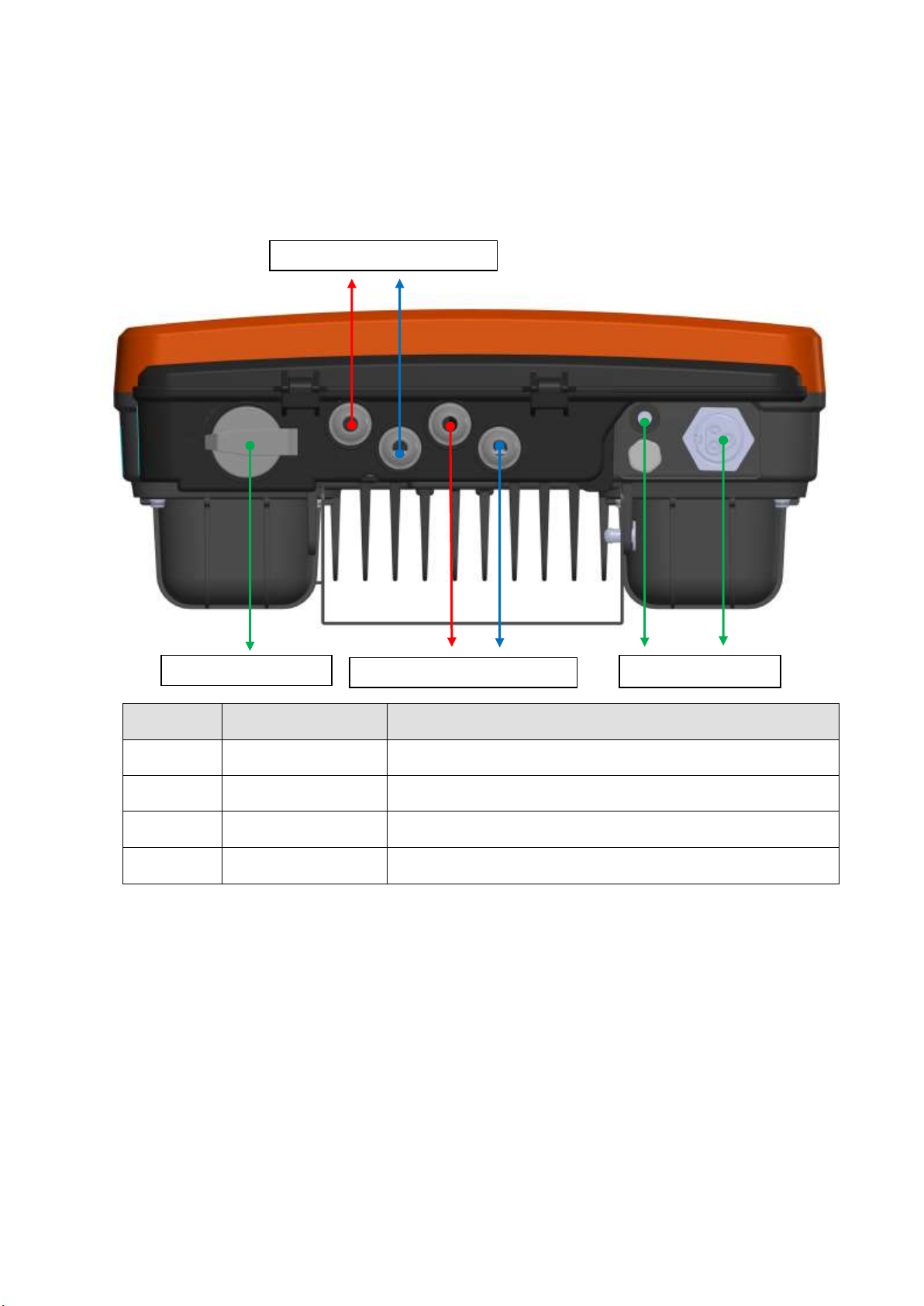

3.3 Wiring diagram for connecting terminal

Section for connection with the connector is situated at the bottom of the inverter.

Read the terminal-wiring diagram carefully before connecting the connector.

