Datacom DFC-0115 User manual

The DFC-0115 is an advanced, precision

15 step power factor control and metering

device, which continuously matches the

target cosø value of the load.

Installation and configuration of the DFC-

0115 is very simple thanks to the auto-

learning function.

Each step output supports single-phase,

two-phase, and three-phase connection of

capacitors and reactors.

Electrical equipment should be installed only

by qualified specialist. No responsibility is

assured by the manufacturer or any of its

subsidiaries for any consequences resulting

from the non-compliance to these

instructions.

Check the unit for cracks and damages due

to transportation. Do not install damaged

equipment.

Do not open the unit. There is no

serviceable parts inside.

Fuses of fast type with a maximum rating of

6A must be connected to the power supply

and phase voltage inputs, in close proximity

of the unit.

Disconnect all power before working on

equipment.

When the unit is connected to the network

do not touch terminals.

Short circuit terminals of unused current

transformers.

Any electrical parameter applied to the

device must be in the range specified in the

user manual.

Do not try to clean the device with solvent or

the like. Only clean with a dump cloth.

Do not allow water to come in the unit.

Verify correct terminal connections before

applying power.

Only for front panel mounting.

Before Installation:

Read the user manual carefully,

determine the correct connection

diagram.

Remove all connectors and mounting

brackets from the unit, then pass the

unit through the mounting opening.

Put mounting brackets and tighten. Do

not tighten too much, this can break

the enclosure.

Make electrical connections with plugs

removed from sockets, then place

plugs to their sockets.

Make sure to use adequate fuses.

Do not subject the unit to water spill.

Below conditions may damage the

device:

Incorrect connections.

Incorrect power supply voltage.

Voltage at measuring terminals

beyond specified range.

Current at measuring terminals

beyond specified range.

Overloaded or short circuited relay

output terminals.

Below conditions may cause abnormal

operation:

Power supply voltage below minimum

acceptable level.

Power supply frequency out of

specified limits

Phase order of voltage inputs not

correct. (Without auto-correct function)

Current transformers not matching

related phases. (Without auto-correct

function)

Incorrect current transformer polarity.

(Without auto-correct function)

Inappropriate delay for switch on,

switch off delays of steps.

DFC-0115

REACTIVE POWER CONTROLLER

SAFETY NOTICE

Failure to follow below

instructions will result in

death or serious injury

INSTALLATION

Current transformers must

be used for current

measurements. No direct

connection allowed.

Although the unit is protected against

electromagnetic disturbances, excessive

disturbance can affect the operation,

measurement precision and data

communication quality.

Always remove the plug connectors

when inserting wires with

screwdriver.

Fuses of fast type with a maximum

rating of 6A must be connected to

the power supply and phase voltage

inputs, in close proximity of the unit.

Always refer to National Wiring

Regulations when conducting

installation.

Use cables of adequate current

carrying capacity (at least 0.75 mm2).

Use cables of adequed temperature

range.

Use at least 1.5mm2cables for

current transformer connection

(AWG15).

The current transformer cable length

should not exceed 1.5 meters. If

longer cable is used, cable section

must be increased proportionally.

Current transformers must have a

5A output.

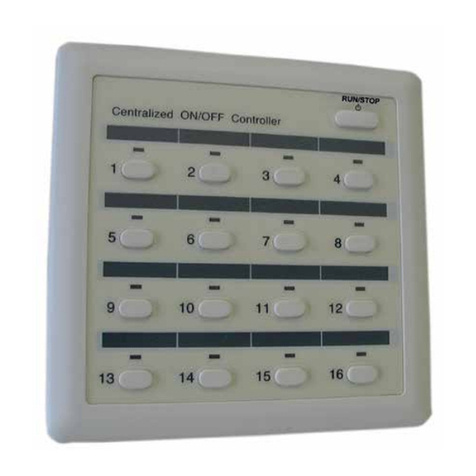

Three buttons on the front panel provide

access to configuration and measurement

screens.

BUTTON

FUNCTION

Remove all alarms in AUTO

mode.

If the same alarm occurs again,

it will not be displayed.

When held pressed for 3

seconds;

Programming mode activated.

All alarms are enabled.

Skip to the next parameter.

(Measurement and parameter

screen)

Increase related parameter.

(Programming screen)

When held pressed for 3

seconds;

Switch on and switch off steps.

Skip to the previous

parameter. (Measurement and

programming screen)

Decrease related parameter.

(Programming screen)

When held pressed for 3

seconds;

AUTO-MANUAL mode switch.

Reactive control is disabled at

MANUAL mode.

