INSTALLATION MANUAL

iii

TABLE OF CONTENTS

PREFACE ..................................................................................................................IV

About this Manual ........................................................................................................... iv

Manual Conventions ........................................................................................................................... iv

Safety REGULATIONS ..................................................................................................... iv

Electrical Safety .................................................................................................................................. iv

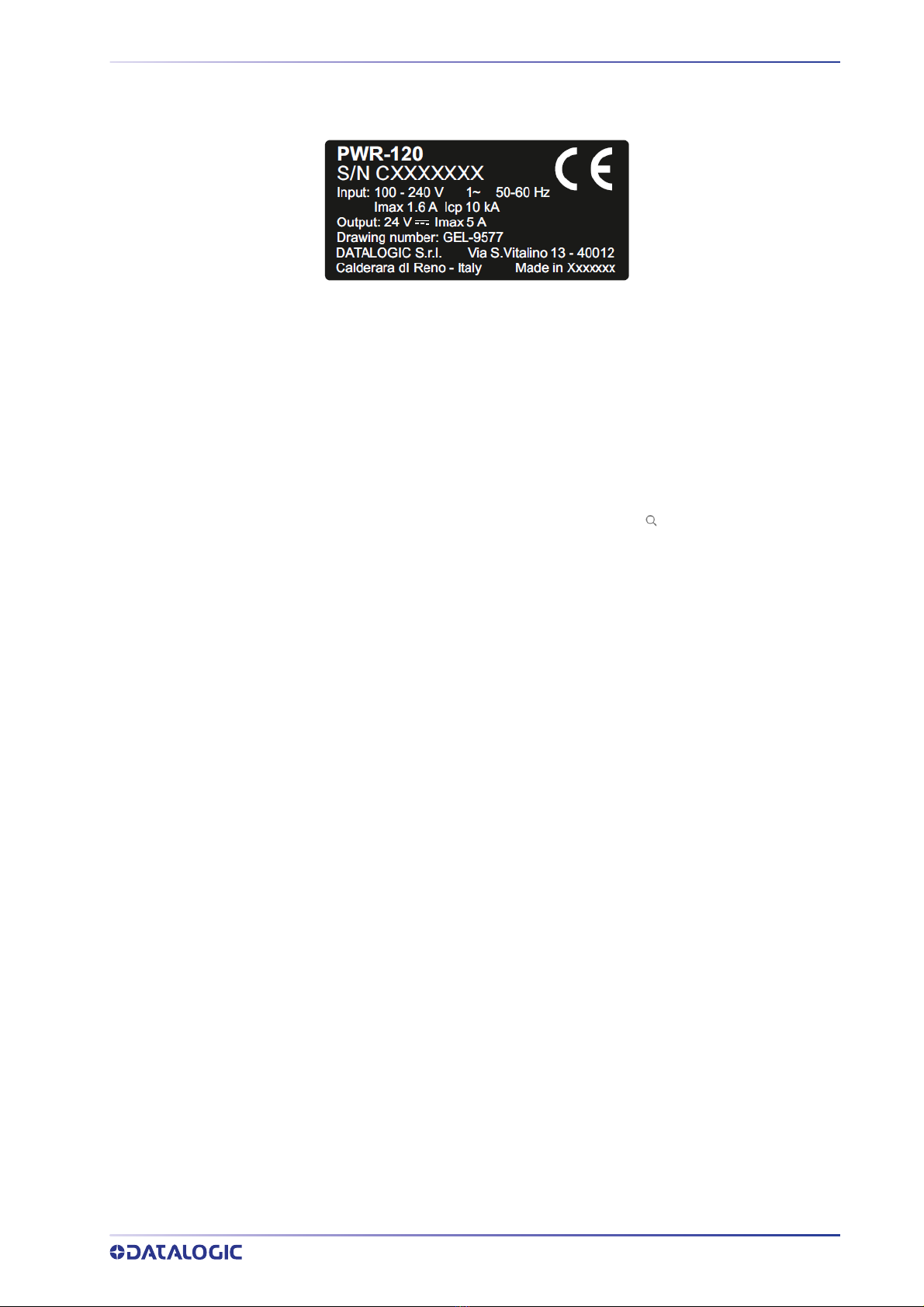

Product Data Label .............................................................................................................................. v

Technical Support ............................................................................................................ v

Support Through the Website ............................................................................................................. v

Reseller Technical Support ................................................................................................................. v

CE Compliance ..................................................................................................................................... v

Warning ............................................................................................................................................... v

