DataCan 109684 User manual

Portable Multi-Gauge Surface Box

DataCan User Manual –V1.1

PN: 109684

www.datacan.ca

Copyright 2022

Page 2 of

57

Table of Contents

TABLE OF CONTENTS................................................................................................................................................................ 2

1ABOUT THIS GUIDE .......................................................................................................................................................... 4

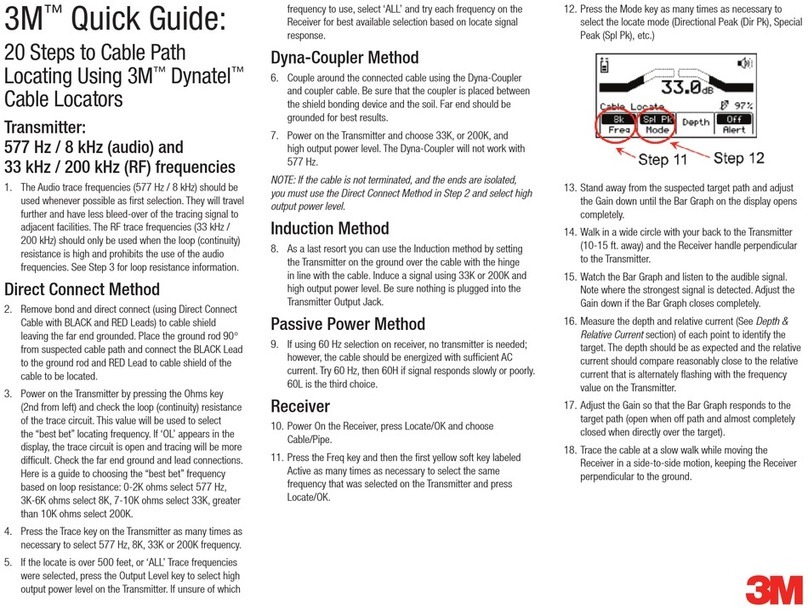

2INTRODUCTION................................................................................................................................................................. 5

3PRODUCT OVERVIEW...................................................................................................................................................... 6

3.1 PRODUCT DESCRIPTION .............................................................................................................................................. 6

3.1.1 USB Connection....................................................................................................................................9

3.1.2 Display On/Off Button........................................................................................................................9

3.1.3 Fuse............................................................................................................................................................9

3.1.4 Backup Clock Battery ..........................................................................................................................9

3.1.5 Main Internal Battery .......................................................................................................................10

3.2 PRODUCT SPECIFICATIONS.......................................................................................................................................... 6

3.3 NETWORK CONNECTIONS........................................................................................................................................... 7

3.4 COMPONENTS .............................................................................................................................................................. 8

4CONNECTING AND CONFIGURING SURFACE BOX WITH GAUGES ...........................................................11

4.1 TOOLS REQUIRED.......................................................................................................................................................11

4.2 CONNECTING GAUGES TO THE SURFACE BOX........................................................................................................12

4.3 INSTRUCTIONS FOR CONNECTING AND CONFIGURING ADDRESSABLE GAUGES ................................................14

4.4 INSTRUCTIONS FOR CONNECTING AND CONFIGURING NON-ADDRESSABLE GAUGES .....................................21

4.5 CONNECTING TO THE SURFACE GAUGES NETWORK..............................................................................................22

5BASIC SOFTWARE OPERATION..................................................................................................................................26

5.1 CONNECTING TO THE SURFACE BOX .......................................................................................................................26

5.2 DIAGNOSTICS..............................................................................................................................................................29

5.3 PROGRAMMING SAMPLE RATE.................................................................................................................................31

5.4 CHANGING UNITS ......................................................................................................................................................33

5.5 DOWNLOADING AND ERASING JOBS.......................................................................................................................35

5.6 GRAPHING DATA........................................................................................................................................................40

5.7 COMPANY NAME AND LOCATION ...........................................................................................................................42

Copyright 2022

Page 3 of

57

5.8 REAL-TIME DATA DISPLAY........................................................................................................................................44

6MODBUS-OUT NETWORK (SCADA).........................................................................................................................46