ELECTRICAL CONNECTIONS

Do not place the unit close

to high electromagnetic

noise emitting devices like

contactors, high current

busbars, switch mode

power supplies.

Do not overload relay

outputs. Use extra

contactors if required.

BUTTON FUNCTIONS

During auto setup :

- Polarity and unmatched current

transformers connection will be corrected.

- Each step’s reactive power and

connection type will be automatically

measured.

BUTTON

FUNCTION

Hold pressed MENU button for 3

seconds to activate auto setup.

LErn should be seen at top

screen.

Push up arrow buttons 4 times to

navigate ctrF parameter.

This parameter refers to primary

value of current transformer.

Secondary value is configured as

5A and can not be changed.

Click MENU button to see the ctrF

parameter. This is the primary

value of current transformer. 500A

is configured as default.

Adjust primary value of current

transformer by using up and down

arrow buttons. If current

transformer is 150/5A, ctrF should

be adjusted to 150.

Click MENU button to save ctrF

(adjusted value will disappear)

Click arrow down button 4 times to

display the LErn parameter.

Click MENU button once more to

see value of LErn parameter. (Will

be 0 as default)

Adjust value of LErn to 1 by

clicking up arrow button.

1 Auto setup (3+2)

2 Step values learning

3 CT connection correction

Click MENU button to enable auto

setup. Device will check and

correct current transformer

connections. After that, reactive

power of each step will be

measured by the auto learning

function.

After successful auto setup, AUTO

led will turn on, and steps will be

swithced on and off depending on

the reactive power demand of the

load.

2. AUTO SETUP

Three phase voltage

inputs must be

connected for successful

auto setup.

Large size three phase

capacitors or reactors

should be connected to

first steps for successful

auto setup.

Disconnecting the installation side is

preferred during auto setup. However,

the device can manage to complete

auto setup with stable installation load.

Fast varying loads might cause

inaccurate detection of reactive power

as well as faulty current transformer

polarity.

In such cases, auto setup should be

repeated and connected capacitors

and/or inductors should be checked.

The DFC-0115 offers a set of adjustable

parameters in order to provide the user

with maximum flexibility.

Adjusted parameters are saved in a non-

volatile memory, not affected by power

failures.

As long as the program mode password is

not enabled, the unit will not ask for

password for programming mode.

Password can be enabled or modified

with the “PASS” parameter.

BUTTON

FUNCTION

Hold pressed MENU button for 3

seconds to enable programming.

USEr should be seen at top screen.

LErn should be seen if password

protection is not activated.

Click MENU button to see value of

USEr. Value of USEr (password)

can be seen as zero at bottom

screen.

Adjust password by using up and

down arrows. Value will increase or

decrease faster if the button is held

pressed.

When the required password is set,

click MENU button. First parameter

should be seen (LErn), if correct

password is typed.

Hold down MENU button for 3

seconds, and LAMP TEST mode

will be activated. (All LEDs on the

device will turn on). Click MENU

button again to navigate through

measurement screens.

BUTTON

FUNCTION

Choose required parameter by

using up and down arrows while

parameter can be seen at top

screen.

Click MENU button when

parameter to be changed is found.

Value of parameter will be seen at

the bottom screen.

Adjust the value with arrow buttons.

You can hold the button pressed for

faster increase/decrease.

Click MENU button to save the

parameter value. Adjusted value

will be recorded in the memory and

the parameter value will be

removed from bottom screen.

PROGRAMMING

ENABLE AND DISABLE

PROGRAMMING MODE

ADJUSTING PROGRAMMING

PARAMETERS

Programming will be

disabled after 3

minutes if no button

is pressed.

DEFINITION

MIN

STD

MAX

“User”

Enter Password

The user password

should be entered.

User password is

set through

“PASS” parameter.

0

0

9999

“Lern”

Auto Setup

1 Auto setup

(3+2)

2 Step values

learning

3 CT connection

correction

0

0

3

“rCAP”

Reset error

counters and

dynamic step

values

When this

parameter is set to

1, error counters

and dynamic

values of each

step will be reset.

0

0

1

“rCnt”

Reset step

counters

When this

parameter is set to

1, switching

counters and

hours-run counters

of all steps will be

reset.

0

0

1

“FCty”

Return to factory

settings

When this

parameter is set to

1, all parameters

will return to their

factory set values.

0

0

1

DEFINITION

MIN

STD

MAX

“CtrF”

Current

Transformer

Primary value of

current

transformers.

Can be set

between 5/5A and

5000/5A.

5A

500A

5000A

“CoS”

Target Cosø

Target Cosø can

be set between

capacitive 0.800

and inductive

0.800. Capacitive

power factor is

displayed as

c.800, while

inductive Cosø is

shown as 0.800

0.800

cap.

