Datakom DKM-0224 User manual

DKM-0224 User Manual V-1.0 (11.08.2016)

-1-

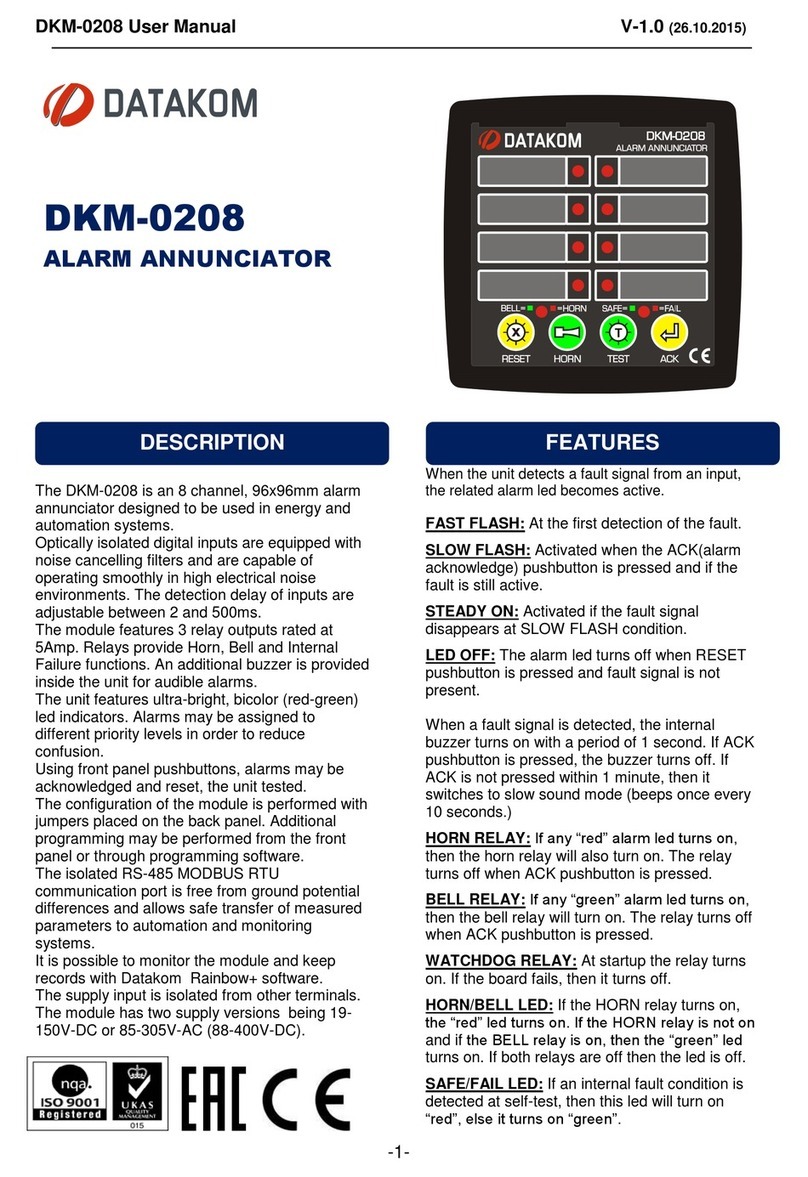

DKM-0224

ALARM ANNUNCIATOR

The DKM-0224 is an 24 channel, 144x144mm

alarm annunciator designed to be used in energy

and automation systems.

Optically isolated digital inputs are equipped with

noise cancelling filters and are capable of

operating smoothly in high electrical noise

environments. The detection delay of inputs are

adjustable between 2 and 500ms.

The module features 3 relay outputs rated at

5Amp. Relays provide Horn, Bell and Internal

Failure functions. An additional buzzer is provided

inside the unit for audible alarms.

The unit features ultra-bright, bicolor (red-green)

led indicators. Alarms may be assigned to

different priority levels in order to reduce

confusion.

Using front panel pushbuttons, alarms may be

acknowledged and reset, the unit tested.

The configuration of the module is performed with

jumpers placed on the back panel. Additional

programming may be performed from the front

panel or through programming software.