6.1 MODBUS-OUT COMMUNICATION SETTINGS .........................................................................................................46

6.2 CONNECTING TO THE MODBUS-OUT NETWORK...................................................................................................48

6.3 MODBUS-OUT REGISTER MAP.................................................................................................................................48

6.4 MODBUS DATA FORMAT ..........................................................................................................................................50

6.5 MODBUS TEST MODE AND MODBUS DEBUGGING................................................................................................51

7SCREEN WARNINGS AND ERRORS..........................................................................................................................52

8ADVANCED SURFACE BOX SETUP............................................................................................................................54

8.1 OUTPUT VOLTAGE......................................................................................................................................................54

8.2 POWER CYCLE TIMER.................................................................................................................................................55

8.3 SCREEN SETTINGS ......................................................................................................................................................56

9SURFACE BOX COMMISSIONING CHECKLIST .....................................................................................................57

History of Changes

Rev. No.

Date

Pages

Description of Changes

1.0

January 2021

47

Modified from V1.6 of Multigauge SRO

1.1

June 2022

59

Updated format, added specifications, reformatted

instructions, updated images, updated instructions

Copyright 2022

Page 4 of

57

1About This Guide

This document is intended as a supplement to formal training. DataCan is constantly working to

improve its products. We must therefore reserve the right to change designs, materials,

specifications and prices without notice. DataCan declines any liability that may arise out of the

potential inaccuracies in this guide.

This guide assumes that you have some computing and tool knowledge. For more information,

contact your local service representative.

www.datacan.ca

info@datacan.ca

We thank you for any feedback or comments that will help us to continue to improve our

products and service.

CONFIDENTIAL

This document and the proprietary information herein are the property of DataCan

Services Corp. It shall not be disclosed nor copied, in whole or in part, without the

written consent of DataCan Services Corp. Unauthorized transmission, reproduction,

transcription, or retrieval system storage in any form is prohibited.

Copyright 2022

Page 5 of

57

2Introduction

DataCan Services Corp. provides technology driven downhole measurement solutions that

deliver productivity, quality, and safety. We design, manufacture and service 200°C plus hybrid

platform instruments, patented multi-cycle instant close shut-in tools, reservoir management

systems and a suite of quartz and piezo-resistive pressure measurement instruments. We offer

specialized solutions that will help you improve productivity in your applications.

We are the leader in ultra-high temperature circuit design, manufacturing, and packaging.

•Our part selection process ensures the best long-term reliability is provided.

•Our fully automated surface mount assembly procedures ensure the highest quality

circuit is constructed every time with minimal heat impact.

•Our Hybrid design and construction techniques will enable DataCan and its customers to

reliably enter the 177ºC to 225ºC market.

•Our metal-to-metal seal and fully welded designs prevent potential leaks.

This manual is supplemented by several other manuals depending on the elements of your

system:

•DataCan Download Software User Manual –for all features of the software and graphing.

•Surface Transmitter Manual

•Multi-Gauge Telemetry Card Manual

•Cablehead Installation Manual

•Permanent Gauge Installation Manual

•Multi-Gauge Surface Box Troubleshooting Guide

To answer questions not covered in the manual about a specific component of your system,

please refer to the manual for that specific component.