0.999

ind.

0.800

ind.

“StEP”

Number of steps

Number of steps

can be adjusted

from 1 to 15.

1

15

15

“ProG”

Compensation

algorithm

Different

compansation

algorithms can be

chosen.

This parameter is

advised to be set

to 10 for “smart

compensation”

1

10

10

PARAMETER LIST

DEFINITION

MIN

STD

MAX

“t-dU”

Step switching

delay

When the unit

decides to switch

the step

configuration, it

continues

measurements

during this delay

and sets the new

step configuration

calculated at the

end of this delay.

1 sec

1 sec

2000

sec

“t-CL”

Step switching

protection delay

When the unit sets

a new step

configuration, all

step switching will

be disabled during

this timer.

0 sec

1 sec

2000

sec

“dCHr”

Discharge timer

This is the

common discharge

timer for all steps.

Any step swithed-

off, cannot be

switched on again

before expiration

of this timer.

3 sec

14

sec

2000

sec

Supply Voltage: 85 - 300VAC (L1-N)

50 - 60Hz nominal (± %10) (L1-N)

Generator Input: 70 - 300 V AC (P-N)

Measurement Inputs:

Voltage: 10 - 300 V AC (Ph-N)

20 - 520 V AC (Ph-Ph)

Current: 0.05 - 5.50 A AC

Frequency: 30 - 100 Hz

Accuracy:

Voltage: % 0.5 + 1 digit

Current: % 0.5 + 1 digit

Frequency: % 0.5 + 1 digit

Power(kW,kVAr): %1.0 + 2 digit

Cos: %0.5 + 1 digit

Measurement Range:

CT Range: 5/5A to 5000/5A

VT Range: 0.1/1 to 200.0/1

kW Range: 0.1 kW to 6.5MW

Power Consumption: < 10 VA

Loading:

Voltage Inputs: < 0.1VA per phase

Current Inputs: < 0.5VA per phase

Number of Steps: 12-15

Relay Outputs: 5A @ 250V A

Serial Port:

Signal Type: RS-485

Communication: Modbus RTU

Baud Rate: 2400-115200 selectable

Isolation: 500V AC, 1 minute

Operating Temperature: -20°C to +70 °C (-4 to +158 °F)

Maximum Humidity: %95 non-condensing.

Degree of Protection:

IP 54 (Front Panel)

IP 30 (Rear Panell)

Enclosure:

Non-flammable,

ROHS compliant,

Flame retardant,

High temp. ABS/PC

UL94-V0

Installation: Flush mounting with rear brackets.

Dimensions: 164x164x69mm (WxHxD)

Panel Cutout: 140x140 mm

Weight: 450 gr (approx.)

EU Directives:

2006/95/EC (LVD)

2004/108/EC (EMC)

Norms of References:

TS-EN 61010 (safety)

TS-EN 61326 (EMC)

TECHNICAL SPECIFICATIONS

CONNECTION DIAGRAM

Table of contents

Other Datacom Controllers manuals

Popular Controllers manuals by other brands

HomeMatic

HomeMatic HM-LC-Sw4-SM-2 Installation and operating manual

Intec

Intec MGC2-12 user manual

Smartwares

Smartwares SH4-99560 instruction manual

Lütze

Lütze LION microPLC installation instructions

EOS

EOS EmoStyle Di Installation and operation manual

Control Resources

Control Resources SmartFan Cirrus-6 Installation & operation manual

Omron

Omron CK3W-AX2323 Series Startup guide

Smartgen

Smartgen HAT520N user manual

Hitachi

Hitachi PSC-A16RS Installation and operation manual

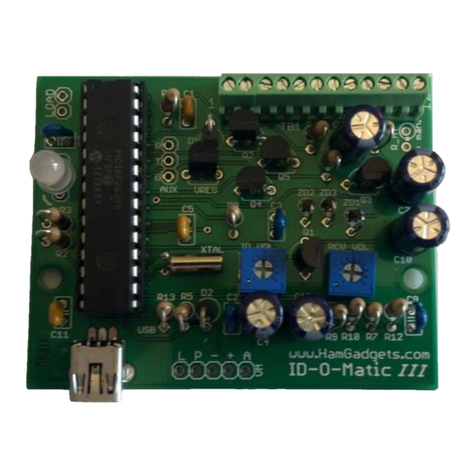

HamGadgets

HamGadgets ID-O-Matic III Assembly, Setup and Use Guide

Telecrane

Telecrane F25-60 operating instructions

Edgewater Networks

Edgewater Networks EdgeProtect 7300 Hardware installation guide