The isolated RS-485 MODBUS RTU

communication port is free from ground potential

differences and allows safe transfer of measured

parameters to automation and monitoring

systems.

It is possible to monitor the module and keep

records with Datakom Rainbow+ software.

The supply input is isolated from other terminals.

The module has two supply versions being 19-

150V-DC or 85-305V-AC (88-400V-DC).

When the unit detects a fault signal from an input,

the related alarm led becomes active.

FAST FLASH: At the first detection of the fault.

SLOW FLASH: Activated when the ACK(alarm

acknowledge) pushbutton is pressed and if the

fault is still active.

STEADY ON: Activated if the fault signal

disappears at SLOW FLASH condition.

LED OFF: The alarm led turns off when RESET

pushbutton is pressed and fault signal is not

present.

When a fault signal is detected, the internal

buzzer turns on with a period of 1 second. If ACK

pushbutton is pressed, the buzzer turns off. If

ACK is not pressed within 1 minute, then it

switches to slow sound mode (beeps once every

10 seconds.)

HORN RELAY: If any “red” alarm led turns on,

then the horn relay will also turn on. The relay

turns off when ACK pushbutton is pressed.

BELL RELAY: If any “green” alarm led turns on,

then the bell relay will turn on. The relay turns off

when ACK pushbutton is pressed.

WATCHDOG RELAY: At startup the relay turns

on. If the board fails, then it turns off.

HORN/BELL LED: If the HORN relay turns on,

the “red” led turns on. If the HORN relay is not on

and if the BELL relay is on, then the “green” led

turns on. If both relays are off then the led is off.

SAFE/FAIL LED: If an internal fault condition is

detected at self-test, then this led will turn on

“red”, else it turns on “green”.

DESCRIPTION

FEATURES

DKM-0224 User Manual V-1.0 (11.08.2016)

-2-

Electrical equipment should be installed only by qualified

specialist. No responsibility is assured by the manufacturer or

any of its subsidiaries for any consequences resulting from the

non-compliance to these instructions.

Check the unit for cracks and damages due to transportation. Do

not install damaged equipment.

Do not open the unit. There are no serviceable parts inside.

Fuses must be connected to the power supply and phase voltage

inputs, in close proximity of the unit.

Fuses must be of fast type (FF) with a maximum rating of 6A.

Disconnect all power before working on equipment.

When the unit is connected to the network do not touch

terminals.

Short circuit terminals of unused current transformers.

Any electrical parameter applied to the device must be in the

range specified in the user manual. Although the unit is designed

with a wide safety margin, over-range parameters may reduce

lifetime, alter operational precision or even damage the unit.

Do not try to clean the device with solvent or the like. Only clean

with a dump cloth.

Verify correct terminal connections before applying power.

Only for panel base mounting.

SAFETY NOTICE

CAUTION

Failure to follow below instructions

will result in death or serious injury

DKM-0224 User Manual V-1.0 (11.08.2016)

-3-

1. INSTALLATION INSTRUCTIONS

1.1. FRONT AND BACK PANELS

1.2. MECHANICAL INSTALATION

1.3. ELECTRICAL INSTALLATION

2. PUSHBUTTON FUNCTIONS

3. LED FUNCTIONS

4. SETTINGS

4.1. JUMPER SETTINGS

4.2. SIGNAL LED RED/GREEN SETTINGS

4.3. BUZZER SETTINGS

5. MODBUS COMMUNICATION

5.1. INTRODUCTION

5.2. PROGRAM PARAMETERS

5.3. COMMANDS

5.4. CALCULATED VALUES

6. TECHNICAL SPECIFICATIONS

TABLE OF CONTENTS

DKM-0224 User Manual V-1.0 (11.08.2016)

-4-

Before Installation:

Read the user manual carefully, determine the correct connection diagram.

Remove all connectors and mounting brackets from the unit, then pass the unit through

the mounting opening.

Put mounting brackets and tighten. Do not tighten too much, this can brake the

enclosure. Spring type brackets do not need to be tightened.

Make electrical connections with plugs removed from sockets, then place plugs to their

sockets. Otherwise, the sockets may get damaged.