Copyright 2022

Page 6 of

57

3Product Overview

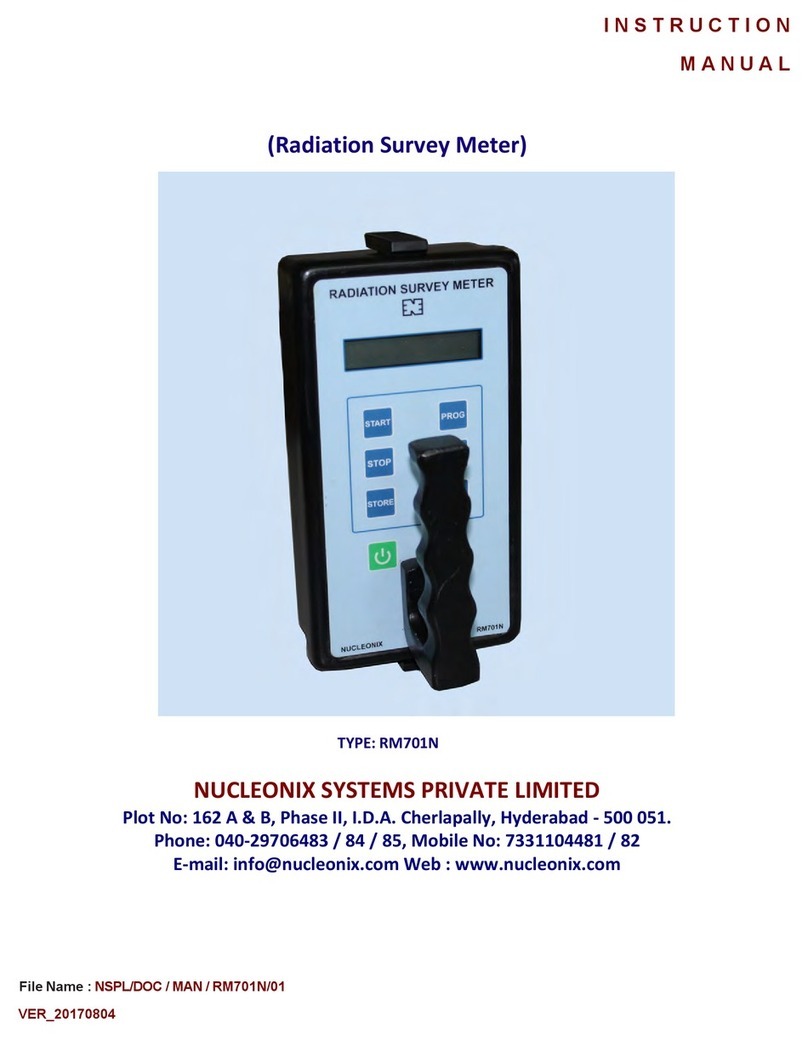

3.1 Product Description

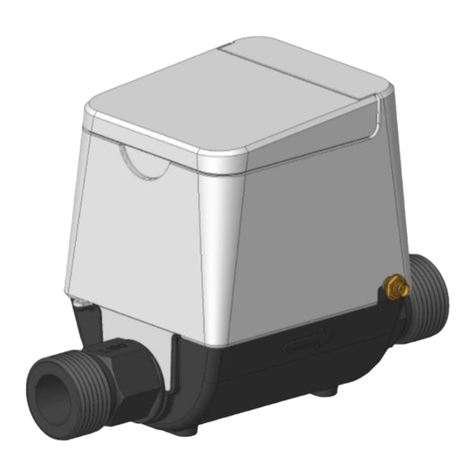

The DataCan Portable Surface Box is a reliable instrument that works in conjunction with

DataCan Downhole Gauges and Surface Gauges. In addition to providing power to the attached

equipment, the Surface Box displays the data collected; also, depending upon user settings, it

stores some of or all the collected information inside its on-board memory. A PC can be plugged

into the Surface Box to program which data is collected, displayed and recorded, as well as

download jobs from the memory using the included DataCan Download Software.

3.2 Product Specifications

NOTE: If your product is not one of the part numbers below, please contact a DataCan

representative to ensure this manual applies to your device.

Portable Surface Box

Description

Part No.

Multigauge Portable Surface Box

109684

Copyright 2022

Page 7 of

57

Specifications

Display

Pressure & Temperature

Memory Capacity

More Than 44 Million Samples

Download Via

USB, RS-485

Output

RS-485 Modbus RTU

Power In

AC Charger

Battery Life

Typical 7 days continuous operation on a full

charge for single gauge installation.

Accessories

Accessory Type

Part No.

USB-B Cable (6ft) [Included]

PE171UU0012

Surface Gauge Connector to 4 pin flywire

[Included] (Required to connect a telemetry

card to box)

111103

SCADA connector to 3 pin flywire [Included]

111108

DH Gauge Connector to Cablehead / Clips

[Included]

109805

DataCan Download Software (Free from the

website)

100872

3.3 Network Connections

The Surface Box connects to 3 different networks, as well as a USB link to a PC.