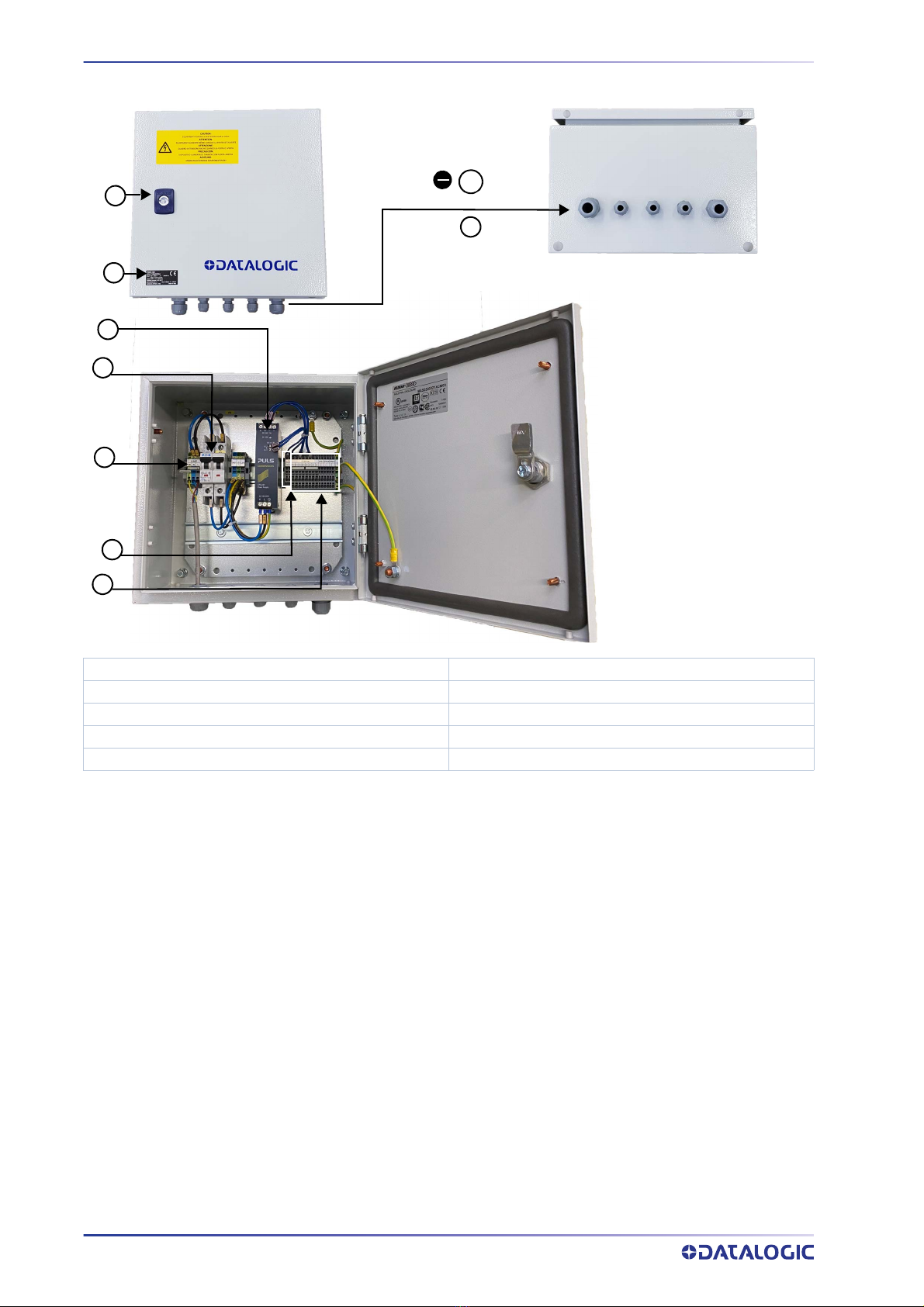

General View .................................................................................................................. vi

CHAPTER 1.

OPERATING FEATURES ......................................................................... 1

Description ...................................................................................................................... 1

