CAUTION – Before performing any service

operation on any Directional Control Valve,

be sure that all pressure has been relieved

from BOTH SIDES of the system.

CAUTION – Before performing any service

operation on any Directional Control Valve,

disconnect or lock off power supply.

CAUTION – Before manually actuating any

Directional Control Valve, be sure that any

resulting machine function will not endanger

persons or equipment.

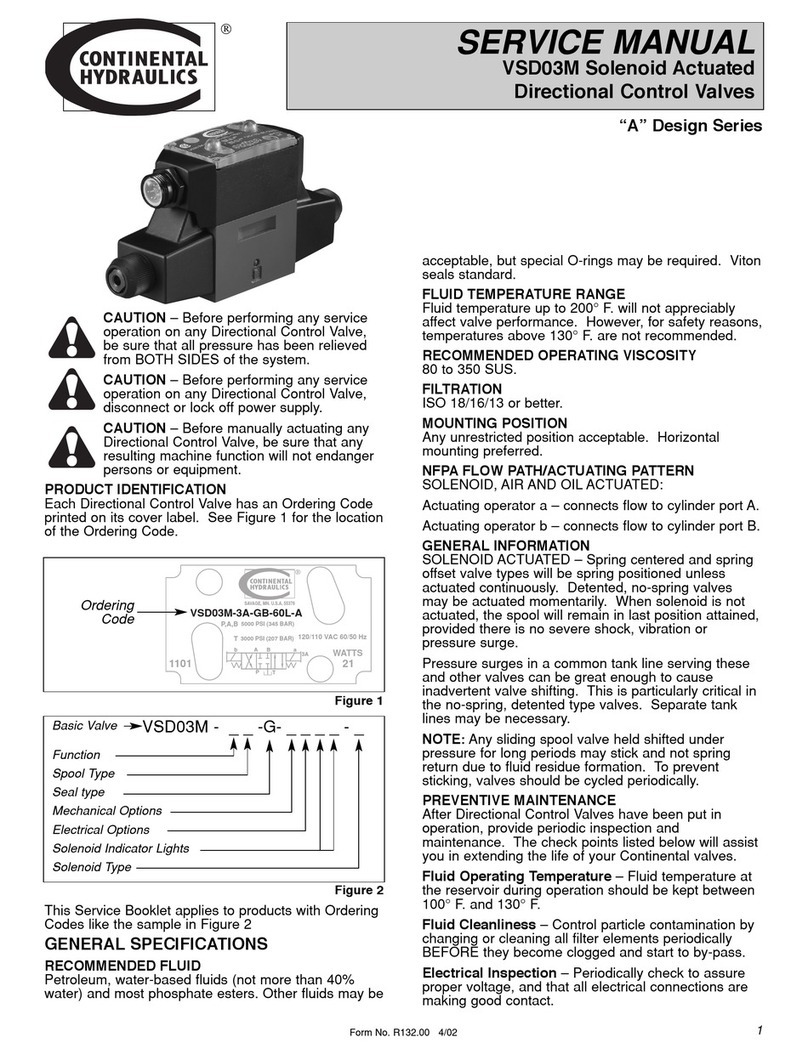

PRODUCT IDENTIFICATION

Each Directional Control Valve has an Ordering Code

stamped on its top label. See Figure 1 for the location

of the Ordering Code.

This Service Booklet applies to products with Ordering

Codes like the sample in Figure 2.

GENERAL SPECIFICATIONS

RECOMMENDED FLUID

Petroleum, water-based fluids (not more than 40%

water) and most phosphate esters. Other fluids may be

acceptable, but special O-rings may be required. Viton

seals standard.

FLUID TEMPERATURE RANGE

Fluid temperature up to 200° F. (93° C.) will not

appreciably affect valve performance. However, for

safety reasons, temperatures above 130° F. (54° C.)

are not recommended.

RECOMMENDED OPERATING VISCOSITY

80 to 350 SUS (16 to 70 cSt).

FILTRATION

ISO 18/16/13 or better.

MOUNTING POSITION

Any unrestricted position acceptable. Horizontal

mounting preferred.

NFPA FLOW PATH/ACTUATING PATTERN

MANUAL:

Push lever – connects flow to cylinder port A.

Pull lever – connects flow to cylinder port B.

The NFPA flow path/actuating pattern is reversed for

Code L Spools

GENERAL INFORMATION

MANUAL ACTUATED – Spring centered and spring

offset valve types will be spring positioned unless

actuated continuously. Detented, no-spring valves

may be actuated momentarily. When solenoid is not

actuated, the spool will remain in last position attained,

provided there is no severe shock, vibration or

pressure surge.

Pressure surges in a common tank line serving these

and other valves can be great enough to cause

inadvertent valve shifting. This is particularly critical in

the no-spring, detented type valves. Separate tank

lines may be necessary.

NOTE: Any sliding spool valve held shifted under

pressure for long periods may stick and not spring

return due to fluid residue formation. To prevent

sticking, valves should be cycled periodically.

PREVENTIVE MAINTENANCE

After Directional Control Valves have been put in

operation, provide periodic inspection and

maintenance. The check points listed below will assist

you in extending the life of your Continental valves.

Fluid Operating Temperature – Fluid temperature at

the reservoir during operation should be kept between

100° F. and 130° F. (38° C. and 54° C.).

Fluid Cleanliness – Control particle contamination by

changing or cleaning all filter elements periodically

BEFORE they become clogged and start to by-pass.

SERVICE MANUAL

VMD03M Manual Actuated

Directional Control Valves

Basic Valve

Function

Spool Type

Seal Type

Mechanical Options

Operator

Design Letter

“A” Design Series

VMD03M - _ _ - G - _ 10 - A

Figure 2

P,A,B

T

SAVAGE, MN. U.S.A. 55378

VMD03M-1A-G-10-A

1101

5000 PSI (345 BAR)

3000 PSI (207 BAR)

ba

PT

AB3A

Ordering

Code

Figure 1

Form No. R133.00 11/03

1