The 3 networks are:

-Modbus-Out network (SCADA connector)

-Downhole tool network (D.H. TOOL connector)

-Surface gauge network (S. GAUGE connector)

The Modbus-Out network is used to connect to a user’s SCADA system. The surface box has its

own configurable address for this network. Multiple surface boxes can be connected to the same

SCADA network.

The downhole network is used to collect data from DataCan Downhole Permanent Gauges or

Surface Readout Gauges. Up to 8 addressable gauges can be connected to the downhole tool

network or a single non-addressable gauge. Each gauge on the downhole tool network needs a

unique tool address. The address of a downhole tool is separate from any Modbus address.

Copyright 2022

Page 8 of

57

The surface gauge network is a Modbus network, separate from the Modbus-Out network that

the surface box can use to poll other Modbus sensors including other DataCan telemetry cards.

Each external Multi-Gauge Telemetry Card has its own downhole tool network. Each device

connected to the surface gauge network needs its own Modbus address on the network. This

can range from 1 to 247, with no two devices having the same address. The internal telemetry in

the Surface Box is address 0 (reserved). Addresses on this network are separate from the

Modbus-Out network, so devices on this network can have the same addresses as devices on the

user’s SCADA network..

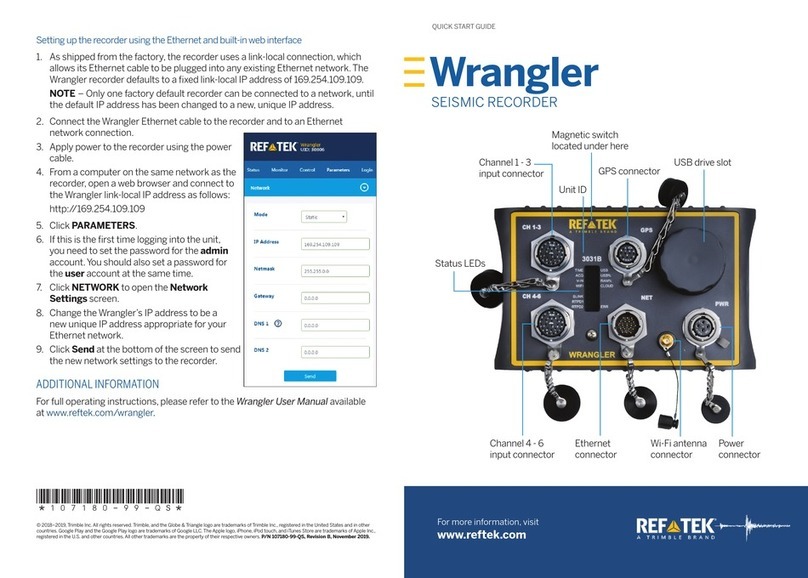

3.4 Components

Your portable surface box may be made up of the following components.

1.Pelican Case

2.Display screen

3.USB cable input

4.Display on/off

5.Fuse holder and fuse

6.Power switch

7.Status indicator

8.SCADA connection

9.Surface Gauge connection

10. Downhole Gauge connection

11. Battery Charger Input

12. Clock back up coin cell (internal)

13. Lead acid batteries (internal)

14. Battery Charger (Not Shown)

Copyright 2022

Page 9 of

57

3.4.1 USB Connection

The USB connection is a standard USB type B socket. Any USB-B cable will connect to it.

Note: The USB connection will provide enough power to the unit to allow for memory download.

This is to allow for access to data even with a dead battery. However, the USB connection will not

run a gauge or recharge the battery.

3.4.2 Display On/Off Button

The green button on the front panel turns the screen off and on. To conserve power, the screen

is by default set to turn off after 1 minute. Refer to Screen Settings to change these settings.

3.4.3 Fuse

DataCan has installed a 1.8A 3AG slow blow fuse. If required, replace with identical component.

3.4.4 Backup Clock Battery

A coin cell is used as backup power to keep time and ensure samples are accurately

timestamped. Some units use a non-chargeable coin cell. If you see the following popup when

you connect the Surface Box to the DataCan Download Software, then your clock backup battery

is not functioning.