Be sure that the relay outputs are not over-loaded. Use auxiliary contactors if necessary.

Below conditions may damage the device:

Incorrect connections.

Incorrect power supply voltage.

Voltage at measuring terminals beyond the specified range.

Current at measuring terminals beyond the specified range.

Overload or short circuit at relay outputs.

Below conditions may cause abnormal operation:

Power supply voltage below minimum acceptable level.

1. INSTALLATION INSTRUCTIONS

DKM-0224 User Manual V-1.0 (11.08.2016)

-5-

DKM-0224 User Manual V-1.0 (11.08.2016)

-6-

Panel Cutout Required Panel Depth

1.1 FRONT and BACK PANELS

1.2 MECHANICAL INSTALLATION

DKM-0224 User Manual V-1.0 (11.08.2016)

-7-

Although the unit is protected against electromagnetic disturbance, excessive disturbance

can affect the operation and measurement precision

ALWAYS remove plug connectors when inserting wires with a screwdriver.

Fuses must be connected in series with the power supply, in close proximity of

the unit.

Fuses must be of fast type (FF) with a maximum rating of 6A.

Use cables of appropriate temperature range.

Use adequate cable section, at least 0.75mm2 (AWG18).

1.3 ELECTRICAL INSTALLATION

Do not install the unit close to high electromagnetic noise

emitting devices like contactors, high current busbars,

switchmode power supplies and the like.

Be sure that the relay outputs are not over-loaded.

Use auxiliary contactors if necessary.

DKM-0224 User Manual V-1.0 (11.08.2016)

-8-

BUTTON

FUNCTION

If the pushbutton is pressed all fault leds turn off, Horn and

Bell relays are released. If the fault signal still persists, the

fault alarm re-appears again. This button is also used in

settings menu.

If the pushbutton is pressed, all leds flash green and red in

sequence, the internal buzzer sounds, Horn, Bell and

Watchdog Relays turn on and off with a period of one

second. During this test, if the pushbutton pressed for 3

seconds, the buzzer function can be disabled/enabled. By

pressing the pushbutton again, module exits from the test.

This button is also used in settings menu.

If the pushbutton is pressed, all leds turn-on with the pre-

adjusted color. (If it is pressed again, the unit returns back

to normal operation.) After pressing it short, if this button

is pressed for 3 seconds, then the first Led flashes with the

pre-adjusted color and the unit enters the settings menu.

If the pushbutton is pressed, fast flashing leds turn into

slow flashing(or Steady On) state, the internal buzzer turns

off. Horn and Bell relays are released. This button is also

used for exiting the settings menu.

2. PUSHBUTTON FUNCTIONS

DKM-0224 User Manual V-1.0 (11.08.2016)

-9-

SIGNAL LEDs: There are 24 red/green

adjustable signal leds on the panel.

According to the input signal and pressed

pushbutton,leds can be on Fast Flash,

Slow Flash, Steady On and Off states.

FAST FLASH: At the first detection of the

fault.

SLOW FLASH: Activated when the

ACK(alarm acknowledge) pushbutton is

pressed and if the fault is still active.

STEADY ON: Activated if the fault signal

disappears at SLOW FLASH condition.

LED OFF: The alarm led turns off when

RESET pushbutton is pressed and fault

signal is not present.

HORN/BELL LED: If the HORN relay

turns on, the “red” led turns on. If the

HORN relay is not on and if the BELL

relay is on, then the “green” led turns on.

If both relays are off then the led is off.

FAIL/SAFE LED: If an internal fault

condition is detected at self-test, then this

led will turn on “red”, else it turns on

“green”.

HORN RELAY: If any “red” alarm led

turns on, then the horn relay will also turn

on. The relay turns off when ACK

pushbutton is pressed.

BELL RELAY: If any “green” alarm led

turns on, then the bell relay will turn on.

The relay turns off when ACK pushbutton

is pressed.

WATCHDOG RELAY: At startup the

relay turns on. If the board fails, then the

wathcdog relay turns off.

