Kinco-HP

User Manual

CONTENT

CHAPTER 1 GENERAL INTRODUCTION........................................................................................................ 3

1.1 SUMMARY......................................................................................................................................................3

1.2 PRODUCT LIST...............................................................................................................................................3

1.3 ENVIRONMENTAL CONDITION........................................................................................................................3

1.4 SPECIFICATION...............................................................................................................................................5

1.4.1 display specification.............................................................................................................................. 5

1.4.2 PLC specification...................................................................................................................................5

1.4.3 Appearance............................................................................................................................................ 7

1.4.4 Dimension.............................................................................................................................................. 8

CHAPTER 2 PLC INTRODUCTION.................................................................................................................... 9

2.1 FUNCTIONS.................................................................................................................................................... 9

2.1.1 CPU Status and LEDs............................................................................................................................9

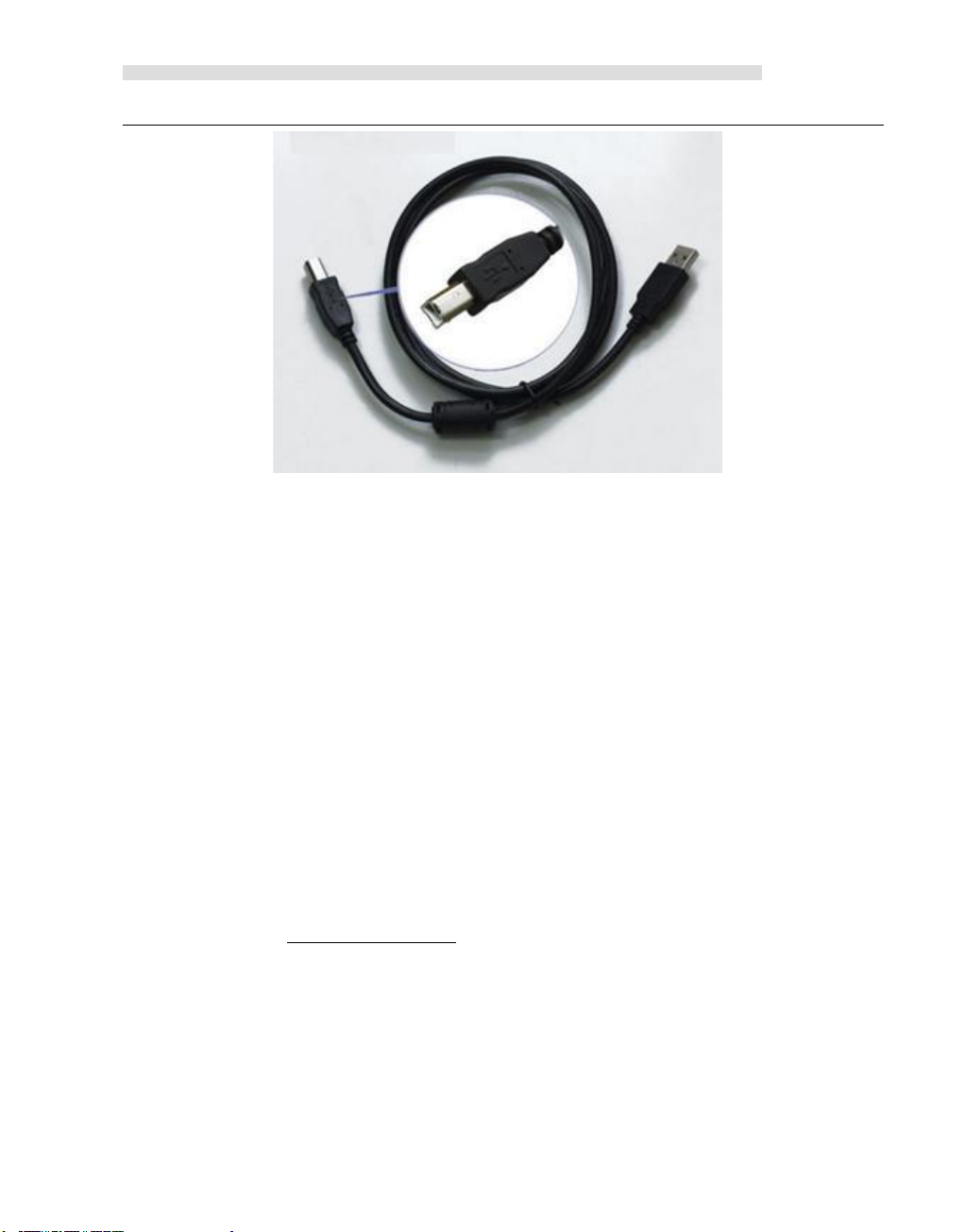

2.1.2 USB Programming port......................................................................................................................... 9

2.1.3 Serial Communication Port................................................................................................................. 10

2.1.4 High Speed Counter and High Speed Pulse Output............................................................................ 10

2.1.5 Edge Interrupts.....................................................................................................................................11

2.1.6 Data Retentive and Data Backup.........................................................................................................11

2.1.7 Real-time Clock (RTC).........................................................................................................................12

2.1.8 Backup Battery.....................................................................................................................................12

2.2 WIRING DIAGRAM........................................................................................................................................13

2.3 DIMENSION..................................................................................................................................................14

2.4 TECHNICAL SPECIFICATION......................................................................................................................... 14

CHAPTER 3 SOFTWARE INTRODUCTION.....................................................................................................17

3.1 HMI PROGRAMMING................................................................................................................................... 17

3.1.1 Create project.......................................................................................................................................17