Note: The backup battery is located behind the screen and can only be accessed by removing

the screws around the edge of the edge of the faceplate. A battery saver tab may have to be

removed in new boxes. To replace the backup battery, use a new CR1632.

Copyright 2022

Page 10 of

57

3.4.5 Main Internal Battery

The portable SRO box contains two 9Ah sealed glass mat lead acid 12V batteries. These should

provide power for 6 days of continuous operation on a full charge.

Battery Charging

DataCan provides a 1A battery charger with the SRO box. To charge the batteries, simply connect

the provided charger to the 2 pin plug on the box and plug the charger into a standard AC wall

outlet. A discharged battery can take up to 20 hours to fully charge. The charger can be left

connected, and it will maintain a float charge that will not overcharge the batteries.

WARNING: Do not allow the batteries to drain below 10 V. It can damage the batteries and

reduce the battery life of your box.

Copyright 2022

Page 11 of

57

4Connecting and Configuring Surface Box

with Gauges

Proper installation of DataCan products ensures high-quality performance and long-lasting

results. The following section highlights the steps required to configure devices to the Surface

Box properly.

FOR MULTI-GAUGE SYSTEMS: The addresses of gauges in a multi-gauge system must be

configured so that each address is unique. The first time a set of gauges is connected, the

gauges must be connected to the system one at a time while the software is used to configure

the Telemetry Card and the gauge. After all gauges have been configured, they may be

connected all at once.

4.1 Tools Required

*If configuring multiple gauges

Ensure the battery is charged before starting an installation. See section Main Internal Battery for

more information about charging.

Description

Part No.

Portable surface box

109684

USB Download Cable

100682

Gauge to Surface Box Test Hookup Cable

109805

Passthru Gauge Test Hookup Cable (comes with passthru gauge for temporary

passthrough connection)*

109377

Windows laptop with DataCan Download Software Installed

N/A

Copyright 2022

Page 12 of

57

4.2 Connecting Gauges to the Surface Box

Warning: DO NOT have the Surface Box connected to a computer when powering it up or

down, it may damage the computer. Only connect the USB cable after the Surface Box has

been powered up.

1. Ensure the power switch is in the OFF position.

2. Before using the Multigauge Surface Box, the plastic tag on the card stack behind the

face plate must be removed. See section Backup Clock Battery

Note: The Battery must be replaced occasionally for the Surface Box to maintain time

during power outages.

Portable Box Switch

Copyright 2022

Page 13 of

57

3. Use the provided test cables to connect the Gauges to the Surface Box D.H. GAUGE

connector.

4. Switch the power switch to the ON position.

Note: The “DH TOOL COMM INDICATOR” will flash immediately to indicate power is on. If not,

confirm that your power supply is on, that you have connected the power lines to the correct

terminals, and that the fuse in the box is intact.

Note: When power is applied the screen should come on and display:

DataCan

Modbus logger

FW: YYYY Week: WW

Initializing….

If after 10 seconds any warnings have been displayed, see Section 6 –Screen Warnings and Errors

for a description of warnings and troubleshooting.

Copyright 2022

Page 14 of

57

If the surface box has already been configured the screen should be displaying pressure and

temperature readings of each gauge attached. If it is not displaying a reading for each gauge

attached or the readings are incorrect, proceed to the next section for configuring gauges and

surface boxes.

4.3 Instructions for Connecting and Configuring

Addressable Gauges

Note: These instructions are for addressable downhole gauges. For non-addressable downhole

gauges, see Section 4.4 –Instructions for Connecting and Configuring Non-Addressable Gauges.

1. Ten seconds after power-up, ensure that no warnings are being displayed on the screen.

See Section 6 –Screen Warnings and Errors for a description of warnings and

troubleshooting.

2. Connect Surface Box to DataCan Download Software via a USB cable.

Note: The Box draws minimal power from the USB if the main power supply is turned off. If you

want to power down the card, you must disconnect the USB cable.