3. DISPLAY AND RELAYS

Horn Button

Reset Button

Signal Leds

(1-24)

Test Button

Ack Button

Horn/Bell Led

Fail/Safe Led

Alarm Labels

(1-24)

DKM-0224 User Manual V-1.0 (11.08.2016)

-10-

The main configuration of the unit is done with DIP switches located on back panel.There

are 8 Dip Switch on the unit and the settings are described below.

1-2-3. Switch: 4. Switch 5-6-7-8 Switch:

Filtering Time Setting: BaudRate Setting: Modbus Adress Setting:

1 2 3 4 5 6 7 8

0 0 0 2ms 0 9600 baud 8 4 2 1

0 0 1 5ms 1 19200 baud There are 16(1-16) adresses

0 1 0 10ms can be defined. For example:

0 1 1 20ms 5(ON),6(ON),7(ON),8(ON)

1 0 0 50ms 1 + 8 + 4 + 2 + 1 = 16

1 0 1 100ms 5(ON),6(OFF),7(OFF),8(ON)

1 1 0 200ms 1 + 8 + 0 + 0 + 1 = 10

1 1 1 500ms 5(OFF),6(OFF),7(OFF),8(OFF)

1 + 0 + 0 + 0 + 0 = 1

Adjusted led colors can be checked by pressing the TEST pushbutton.(If the TEST

pushbutton is pressed again, the unit returns back to normal operation) After that, if the

TEST pushbutton is pressed long (for 3 seconds) first led flashes with the adjusted color.

By pressing RESET pushbutton, signal leds can be selected from up to down, by

pressing HORN pushbutton signal leds can be selected from left to right. The color of the

signal can be adjusted by pressing the TEST pushbutton. After pressing the ACK

pushbutton all leds are seen with the adjusted color.(If the ACK pushbutton is pressed

again, the unit returns back to settings menu) After that, if the ACK pushbutton is

pressed long(for 3 seconds) the unit saves all settings and exist from the menu.

If the HORN pushbutton is pressed, all leds flash green and red in sequence, the internal

buzzer sounds, Horn, Bell and Watchdog Relays turns on and off with a period of one

second. During this test, if the pushbutton pressed long(for 3 seconds) buzzer function

can be disabled/enabled. By pressing the pushbutton again, the unit exists from the test.

4. SETTINGS

4.1 DIP-SWITCH SETTINGS

4.2 SIGNAL LED RED/GREEN SETTINGS

4.3 BUZZER SETTINGS

DKM-0224 User Manual V-1.0 (11.08.2016)

-11-

The unit has serial communication port that can be integrated to automation systems.

Serial port is a standart RS-485 MODBUS-RTU isolated from supply input and

measuring terminals. Therefore, the unit survives under harsh industrial conditions

without any damage.

The MODBUS properties of the unit are:

-Data transfer mode: RTU

-Serial data: 9600 and 19200 bps, 8 bit, no parity, 1 bit stop

-The unit replies within 4.3ms when it receives a message.

Each register consists of 2 bytes(16 bits). Larger data structures will contain multiple

registers.

For further details of Modbus Protocol, “Modicon Modbus Protocol Reference Guide”

can be rewieved. The guide can be downloaded from

www.modbus.org/docs/PI_MBUS_300.pdf

Supported Function:

- Function 3 (Read multiple registers)

- Function 16 (Write multiple registers)

Error Codes:

There are only 3 error codes are being used:

01: Invalid function code

02: Invalid adress

10: Read protection (try to write Read-Only memory)

Data Types:

Each register consists of 16 bits (2 bytes)

If the data type is byte, only low byte is valid. Ignore high byte.

A larger data structure(more than 16bit) will contain multiple registers.

Least significant register comes first.

Baudrate Options:

4th jumper determines Modbus Baudrate.

BaudRate

Value

9600

0

19200

1

5. MODBUS COMMUNICATION

5.1 INTRODUCTION

5.2 PROGRAM PARAMETERS

DKM-0224 User Manual V-1.0 (11.08.2016)

-12-

There are 3 parameters for this unit. Function 10 (Write multiple registers) is used for

changing the parameter value.

