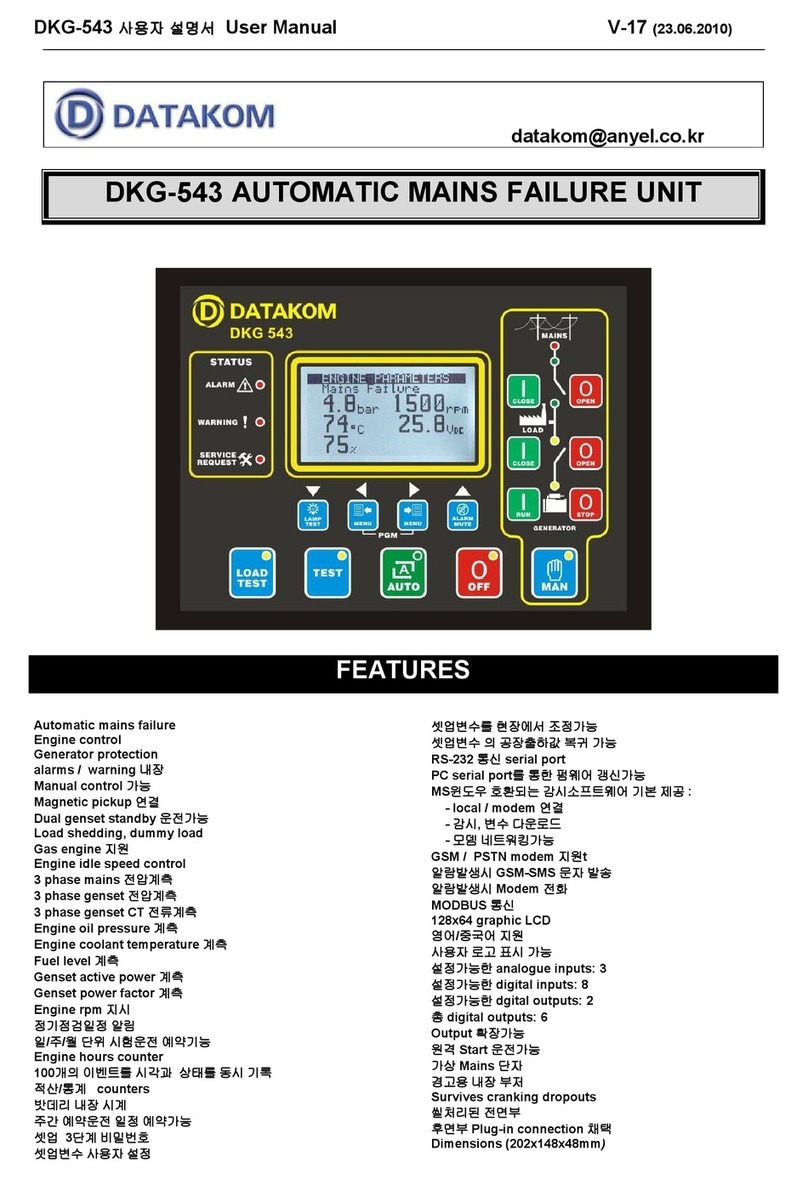

DKG-153

MANUAL START UNIT

INSTALLATION AND OPERATING INSTRUCTIONS

The model DKG-153 is a microprocessor controlled

unit used to start and stop the genset manually

using the key switch and pushbuttons on the front

panel.

When the engine is running, the unit monitors fault

conditions and shuts-down the engine automatically

in the occurrence of an alarm. The alarms are

identified by a group of LEDs displaying only the

first occurring one.

The unit has jumper selectable options for 50/60Hz

nominal frequency and the auxiliary output function.

The selection is made by the position of a single

jumper situated at the left side panel of the unit.

If the jumper is placed between:

A & B : 50Hz nominal, AUX is Preheat output

B & C : 60Hz nominal, AUX is Preheat output

C & D : 60Hz nominal, AUX is Stop output

D & A : 50Hz nominal, AUX is Stop output.

In the OFF position, the DC supply is removed from

the module, thus zero power consumption is

achieved.

The unit powers up when the RUN position on the

front panel is selected. If required, the

PREHEAT/STOP ( ) button may be depressed

as long as needed. This will activate the

AUXILIARY relay output and the related front panel

led marked ( ).

The engine is started using the pushbutton marked

CRANK (I). This will also energize the fuel solenoid

output. Once the engine is running, the switch

should be released. However the internal logic

inhibits cranking when the engine fires up.

The alarm checking is only enabled after the

protection hold-off timer is expired. This timer

resets to 12 seconds if:

-the unit is powered up,

-or CRANK (I) button is pressed,

-or PREHEAT/STOP ( ) button is pressed,

-or the engine gets running.

The occurrence of below fault signals (which are

close on fault) will cause the engine to be stopped

immediately:

-Overspeed,

-Underspeed,

-High engine temperature,

-Low oil pressure,

-Auxiliary shutdown.

If a fault condition occurs, the FUEL solenoid will

be deenergized. If the auxiliary output is set to Stop

option, it will be energized during stop timeout and

the led associated with this condition will turn on.

To reset the fault condition, turn the switch to the

OFF position for a few seconds.

The Charge Fail condition is treated as a warning

only and do not cause the engine to stop. The input

monitors the D+ terminal of the charge alternator.

To shut-down the engine manually:

-if the AUX output is set to Stop option, press the

PREHEAT/STOP ( ) button until the engine

comes to rest. Then select the OFF position on the

switch.

-else select the OFF position on the switch.