1) Explanations on the main circuit connecting terminal section

Terminal

signs

Terminal names

Explanations

DC [+]

PV input power (+)

Connect with the (+) terminal of the output power of solar cell

DC [-]

PV input power (-)

Connect with (-) terminal of output power of solar cell

RS485

Communication

terminal

Connect with the signal line of monitoring system

AC

System power

connection terminal

Output from the inverter is connected to the KEPCO system

and grounding line.

Note) Refer to 6. Explanations on connection board for more details

CH1 DC(+) CH1 DC(-)

RS485 AC

CH2 DC(+) CH2 DC(-)

DC Switch

11

2) Explanations on RS485C communication terminal and connector

Communication output terminal (inside the inverter):

RS485

Communication

BUS(+)

BUS(-)

Red

Black

①

②

Communication connector terminal (outside the inverter):

R485 communication terminal is designed as above.

Communication connector is an optional item. Please inquire with our company if you need

communication connection.

3) Setting of communication protocol

This product supports 2 different communication protocol modes, namely, Dass Tech protocol and

integrated new renewable energy convergence support monitoring system (REMS).

The basic value is set at integrated new renewable energy convergence support monitoring system

(REMS) at the time of shipping from the factory. ID is set at ‘1’as the basic value.

There is a need to change the communication protocol setting at the time of using Dass Tech protocol.

After having accessed Setting menu - Selection Set –REMS Monitor menu, change the set value to

Disable and save with Enter key. Then, cut off the input power to and discharge inverter prior to

reconnecting the power to convert to Dass Tech protocol.

3.4 Wiring

3.4.1 Main circuit wiring

1) Precautions at the time of wiring the main circuit

For input power, connect the CH1/CH2(+)terminal of solar cell panel to the internal

PV1(+)/PV2(+) terminal inside the junction box and CH1/CH2(-)terminal of solar cell panel to

the PV1(-)/PV2(-)terminal inside the junction box before inputting power.

Take precaution against loss due to fire arising from erroneous wiring of the junction box.

Do not disassemble connector during operation.

In the event of emergency power OFF during operation, turn OFF the DC switch of junction box.

12

In the event of altering wiring due to occurrence of incongruity, make sure that the LCD on the

keypad of the main body is turned off prior to conducting rewiring work. Since the internal capacitor

of inverter is charged at high voltage immediately after the power has been turned off. As such, take

precaution against danger of electrocution.

For prevention of electrocution, make sure to execute Class 3 grounding for the inverter and keep

the grounding resistance to less than 100Ω.

For grounding of inverter, connect to the dedicated grounding terminal. Do not use casing or bracket

screw as grounding terminal.

Use dedicated grounding cable. Use the grounding point as near to the inverter as possible. Use

grounding cable with the following thickness by maintaining the length as short as possible.

Capacity

Ground cable thickness (mm²)

1.5 ~ 3.5 kW

4.0

5 kW

6.0

Check the maximum input voltage of inverter and output voltage of solar cell array. If the output

voltage of solar cell array exceeds the maximum input voltage of inverter, it could result in severe

damage of the inverter.

Set the output voltage by considering the temperature coefficient at the time of wiring of solar cell

module. If the output voltage of solar cell array is set without such consideration, excessive or

substandard input voltage of inverter can occur depending on the atmospheric temperature.

13

2) AC Connector installation

3.4.2 Communication circuit wiring

1) Precautions at the time of communication circuit wiring

Use communication connector at the time of control circuit terminal wiring. Refer to 3.3 Terminal

wiring diagram.

14

4. Operation

4.1 Explanations on the display window functions

4.1.1 Exterior of display window

4.1.2 Display window functions and LED indications

Status LED

Explanations

PV

Indicates the status of solar cell string (Green light: Normal solar cell string)

GRID

Indicates the status of the system (Green light: Normal system)

RUN

Indicates the status of inverter operation (Green light: Normal inverter power generation)

FAULT

Indicates inverter breakdown (Red light: Lights up if inverter breakdown occurs)

CH-1,CH-2

Indicates breakdown for each channel at the time of disconnection of junction box FUSE

(Red light: Disconnection of junction box FUSE)

LCD display

window for power

generated

Explanations

100% LED

Lights up at the time of 61 ~ 100 [%] power generation

60% LED

Lights up at the time of 31 ~ 60 [%] power generation

30% LED

Lights up at the time of initial operation and 1 ~ 30 [%] power generation

15

4.2 Display mode for basic status (2-line and 16-character LCD)

Once the power to inverter is turned ON, information on the LCD display window is automatically

converted at every 10-second intervals.