ADDRESS

NAME

DESCRIPTION

SIZE

R/W

TYPE

X

0

Led 1-8 Settings

Led Color Setting Red: 1,

Green:0

16 BIT

R/W

unsigned word

1

1

Led 9-16 Settings

Led Color Setting Red: 1,

Green:0

16 BIT

R/W

unsigned word

1

2

Led 17-24

Settings

Led Color Setting Red: 1,

Green:0

16 BIT

R/W

unsigned word

1

Function 16 (Write multiple register) is used for sending commands.

ADDDRESS

VALUE

R/W

DESCRIPTION

4

1 and 0

R/W

Buzzer active/deactive( Deactive:1, Active:0)

16384

1

W-O

Reset Button short press

16385

1

W-O

Horn Button short press

16386

1

W-O

Test Button short press

16387

1

W-O

ACK Button short press

16388

1

W-O

Reset Button long press

16389

1

W-O

Horn Button long press

16390

1

W-O

Test Button long press

16391

1

W-O

ACK Button long press

ADRESS

NAME

DESCRIPTION

LENGTH

R/W

TYPE

X

20480

Filtering Time

Filtering Time of Inputs

16 BIT

R-O

unsigned

word

1

20481

Baudrate

Modbus Baudrate Value

16 BIT

R-O

unsigned

word

1

20482

Node Adress

Modbus Node Adress Value

16 BIT

R-O

unsigned

word

1

20483

Jumper Value

Jumper Value

16 BIT

R-O

unsigned

word

1

20484

LED 1-2

1. and 2. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20485

LED 3-4

3. and 4. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20486

LED 5-6

5. and 6. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20487

LED 7-8

7. and 8. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20488

LED 9-10

9. and 10. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20489

LED 11-12

11. and 12. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

ADRESS

NAME

DESCRIPTION

LENGTH

R/W

TYPE

X

5.3 COMMANDS

5.4 CALCULATED VALUES

DKM-0224 User Manual V-1.0 (11.08.2016)

-13-

20490

LED 13-14

13. and 14. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20491

LED 15-16

15. and 16. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20492

LED 17-18

17. and 18. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20493

LED 19-20

19. and 20. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20494

LED 21-22

21. and 22. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20495

LED 23-24

23. and 24. Led Instant State

16 BIT(2x8)

R-O

unsigned

word

1

20496

Horn/Bell&Fault Led

Horn/Bell&Fault Led State

16 BIT(2x8)

R-O

unsigned

word

1

20497

Horn&Bell Relay

Horn&Bell Relay State

16 BIT(2x8)

R-O

unsigned

word

1

20498

Fault Relay&Buzzer

Fault Relay ve Buzzer State

16 BIT(2x8)

R-O

unsigned

word

1

Led Instant States: Buzzer Instant States:

0 Led Off 0 Buzzer Off

1 Led Steady On 1 Buzzer Steady On

2 Led Slow Flash 2 Buzzer slow frequency(10sec) buzzing

3 Led Fast Flash 3 Buzzer fast frequency(1sec) buzzing

Supply Input: 88-400VDC, 85-270VAC

(optional 19-150VDC)

Power Consumption: < 4 VA

Fault Inputs: 24. Optically isolated, equipped

with noise cancelling filters allowing

smooth operation in high electrical noise

environments, positive inputs and common

negative terminal.

Input Impedance: 130K-ohm (opt. 40K-ohm)

Max Input Voltage: 250VDC/AC (opt 140VAC/DC)

Input Current: max. 1mA (110VDC)

Surge Protection: 1000V / 50us

Isolation: 1000VAC, 1 minute

Filter Timing: 2-5-10-20-50-100-200-500msec

optional

Optical Warning: 26 red-green bicolor, ultra bright

led indicators.

Audible Warning: Internal 23mm buzzer, 80dB

Relay outputs:3 x 5A @ 250V AC

Serial Port:

Signal Type: RS-485

Protocol: Modbus RTU

Data Rate: 9600-19200baud

Isolation: 1000V AC, 1 minute

Operating Temperature Range: -20°C...+70 °C

Storage Temperature Range: -40°C...+85 °C

Max. Relative Humidity: %95 non-condensing.

Protection: IP 65 (Front Panel, with gasket)

IP 30 (Back panel)

Enclosure: Flame retardant, ROHS compliant,

high temperature ABS/PC (UL94-V0)

Installation: Panel mount, rear retaining plastic

brackets.