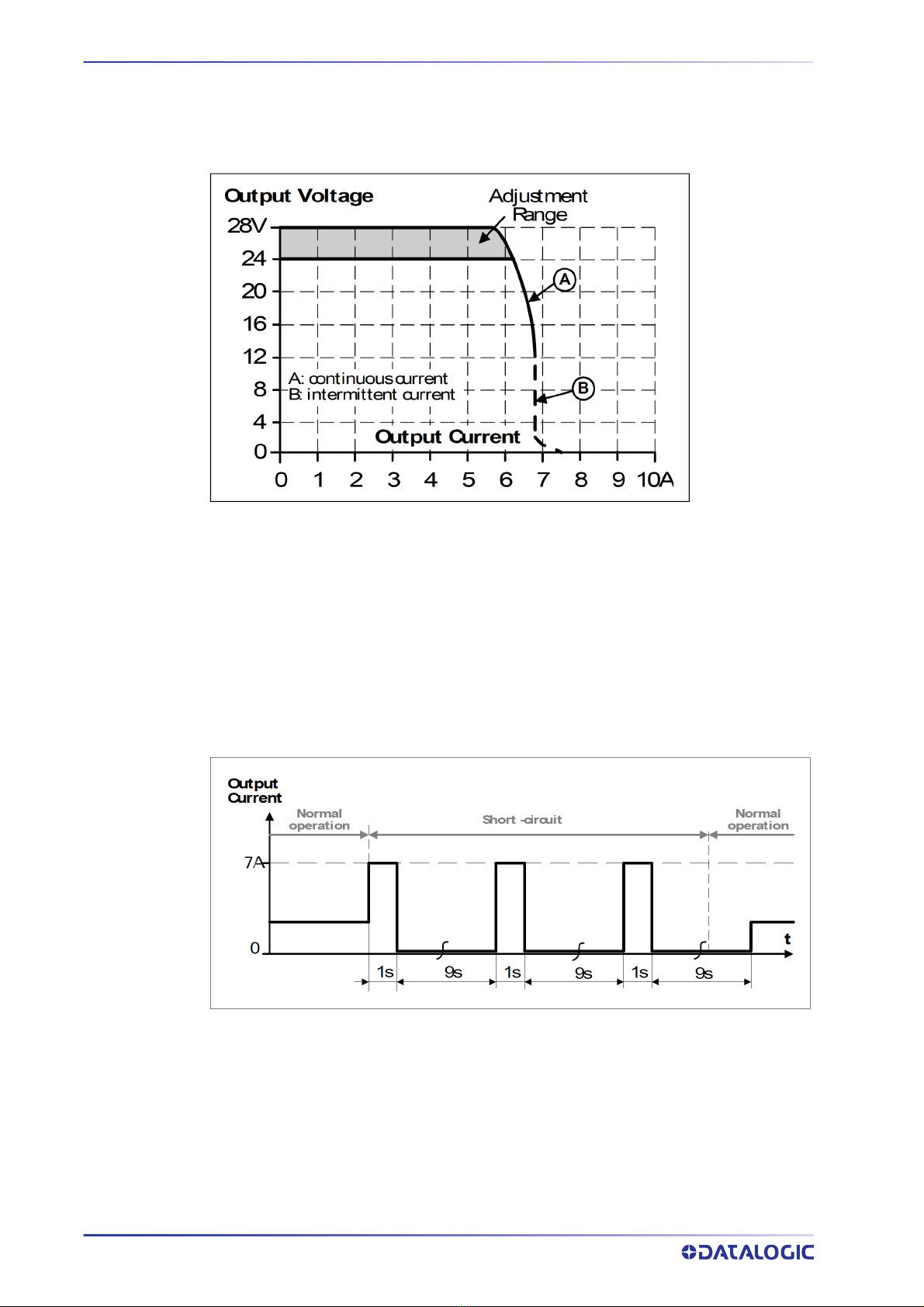

Output Protection ............................................................................................................. 1

Light Overload .....................................................................................................................................2

Heavy Overload (including short-circuit) ...........................................................................................2

CHAPTER 2.

PRE-INSTALLATION CHECKLIST ........................................................... 3

System Wiring: DC Output ................................................................................................ 3

System Wiring: AC Input .................................................................................................. 3

System Wiring: Test ......................................................................................................... 4

CHAPTER 3.

MECHANICAL INSTALLATION................................................................5

Cabinet Mounting ............................................................................................................. 5

CHAPTER 4.

LOW VOLTAGE ELECTRICAL CONNECTIONS........................................... 6

DC Low Voltage Cable insertion ........................................................................................ 6

Compression Connectors ...................................................................................................................6

Installing the AS-I Cable ......................................................................................................................7

DC Voltage Terminal Block ............................................................................................... 8

DC OK Monitoring ................................................................................................................................8

DC Direct Output ..................................................................................................................................8

Laser Barcode Scanners ................................................................................................... 9

Supply Capacity When Wiring Directly to AS-I Compatible Scanners ..............................................9

Image-Based id Readers ................................................................................................ 10

Supply Capacity When Wiring to XRF410N Readers .......................................................................10

Supply Capacity When Wiring to Matrix 450N Readers ...................................................................12

CHAPTER 5.

AC LINE VOLTAGE ELECTRICAL CONNECTIONS ................................... 13

AC Line Input Voltage ..................................................................................................... 13

CHAPTER 6.

TECHNICAL FEATURES ....................................................................... 15

APPENDIX A.

ELECTRICAL DIAGRAMS ................................................................... 16

PWR-120 Electrical Diagram .......................................................................................... 16