4.2.1 Solar cell input

Input display Input voltage Input current

PV: solar cell DC voltage DC current

Status of inverter operation Unit

4.2.2 System power input

Input display System power frequency System power current

Line: System 60.0 Hz Output current

Status of inverter operation Output voltage

4.2.3 Check total power generated

Input display Total power generated

Total: Total power generated kWh

Status of inverter operation Unit

4.2.4 Check power generated on the day

Input display Total power generated

TODAY: Power generated on the day kWh

Status of inverter operation Unit

→PV 412V 9.0 A

▶▶▶▶▶▶▶▶▶▶ 3.5 kW

→Line 60Hz 16.0A

▶▶▶▶▶▶▶▶▶▶ 220V

→Total 500 kWh

▶▶▶▶▶▶▶▶▶▶ 3.5 kW

→TODAY 10 kWh

▶▶▶▶▶▶▶▶▶▶ 3.5 kW

16

4.2.5 Check power generated on the previous day

Input display Total power generated

DAY-1: Power generated on previous day kWh

Status of inverter operation Unit

4.2.6 Check current power generation

Input display Power generated at the moment

RUN: Status of operation kW

Status of inverter operation Unit

4.2.7 Error status

- Indicated for 5 minutes at the time of error occurrence

Input display Name of error

Error code: S-OV

Explanations on error

→DAY-1 10 kWh

▶▶▶▶▶▶▶▶▶▶ 3.5kW

→RUN 3.5kW

▶▶▶▶▶▶▶▶▶▶ 97.2%

[E012] Sol_OV

Solar Over Voltage

17

4.3 Operating method

4.3.1 Issues to be checked prior to operation

Check the status of wiring and installation of inverter.

In particular, check whether the input polarity of solar cell is accurately connected and whether the

system line connection is made accurately.

Supply DC solar cell power to inverter. When DC power is supplied, the inverter will automatically

check abnormality in AC power before commencing operation automatically after having undergone

300 seconds of operation countdown.

(If needed, apply power by turning ON the DC switch after having checked DC voltage by turning off

the DC switch of junction box.)

4.3.2 Automatic operation

At the time of shipment from factory, the initial setting is in automatic operation mode.

If the solar cell module voltage increases above the set value due to sunlight, the inverter will be

initiated automatically.

At the time of sunset, the solar cell module voltage will be dropped. If it falls below the set voltage, the

inverter will stop operating automatically. The system power is always monitored and the operation will

be stopped automatically in the event of abnormality.

5. Functions

5.1 Explanations on functions

5.1.1 System monitoring

Presence of normal and abnormal system voltage is determined by the difference in the voltage with the

normal voltage (Fault high vtg., Fault low vtg.). If this value is larger or smaller than the designated

value, the inverter will be stopped. If the frequency of the system voltage (Line frequency) is outside the

range of Fault high freq. and Fault low freq. values, it does not operate and stops the inverter.

In order to initiate power generation in normal system status, wait until operation countdown (Line tran.

time) is completed before operating with the system. The frequency of system voltage used can be set

in accordance with the system frequency.

5.1.2 MPPT control and total power generated

Since the output of the solar cell module changes in accordance with the ambient temperature, humidity

and sunlight, Maximum Power Point Tracking (MPPT) algorithm needs to be executed harmoniously.

Format applied to this product has almost no pulsation of current. Inverter will be stopped if the inverter

cannot be operated anymore due to the solar cell reaching the stop voltage (PV stop voltage).

Since the total power generated (Total power) is remembered by being accumulated, it is possible to

check the total power generated.