Connections: Two part connection system.

Cable section: max. 2.5mm2

Dimensions: 164x164x60mm (WxHxD)

Panel Cut-ot: 140x140mm

Weight: 400 gr

EU Directives:

2006/95/EC (LVD)

2004/108/EC (EMC)

Norms of Reference

EN 61010 (safety)

EN 61326 (EMC)

DATAKOM Electronics Ltd.

5. TECHNICAL SPECIFICATIONS

Table of contents

Other Datakom Security System manuals

Popular Security System manuals by other brands

System Sensor

System Sensor APA151 Installation and maintenance instructions

Micron

Micron Scorpion Z4120C Features & operation

Honeywell

Honeywell FBII OMNI 624 Installation and setup guide

GARDINER TECHNOLOGY

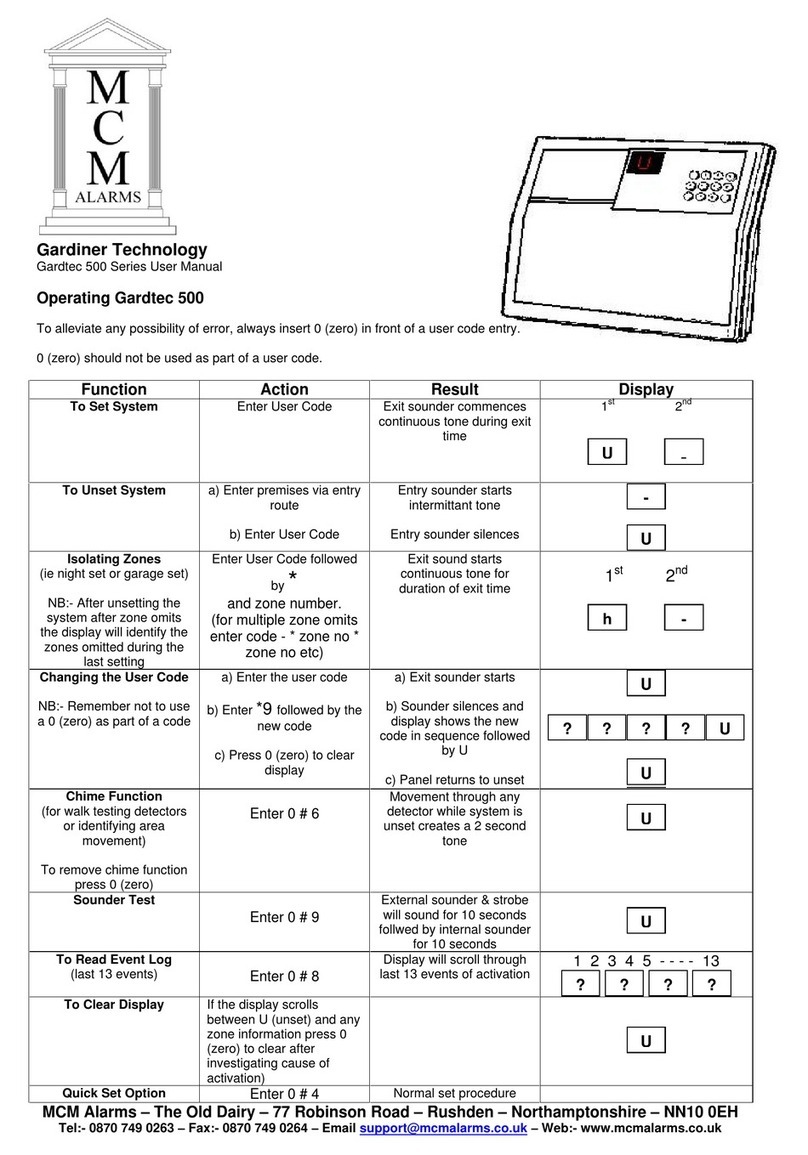

GARDINER TECHNOLOGY Gardtec 500 series user manual

FAAC

FAAC HSE Installation and use instructions

Interlogix

Interlogix Simon 3 user manual