Warning: DO NOT have the Surface Box connected to a computer when turning the box on

or off, it may damage the computer. Only connect the USB cable after the Surface Box has

been powered up.

Copyright 2022

Page 15 of

57

3. Open DataCan Download Software on your Windows PC. The startup page should

appear as shown below.

4. Press the Connect Button. See Section 5.1 –Connecting to the Surface Box for more

information about the Information screen and what happens when the Card connects.

Note: If configuring a multigauge system the sample rate should be set before configuring

gauges. The minimum sample rate for multi-gauge systems is 1 second per gauge. E.g. the

minimum for a 5 gauge system is 5 seconds. If you set the sample rate faster than that, the

system will sample at the best effort speed and the “tool current” diagnostic reading will be

affected. Setting the sample rate to 1 second even with a single gauge attached may affect the

“tool current” reading.

Copyright 2022

Page 16 of

57

5. If setting the sample rate click Program from the buttons in the top row, otherwise skip

to step 9.

6. Beside the Single Rate in Seconds, enter an appropriate sample rate. If the rate is

already appropriate there is no need to change anything.

7. If you have changed the sample rate, click on the Program Tool button found at the

bottom left of the screen. A pop-up window should appear with a message confirming

success.

Copyright 2022

Page 17 of

57

8. Click Information.

9. Enter Supervisor mode by pressing Ctrl+SHIFT+D at the same time. “-Supervisor

Mode” should appear in the top bar.

10. Once in Supervisor Mode, press the Edit button.

11. In the window that pops up, select “Multi Gauge” for addressable gauges, “Single

Gauge” is for non-addressable gauges. If buttons are not available, supervisor mode was

not entered, return to step 5. If there are any gauges listed that will not be connected to

this Telemetry Card, press the Remove button next to the corresponding gauge. With all

unneeded gauges removed, press the Update button.

Copyright 2022

Page 18 of

57

12. If needed, repress the Edit button once you have cleared the list of gauges. If needed,

reselect “Multi Gauge” in the reopened window. It will display the message “Gauge(s)

Not Configured…”.

13. To add gauges to the Surface Box list:

A) If connecting only once gauge to this Box, press the Discover button.

B) If multiple previously configured gauges are connected, press the Discover

button (This should be the case with installed gauges).

C) If connecting a set of multiple gauges together that have never been

configured:

a. Ensure only the gauge that is to be first in the list is attached.

b. Enter the Serial # of the gauge and press Add.

c. Once the first gauge has been added, connect the next gauge, enter

its Serial # and press Add.

d. Repeat for every gauge to be connected. The software will set the

address of each gauge in the order that they are added.

Copyright 2022

Page 19 of

57

Note: If multiple gauges with the same address are connected, communication errors

when adding the gauges may occur.

Note: Once a gauge has been added, it does not have to remain connected during the

rest of the configuration procedure.

14. Once a Gauge or Gauges have been detected and added, a window will appear

displaying the Gauge(s) connected.

15. If desired, labels can be applied to data that will be downloaded and appear on the

screen. This can be done for each Gauge in a Multi-Gauge or Single Gauge System.

Note: Labels can be edited at any time by pressing the Edit button.

16. When the configuration is complete, press the Update button.

Multi Gauge Window

Single Gauge Window

Copyright 2022

Page 20 of

57

17. If you have connected all devices for the system, and are going to use remote

monitoring, generate a Modbus map by clicking Utilities -> Generate Modbus Map

(PDF), and choosing a location and file name to save the PDF. If you have devices to

connect to the Surface Gauges network, wait until those are added to generate the map.

18. Connect all configured gauges and confirm the system is working through the

diagnostics screen by clicking Utilities -> Diagnostics. For full information on using the

diagnostics screen see section 5.2 –Diagnostics.

Data should also be flashing on the main display.

Note: If you have multiple devices connected to your Surface Box, the display screen will switch

between data from each device. By default, the display screen will automatically turn off after 1

minute. The green button on the side of the Surface Box or the grey button beside the power

switch of the Rackmount Unit turns the display screen on and off. To change the display screen

settings, refer to Screen Settings.

Table of contents