18

5.1.3 Initialization and measures to be taken at the time of abnormality

In the event of occurrence of abnormality in which the inverter is stopped, relevant message will be

displayed. Once the cause of the abnormality is removed, the system will recommence operation after

the standby time. If the same symptom occurs or reoperation does not occur, please contact our

company. A total of 100 faults will be stored in the order of the faults being scanned scan from No. 0 to

99 with the most recent fault being numbered with 0.

It is possible to discern the variables or the past abnormal status by using the UP and DOWN button on

the keypad inside the inverter.

Parameter values can be changed by using the internal keypad in the event of stoppage of inverter.

Initialization includes Parameter initialization and Fault initialization. Parameter initialization sets all

parameters or optional functions at the value set at the time of the shipment from factory, while Fault

initialization put the system in ready status by removing all the records of faults generated in the past.

Erroneous operation of inverter can occur if the internal keypad is manipulated arbitrarily. Please

contact our company in such event.

5.1.4 Breakdown (Fault)

1) Breakdown (Fault)

Protection against Input over voltage

If the voltage of solar cell is above the stipulated voltage, the system will be stopped to protect the

inverter.

Protection against output overcurrent

If output overcurrent occurs in the inverter under the abnormal conditions of load state, the system will

be stopped to protect the inverter.

Protection against output overload

If there is abnormal output over prescribed period of time in excess of the rated output of the inverter,

the system will be stopped to protect the inverter.

Protection against overheating of inverter

If the internal temperature of the inverter exceeds 105℃, overheating is prevented by stopping the

operation of the system. Once the internal temperature of the inverter returns to normal level, it will be

reset and re-operated normally.

Protection against earth fault

System will be stopped if leakage current occurs due to earth fault.

Protection against system fault (Over/Under frequency fault, Over/Under voltage fault)

System will be stopped in the event of abnormality in the system power (protection of the system and

voltage, low system voltage, over-frequency and under-frequency of the system)

PWM control fault (Over current 2)

System will be stopped in the event of occurrence of abnormality in the internal PWM control of the

inverter.

19

6. Explanations on junction box (DSP-123JB-OD)

6.1 Basic issues

6.1.1 Issues to be aware prior to the use

①Please use the product after having sufficiently familiarized with the contents of this User Manual.

②Make sure to install away from direct sunlight and in a cool location with good ventilation. Fuse may

become short-circuited due to heat if the internal temperature increases because of direct sunlight.

③Do not open the junction box cover unless by skilled technician. Even if the lamp for confirmation of

power doesn’t light up at the time of inverter breakdown, there could be high current flowing in the

junction box. In addition, even of the fuse is short-circuited, electricity is continuously being supplied by

the solar cells. As such, arbitrary removal of fuse can induce electric shock, burn, fire and death. Make

sure to request inspection to specialist solar cell technician.

④Never remove the internal fuse while the inverter is in operation. Since high current flows through the

inverter generating power, you can get burnt or fire can generate along with risk of death in serious

cases due to generation of powerful sparks if fuse is removed forcibly.

⑤Install the junction box in a location that allows the user to inspection it conveniently. Power lamp doesn’t

light up for the photovoltaic inverter in the event of short-circuiting of junction box fuse. Under normal

state, CH1 and CH2 lamps of the inverter section do not operate. (If CH1 and CH2 LED of the inverter

section flickers, inspect the fuse of connection board.)

⑥Do not use impact wrench or motorized tools at the time of connecting cable and tightening of the

external cover of the junction box. Take precaution against breakage of fixation bolt for the terminal

block and external cover of internal PCB at the time of tightening them.

※Repair for breakage arising from negligence in installation will be charged.

⑦If power has not been applied to inverter, check the status of ON and OFF of the DC switch first.

⑧This product is a junction box for exclusive use in DSP-123K6-OD and cannot be used for separation

type or other type of products.

6.2 Components block diagram and names

①DC switch: 600Vdc 25A

②DC FUSE: 1000VDC 20A

③DC (-) input terminal: 30A

④DC (+) input terminal: 30A

⑤DC input (CH 1+,CH1-,CH2+,CH2-)

1

1

3

1

5

1

2

1

1

4

1

This manual suits for next models

1

Table of contents

Other Dass Inverter manuals